MNL151-4.3 Revision 4/12/2023

Power Innovations—MPDU™User’s Manual i

TABLE OF CONTENTS

TABLE OF CONTENTS ..............................................................................................................................................I

SAFETY ...................................................................................................................................................................... III

SPECIAL INSTRUCTIONS..............................................................................................................................................

III

WARNINGS ..................................................................................................................................................................

III

IMPORTANT SAFETY INSTRUCTIONS ..........................................................................................................................

III

1. INTRODUCTION .....................................................................................................................................................1

1.1 DESCRIPTION ........................................................................................................................................................1

1.2 WTT MPDU Front Panel..................................................................................................................................... 3

1.3 WTT MPDU BACK PANEL .................................................................................................................................4

1.4 TSSC MPDU FRONT PANEL ...............................................................................................................................5

1.5 TSSC MPDU BACK PANEL ............................................................................................................................... 6

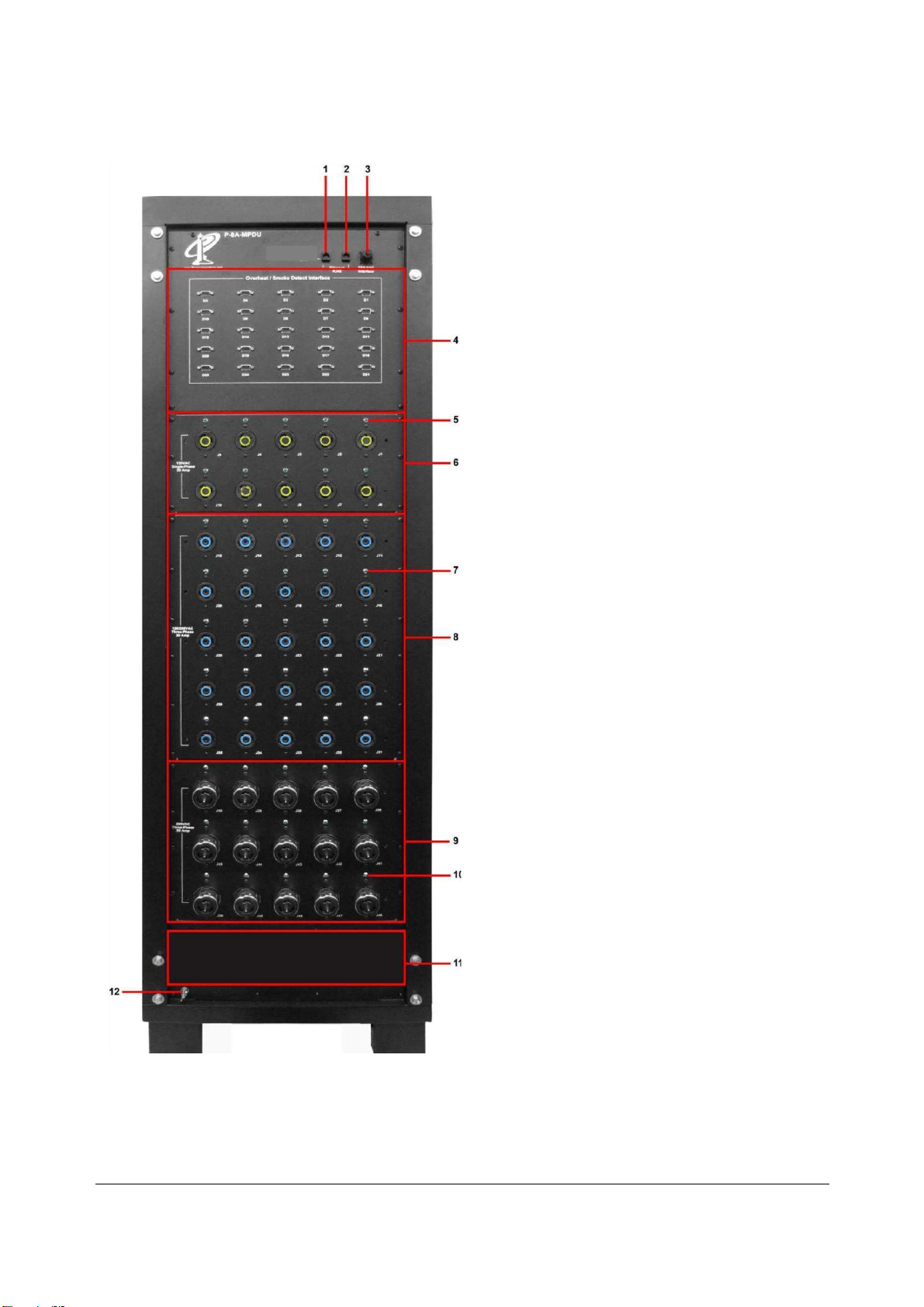

1.6 PTT MPDU FRONT PANEL................................................................................................................................. 7

1.7 PTT MPDU BACK PANEL ................................................................................................................................. 8

1.8 VMT MPDU Front Panel.................................................................................................................................... 9

1.9 VMT MPDU Back Panel............................................................................................................................... 10

1.10 WTT MPDU PROGRAMMABLE LOGIC CONTROLLER (PLC)......................................................................... 11

1.11 TSSC/PTT MPDU PROGRAMMABLE LOGIC CONTROLLER (PLC)................................................................ 12

1.12 VMT MPDU PROGRAMMABLE LOGIC CONTROLLER (PLC)......................................................................... 14

2. INSTALLATION.....................................................................................................................................................16

2.1 UNPACKING THE SYSTEM ..................................................................................................................................16

2.2 CONTENTS OF THE SYSTEM ...............................................................................................................................16

2.3 INSPECTION OF THE SYSTEM.............................................................................................................................. 16

2.4 SITE AND ENVIRONMENT CONSIDERATIONS..................................................................................................... 16

2.5 Q-LS OUTPUT CONNECTIONS ............................................................................................................................17

2.6 MPDU INPUT CONNECTIONS ............................................................................................................................18

2.7 Q-LS / MPDU DATA CONNECTION .................................................................................................................. 20

3. OPERATION ..........................................................................................................................................................21

3.1 PRE-START RE-CHECK .......................................................................................................................................21

3.2 OPERATING PROCEDURE.................................................................................................................................... 21

Startup Procedure................................................................................................................................................... 21

Shutdown Procedure...............................................................................................................................................21

4. TOUCHSCREEN..................................................................................................................................................22

4.1 MPDS™SOFTWARE USER GUIDE.................................................................................................................... 22

5. PROGRAMMABLE LOGIC CONTROLLER (PLC)..................................................................................... 23

5.1 PLC OVERVIEW................................................................................................................................................... 23

5.2 PLC INPUTS .........................................................................................................................................................23

5.3 PLC CONTROL .....................................................................................................................................................24

5.4APPENDIX A.........................................................................................................................................................24

6. PLC SOURCE CODE EXAMPLE ..................................................................................................................... 25

6.1INTRODUCTION ....................................................................................................................................................25

6.2I/OMAPPING........................................................................................................................................................ 26