7

Safety

WARNING: Do not use gasoline crankcase draining

or oil containing gasoline, solvents or alcohol.

Doing so will result in fire and/or explosion.

AVERTISSEMENT: Ne pas utiliser d'essence, de

drainage du carter de moteur ou d'essence

contenant de l'huile, de solvants ou de l'alcool. Ne

pas tenter de faire évaporer les résidus inflamma-

bles de toute sorte, c.-à-d. ne pas traiter les

solvants, les huiles pures, etc. Agir de la sorte

risquerait de créer un incendie et/ou une explosion.

7. Allow engine to cool for 1-2 minutes before

refueling. If any fuel is spilled, make sure the area

is dry before testing the spark plug or starting the

engine. (Fire and/or explosion may occur if this is

not done.)

Gasoline engines on mobile or portable equipment

shall be refueled:

a. outdoors;

b. with the engine on the equipment stopped;

c. with no source of ignition within 10 feet of

the dispensing point; and

with an allowance made for expansion of the fuel

should the equipment be exposed to a higher ambient

temperature.In an overfilling situation, additional

precautions are necessary to ensure that the situation

is handled in a safe manner.

WARNING: Risk of injury. Disconnect battery

ground terminal before servicing.

AVERTISSEMENT: Risque de blessures.

Débrancher la borne de mise à la terre de la batterie

avant de procéder à des opérations d'entretien.

8. When in use, do not place machine near

flammable objects as the engine is hot.

9. Oil burning appliances shall be installed only in

locations where combustible dusts and flammable

gases or vapors are not present. Do not store or

use gasoline near this machine.

10. Use No. 1 or No. 2 heating oil (ASTM D306) only.

NEVER use gasoline in your fuel oil tank. Gasoline

is more combustible than fuel oil andcould result in

a serious explosion. NEVER use crankcase or

waste oil in your burner. Fuel unit malfunction could

result from contamination.

Do not confuse gasoline and fuel oil tanks. Keep proper

fuel in proper tank.

WARNING: Risk of injury. Hot

surfaces can cause burns. Use

only designated gripping areas

of spray gun and wand. Do not

place hands or feet on non-

insulated areas of the pressure

washer.

AVERTISSEMENT: Risque de

blessures. Les surfaces

chaudes peuvent causer des

brûlures. Utiliser uniquement

les zones de prise désignées du pistolet pulvérisa-

teur et de la lance. Ne pas placer les mains ou les

pieds sur des endroits non isolés de la laveuse à

pression.

11. Transport/Repair with fuel tank EMPTY or with fuel

shut-off valve OFF.

WARNING: Hot discharge fluid.

Do not touch or direct

discharge stream at persons or

animals.

AVERTISSEMENT: Liquide de

décharge chaud. Ne pas diriger

le débit de décharge vers des

personnes ou des animaux.

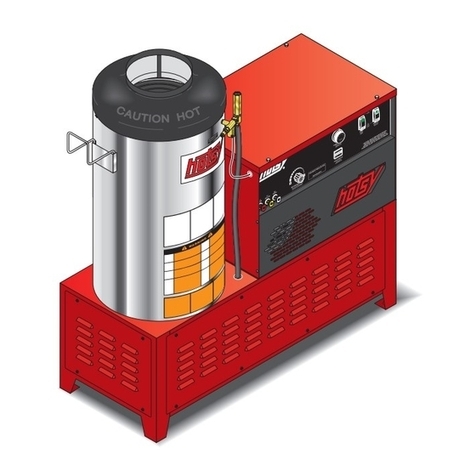

WARNING: This machine

produces hot water and must

have insulated components attached to protect the

operator.

AVERTISSEMENT: Cette machine produit de l'eau

chaude et doit comporter des composants isolés

attachés pour protéger l'opérateur.

12. To reduce the risk of injury, close supervision is

necessary when a machine is used near children.

Do not allow children to operate the pressure

washer. This machine must be attended during

operation.

WARNING: Grip cleaning wand

securely with both hands

before starting. Failure to do

this could result in injury from a

whipping wand.

AVERTISSEMENT: Agripper la

lance de nettoyage avec les

deux mains avant de

commencer. Le non-respect de

cette consigne pourrait mener à

des blessures causées par le

mouvement violent de la lance.

WARNING

RISK OF INJURY.

HOT SURFACES

CAN CAUSE BURNS

WARNING

HOT DISCHARGE FLUID:

DO NOT TOUCH OR

DIRECT DISCHARGE

STEAM AT PERSONS.

WARNING

TRIGGER GUN KICKS

BACK — HOLD WITH

BOTH HANDS

Hotsy 1200 Operator’s Manual 8.914-366.0 - AL