10

Vent Pipe Installation

The following guidelines should be followed when installing

the exhaust outlet piping:

• Venting should be as direct as possible with a

minimum number of pipe fittings.

• Vent diameter must not be reduced unless

specifically noted in the installation instructions.

• Support all horizontal pipe runs every four feet

and all vertical pipe runs every six feet or

according to local codes.

• Vents run through unconditioned spaces where below

freezing temperatures are expected should be prop-

erly insulated to prevent freezing. For horizontal runs,

wrap the vent pipe with self-regulating 3 or 5 watt heat

tape. The heat tape must be U.L. listed and installed

per the manufacturer’s instructions.

• Do not connect this venting system with an existing

vent or chimney.

• Do not common vent with the vent pipe of

any other water heater or appliance.

The exhaust outlet piping and termination may be installed

in one of the following type terminations:

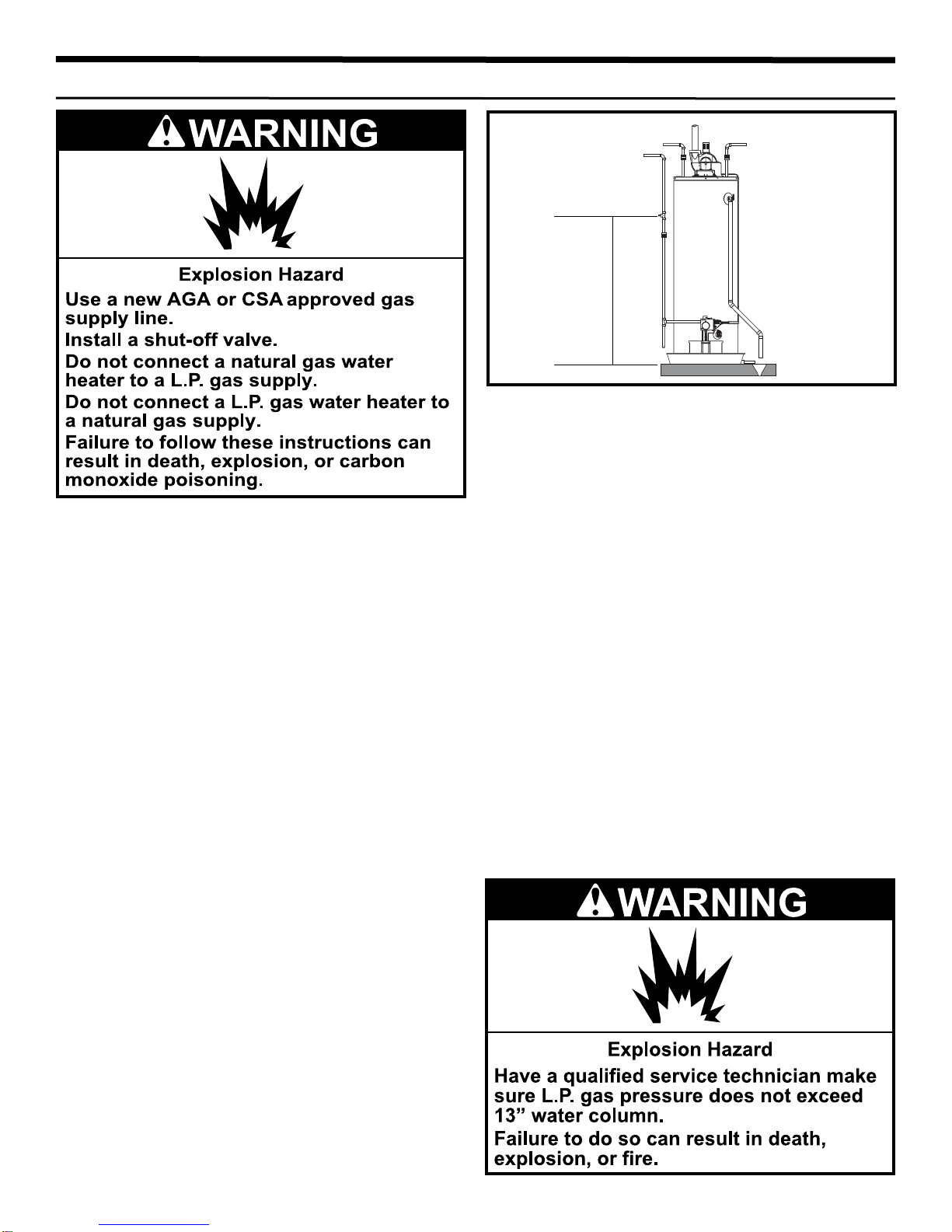

1. Standard Horizontal

2. Vertical

All pipe, fittings, pipe cement, primers and procedures

must conform to American National Standard Institute and

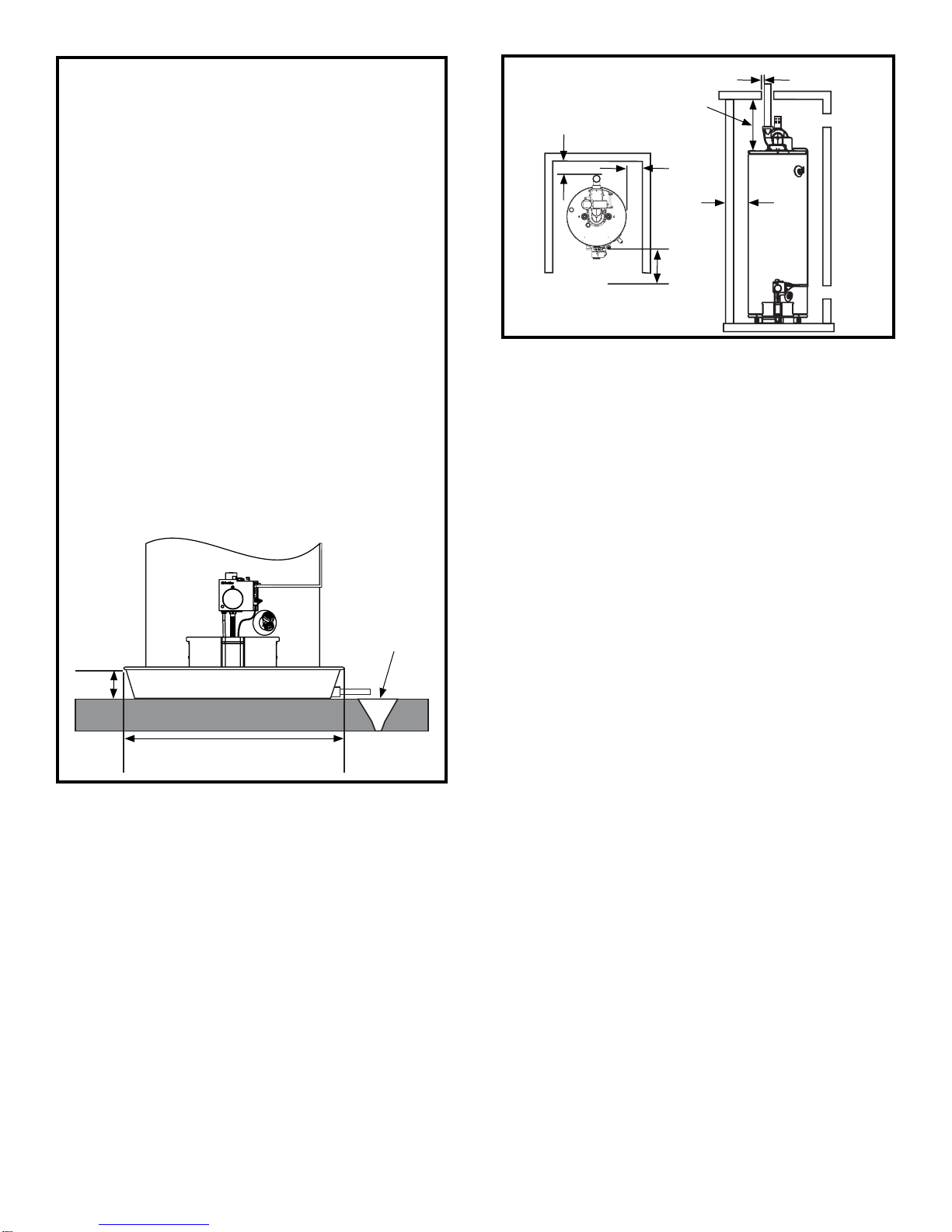

Figure 8

Correct and Incorrect

Pipe Fittings

American Society for Testing and Materials (ANSI/ASTM)

standards in the United States. This water heater has been

design certified by CSA International for use with the speci-

fied (CSA) listed plastic vent pipe. Important: Do not use

vent elbows in this vent pipe installation (see figure 8).

All joints in the outlet piping

must be properly cemented.

Size and cut all piping before

cementing.

1. Cut the pipe end square

and remove all ragged

edges and burrs. Make

sure the inside of the

pipe is clean and free of

cuttings and loose dirt.

Chamfer the end and

apply primer to the fitting

and pipe.

2. Using a suitable grade of pipe cement, apply a moder-

ate, even coat inside the fitting. Apply a liberal amount

of cement to the outside of the pipe to socket depth.

NOTE: It is important to select the proper pipe cement

for the type plastic pipe being used.

3. Assemble the parts quickly while the cement is still

wet. Twist the pipe 1/4 turn during insertion and hold

for 30 seconds.

Vent Pipe Length

Size the exhaust outlet as specified in Tables 5 & 6 below.

These tables list the maximum allowable length in feet of

the exhaust outlet pipe as related to the number of required

elbows and the termination. The specified maximum

lengths are for exhaust pipe systems. Minimum pipe length

is 3 feet with one elbow.

1. Determine termination type and pipe size.

2. Determine number of elbows in exhaust pipe (Do not

include elbows in the termination.) Corresponding

number indicates the maximum length of exhaust pipe.

Vent Pipe System

This water heater must be properly vented for removal of

exhaust gases to the outside atmosphere. Correct instal-

lation of the vent pipe system is mandatory for the

safe and efficient operation of this water heater and is

an important factor in the life of the unit.

Vent pipe installation must be performed in accordance

with state and local codes, or in the absence of such, the

National Fuel Gas Code, NFPA 54, ANSI Z223.1-latest edi-

tion. Canadian installations must be performed

in accordance with CAN/CGA-B149.

Important: Check to make sure the vent pipe is not blocked

in any way. NOTE: Do not common vent this water heater

with any other appliance. Do not install in the same chase

or chimney with a metal or high-temperature plastic from

another gas or fuel burning appliance.

Vent Pipe Material

The following plastic materials may be used for both the

combustion air inlet and exhaust outlet piping subject to

state and local codes:

• 2 or 3 inch Schedule 40 PVC or ABS

• 2 or 3 inch Schedule 40 or 80 CPVC

• DWV Pipe is acceptable

NOTE: Use only solid (not foam core) piping.

Plastic pipe and fittings are available through most plumb-

ing suppliers. Always check the marking on the pipe to

make sure you are using the correct material.

Vent Pipe Connection to Blower

A 3x2” reducer is supplied with the water heater to connect

either 2” or 3” venting to the blower. Important: These

connections must be properly sealed to prevent the leak-

age of the products of combustion into the living area.

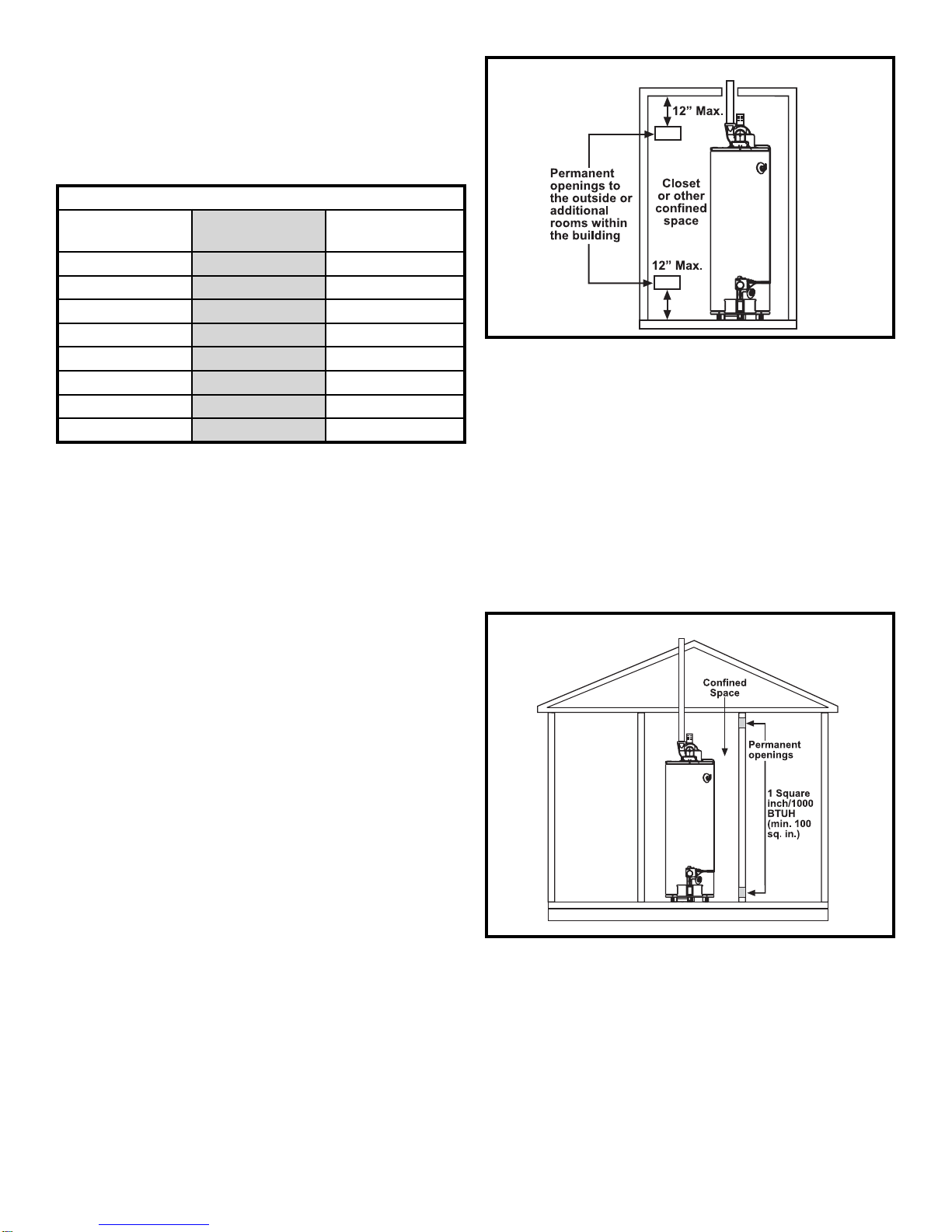

Table 5 - Maximum Allowable Length in Feet of

Exhaust Pipe - (42K BTU/Hr models only)

Pipe

Size

(in)

Number of 90° Elbows (medium or long sweep only) Termination

Options

0123456

250 45 40 35 30 25 20 Std. Horizontal

240 35 30 25 20 15 10 Vertical

3125 120 115 110 105 100 95 Std. Horizontal

3115 110 105 100 95 90 85 Vertical

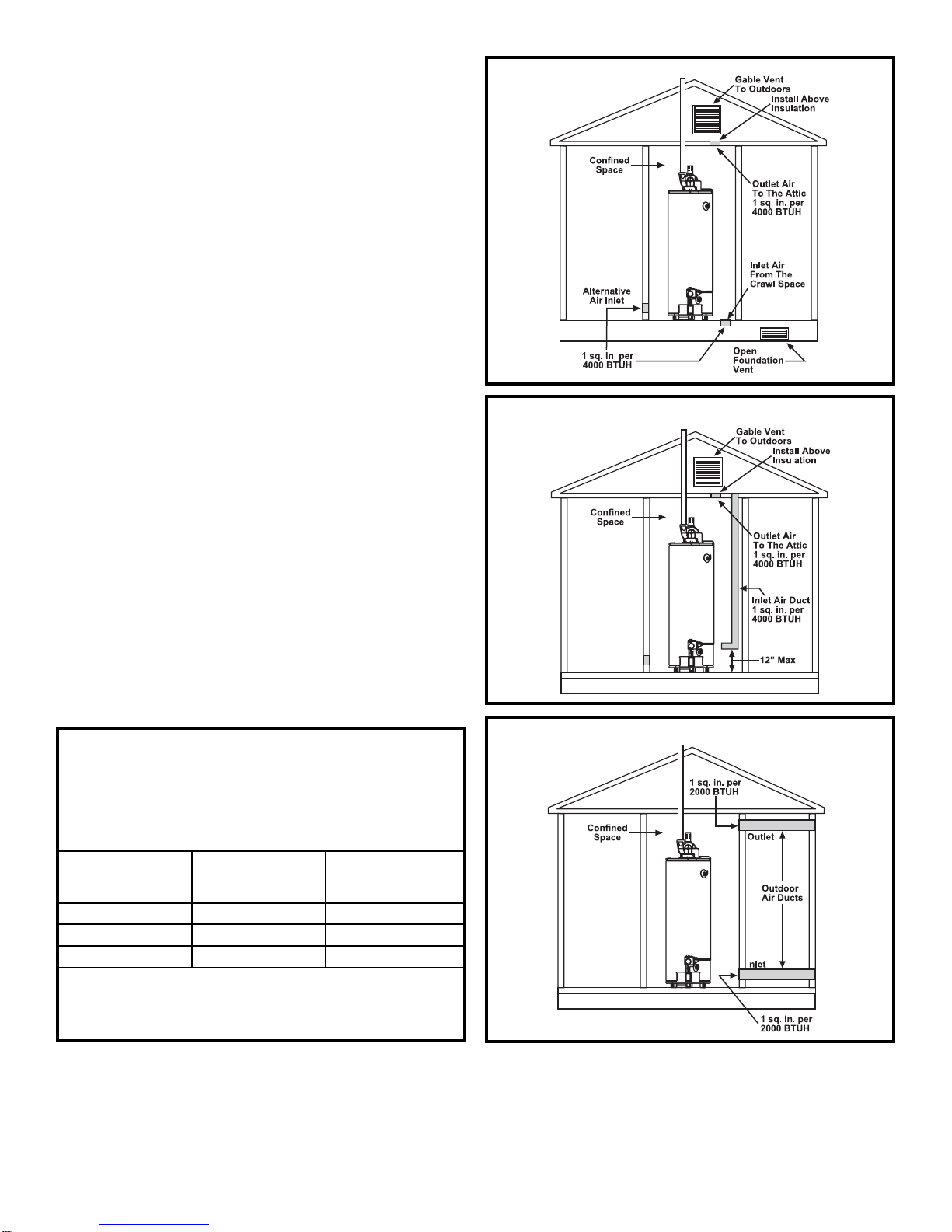

Table 6 - Maximum Allowable Length in Feet of

Exhaust Pipe - (50K/60K BTU/Hr models only)

Pipe

Size

(in)

Number of 90° Elbows (medium or long sweep only) Termination

Options

0123456

2N/A Std. Horizontal

2N/A Vertical

365 60 55 50 45 40 35 Std. Horizontal

355 50 45 40 35 30 25 Vertical

Notes:

1. N/A - Not Applicable

2. The above maximum lengths are for outlet pipe systems.

3. Maximum of 6 elbows may be used. Use only medium or long

sweep elbows. See figure 8 for details.

4. Two 45° elbows are considered equivalent to one 90° elbow.

5. Minimum length is 3 foot with 1 elbow.

6. Use schedule 40 CPVC, ABS, or PVC pipe and fittings.