For further information please contact Portable pace on 01449 782123 or email info@portablespace.co.uk

FLAT PACK STORE ASSEMBL INSTRUCTIONS

Store 2m 271kg

CONTAINER PARTS

Container Rear Panel 30kg 1 Piece

Container ide Panel 26kg 2 Piece

Door Panel 51kg 1 Piece

Door 1 Piece

Container Roof 50kg 3 Piece

Container Chassis 88kg 1 Piece

HARDWARE PARTS

M5 Nut 2 Piece

M5 Washer 2 Piece

M8 x 25mm Bolt 28 Piece

M8 Nut 22 Piece

M8 Washer 44 Piece

Brass Door Handle 2 Piece

Countersunk M5 x 50 Bolt 2 Piece

Barrel With Key 2 Piece

M12 Washer 18 Piece

M12 x 40mm Bolt 4 Piece

M12 Nut 4 Piece

Hinge 2 Piece

M12 x 25 Bolt 14 Piece

M10 Nut 14 Piece

M10 Washer 14 Piece

Store 3m 351kg

CONTAINER PARTS

Container Rear Panel 30kg 1 Piece

Container ide Panel 40kg 2 Piece

Door Panel 51kg 1 Piece

Door 1 Piece

Container Roof 70kg 3 Piece

Container Chassis 120kg 1 Piece

HARDWARE PARTS

M5 Nut 2 Piece

M5 Washer 2 Piece

M8 x 25 mm Bolt 30 Piece

M8 Nut 22 Piece

M8 Washer 46 Piece

Brass Door Handle 2 Piece

Countersunk M5 x 50 Bolt 2 Piece

Barrel with Key 2 Piece

M12 Washer 4 Piece

M12 x 40 mm Bolt 4 Piece

M12 Nut 4 Piece

Hinge 2 Piece

M12 x 25 Bolt 14 Piece

M10 Nut 14 Piece

M10 Washer 14 Piece

Store 4m 421kg

CONTAINER PARTS

Container Rear Panel 30kg 1 Piece

Container ide Panel 54kg 2 Piece

Door Panel 51kg 1 Piece

Door 1 Piece

Container Roof 79kg 3 Piece

Container Chassis 153kg 1 Piece

HARDWARE PARTS

M5 Nut 2 Piece

M5 Washer 2 Piece

M8 x 25 mm Bolt 32 Piece

M8 Nut 22 Piece

M8 Washer 48 Piece

Brass Door Handle 2 Piece

Countersunk M5 x 50 Bolt 2 Piece

Barrel with Key 2 Piece

M12 Washer 4 Piece

M12 X 40 mm Bolt 4 Piece

M12 Nut 4 Piece

Hinge 2 Piece

M12 x 25 Bolt 14 Piece

M10 Nut 14 Piece

M10 Washer 14 Piece

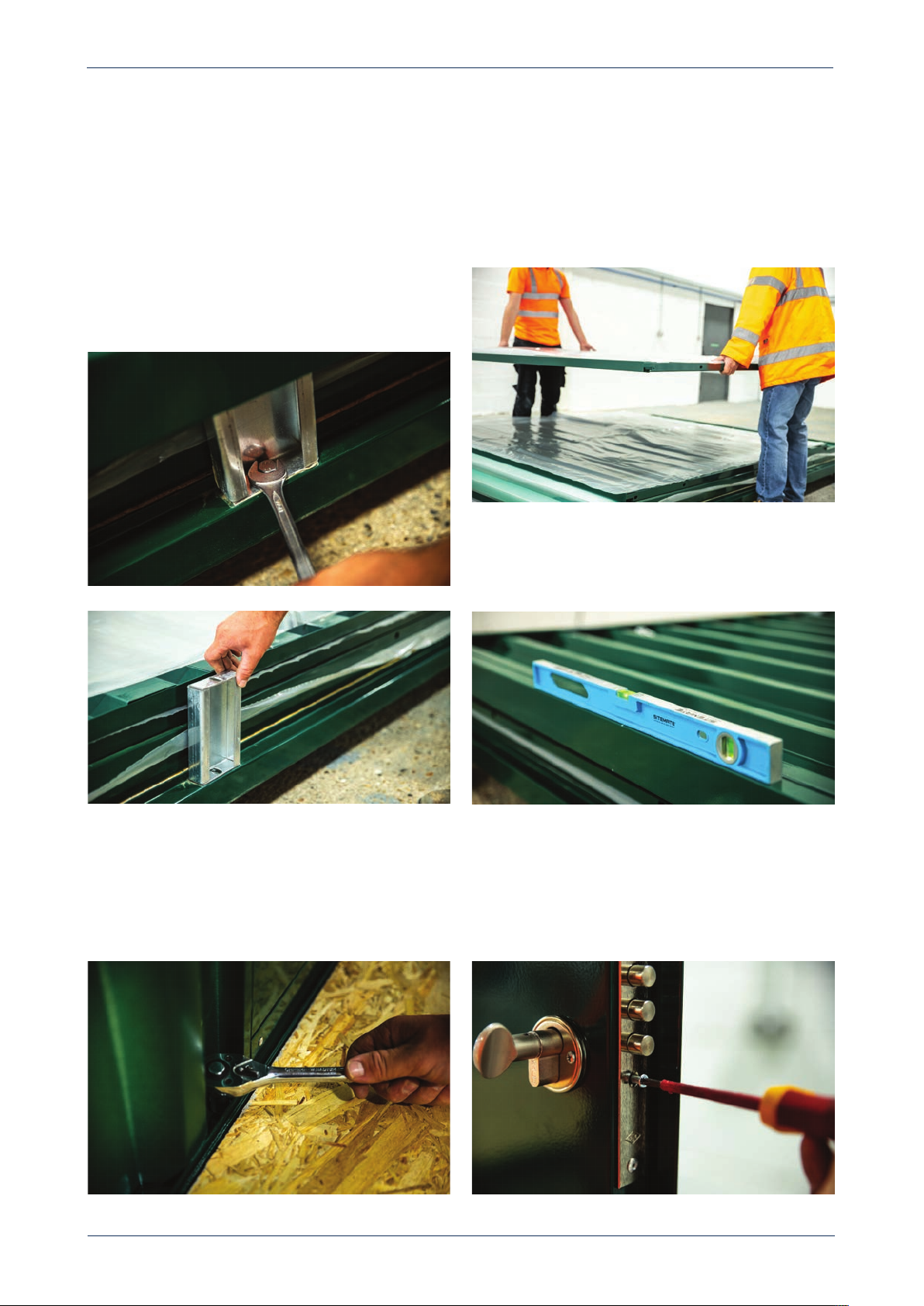

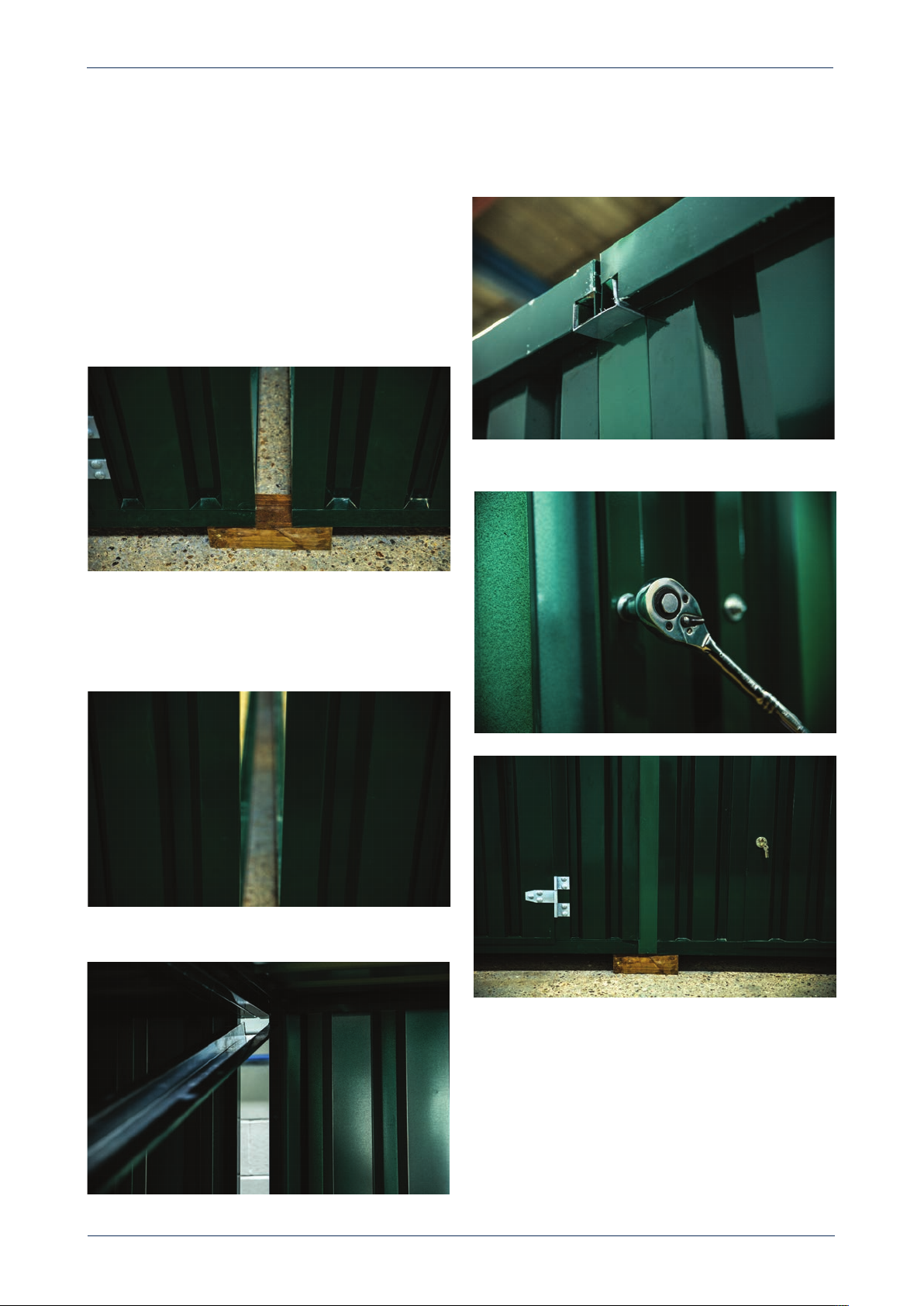

Assembly hints

1. Try to get the pack delivered as close as possible to

the erection area. If it arrives on one of our HIAB lorries,

please let the driver know and they will help by

levelling it up with you. To ensure the chassis is level, it’s

best to use each of the four corners and once level

support the base in the middle to help prevent any

sag over time.

2. Ideally concrete bases are the best option for long-

term installations although paving slabs can provide

the simplest solution. Plywood packing is ideal for small

adjustments or short/medium-term installations.

3. The erection process is made much easier when the

chassis is level at the start.

4. Don’t assemble in windy conditions as this can be

dangerous and make sure you have enough people

available to move and erect the panels safely.

Maintenance

1. Check foundations periodically to make sure that the

unit remains level. igns that the unit might have

moved usually result in the door becoming difficult to

open or close, or the unit rocking on the pads.

2. The only moving parts are the lock and hinges which

need a light oiling on a periodic basis.

3. Check the roof from time to time and remove any

debris, especially leaves, to ensure the gutters work

correctly.

Othe info mation

1. If you keep all the packaging material, it can be used

to re-pack the unit at a later date. Otherwise please

recycle it.

2. The unit is not designed to be stacked.

3. The unit once correctly assembled, can be lifted and

moved using the lifting hooks. Please check the

security of all fixings each time before lifting.

Components fo 2m, 3m and 4m sto es