Porsche 912E Instruction manual

Other Porsche Automobile manuals

Porsche

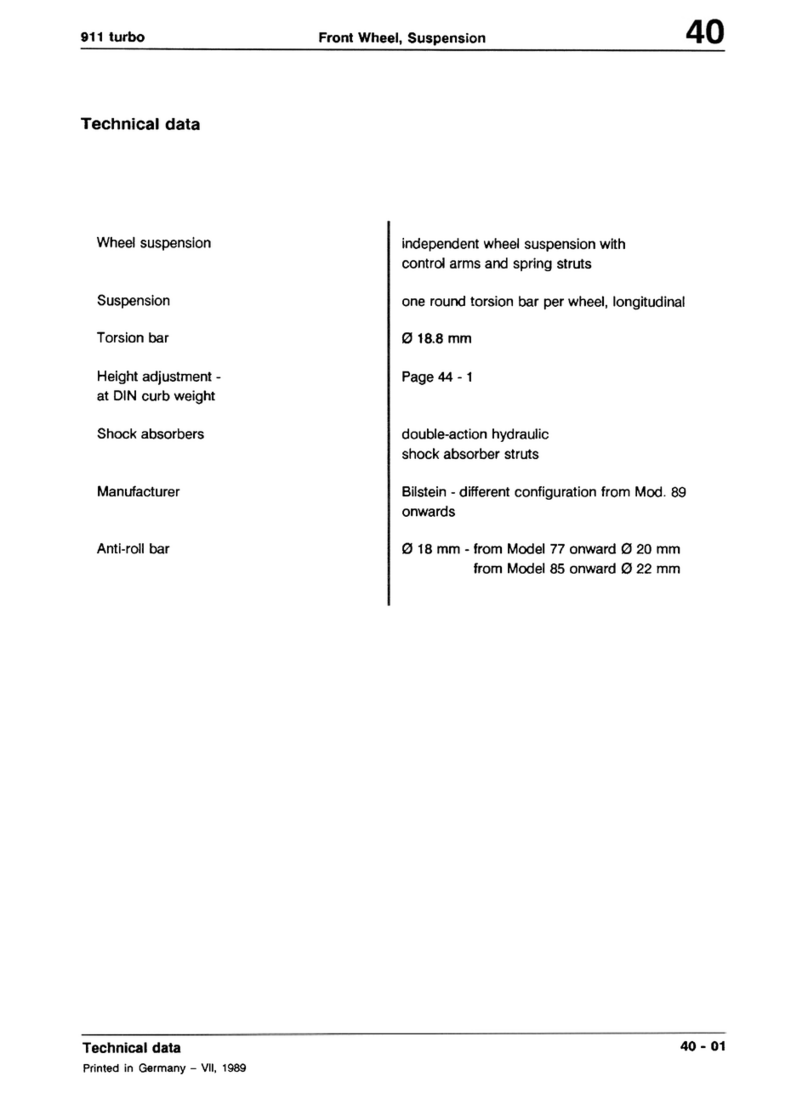

Porsche 911 TURBO - 1989 Instruction manual

Porsche

Porsche 911 TURBO - 1975 WORSHOP User manual

Porsche

Porsche 911 TURBO - 1975 WORSHOP User manual

Porsche

Porsche cayman gt4 User manual

Porsche

Porsche 911 CARRERA 4 - Guide

Porsche

Porsche Boxster S User manual

Porsche

Porsche 911 CARRERA 4 - User manual

Porsche

Porsche 911 CARRERA 4 - User manual

Porsche

Porsche 911 - VOLUME 7 ELECTRICS WIRING DIAGRAMS Instruction manual

Porsche

Porsche CAYMAN - User manual

Porsche

Porsche 911 GT3 Cup MR Gen. II User manual

Porsche

Porsche 911 CARRERA 4 - Instruction manual

Porsche

Porsche 928 1982 Operating and installation instructions

Porsche

Porsche Boxster S User manual

Porsche

Porsche 911 TURBO - 1989 Instruction manual

Porsche

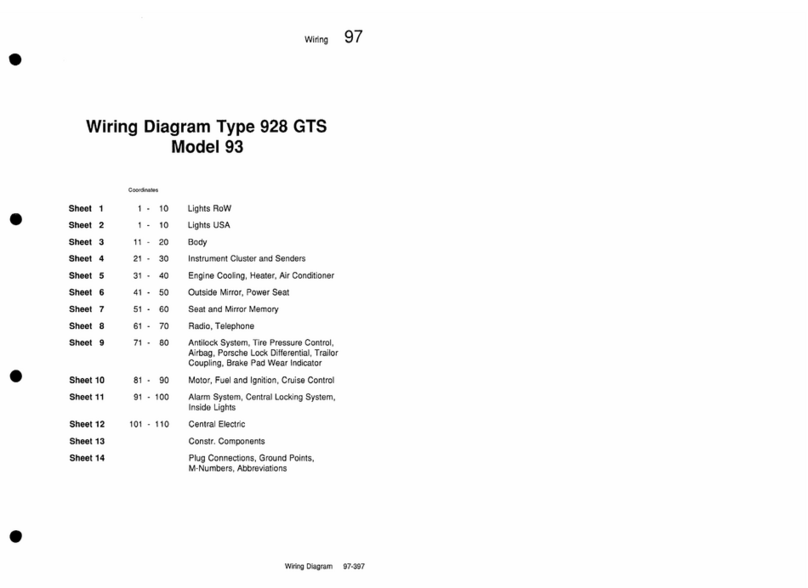

Porsche 928 GTS MODEL 93 - Quick start guide

Porsche

Porsche P-80 2005 User manual

Porsche

Porsche 911 CARRERA 4 - User manual

Porsche

Porsche 718 Cayman GT4 Clubsport MR 2019 User manual

Porsche

Porsche Cayenne Turbo Release note