English

4

Cautions when

using this product

This product can be used for the following agricul-

tural work. Avoid use for purposes other than the

following.

1) Spraying chemicals for blight or harmful

insects on general farm crops

2) Spraying chemicals for blight or harmful

insects on fruit trees

3) Spraying chemicals for blight or harmful

insects on crops cultivated in greenhouse

4) Spraying chemicals for blight or harmful

insects on flowers

5) Spraying disinfecting liquid or insecticide on

farm house or chicken house

6) Spraying chemicals and water for blight or

harmful on garden trees, bonsai, or lawns

7) Spraying disinfecting liquid and insecticide

for urban sanitation

8) Spraying chemicals for blight or harmful

insects on flower beds and in parks

9) Spraying weed killer to control weeds

10) Cleaning and spraying water for vegetables

or root vegetables

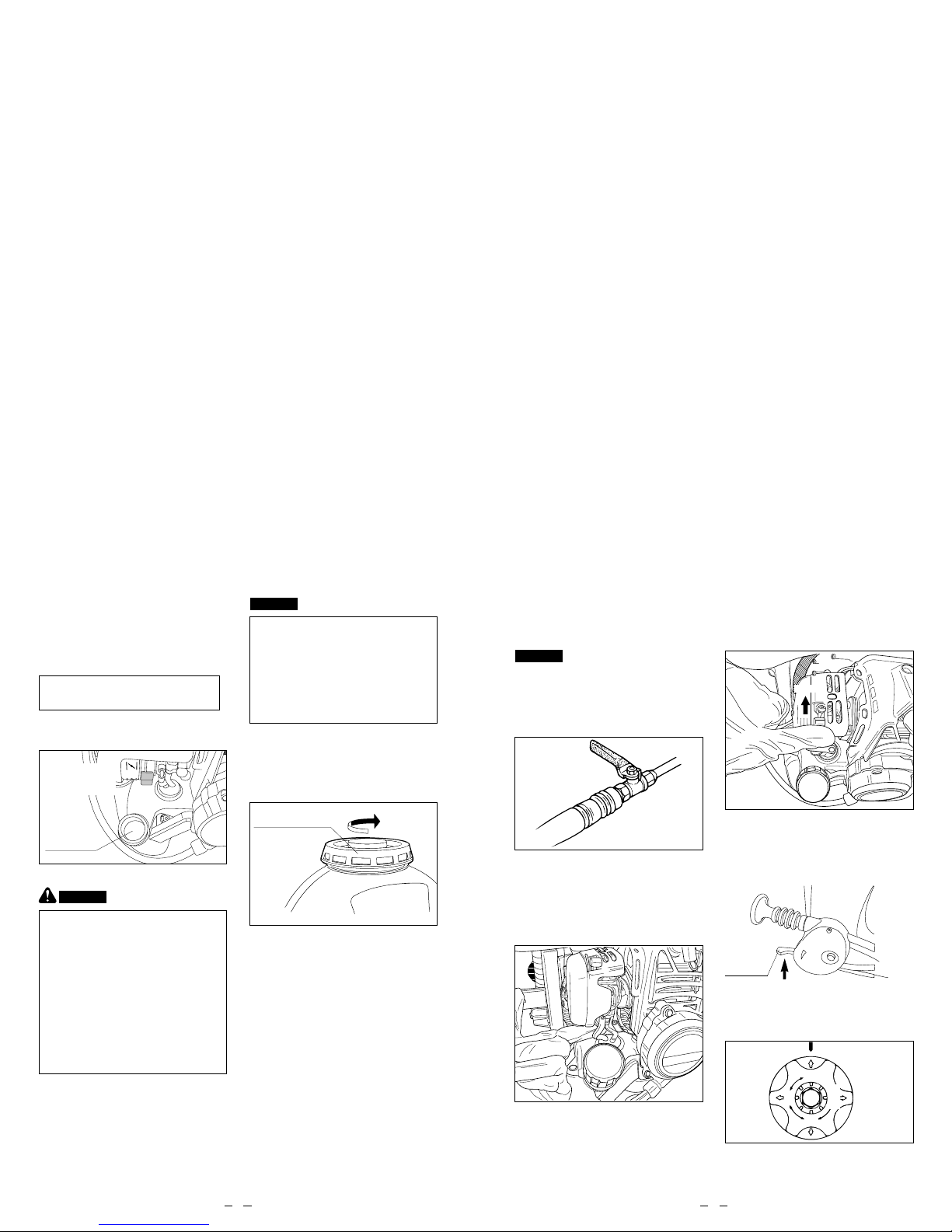

When transporting by automobile, take action

to prevent the machine from falling.

Chemicals

・Read labels of chemicals to be used carefully,

and understand the method of use and cau-

tions. When spraying quantity per tank

(1000m2) or if the chemical is mistaken, agri-

cultural chemicals can cause damage.

・Store chemicals in a safe place, and be careful

not to break open their containers during trans-

portation.

・Treat chemical containers to ensure safety.

・Pay attention to the handling of chemicals. If a

chemical enters into eye or mouth, wash it off

with water immediately.

・If you feel ill, see a doctor immediately.

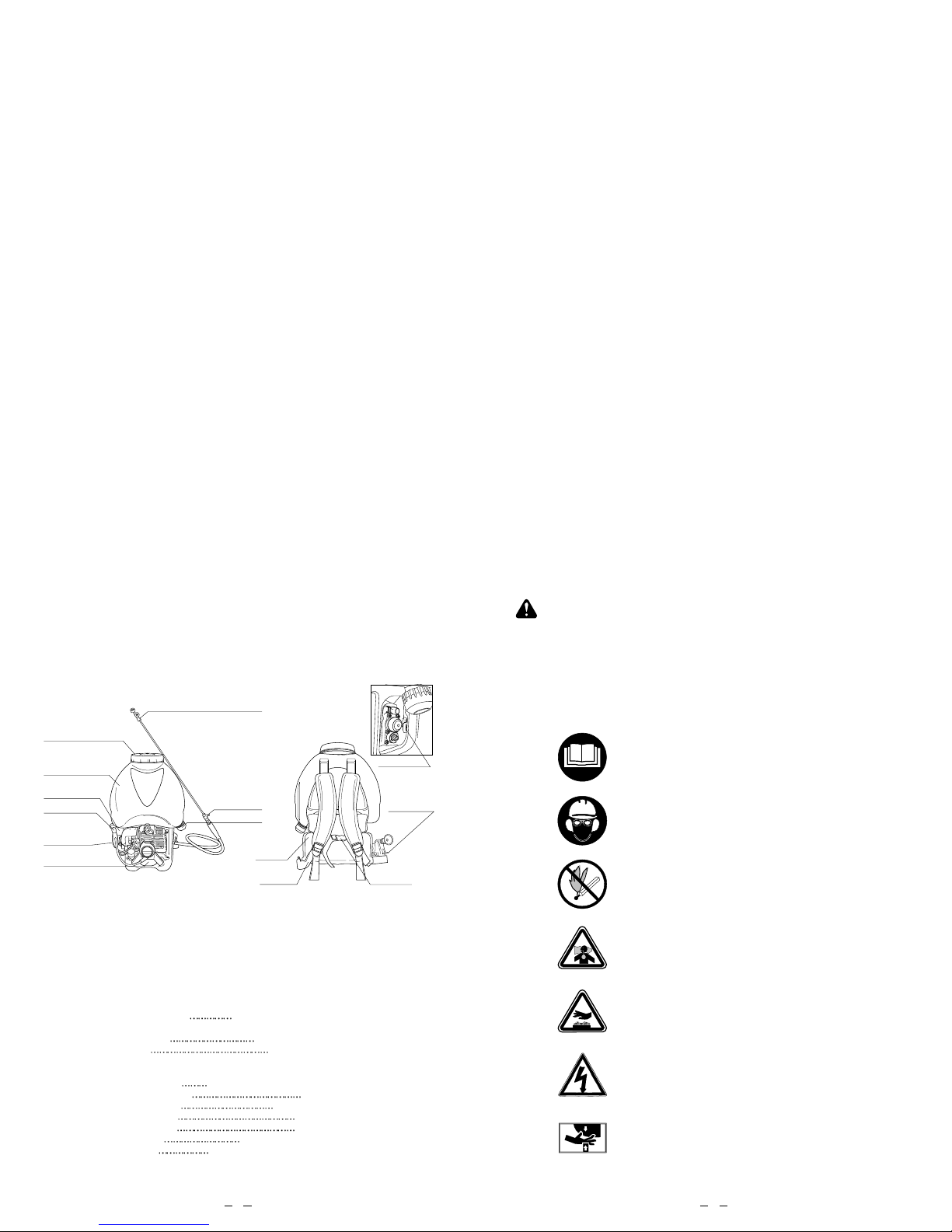

・According to wind direction, change the spray-

ing method to protect workers and houses.

When spraying chemicals, work from upwind

to downwind. Also give consideration to pre-

vent chemicals from drifting or scattering on

crops, enclosures, fish-breeding ponds, and

houses nearby.

・When working in and greenhouse, pay

attention to ventilation.

・When preparing chemicals, prepare the

necessary amount only in accordance with the

established spraying plan. If too much

chemicals are left over, acton is difficult.

・Do not use this machine when there are people, especially children, near the site.

・Because the tank when completely filled with the chemical is very heavy, pay

careful attention not to hurt your lower back when carrying it.

・Always adopt a safe working posture when carrying the tank. Do not work at

elevated sites using stairs or ladders while carrying the tank.

Upwind

English

3

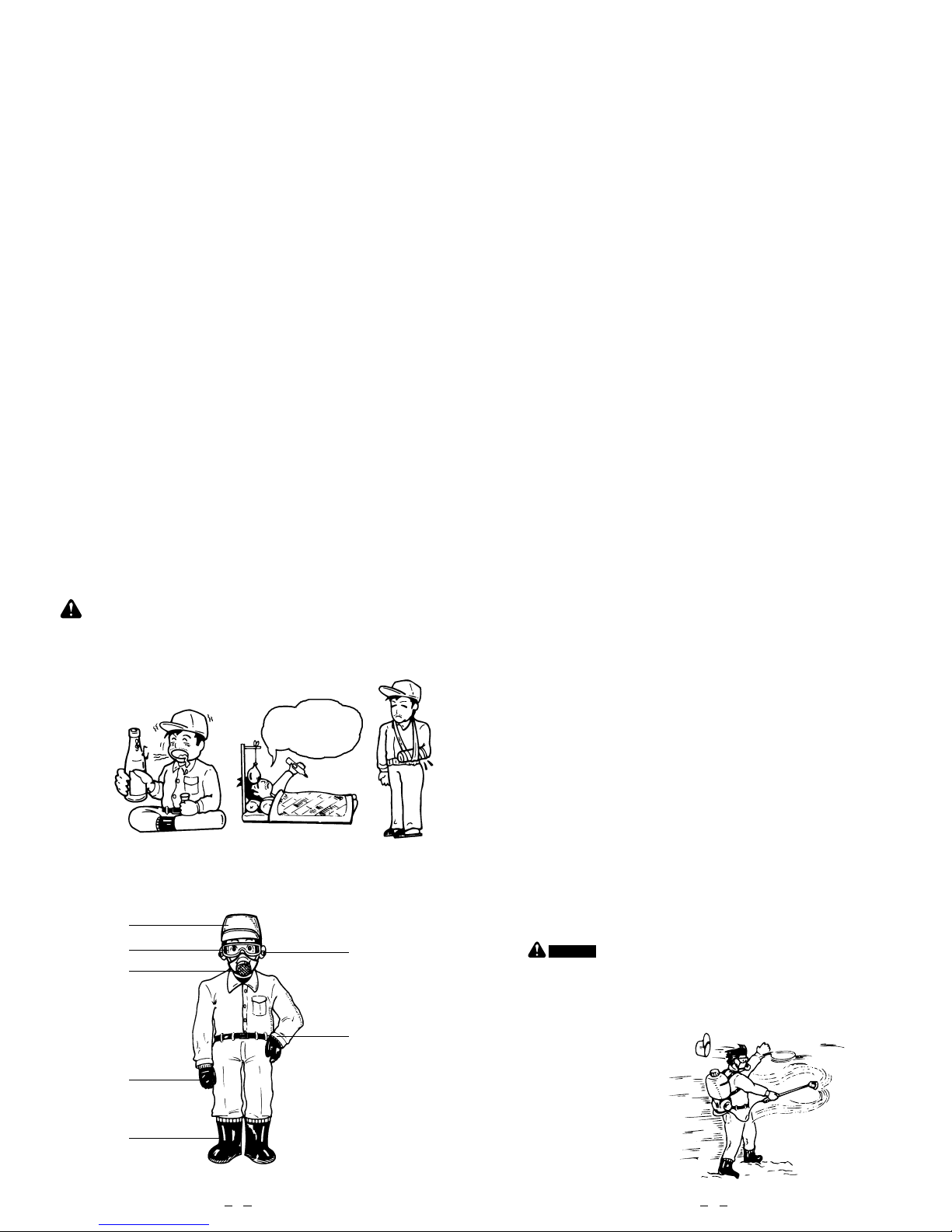

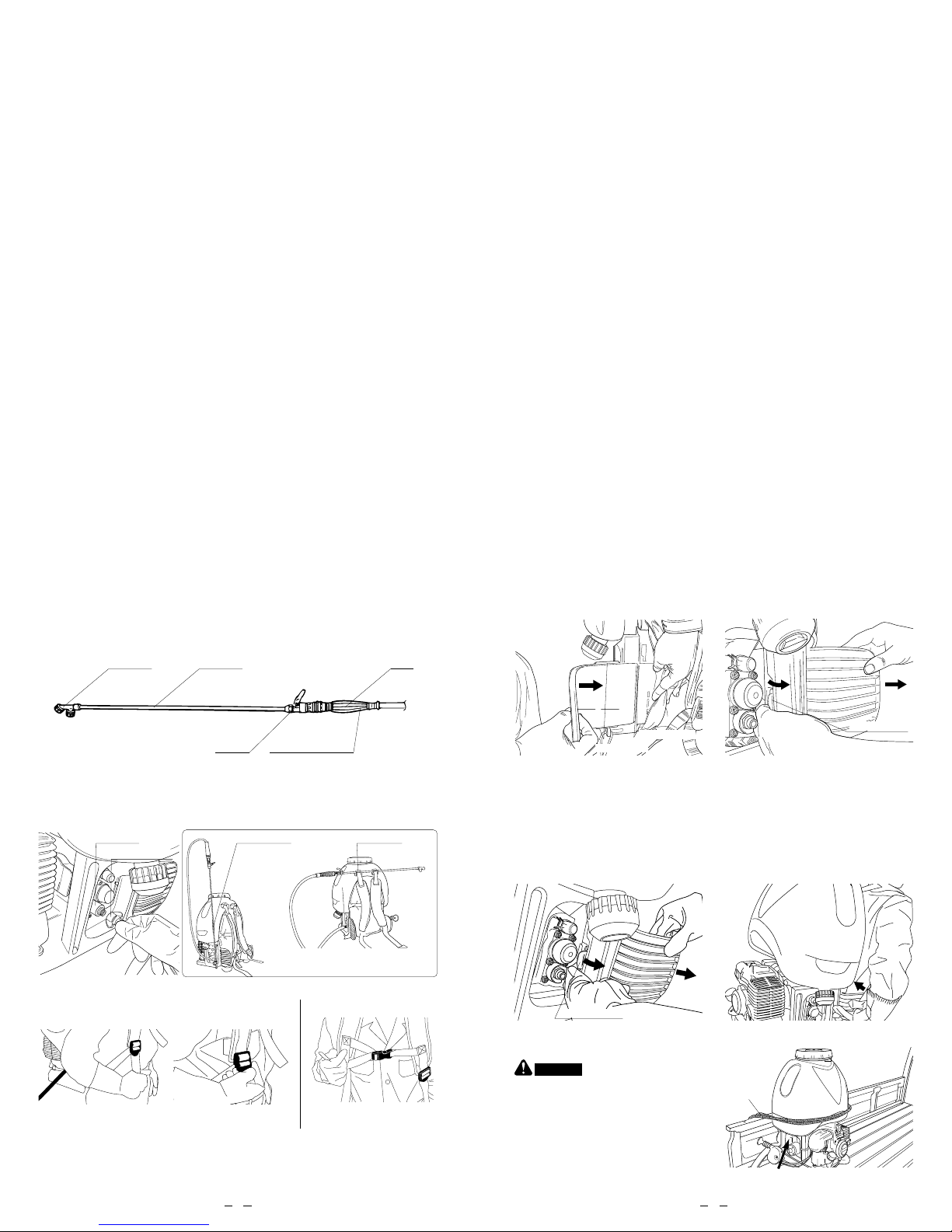

Check and maintain protective equipment to maintain their normal functions at all times, and use them correctly.

Spray operator who wears

appropriate clothes.

Hat

Ear plugs(noisy work)

Protective

clothes

(tidy cuffs)

Safety glasses

Safety mask

Safety gloves

Working shoes

(rubber boots)

1. In order to work safely

Cautions prior to work

The following persons shall not do spraying work.

・Person who cannot do normal spraying work due to fatigue, illness, effects of chemicals.

・Person who is under the influence of liquor

・Person who is pregnant

・Other than spray operator

・Children should be prevented

from using this machine.

Appropriate clothes for the work shall be worn.

I will not

work today.

Liquor