- 5 -

1200_Symbolerklärung_EN

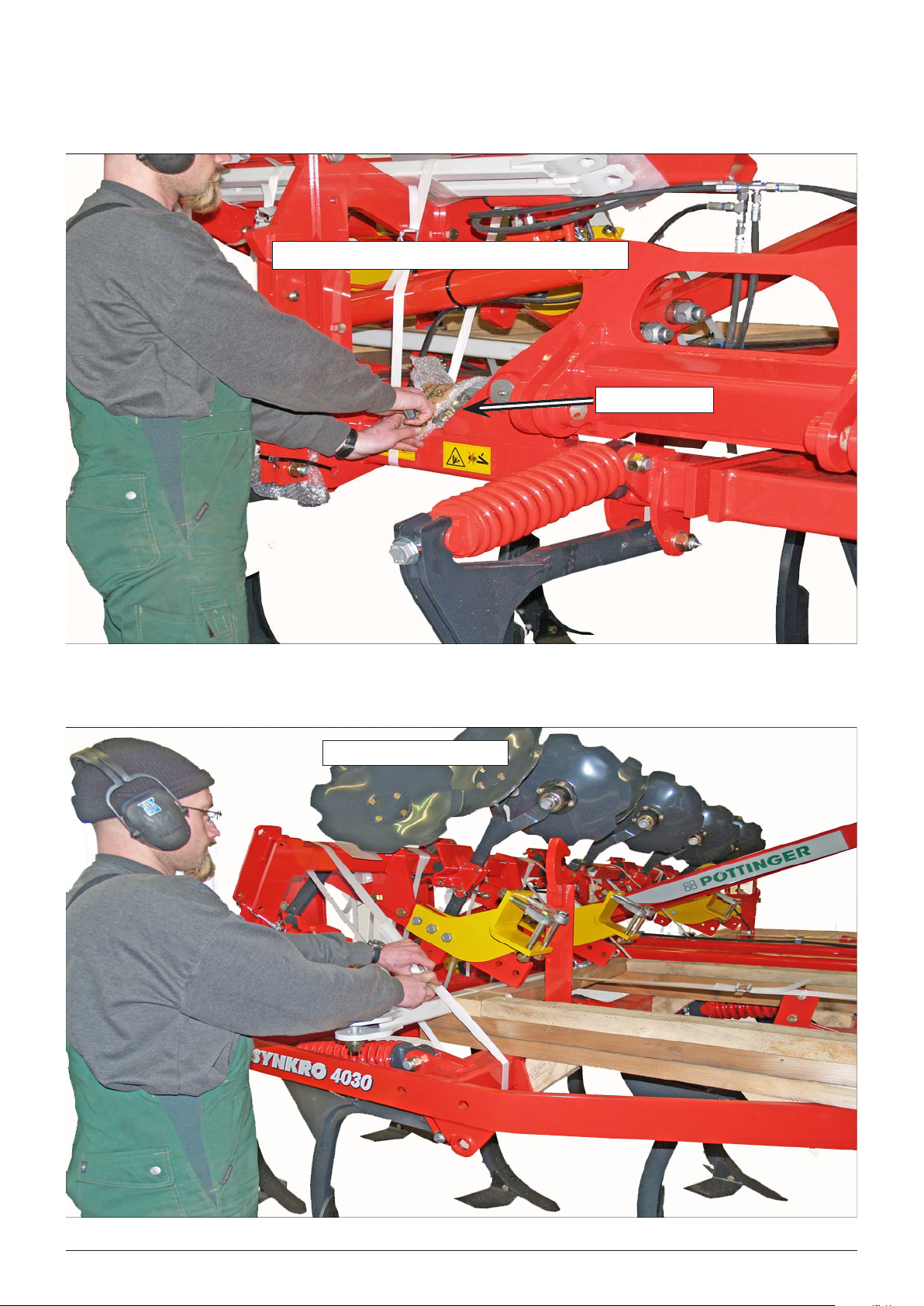

This arrow points at parts associated with a text box.

The part will be named in the text box or the assembly

will be described in detail. This arrow also marks the

relationship to illustrations or particular marked points

in the illustrations.

„Textboxes“containmaterialnumbers,denominations,

safety notes and assembly notes.

Text box Text box Text box

Text box Text box Text box

Text box Text box Text box

This arrow indicates the direction of motion or

rotation. In connection with tools, this arrow shows

the tightening or loosening direction of nuts and bolts.

Arrow 1

Arrow 2

This arrow shows the point where parts are to be

installed or bolts have to be mounted. For the sake

of clarity, not all parts are provided with these arrows,

e.g. when several bolts adjacent to each other have

to be mounted at the same time.

137

The „Item number“ designates a part. As the same

number is used in the parts list, the part can be

identified unambiguously.

Arrow 3

Item number

The „Book“shows thatfurtherimportantinformation to

be observed is included in the operating instructions.

Book

The „Tool“ shows that specific assembly procedures

need to be performed at this point of progress, e.g.

insertion of a spring pin or tightening of a screw. In

connection with „Arrow 2“, a specific direction of

rotation can be indicated. The illustration on the left

only shows some of the symbols used.

Tool

The „Grease gun“ indicates a point of lubrication,

grease nipple, plain bearing, etc. to be lubricated with

universal grease. Any other lubricant to be applied

will be indicated in a separate text box.

Grease gun

MeaningSymbol