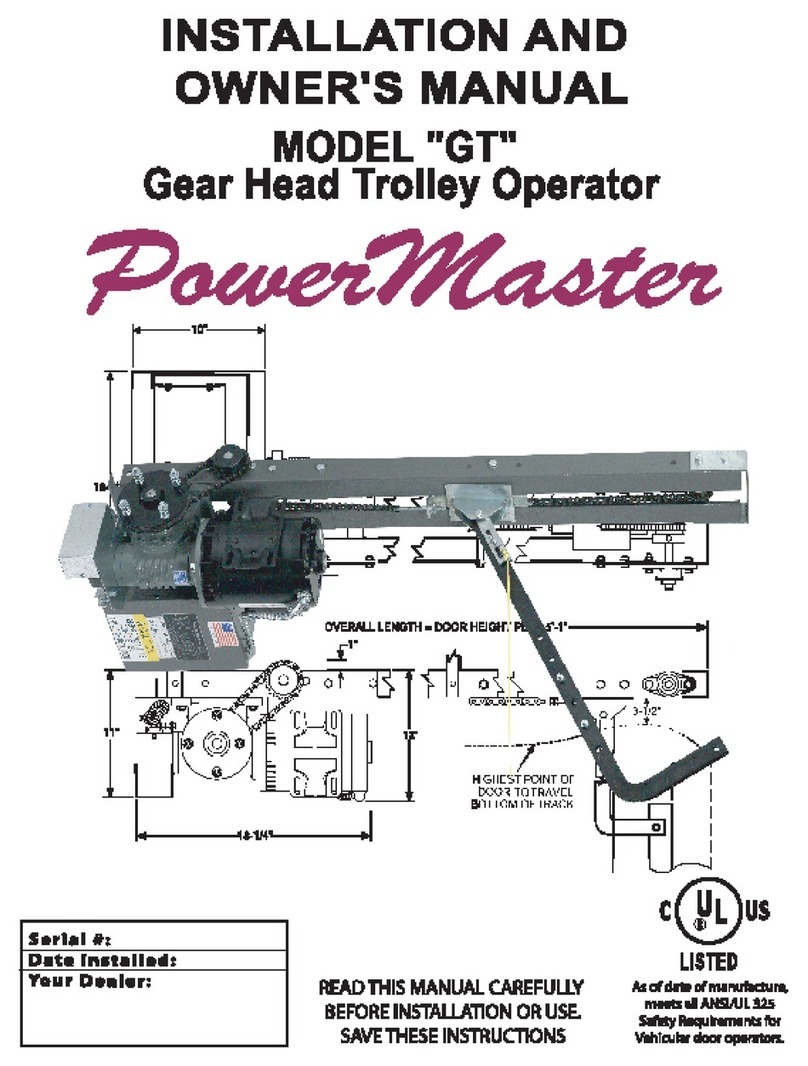

Power Master GSL Installation instructions

5"

OVERALL LENGTH = DOOR HEIGHT PLUS 5’1”

18-1/4”

15-1/2”

2”

11”

TOP EDGE

OF DOOR

6-1/2”

12-1/2”

6”

C OF DRIVE CHAIN

L

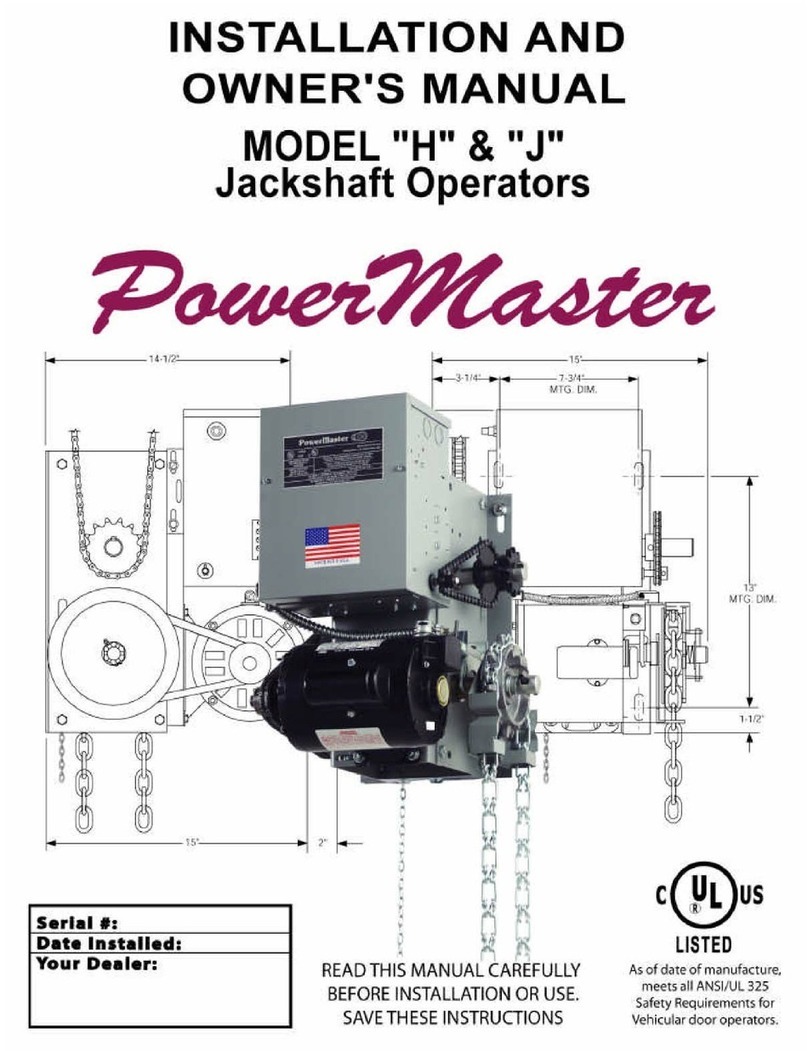

INSTALLATION AND OWNER’S MANUAL

MODEL GSL

Gearhead Slide Door Operator

UL 325 and UL 991 Listed

READ THIS MANUAL CAREFULLY

BEFORE INSTALLATION OR USE.

SAVE THESE INSTRUCTIONS.

Serial #:

Date Installed:

Your Dealer:

As of date of manufacture,

meets all ANSI/UL 325

Safety Requirements for

Vehicular door operators.

CAUTION

Product Features....................................................................................................3

Preparation........................................................................................................ 4-9

Component Identication...................................................................................5

Important Installation Notes (Things to do Before & During Installation)...........6

Installation Instructions ......................................................................................7

Rail/Chain Assembly Instructions ................................................................. 7-8

Operator Assembly Instructions ...................................................................9-11

Operator Installation .....................................................................................11-18

Chain Routing..................................................................................................11

Hanger Installation ..........................................................................................12

Hanger Layout ................................................................................................14

Mounting Disconnect Assembly ......................................................................15

Setting the Limit Switches ...............................................................................16

Electrical Wiring Instructions ...........................................................................17

Accepted Safety Equipment ............................................................................18

Operation and Adjustment Instructions..................................................... 20-22

Clutch Adjustment ...........................................................................................20

Brake Adjustment ............................................................................................21

Fire Door Disconnect Installation ....................................................................22

Testing .............................................................................................................24

Maintenance.........................................................................................................25

Trouble Shooting Chart ........................................................................................26

Warranty ...............................................................................................................29

READ THESE STATEMENTS CAREFULLY

AND FOLLOW THE INSTRUCTIONS CLOSELY

The Warning and Caution boxes throughout this manual are there to protect you and your

equipment. Pay close attention to these boxes as you follow the manual.

Indicates a Mechanical

hazard of injury or death.

Gives instructions to avoid

the hazard.

Indicates a Mechanical hazard

of damage to your operator or

equipment. Gives instructions

to avoid the hazard.

Indicates an electrical

hazard of injury or death.

Gives instructions to avoid

the hazard.

Indicates an electrical hazard

of damage to your operator or

equipment. Gives instructions to

avoid the hazard.

CAUTION

WARNING

WARNING

Table of Contents

Model GSL Gearhead Slide Door Operator

3

The purpose of this booklet is to provide assembly, installation, and operation information

concerning PowerMaster Model GSL Commercial Slide Door Operators and related Accessory

Products.

NOTE: IT IS IMPORTANT THAT THIS INSTRUCTION MANUAL BE READ AND

UNDERSTOOD COMPLETELY BEFORE INSTALLATION OR OPERATION IS ATTEMPTED.

IT IS INTENDED THAT THE INSTALLATION OF THIS UNIT WILL BE DONE ONLY BY

PERSONS TRAINED AND QUALIFIED IN THE INSTALLATION, ADJUSTMENT, AND

SERVICE OF COMMERCIAL DOORS AND DOOR OPERATORS, AND BY QUALIFIED

ELECTRICIANS.

The important safeguards and instructions in this manual cannot cover all possible

conditions and situations which may occur during its use. It must be understood that

common sense and caution be exercised by the person(s) installing, maintaining, and

operating the equipment described herein.

Do not use this equipment for any purpose other than its intended use: the operation of an

commercial vehicular slide door.

STANDARD FEATURES:

Limit Switches: Rotary limit switches, easily adjusted over a wide range. The motor may be

removed without aecting the limit switch adjustments.

Manual Release: Permits manual operation of the door in the event of a power failure. The

Model GSL Operator is equipped with a door arm disconnect to aid in manual operation. Use

of this feature will not aect the limit switch adjustment.

Control circuit: Standard 3-button open, close, and stop. 24 Volts AC.

Connections for Auxiliary Entrapment Protection Devices: Use with reversing door edge

components or a photoelectric beam device across the opening.

Constant pressure to close: Standard operation.

MODEL GSL OPERATOR APPLICATIONS:

Slide Door operators are intended for commercial and industrial use on sliding doors which

use horizontal track. A drawbar operator - when properly installed - will eectively lock the

door in the closed position.

Model GSL Slide Door operators are used in the following applications:

• Continuous Duty, Indoor Commercial installations only

• For doors that require 1/2HP to 1-1/2HP motors using single or 3-phase power.

OPTIONAL FEATURES:

Digital Radio Controls: Open, Close and Stop operation. Radio units are available to control

multiple doors from one transmitter.

Keyless Entry System: Connection terminals provided for hard wired or wireless keyless

entry systems.

PRODUCT FEATURES

4

Before starting the installation of the

operator, the door must be in good working

condition, properly operating, and be

properly counterbalanced. Inspect the door

and track for loose or missing hardware.

Test the door manually for balance and

ease of operation. Lubricate door hinges

and rollers. If necessary, employ a qualied

technician to adjust the springs for proper

counterbalance of the door.

Before removing the operator powerhead

from the shipping carton, inspect the

nameplate on the cover of the operator

control box to verify that it is the correct

model for the intended application, and that

the voltage and phase are in accordance

with electrical power provided at the job

site. The rails are shipped separately from

the powerhead.

SPRINGS ARE SUBJECT TO VERY HIGH

FORCES AT ALL TIMES. ADJUSTMENTS

ARE TO BE MADE BY QUALIFIED

PROFESSIONAL DOOR INSTALLER ONLY.

WARNING

REMOVE OR DISABLE ANY LOCKING

DEVICES FROM DOOR. REMOVE

ALL ROPES.

WARNING

PREPARATION

ELECTRIC DOOR OPERATORS ARE DESIGNED FOR DOORS IN

GOOD WORKING CONDITION: PROPERLY OPERATING, PROPERLY

COUNTERBALANCED, AND PROPERLY ADJUSTED IN ACCORDANCE

WITH THE DOOR MANUFACTURER’S INSTALLATION INSTRUCTIONS.

WARNING

Warning: Rope o the area to keep personnel and vehicles clear of the door and oor

space in the vicinity of the operator during the installation.

GSL POWER HEAD

5

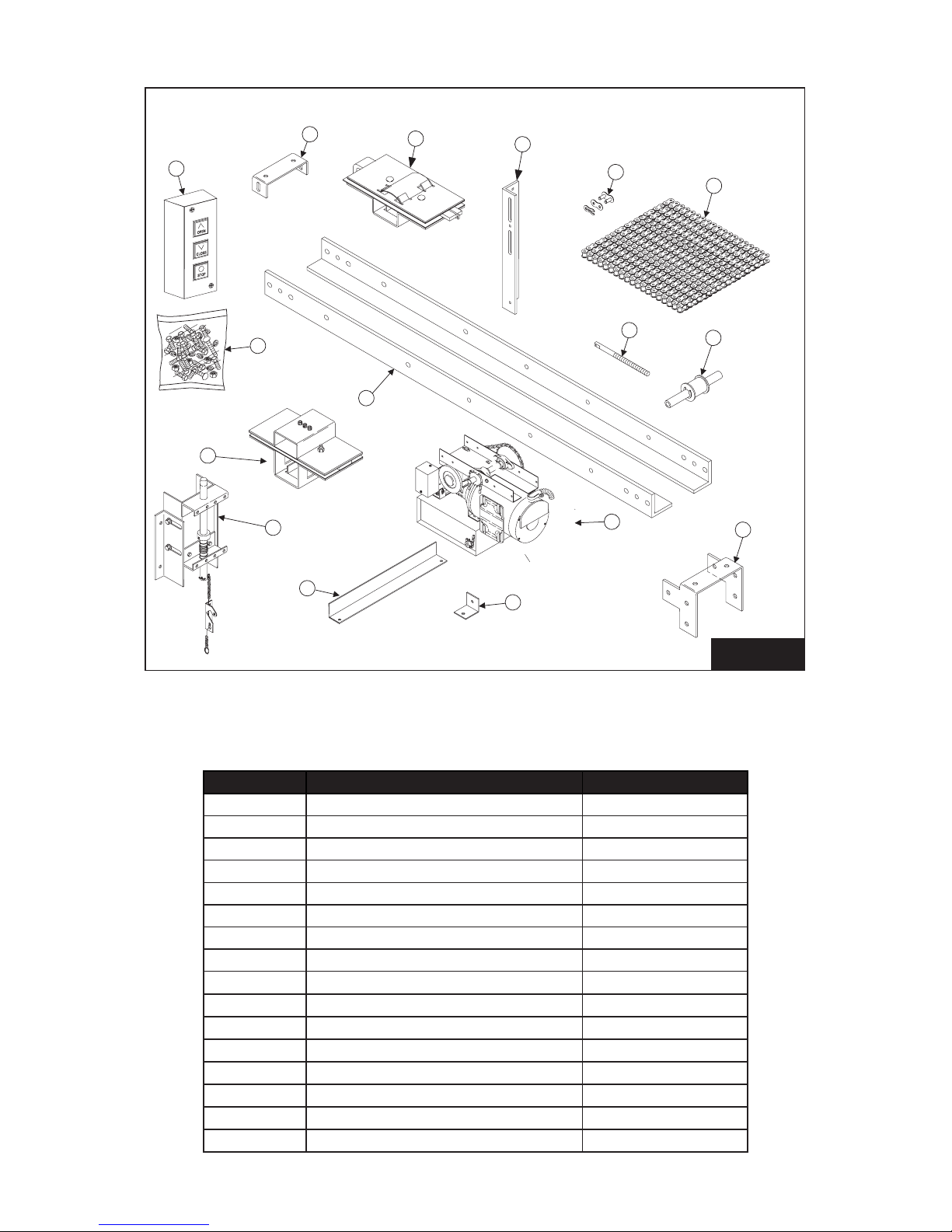

Item# Description Quantity

1 Track Rails 2

2 Spreader Bracket(s) As reqd.

3 Idler Roller Assembly (2 for Bi-part) 1

4 Drive/disc. Assembly (2 for Bi-part) 1

5Trolley Assembly (standard) 1

6Hanger Bracket Angle As reqd.

7Chain Take-Up Bolt 1

8 Operator Power Head 1

9 Drive Chain 1

10 Chain Connecting Link 2

11 Sway Brace 1

12 Sway Brace Clip 1

13 Hardware Package 1

14 3 Button Station 1

15 Trolley Assembly (Bi-Part) 1

16 Bi-Part Front Idler Bracket 1

FIGURE 1

COMPONENT IDENTIFICATION

COMPONENT IDENTIFICATION LISTING

IDLER

ROLLER

ASSEMBLY

BI-PART FRONT

IDLER BRACKET

3

CHAIN

9

6

5

2

STANDARD TROLLEY

SLIDE ASSEMBLY

SPREADER

BRACKET

THREE

BUTTON

STATION

HARDWARE

PACKAGE

TRACK RAILS

DRIVE/DISCONNECT

ASSEMBLY

SWAY BRACE SWAYBRACE CLIP

OPERATOR

POWER HEAD

7

10

16

14

13

1

8

4

15

11

12

HANGER

BRACKET

ANGLE CHAIN

CONNECTING

LINK

CHAIN TAKE-UP

BOLT

BI-PART

TROLLEY SLIDE

ASSEMBLY

6

IMPORTANT INSTALLATION NOTES

TO REDUCE THE RISK OF SEVERE INJURY OR DEATH, READ

& FOLLOW ALL INSTALLATION INSTRUCTIONS!

WARNING

• Install only on a properly operating Slide Door. An improperly operating door could cause

severe injury. Have a qualied service person make repairs to cables, spring assemblies,

and other hardware before installing the opener.

• Remove all ropes, and remove or make inoperative all locks that are connected to

the garage door before installing the opener (unless mechanically and/or electrically

interlocked to the power unit).

• Lightweight doors (berglass, aluminum etc.) must be reinforced to avoid door damage.

Check the door manufacturer’s instruction manual for a bracing procedure or the

availability of a Reinforcement Kit.

• PowerMaster Model GSL Slide Door operators are for Commercial Vehicular Slide Doors,

and as such, are NOT recommended for pedestrian trac. In installations where it is

known that the pedestrians will be nearby, ensure a pedestrian door is available for

entrance and exit to the building. In addition, YOU MUST install an auxiliary entrapment

protection device that is UL recognized and has been tested for use with this unit

(such as a reversing door edge or photoelectric beam device) as part of the compete

operator system.

• Connect an auxiliary entrapment protection device (reversing edge or photoelectric

device across the door opening). A device of this type is STRONGLY ADVISED FOR ALL

commercial operator installations. An auxiliary entrapment protection device is REQUIRED

when the three button control station is out of sight of the door or any other automatic or

manual control is used.

• Install the opener at least 8 feet or more above the oor.

• Do not connect the opener to the source of power until instructed to do so.

• Locate the control station:

a. Within sight of the door;

b. At a minimum height of 5 feet above the oor so small children cannot reach it; and

c. Away from the door, so the user is prevented from coming in contact with the door

while operating the controls.

• Do not overtighten the clutch adjustment to compensate for a poorly working door.

• Securely attach any WARNING signs or placards to either the door or above the control

station as directed.

• After installing the opener, all safety features must be tested for proper operation.

7

INSTALLATION INSTRUCTIONS

WARNING

SPRINGS, PULLEYS, CABLES AND MOUNTING HARDWARE

USED TO BALANCE YOUR GARAGE DOOR ARE UNDER EXTREME

TENSION AT ALL TIMES AND CAN CAUSE SEVERE INJURY OR

DEATH IF DISTURBED. DO NOT ATTEMPT ADJUSTMENT.

RAIL/CHAIN ASSEMBLY

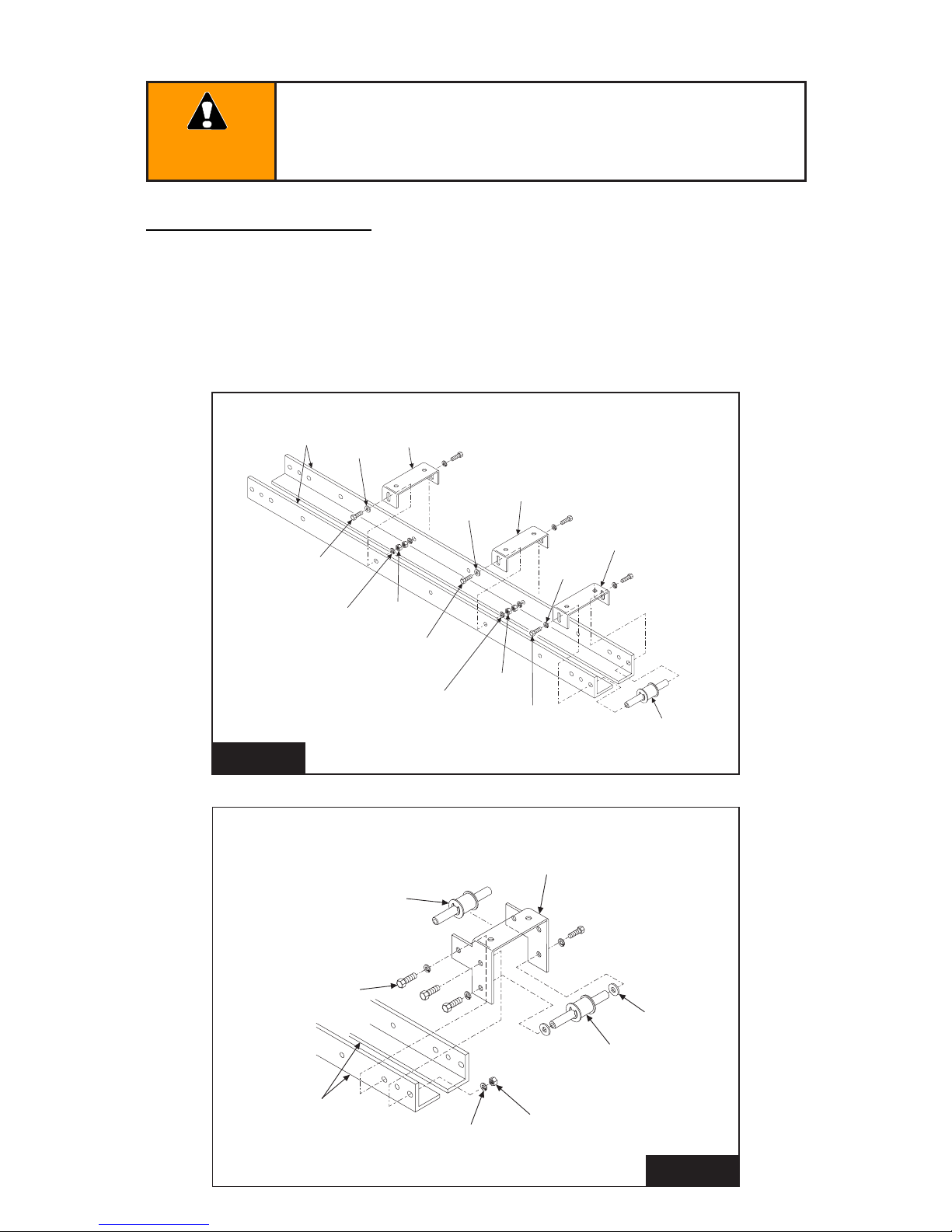

TRACK ASSEMBLY

1. Lay Track Angles [#1] on work surface as shown in Figure 2.

2. Install Track Spreader Brackets [#2] and Front Idler Roller Assembly [#3] to one end of track

using 3/8 x 3/4 long hex head bolts and 3/8 lock washers, as shown in Figure 2.

FIGURE 2

FIGURE 2A

TRACK

ANGLE

[#1]

SPREADER

BRACKET

[#2]

SPREADER

BRACKET

[#2]

SPREADER

BRACKET

[#2]

3/8”

WASHERS

3/8” X 3/4”

LG. HEX HEAD

BOLTS

3/8” X 3/4”

LG. HEX HEAD

BOLTS

IDLER ROLLER

ASSEMBLY

[#3]

3/8” X 3/4”

LG. HEX HEAD

BOLTS

3/8”

WASHERS

3/8” LOCK

WASHERS

3/8” LOCK

WASHERS

3/8”

LOCK WASHERS

3/8”

HEX NUTS

3/8”

HEX NUTS

(6) 3/8” X 3/4”

LG. HEX HEAD

BOLTS

IDLER ROLLER

ASSEMBLY

[#3]

BI-PART FRONT

IDLER BRACKET

[#16]

IDLER ROLLER

ASSEMBLY

[#3]

(6) 3/8”

LOCK WASHERS

(2) 3/8”

WASHERS

(2) 3/8”

HEX NUTS

TRACK

ANGLE

[#1]

8

SLIDE ASSEMBLY

1. Assemble Top Plate, Lower Drive Plate, Center Drive Bar and two Nylon Inserts using two

5/16 x 1-1/4 carriage bolts, two 5/16 Lock Washers and two 5/16 Hex Nuts as shown in

Figure 3.

2. Install 3/8 Chain Take-up Bolt into Slide Assembly using one 3/8 Lock Washer and two 3/8

Hex Nuts as shown in Figure 3A. DO NOT TIGHTEN NUTS!

3. For Bi-Part Slide Assembly, see Figure 3B.

5/16 X 1-1/4”

CARRIAGE BOLTS

NYLON CHAIN

DEFLECTOR

CENTER

DRIVE BAR

LOWER

DRIVE PLATE

NYLON INSERTS

TOP PLATE

3/8” HEX NUT

3/8” HEX NUT

5/16” HEX NUTS

CENTER BAR

3/8” LOCK WASHER

5/15” LOCK WASHER

5/15” LOCK WASHER

TAKE UP

BOLT

#10 SOCKET HEAD

CAP SCREWS (3)

TROLLEY

CENTER GUIDE

DEEP ENGAGEMENT

LOWER DRIVE PLATE

5/16 X 1-1/4”

LG. CARRIAGE BOLTS

BI-PART TROLLEY

UPPER DRIVE PLATE

3/8” HEX NUT

3/8” HEX NUT

3/8” LOCK WASHER

3/8” LOCK WASHER

NYLON

INSERT

FIGURE 3A

FIGURE 3B

9

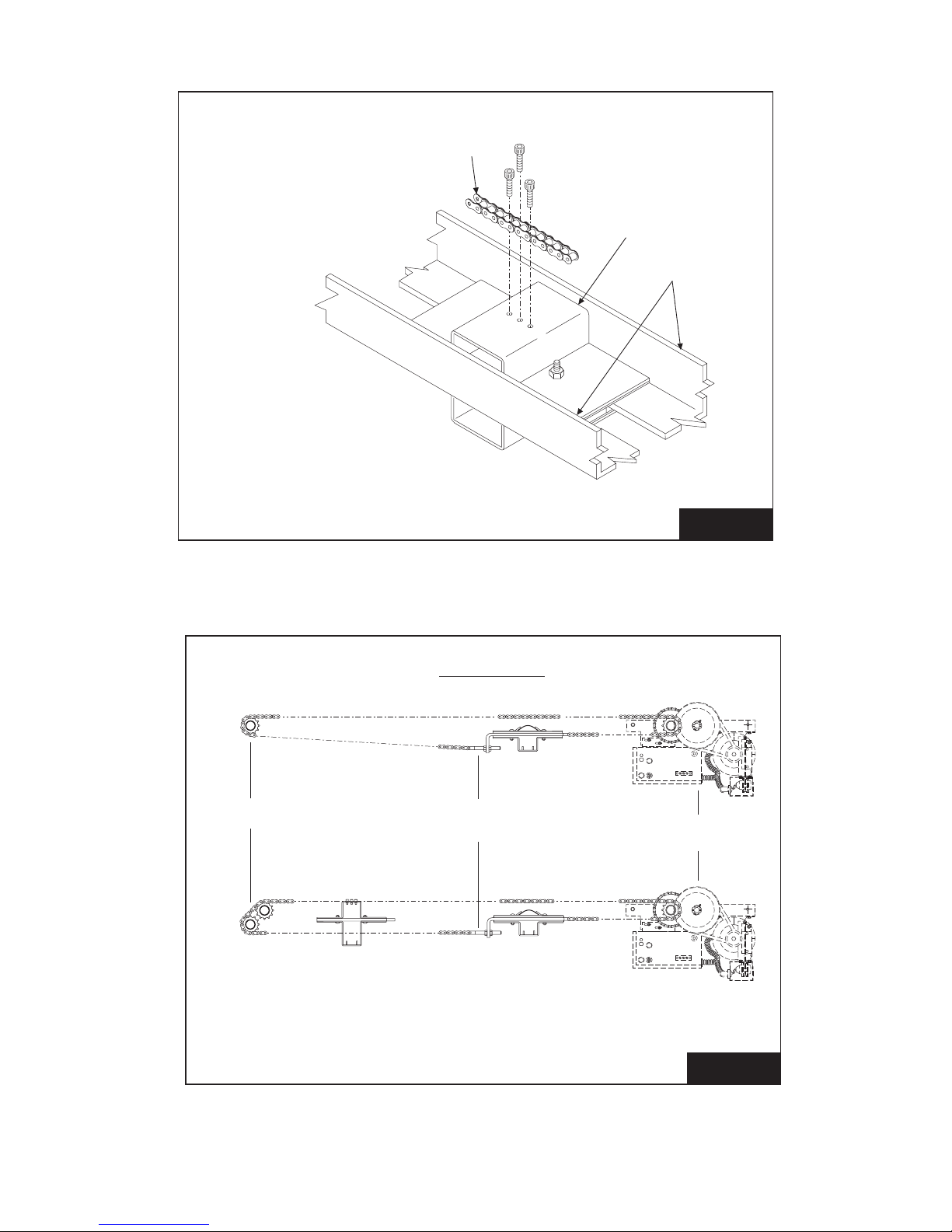

OPERATOR ASSEMBLY

1. Install Trolley Slide Assembly on Track Assembly with Chain Take-up Bolt [#7] pointing away

from end of track where Power Head [#8] will be mounted as shown in Figure 4.

NOTE: If Bi-Part installation, slide Bi-Part trolley slide on rst.

2. Mount Power Head to Track Assembly using four 3/8 x 3/4 Long Hex Head Bolts, four 3/8 Lock

Washers and four 3/8 Hex Nuts, as shown in Figure 4.

3. Turn operator assembly over and back o Chain Adjustment Nut to the end of the threads

on Chain Take-up Bolt [#7]. See Figure 5.

4. Lay out Drive Chain [#9] next to operator assembly work surface.

5. Thread one end of the Operator Drive Chain around Operator Drive Sprocket and connect to

the Drive Tab on the Trolley Slide Assembly with a Chain Connecting Link. See Figure 5A and

Figure 6.

6. Thread the other end of the Drive Chain [#9] around the Idler Roller Assembly [#3]. See

Figure 6.

7. Pull Drive Chain [#9] tight up to Trolley Traveler Assembly. Mark the link that lines up with

the hole on the chain take up bolt on Slide Assembly on Traveler Assembly and cut Drive

Chain to length.

NOTE: If installing a bi-part operator, Drive Chain [#9] must pass through Bi-Part Slide

Assembly [#15] before being connected to Chain Take Up Bolt [#7] on Standard Slide

Assembly [#5]. See Figure 5B and Figure 6.

8. Attach cut end of Drive Chain [#9] to Drive Tab on Trolley Traveler Assembly with a Chain

Connecting Link. See Figure 5A.

9. Adjust chain tension using Chain Adjusting Nut to remove excess slack. See Figure 5A.

Track

Assembly

Power Head

[#8] (4) 3/8”

Hex Head Bolts

(4) 3/8”

Hex Bolts

(4) 3/8”

Lock Washers

Standard Trolley

Slide Assembly

[#5] Bi-Part Trolley

Slide Assembly

(When Required)

[#15]

FIGURE 4

10

10. Lock in adjustment using Lock Washer and Lock Nut on Chain Take-up Bolt. See

Figure 5A.

NOTE: Leave Bi-part slider carriage free at this time.

11. Bolt the hanger bracket angles together as shown in Figure 7 to form mounting brackets.

Attach the mounting brackets to the track spreader brackets using the 3/8”bolts, lock

washers and nuts (See Figure 7A). Do not tighten as the distance from the wall to the

track will have to be adjusted later.

DRIVE CHAIN

[#9]

TRACK

ASSEMBLY

ASSEMBLY SHOWN IN THE

INVERTED POSITION

BI-PART

TROLLEY ASSEMBLY

[#15]

FIGURE 5A

FIGURE 5B

DRIVE

CHAIN

[#9]

LOCK

NUT

DRIVE TAB

[#9]

LOCK

WASHER

CHAIN

CONNECTING

LINK

[#10]

CHAIN

CONNECTING LINK

[#10]

CHAIN

ADJUSTING

NUT

CHAIN

TAKE-UP BOLT

[#7]

TROLLEY

ASSEMBLY

[#5]

11

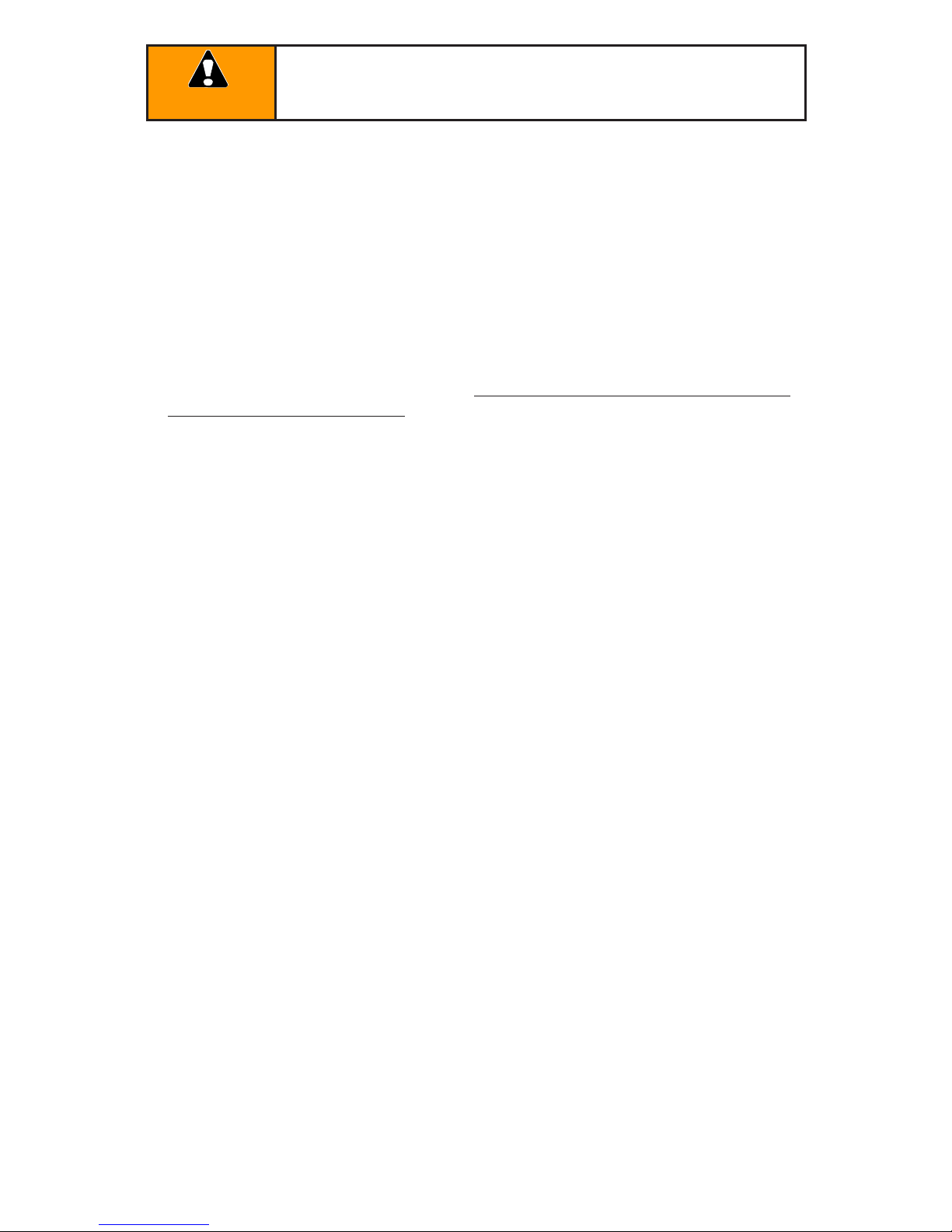

ASSEMBLY SHOWN IN THE

NORMAL POSITION

DRIVE CHAIN

[#9]

TRACK

ASSEMBLY

BI-PART

TROLLEY ASSEMBLY

[#15]

FRONT IDLER

BI-PARTING SLIDE

SINGLE SLIDE

CHAIN ROUTING LAYOUT FOR SLIDE DOOR

OPERATORS WITH IDLER SPROCKETS

CHAIN TAKE UP

BOLT POWER HEAD

FIGURE 5C

FIGURE 6

(3) 3/8” HEX

HEAD BOLTS

HANGER

BRACKET ANGLE

[#6]

HANGER

BRACKET ANGLE

[#6]

HANGER

BRACKET ANGLE

[#6]

(3) 3/8” HEX NUTS

(3) 3/8” LOCK

WASHERS

56-1/2” FOR 8’, 12’, & 16’TRACK

32-1/2” FOR 10’ & 14’ TRACK

MOUNTING

BRACKET ANGLE

ASSEMBLY

LEFT TRACK ANGLE

RIGHT TRACK ANGLE

POWER HEAD

STANDARD

TROLLEY TRAVELER

BI-PART

TROLLEY TRAVELER

FRONT IDLER

SHAFT

SPREADER

BRACKET

SWAY BRACE

ANGLE CLIP

48”

(ALL CENTER SPACERS)

46”

FIGURE 7

FIGURE 7A

HANGER INSTALLATION

13

WARNING

TO AVOID DAMAGE TO DOOR AND OPERATOR, ENSURE ALL DOOR

LOCKS ARE DISABLED. USE AN INTERLOCK SWITCH IF A LOCK IS

REQUIRED TO RETAIN FUNCTIONALITY.

1. For single slide doors sliding right to open, locate rst angle mounting bracket 9” to the

left of the opening. For doors sliding left to open, locate rst angle mounting bracket 9”to

the right of the opening (See Figure 8).

NOTE: For bi-parting doors, this measurement is 15”. See Figure 9.

2. Set the assembled operator into position and mark the holes for the angle mounting

brackets on the wall, as low as possible without interfering with door travel (See

Figure 10). Drill holes in the wall for mounting. Through bolts are recommended for

this purpose. If wall construction does not permit the use of through bolts, lag bolts and

shields may be used.

3. Secure the assembled operator to the wall. IMPORTANT: BE SURE THE OPERATOR TRACK

AND DOOR TRACK ARE PARALLEL. Check that the door clears the power head when

moving. Adjust the track location on the mounting brackets to the desired position and

tighten all the bolts. It is recommended that at least one sway brace be used between

the wall and one of the track hangers for increased rigidity - especially on large or heavy

doors. See Figure 7A.

4. Mount the disconnect mechanism so that the top of the bracket is no more than 2”

below the slider carriage (See Figures 8, 10, 11). This mechanism may be adjusted

both front and back and up and down to align the disconnect pin. It may be necessary

to shim between the mechanism and the door to bring the pin out into the center line

of the track.

NOTE: For Bi-parting doors, mount both door disconnect mechanisms (See Figures 9,

10, 11)

5. It is necessary on a bi-part installation to bring the doors to a fully closed position for

proper synchronization. WIth both disconnect pins engaged in their respective carriages,

connect the drive chain to the bi-part slide assembly with the hardware provided (See

Figures 5C and 7).

6. Install disconnect chain lock as shown in Figure 11 so it will function as described in

Figure 12.

14

FIGURE 9

FIGURE 8

HANGER LAYOUT RIGHT HAND OPERATOR

BI-PART INSTALLATION

DISCONNECT CHAIN LOCK

9” DOOR OPENING

46”

1-1/4”

46”

1-1/4”

DISCONNECT CHAIN LOCK

DOOR OPENING

15”

15

SUITABLE FASTENERS BY

INSTALLER

POSITION 1

DOOR ENGAGED

DISCONNECT CHAIN LOCK

FOR MANUAL OPERATION,

PULL CHAIN AND LATCH

POSITION 2

DOOR

DISENGAGED

KEEP AS NARROW

AS POSSIBLE TO

REDUCE SWAY

TROLLEY SLIDE

ASSEMBLY

2” MAX.

4-1/4” MIN.

6-1/4” MAX.

(AVAILABLE ADJUSTMENT)

NOTE:

DISCONNECT SHAFT MUST

CLEAR TROLLEY TRAVELER

WHEN FULLY RETRACTED

DISCONNECT

DRIVE PLUNGER

AS REQUIRED

DISCONNECT

CHAIN LOCK

DISCONNECT

ASSEMBLY

6-3/4”

5-1/2”

2-1/2”

2” MIN.

4” MAX.

ADJUST HEIGHT OF

DISCONNECT ASSEMBLY

TO CENTER DRIVE

PLUNGER IN TROLLEY

SLIDE ASSEMBLY

THIS DIMENSION IS

DETERMINED BY ENGAGING

DRIVE PLUNGER ON

DISCONNECT ASSEMBLY WITH

TROLLEY SLIDE ASSEMBLY.

FIGURE 10

FIGURE 11

FIGURE 12

16

TO AVOID RISK OF ENTRAPMENT AND POSSIBLE DAMAGE

TO THE DOOR AND OPERATOR, THE LIMITS MUST BE

ADJUSTED BEFORE APPLYING POWER TO THE OPERATOR.

WARNING

SETTING THE LIMIT SWITCHES

1. Remove the cover on the electrical enclosure. There are two limit nuts on the threaded

limit shaft that move laterally along the shaft as the operator opens and closes the door.

When a limit nut nears the end of the shaft, it activates a (set of) switch(es). The Open Limit

Switch is on the LEFT, and the Close Limit Switch is on the RIGHT. Auxiliary switches may

also be present to control other function (They are mounted to a separate bracket and

should not be confused with the Open and Close limit switches, which are mounted on the

back of the electrical enclosure box and are somewhat hidden from view).

2. Manually set the door to a nearly closed position.

3. Refer to Figure 8. Depress the Limit Nut Retaining Bracket away from the slots in the limit

nuts. Turn the Close Limit Nut on the shaft until it engages the Close Limit Switch. The

switch will sound an audible “click” when engaged. If there are auxiliary switches present,

the limit switch will be the second“click.” Release the Retaining Bracket and be sure that it

engages in slots of both limit nuts.

4. Manually raise the door to a Nearly Open position, and repeat Step #3 with the Open Limit

Nut and Switch.

5. If auxiliary switches are present, the limit nut will actuate them just prior to activating the

Open or Close Limit Switch (This is pre-set at the factory).

6. Manually move the door

to a half-open position

to avoid door damage

due to incorrect power

supply phasing. On three-

phase units, the door may

initially run in the wrong

direction when power

is rst applied. With the

door in mid-position,

there will be time to stop

the door before damage

can happen if incorrect

phasing occurs.

7. A nal limit adjustment

will be necessary after

the connection of the

power supply in order to

ensure the door stops in

the proper Open and Close

positions. FIGURE 13

OPEN

LIMIT NUT

CLOSE

LIMIT NUT

LIMIT

SHAFT

LIMIT NUT

RETAINER PLATE

OPEN

LIMIT SWITCH

CLOSE

LIMIT SWITCH

17

NOTE: PowerMaster GSL operators have been

designed and constructed for use with voltages

from 115 Volts AC to 575 Volts AC, in single or

three phase. Check the operator nameplate

label on the control box cover for the proper

voltage and phase. The application of an

improper input voltage or phase will result in

catastrophic failure to the internal electrical

components. Observe local electrical codes

when wiring the operator.

When hard wiring, observe state and local

electrical codes. A wiring diagram is attached

to the inside of the control box cover. Connect

the appropriate voltage and phase power

leads to the appropriate terminals as per the

wiring diagram and connect a ground wire to

the grounding screw. On three phase units,

incorrect phasing of the power supply will cause

the motor to rotate in the wrong direction (It

will open when Close button is pushed and vice

versa). To correct this, interchange any two of the

incoming three phase conductors.

The wiring diagram attached inside the cover

of the control box details all of the eld wiring

terminal connections for the operator. Always

connect the wires to the push button controls

and auxiliary devices exactly as shown.

Warning: Control voltage of the operator is 24 Volts AC, Class 2. Do not run the power

leads and control circuit wiring in the same electrical conduit.

NOTE: All GSL operators are pre-wired to accept reversing edge components. To comply with

UL requirements, one of these systems must be installed and wired to the operator.

For operator models not installed with

reversing edge components or photoelectric

device, ONLY ONE THREE BUTTON STATION OR

A CONTROL WIRED FOR CONSTANT PRESSURE

TO CLOSE MAY BE USED TO CONTROL THE

OPERATOR. THIS IS TO COMPLY WITH UL

SAFETY REQUIREMENTS. IN THIS CASE, THE

CONTROL STATION MUST BE LOCATED WITHIN

CLEAR SIGHT OF THE DOOR ADJACENT TO THE

CONTROL STATION, THE WARNING PLACARD

INCLUDED WITH THE OPERATOR MUST BE

INSTALLED (Figure 14)

TO PREVENT THE RISK OF PERSONAL

INJURY AND/OR DAMAGE TO DOOR

OR PROPERTY, ONLY OPERATE DOOR

CONTROL WHEN DOOR IS IN CLEAR

VIEW. IF CONTROL STATION CANNOT BE

LOCATED WHERE THE DOOR IS VISIBLE,

OR IF ANY OTHER DEVICE IS USED TO

CONTROL THE DOOR, AN AUXILIARY

ENTRAPMENT DEVICE MUST BE

CONNECTED TO THE UNIT.

WARNING

ELECTRICAL WIRING INSTRUCTIONS

TO PREVENT THE RISK OF PERSONAL

INJURY OR DEATH:

• DISCONNECT POWER AT THE FUSE

BOX BEFORE PROCEEDING

• ELECTRICAL CONNECTIONS

MUST BE MADE BY A QUALIFIED

INDIVIDUAL

• OBSERVE LOCAL ELECTRICAL CODES

WHEN WIRING THE OPERATOR

WARNING

WARNING: TO PREVENT

ENTRAPMENT, DO

NOT START DOOR

DOWNWARD TRAVEL

UNLESS DOORWAY IS

CLEAR

FIGURE 14

18

TO AVOID DAMAGE TO DOOR AND

OPERATOR, ENSURE ALL DOOR LOCKS

ARE DISABLED. USE AN INTERLOCK

SWITCH IF A LOCK IS REQUIRED TO

RETAIN FUNCTIONALITY.

CAUTION

ACCEPTED SAFETY EQUIPMENT

• Photoelectric safety sensors manufactured

by Linear Corp.

• Door Edge Sensor and Interface Module

manufactured by Miller Edge model series

designated ME, MT, MU and CPT223 with

sux T2 provided with interface module

model Signature Module model SM-102.

• Optical Door Edge Sensor and Photo Eye manufactured by Fraba Inc. models

OPTOEDGE, OPTOEYE; Part Nos. OSE-T, OSE-R, OSE-P, OPE.

SEE MANUFACTURER’S INSTRUCTIONS FOR INSTALLATION OF THIS SAFETY EQUIPMENT.

RISK OF ENTRAPMENT THAT MAY RESULT IN SERIOUS PERSONAL INJURY

OR DEATH. DISCONNECT POWER TO THE OPENER BEFORE AND DURING

INSTALLATION OF AN ACCESSORY, REVERSING DOOR EDGE OR PHOTOELECTRIC

DEVICE. DO NOT RECONNECT POWER TO OPENER UNTIL INSTRUCTED TO DO SO.

ENSURE DOORWAY IS CLEAR BEFORE STARTING TESTING OF UNIT.

WARNING

19

• NEVER let children operate or play with door controls. Keep remote control away from

children.

• ALWAYS keep a moving door in sight and keep people and objects away from the door

area until the door is completely closed. NO ONE SHOULD CROSS THE PATH OF A

MOVING DOOR.

• TEST THE DOOR OPENER’S REVERSING FEATURE MONTHLY (where applicable).

• After adjusting the force setting, if equipped with a clutch or the limit of travel, ALWAYS

RETEST THE OPENER. Failure to adjust the opener properly may result in damage to the

door or operator.

• DO NOT over adjust the force setting (clutch) to compensate for a poorly

working door.

• KEEP THE GARAGE DOOR PROPERLY BALANCED (See the door owner’s manual).

• AN IMPROPERLY BALANCED DOOR MAY CAUSE SEVERE INJURY OR DEATH.

• Have a QUALIFIED SERVICE PERSON make repairs to cables, spring assemblies and

other hardware.

• SAVE THIS INSTRUCTION MANUAL AND GIVE IT TO THE END USER.

NOTE: It is now necessary to turn on the power in order to run the Opener to check for

proper operation and limit settings. Before doing so, ensure that all mounting hardware

are installed and properly tightened, that all electrical connections are per local code

requirements, and that proper wiring practices have been followed. Also, double-check

that all ropes and installation support hardware have been removed from the door and

that the doorway is clear.

WIRING TERMS

MOMENTARY CONTACT: Button can be

pushed and then released and door will keep

moving or stop without maintaining pressure

on the button.

CONSTANT PRESSURE: Constant pressure is

required on the button in order for continued

door movement. When the button is released,

the door will stop and possibly reverse to full

open depending on wiring type.

DOOR EDGE/ PHOTOELECTRIC INPUT: The

operator wiring provides for input from an

electric door safety edge or photoelectric

device that will cause a closing door to stop

and reverse it to open.

IMPORTANT SAFETY INSTRUCTIONS FOR OWNER

TO REDUCE THE RISK OF SEVERE INJURY OR DEATH:

READ AND FOLLOW ALL INSTRUCTIONS!

WARNING

FAILURE TO TEST REVERSING SYSTEM

COULD RESULT IN DEATH OR SERIOUS

INJURY. TEST THIS SYSTEM ONCE A

MONTH.

WARNING

AVOID ELECTROCUTION: DO NOT

ROUTE LOW VOLTAGE WIRES IN SAME

CONDUIT AS HIGH VOLTAGE WIRES.

FOLLOW ALL LOCAL ELECTRICAL

CODES OR THE NATIONAL

ELECTRICAL CODE (NEC).

WARNING

20

RISK OF ENTRAPMENT THAT MAY

RESULT IN SEVERE INJURY OR DEATH!

DISCONNECT POWER TO THE OPERATOR

BEFORE SERVICING OR MAKING

ADJUSTMENTS. ENSURE DOORWAY

IS CLEAR BEFORE STARTING TESTING

OF UNIT.

WARNING

ALWAYS DISCONNECT POWER TO

THE OPERATOR BEFORE SERVICING,

CONNECTING ACCESSORY DEVICES

OR MAKING ADJUSTMENTS.

CAUTION

The clutch serves to protect the door, the

electric operator and other equipment from

undue stress or damage caused by starting

forces and/or an obstruction to the door. It

should be set NO TIGHTER than is necessary

to smoothly and consistently move the door

throughout its full range of travel. When

properly set, it will slip freely if the door should

encounter an obstruction, and it should be

possible to stop the travel of the door by hand.

WARNING: BEFORE ADJUSTMENT, REMOVE

POWER TO THE OPERATOR!

CAUTION: NEVER COMPRESS CLUTCH SPRING

BEYOND POINT LIMITED BY THE DESIGN

OF THE OPERATOR OR REPLACE IT WITH A

HEAVIER SPRING.

Due to changing conditions of the door

and normal wear, it may be necessary to

occasionally re-adjust the clutch to obtain

dependable operation.

WARNING: BEFORE DOING SO, BE

CERTAIN THAT THE DOOR IS IN GOOD

WORKING CONDITION, IS PROPERLY

COUNTERBALANCED, AND THAT THE CLUTCH IS NOT SLIPPING BECAUSE OF LOOSE OR

MISSING HARDWARE, BINDING IN THE TRACK, RUBBING AGAINST THE DOOR STOPS, OR

DEFECTIVE OR MISADJUSTED SPRINGS. ANY SERVICE REQUIRED TO THE DOOR, DOOR SPRINGS

OR DOOR OPERATOR MUST BE PERFORMED BY A QUALIFIED PROFESSIONAL DOOR INSTALLER.

The clutch pads will wear during normal operation and should be replaced when it becomes

dicult or impossible to suciently tighten the clutch to obtain smooth operation of the

door when it is in good working condition. To

replace the clutch pad, rst move the door to

the closed position. Loosen and remove the

clutch nuts and spring. Remove the pressure

plate and other clutch pad.

To replace the inside clutch pad, loosen the

set screws on the drive hub and remove it.

When reassembling the clutch, tighten the

drive hub set screws after the adjustment

nuts are tightened enough to compress the

clutch springs.

IMPROPER ADJUSTMENT OF CLUTCH

SETTING COULD CAUSE ENTRAPMENT,

INJURY OR DEATH. SET CLUTCH

ADJUSTMENT FOR JUST ENOUGH FORCE

TO OPERATE THE DOOR RELIABLY, BUT

NO STRONGER. CONTACT A SERVICE

PROFESSIONAL TO CORRECT ANY

BINDING, STICKING OR OTHER DOOR

PROBLEMS. DO NOT OVERADJUST

CLUTCH SETTING TO COMPENSATE FOR

A POORLY WORKING DOOR.

WARNING

CLUTCH ADJUSTMENT

FIGURE 15

ADJUSTING

NUTS (4)

CLUTCH

ASSEMBLY

Clutch Adjustment: The clutch is set to its lightest

adjustment by the manufacturer. To tighten the

clutch, turn all four of the clutch adjustment nuts

clockwise in 1/4 turn increments.

OPERATION AND ADJUSTMENT INSTRUCTIONS

Table of contents

Other Power Master Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

Serai

Serai KIT/18F installation manual

quiko

quiko SCARABEO QK-SCA24 manual

Overhead door

Overhead door RapidSlat 611 Operational & maintenance manual

Craftsman

Craftsman 139.53902D owner's manual

Chamberlain

Chamberlain 182649 owner's manual

Wayne-Dalton

Wayne-Dalton 7100 Series Installation instructions and owner's manual