GB

TABLE OF CONTENTS

212.GB.809.0 INHALT

- 4 -

Observe Safety Hints in the supplement!

CE sign

The CE sign, which is affixed by the

manufacturer, indicates outwardly

that this machine conforms to the

engineering guideline regulations

andthe other relevantEUguidelines.

EU Declaration of ConformityBy signing the EU

Declaration of Conformity, the manufacturer declares that

the machine being brought into service complies with all

relevant safety and health requirements.

495.151

Meaning of warning signs

Never reach into the crushing danger area

as long as parts may move.

Do not enter rotor area while driving motor is

running.

Stay clear of swinging area of implements

Table of contents

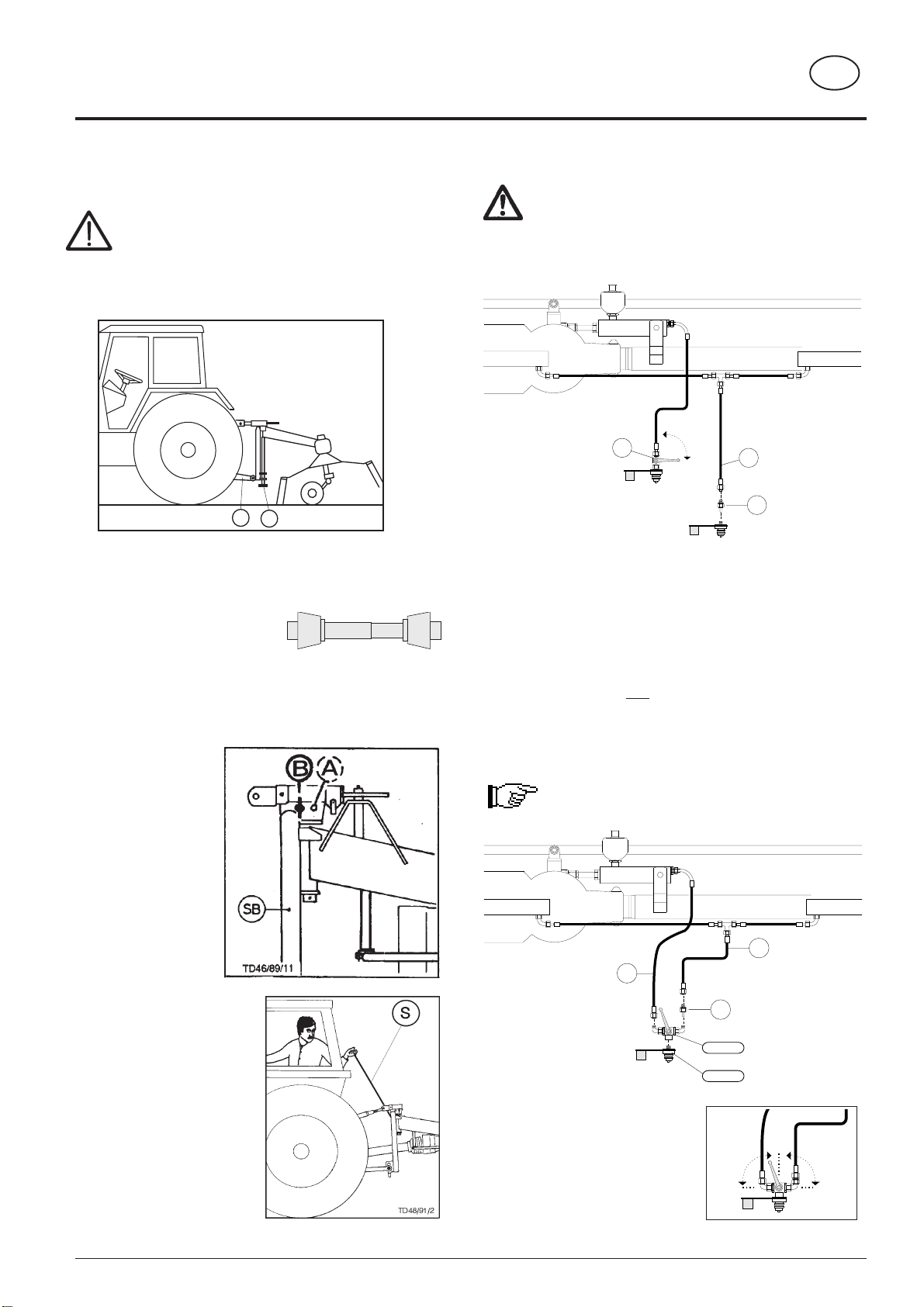

Hitching of machines with three point linkage ........................................ 5

Locking the headstock during use on roads and when lowering ........... 5

Release rope .......................................................................................... 5

Note ....................................................................................................... 5

HITCHING =================================== 5

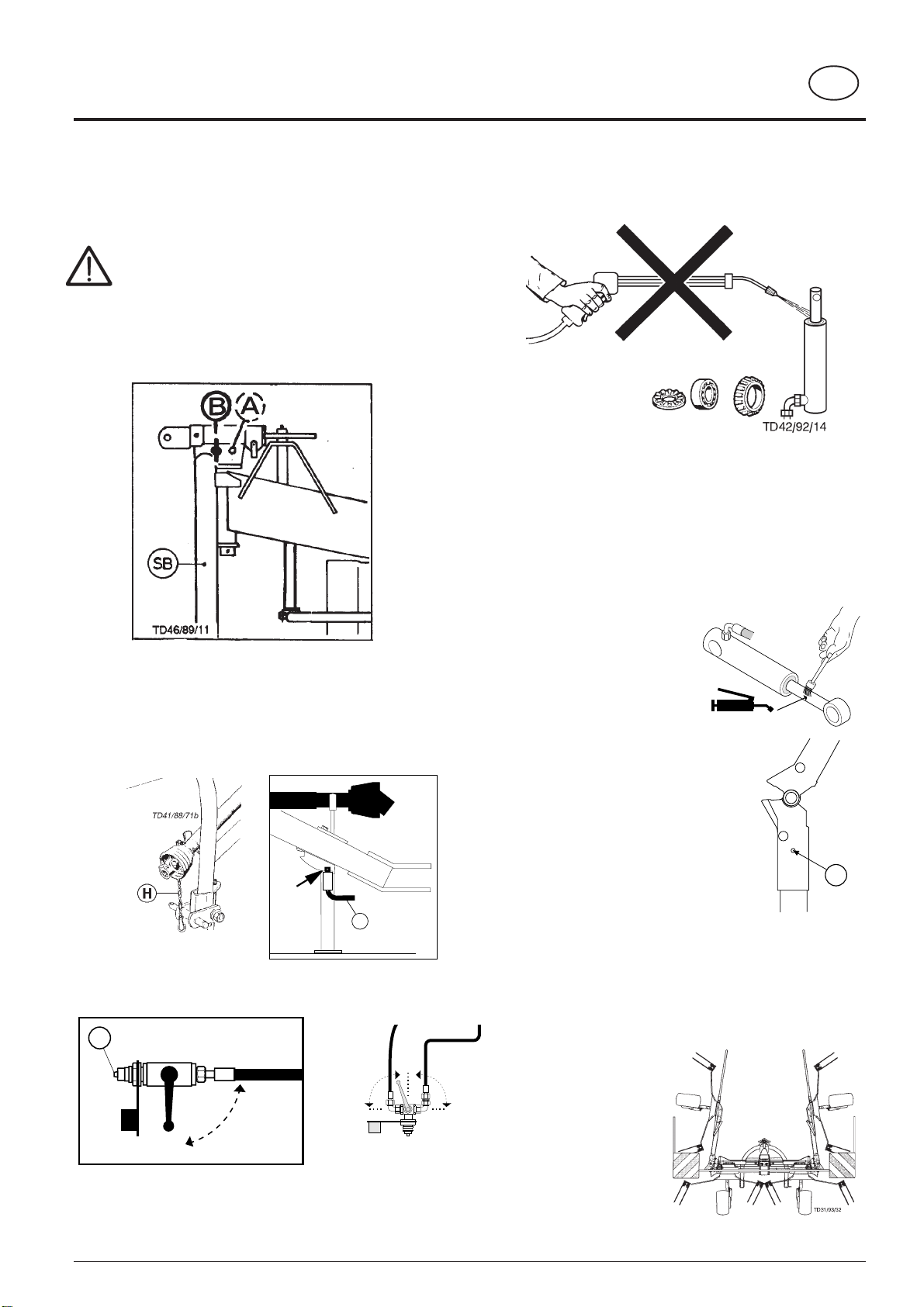

Lowering the rotary tedder ..................................................................... 6

LOWERING THE MACHINE====================== 6

Cleaning of machine parts ..................................................................... 6

Parking in the open ................................................................................ 6

Winter storage ........................................................................................ 6

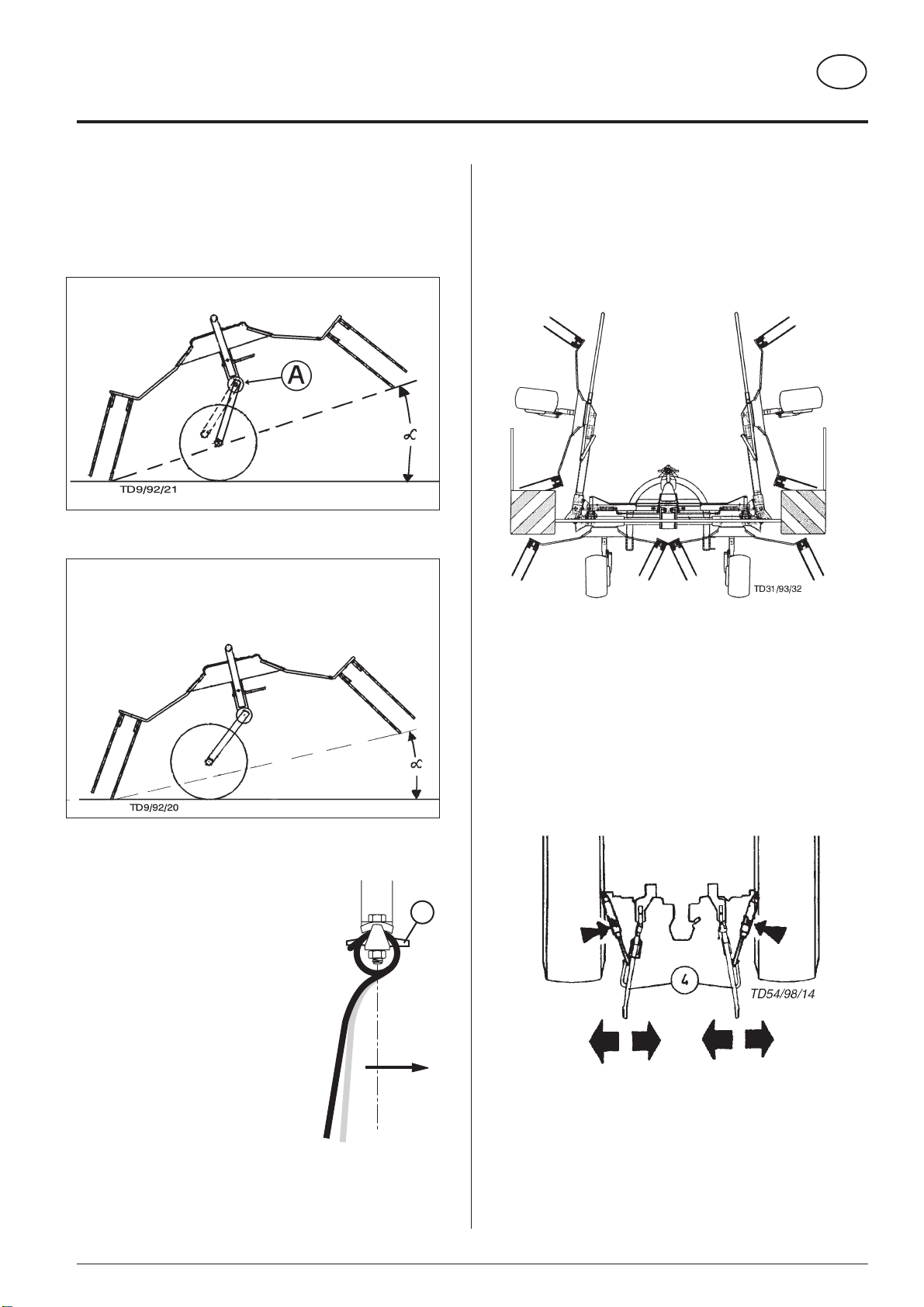

Adjustment of rotor inclination ................................................................ 7

Tine adjustment ...................................................................................... 7

ADJUSTMENTS BEFORE OPERATION ============ 7

Driving on public roads: ......................................................................... 7

Driving on public roads: ......................................................................... 8

Conversion from working to transport position ....................................... 8

Attention! ................................................................................................ 8

The order of operation must be adhered to. .......................................... 8

Locking the headstock during use on roads : ........................................ 8

TRANSPORTPOSITION========================= 8

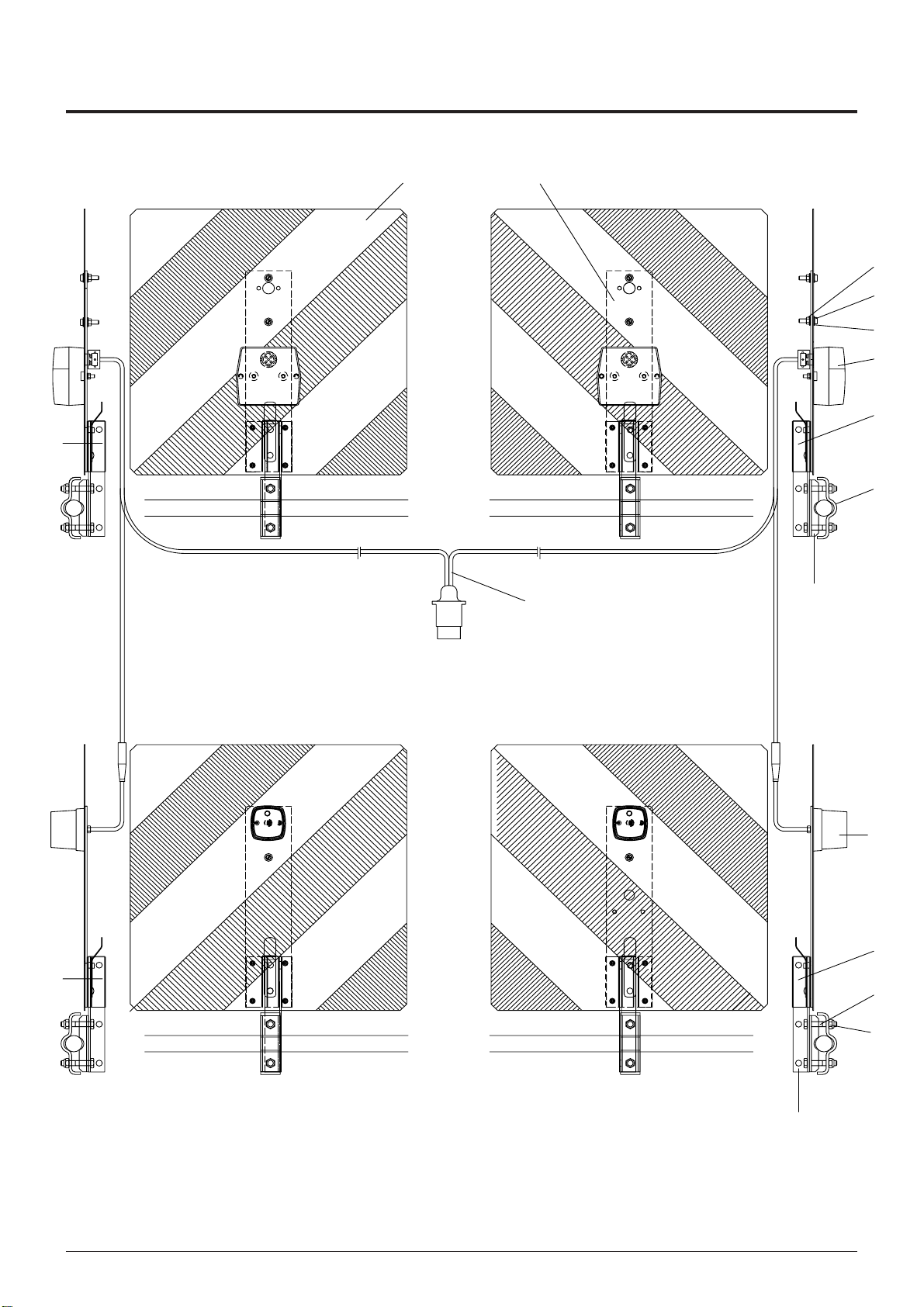

Warntafeln .............................................................................................. 9

Tableau de signalisation ......................................................................... 9

Warning plates ....................................................................................... 9

ECLAIRAGE ================================= 9

REMOVABLE LIGHTNING ======================= 9

Conversion from transport to workingposition ...................................... 11

WORKING POSITION ========================= 11

General guidelines for working with the machine ................................ 12

Beware! implements with three-point-linkage ...................................... 12

Operating on slopes ............................................................................. 12

Adjustment to implements with three-point-linkage: ............................ 12

Unterlenker fixieren .............................................................................. 12

P.t.o. speed .......................................................................................... 12

Tractor control device (ST) ................................................................... 12

Zinkeneinstellung ................................................................................. 12

USE ======================================= 12

Clearing field edges (border tedding) to the left or to the right ............. 13

Anti-vibration braces ............................................................................ 14

Remedy for noisy machine running ..................................................... 14

Turning manoeuvre in working position ............................................... 14

Maintenance and servicing .................................................................. 15

Intake transmission .............................................................................. 15

Changing tines ..................................................................................... 15

Gas container ....................................................................................... 15

Note ..................................................................................................... 15

Alteration of gas container pressure .................................................... 15

MAINTENANCE ============================== 15

Technical Data ..................................................................................... 16

Optional extras ..................................................................................... 16

Position of Vehicle Identification Plate ................................................. 16

TECHNICAL DATA =========================== 16

The defined use of the rotary tedder .................................................... 16

SUPPLEMENT =============================== 17

Recommendations for work safety ....................................................... 19

DRIVESHAFT ...................................................................................... 20

Lubrication chart .................................................................................. 21

Important! Additional Information ......................................................... 25

Combination of tractor and mounted implement .................................. 25