Table

Of

Contents

PAGE

1

.

SAFETY

SAFETY

RULES

FOR

POWER

TOOLS

...............................

...

...........................

1

ADDITIONAL

SAFETY

INSTRUCTIONS FOR

BUFFERS

...................

.......

....

3

2

.

CIRCUIT

REQUIREMENTS

..................................................................................................

120V

OPERATION

4

..................................

....................................................

EXTENSION

CORDS

...

4

..........................................................................................................

GROUNDING

5

3

.

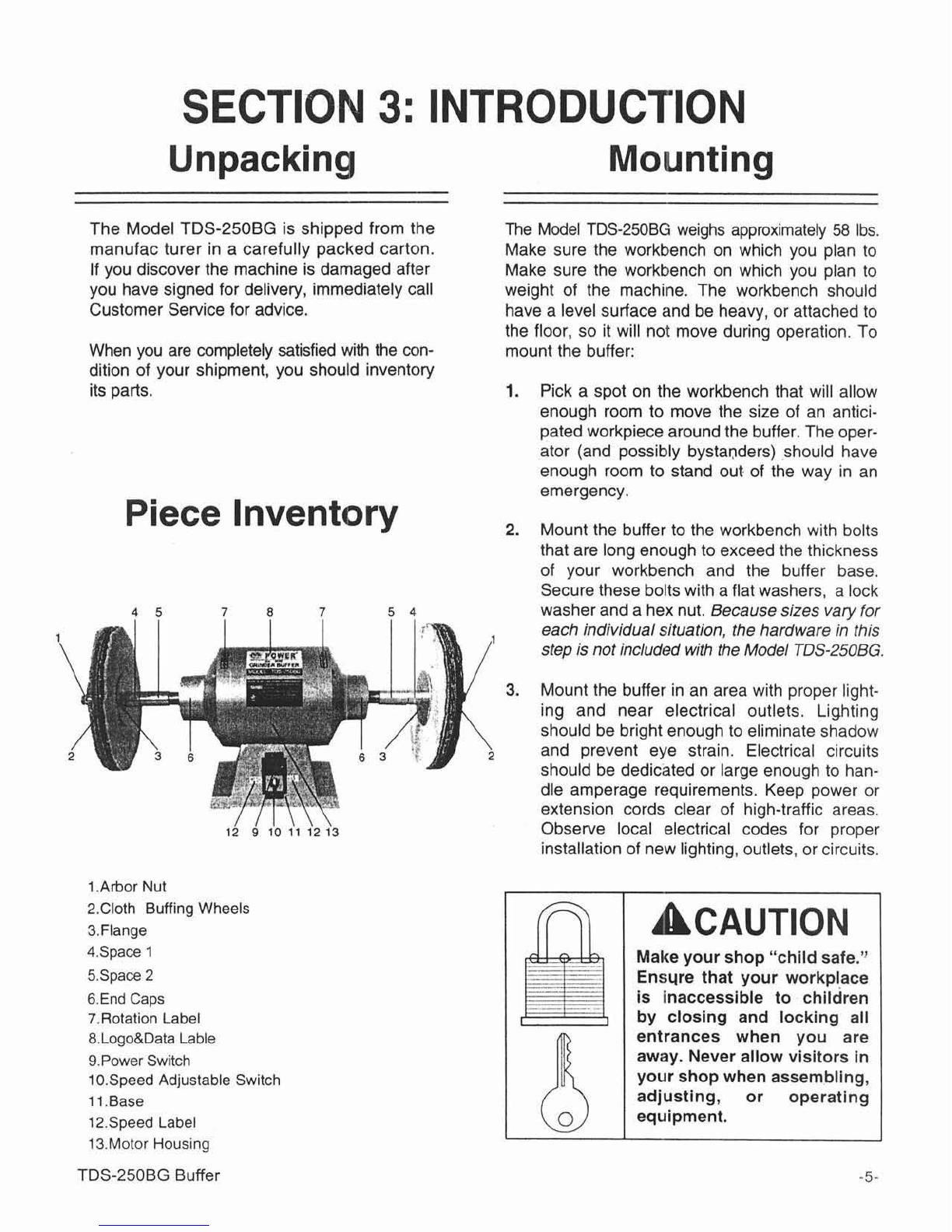

INTRODUCTlON

.......................................................................................................

COMMENTARY

-5

..................................................................................................

UNPACKING

5

MOUNTING

.........................................................................................................

5

4

.

OPERATIONS

TEST

RUN

...............

....

........

..

.....

.......*..

..........................

6

GENERAL

.............................................................................................................

6

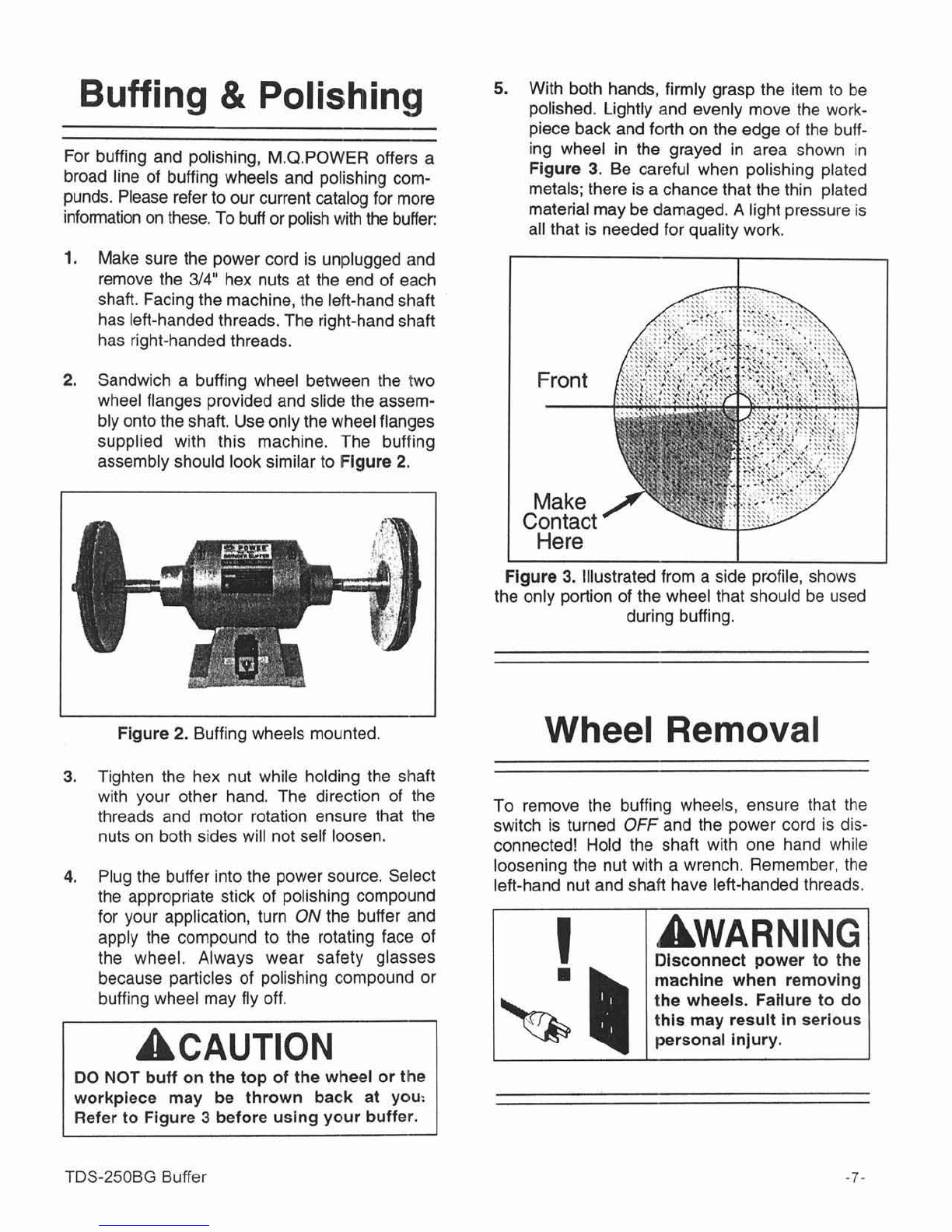

BUFFING&POLTSHING

..........................................................................................

7

WHEEL

RENOVAL

............................................

.....

...............

7

...*...............

...................................................

BUFFING

WHEEL

SELECTION

..

8

......................................................................

BUFFING

COMPOUND

SELECTION

8

........................................................................................................

BUFFING

TIPS

-8

5

.

MAfNTENANCE

........................................................................................................

..I

0

LUSRlCATlQN

....................................................................................................

10

MISCELLANEOUS

.....................

..

....................................................................

10