SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

4

14

15

16

8

9

10

11

12

13

1

1

2

6

3

5

4

7

2

1

DESCRIPTION

UNPACKING

SAFETY MEASURES

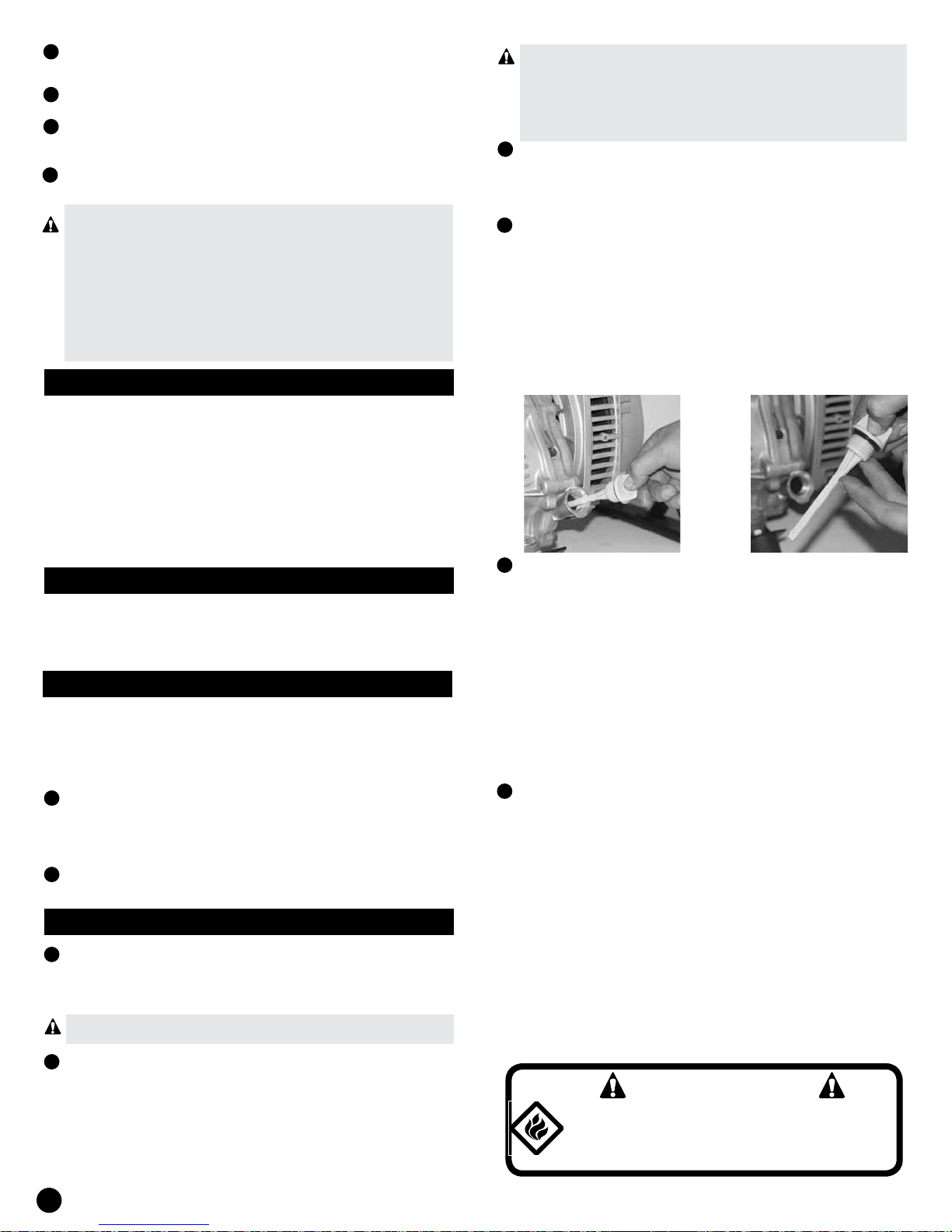

These units are provided with four strokes air cooled

engines designed to run at 3750 RPM max. and

continuously deliver a current corresponding to its

rated power. In these models a device is provided for

automatic engine turning off when the engine has low

oil level, so protecting it. This characteristic is generally

associated with long running models.

The alternator is thermally protected. To operate this unit

as a generator or a welder, place the front panel switch

according to what you want.

When you unpack, inspect carefully for any damage

that may had occurred during shipment. Make sure that

any xture, screws, etc., are tightened before operating

the unit.

Report any missing item by contacting the place of

purchase.

Before starting or servicing the welder/generator, read

and understand all instructions. Failure on complying

with safety precautions or instructions can cause

damage to the equipment and/or personal injury or

death.

The instructions about the engine for these units are

included in a separate manual. Keep all the manuals

for future references.

Never use this welder/generator for any application

other than that specied by the manufacturer. Never

operate this welder/generator under conditions not

approved by the manufacturer. Never attempt to modify

the equipment to operate in a way other than that for

which it was designed.

For maintenance and repairs use only products and

original components.

Before operation, make sure your equipment is properly

connected to ground. For proper grounding procedures

refer to “grounding instructions” section in this manual.

Make sure that your equipment is used only by persons

who have read and understood these instructions.

If your welder/generator is going to be in a xed place,

hold it rmly to the oor (use anchors, expansive dowels

or similar) if not, make always sure that it will not move

with the vibrations.

Keep all persons away from the equipment during its

operation. Do not allow people wearing jewelry or loose

clothing manage the equipment, since these can be

caught by moving parts, causing damage to equipment

and/or personal injury. Keep the people away from

movable pieces or that which can become hot during

functioning.

Be sure that all electrical appliances are switched off

before connecting them to your equipment.

Keep always the welder/generator clean and well

maintained.

NEVER OPERATE THIS WELDER/GENERATOR IN AN

EXPLOSIVE OR FLAMMABLE ENVIROMENT OR IN

AREAS WITH INSUFFICIENT VENTILATION.

Be sure that all tools and accessories are well prepared

for use and are properly grounded. Use one phase tools

or apparatus provided with three-prong plug power cord.

If an extension cord is used, be sure this has three- prong

plugs with a suitable ground connection..

DO NOT OPERATE YOUR EQUIPMENT ON WET

SURFACES OR UNDER THE RAIN.

TURN OFF AND DISCONNECT THE SPARKPLUG

WIRE BEFORE PERFORMING ANY SERVICE OR

MAINTENANCE TO THE UNIT.

Use only unleaded fuel. Do not ll the fuel tank with the

engine running. Take precautions to avoid spilling of

fuel while lling the tank. Make sure that fuel tank cap is

securely in place before starting the engine. Clean any

spilled fuel before starting the engine. Allow engine to

cool for at least two minutes before lling the tank.

This welder/generator can be used for auxiliary

emergency electrical service, in these cases, a double

throw switch shall be installed between the entrance main

switch and the electrical distribution box. This switch must

be installed by a licensed electrician

NEVER MIX OIL WITH GASOLINE. THIS FOUR-

STROKE ENGINE IS DESIGNED TO BE FUELED WITH

PURE GASOLINE. OIL IS ONLY USED FOR ENGINE

LUBRICATION

KEEP ALWAYS ACCESSIBLE A FIRE EXTINGUISHER

WHILE YOU ACCOMPLISHE ARC WELDING WORKS.

All installation, maintenance, repair and operation of this

equipment shall be carried out by persons qualied in

accordance with national, state and local codes.

THE INAPPROPRIATE USE OF ELECTRIC ARC

WELDING WELDERS CAN CAUSE INJURY,

ELECTRIC SHOCK AND EVEN DEATH. TAKE ALL

PRECAUTIONS DESCRIBED IN THIS MANUAL TO

REDUCE THE POSSIBILITY OF ELECTRIC SHOCK

Check that all components of the arc welder are clean

and in good condition prior to operating the welder. Make

sure that the insulation of all cables, electrode holders

and power cords are not damaged. Always repair or

replace damaged components before operating the

welder. Always keep panels, guards, etc. of the welding

machine in place when you operate.

Wear always dry protection clothing, welder gloves and

insulated footwear.

Always operate the welding machine in a clean, dry and

well-ventilated area. Do not operate the welding machine

in humid, wet, rainy areas or with insufcient ventilation.

Make sure that the work piece is properly supported

and grounded prior to begin any electric arc welding

operation.

You must stretch the welding cable before use to avoid

overheating and damage to the cable insulation.

18

17

19

20