6

4. Installation of Air Heater(s)

4.1 General

Before installation, check that the local distribution conditions,

nature of gas and pressure, and adjustment of the appliance are

compatible.

The air heater must be installed in accordance with the rules in

force and the relevant requirements of any fire regulations or

insurance company's requirements appertaining to the area in

which the heater is located, particularly where special risks are

involved such as areas where petrol vehicles are housed, where

cellulose spraying is carried out, in wood working departments

etc.

NV/C units are supplied with the centrifugal fan/silencer section

seperate from the heater which must be fitted at the rear of the

NV heater i.e the fan is blowing across the heat exchanger.

The following minimum clearances must be observed for

installation and servicing .

HS Clearance (looking at front of heater) 1.0m

LHS Clearance (looking at front of heater) 0.2m

Top of the heater to ceiling 0.2m

ear of heater to nearest wall 0.6m

(Depending on flue system used)

For multi air heater installations the following minimum distances

between units must be observed.

Between units, side to side 3.0m

Between units, back to back 3.0m

ecommended mounting heights, floor level to the underside

of the unit, are:-

NV10F - 30F 2.5m - 3m

NV40F - 150F 3m - 5m

NV/D Models Mounting heights not applicable

All models must not be installed at a height of less than 2.5m

to the base of the unit.

Any combustible material adjacent to the air heater and the flue

system must be so placed or shielded as to ensure that its

temperature does not exceed 65 °C.

When NV modular components are used in conjunction with

the heater each component must be individually supported.

4.2 Fitting the Air Heater

The air heater may be installed either:

a) suspended from suitable vertical drop rods,

chains or straps.

b) on specifically designed cantilever brackets from a

non-combustible wall.

c) on a level non-combustible surface. The surface must

not extend past the front edge of NV/F heaters.

The method of installation must be capable of adequately

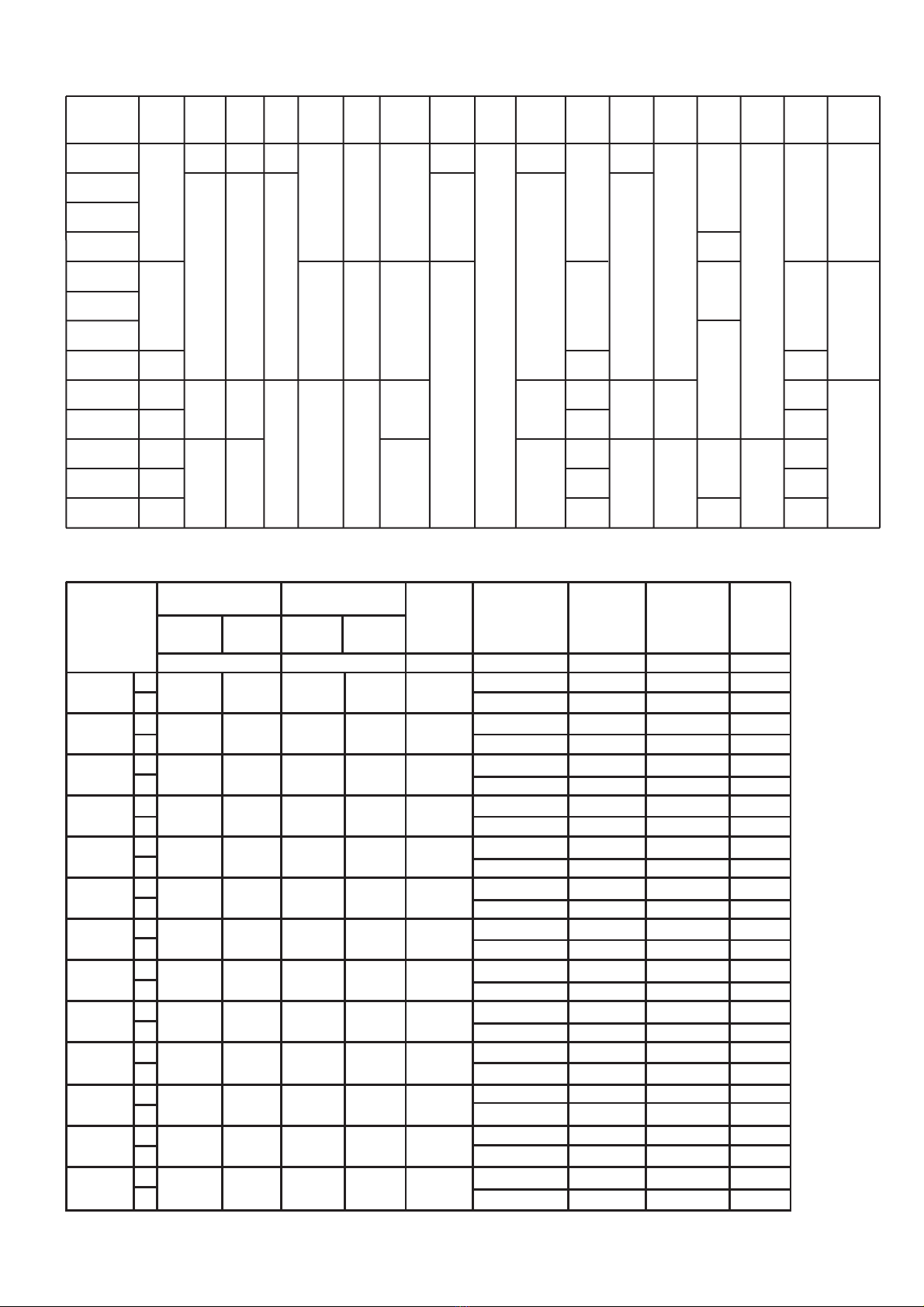

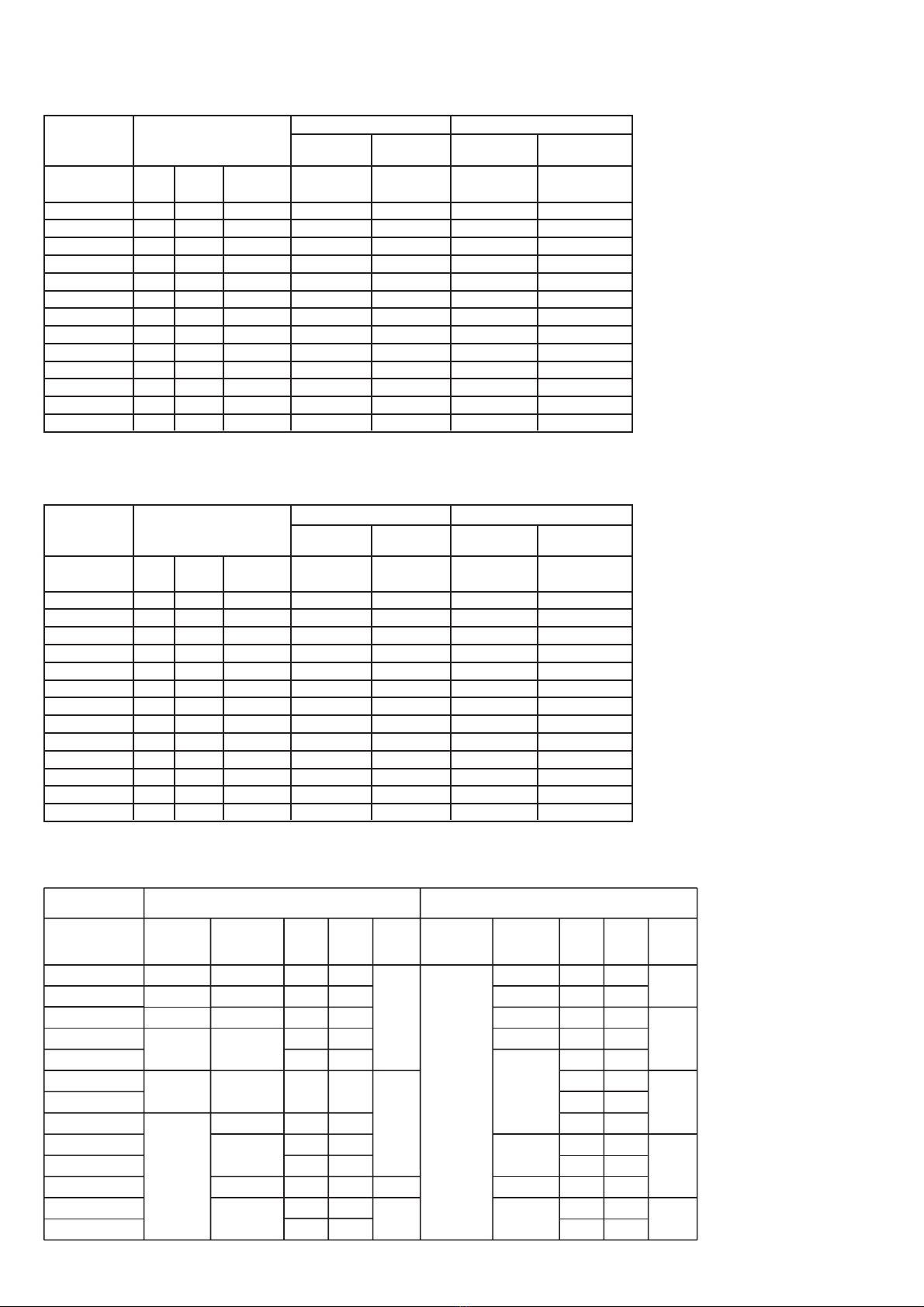

supporting the weight of the unit (See Table 2, Page 3) and any

ancillary equipment. Before installing the heater the existing

structure must be inspected to ensure it is suitable. All supports

should be protected against the effects of rust or corrosion.

Threaded drop rods must have lock nuts fitted that are tightened

down onto the 10mm fixings in the heater.

If reducing noise levels is important the heater should be

insulated from the structure by installing it on suitable anti-

vibration mountings. In all such cases and when the heater is

suspended it is essential that all gas, duct, and electrical

connections to the heater are made with flexible connections

to maintain continuity of connection.

4.3 Flue/Combustion Air Duct System

All models are supplied as standard with a top flue outlet and

the flue outlet and combustion air sockets are loose inside the

controls section.

or flooded or in any position adjacent to an extraction system

which is carrying flammable vapour.

Grilles or louvres should be so designed that high velocity air

streams do not occur within the plant room.

The basic minimum effective area requirements of the air vents

are as follows:

(a) Low Level (inlet)

(1) for heaters of total rated heat input less than 60kW:

9cm² per kilowatt of rated heat input.

(2) for heaters of total rated heat input 60kW or more:

540 cm² plus 4.5 cm² per kilowatt in excess of 60

kW total rated input.

(b) High Level (outlet)

(1) for heaters of total rated heat input less than 60kW:

4.5cm² per kilowatt of rated heat input.

(2) for heaters of total rated heat input 60kW or more:

270 cm² plus 2.25 cm² per kilowattin excess of 60kW

total rated input.

3.6 Air Distribution System

Where single NV/F units are required to cover a large floor

area, and in buildings with high roof or ceiling heights Calecon

thermal economiser units should be fitted to ensure even heat

distribution and minimise stratification.

Care should be taken to avoid impeding the air throw with

racking, partitions, plant or machinery etc. Various outlet

configurations are available as optional extras to modify the air

throw pattern to suit particular site conditions.

For ducted units all delivery and return air ducts, including air

filters, jointing and any insulation or lining must be constructed

entirely of materials which will not contribute to a fire, are of

adequate strength and dimensionally stable for the maximum

internal and external temperatures to which they are to be

exposed during commissioning and normal operation.

Where inter-joist spaces are used as duct routes they should be

suitably lined with a fire-resisting material.

A full and unobstructed return air path to the air heater(s) must

be provided.

If the air heater(s) is installed in a plant room the return air

intake(s) and the warm air outlet(s) from the heater(s) must be

fully ducted, into and out of the plant room to avoid interference

with the operation of the heater.

The openings in the structure of the plant room through which

the ducting passes must be fire stopped.

Care must be taken to ensure that return-air intakes are kept

clear of sources of smells and fumes, and where there is any

possibility of pollution of the air by dust, shavings etc.,

precautions must be taken to prevent contamination.

If necessary suitable barrier rails should be provided to prevent

any combustible material being placed within 900mm of the

outlets.

3.7 lectrical Supply

Wiring external to the air heater must be installed in accordance

with the I.E.E. egulations for Electrical Installations and any

local regulations which apply.

All standard heaters are supplied by 230V - 1ph, 50Hz. The

method of connection to the main electricity supply must:-

- facilitate the complete electrical isolation of the unit(s)

- be in a readily accessible position adjacent to the unit(s)

- serve only the unit(s)

- have a contact separation of at least 3mm in all poles. See the

accompanying wiring diagram for the heater electrical

connections

NV centrifugal fan/silencer units can also be supplied for 400V

3N, 50Hz.