Powtran PI9000 series User manual

Service center of POWTRAN technology company

My future ,drive and control

Quick guide of PI9000 operation

1.The introduction of new generation of PI9000

2. The new generation of PI9000 has following feature .

3. Installation of PI9000 procedure :

4.Connection of peripheral devices.

5.Keyboard operating instruction.

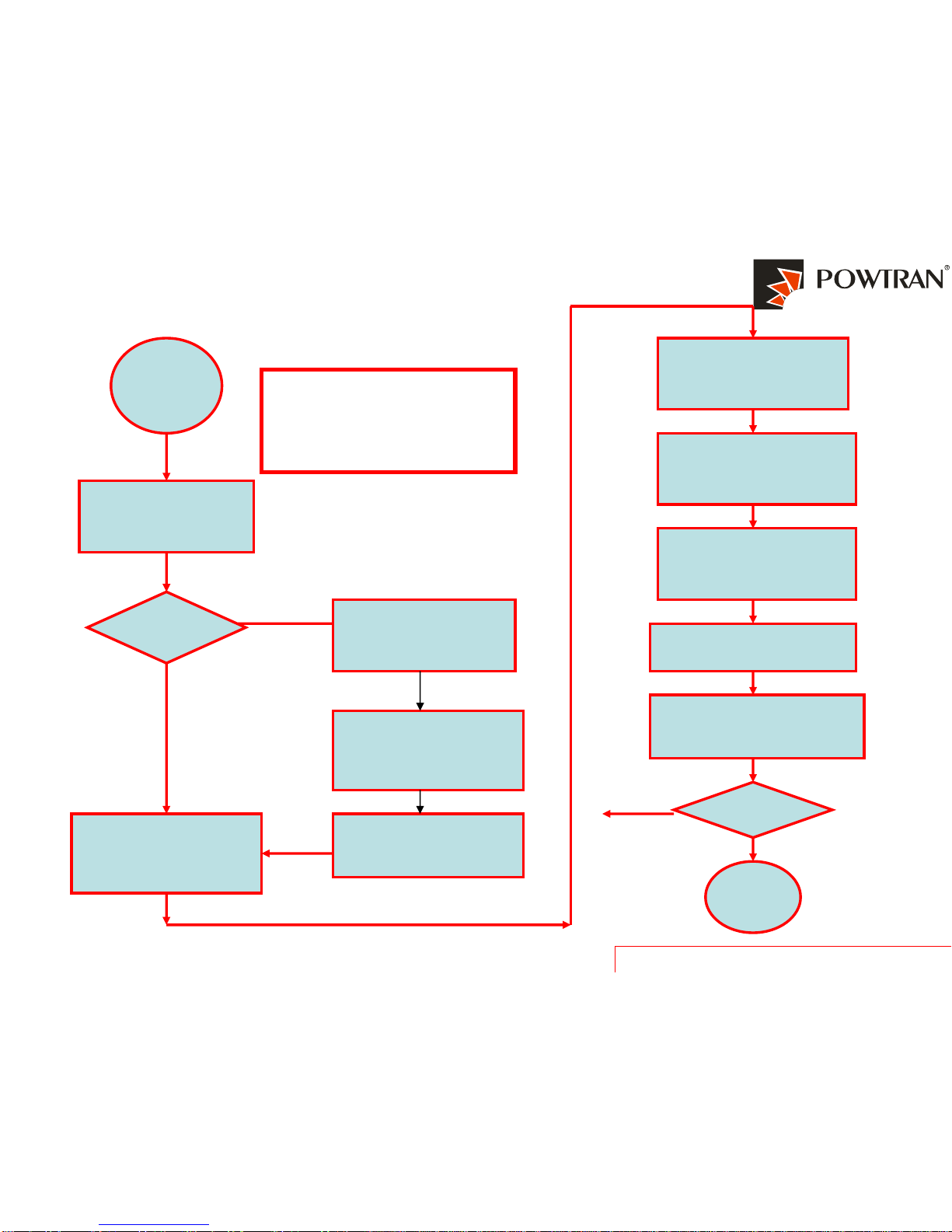

6.Trial operation follow chart

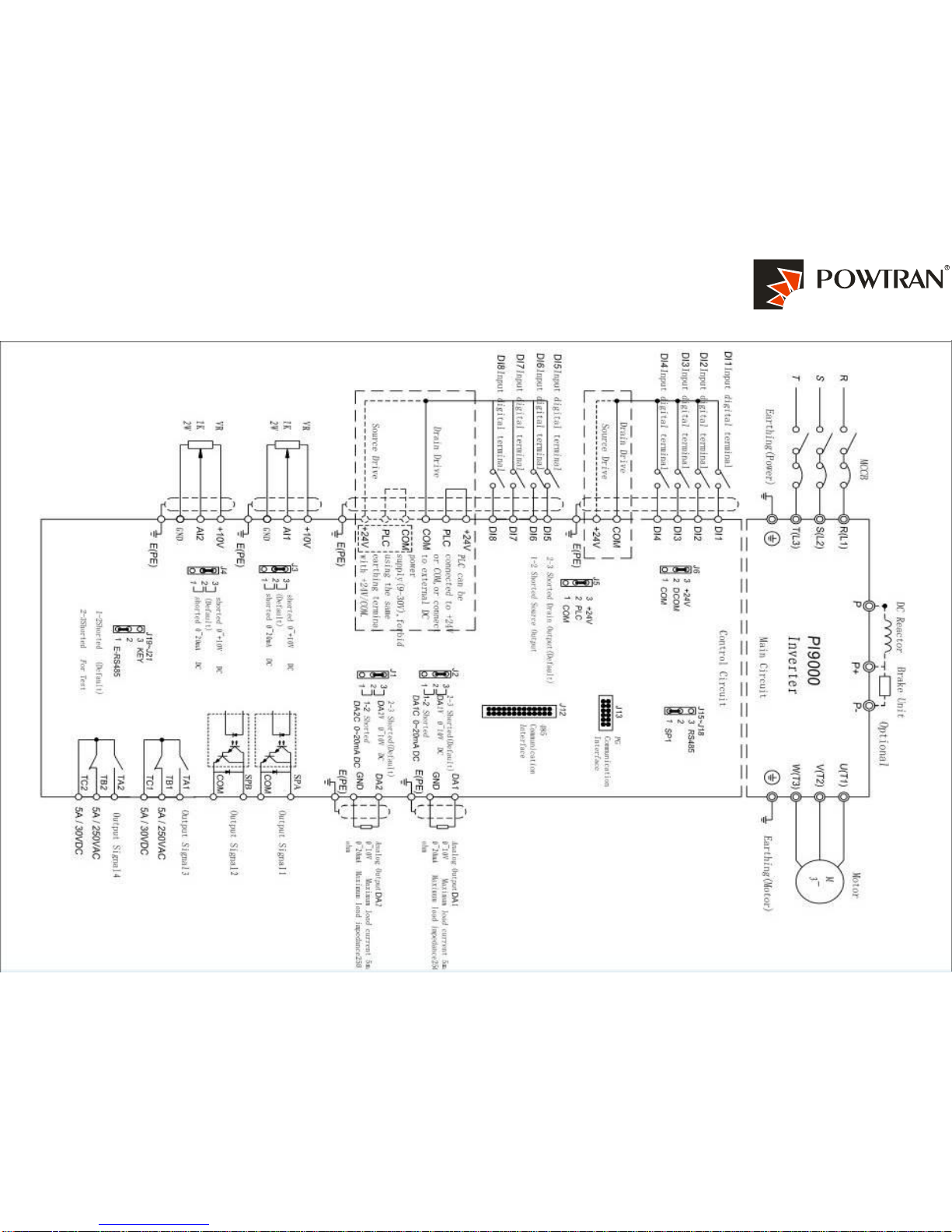

7.Wiring Of PI9000 inverter

8.How to perform motor auto-turning

9. Apply the braking unit and braking resistor

10.1. Operate the VFD with keyboard

10.2 Operating Forward and reverse key of key board for JOG running

10.3.Operating VFD by I/O terminals board.

10.3.2. wiring of I/O interface terminal

10.3.3. FWD and REV running controlled by I/O terminal .

10.3.4. FWD and REV JOG running controlled by I/O terminal

10.3.5. three line control mode

11. Frequency setting with external potentiometer (Variable resistor)

12. Frequency setting by analog current (AI2)

13.Employ output analog signal for monitoring current ,frequency ,speed etc.

14. Multi-speed applying with I/O interface terminal

15.Frequency UP and Down controlled by I/O interface terminal board

16.1.Application of multi-function output .(1) alarm output

16.2.Application of multi-function output 2. ( frequency arrival and frequency detecting )

17. PID control for constant pressure water supply-electrical diagram ( 0-10V signal feedback )

18. PI9000 apply in air compressor retrofitting with PID control function.

19.Application of PI9000 series inverters in crane

20. Fault Diagnosis

Service center of POWTRAN technology company

My future ,drive and control

1.The introduction of new generation of PI9000 of POWTRAN

Technology.

The PI9000 series inverter is high-performance motor control

module and consists of V/F, sensorless vector control (SVC) and torqure control. It is

mainly responsible for high performance control and overall protection of the motor,

controlling the motor through sending running commands to multiple channels or

performing close loop vector control through encoder interface.

which mainly ,includes most of functions of the inverter, such as PID control, MS

speed, and swing frequency and so on .

Service center of POWTRAN technology company

My future ,drive and control

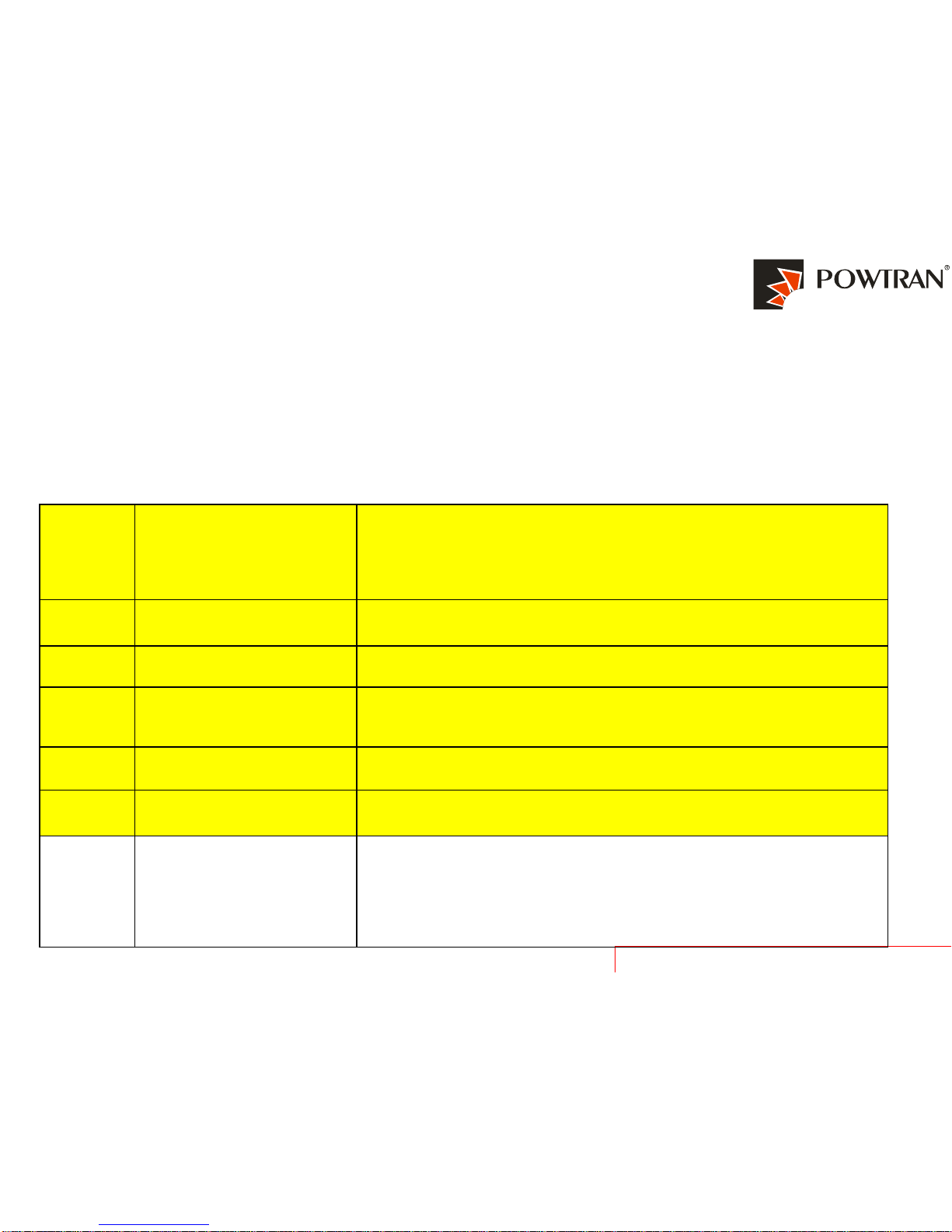

2. The new generation of PI9000 has following feature .

Input/output terminal Five digital two analog input signal, two analog output ,two high speed

port and one relay

Control mode

0:V/Fz1:open loop flux vector control

2:open loop without sensor flux vector control

3:closed loop with sensor flux vector control

MS speed Be able to realize 16S speed

PLC Simple PLC Be able to realize 16S timing operation

Swing frequency and fixed-

length control Available

Swing frequency and Available

Main/auxiliary setup Available

Communication function standard RS485 ,Modbus

PID control Available

Protection function

It can implement power-on motor short-circuit detection,

input/outputphase loss protection, over current protection,

over voltage protection, under voltage protection, over heat

protection and overload protection. Over voltage stall protection ,current limit ….

Parameter copy It enables the parameter copy unit to copy the parameters

quickly.

Optionalparts LCD operation panel, braking components, communication card,,

PG card, water supply card, etc

Service center of POWTRAN technology company

My future ,drive and control

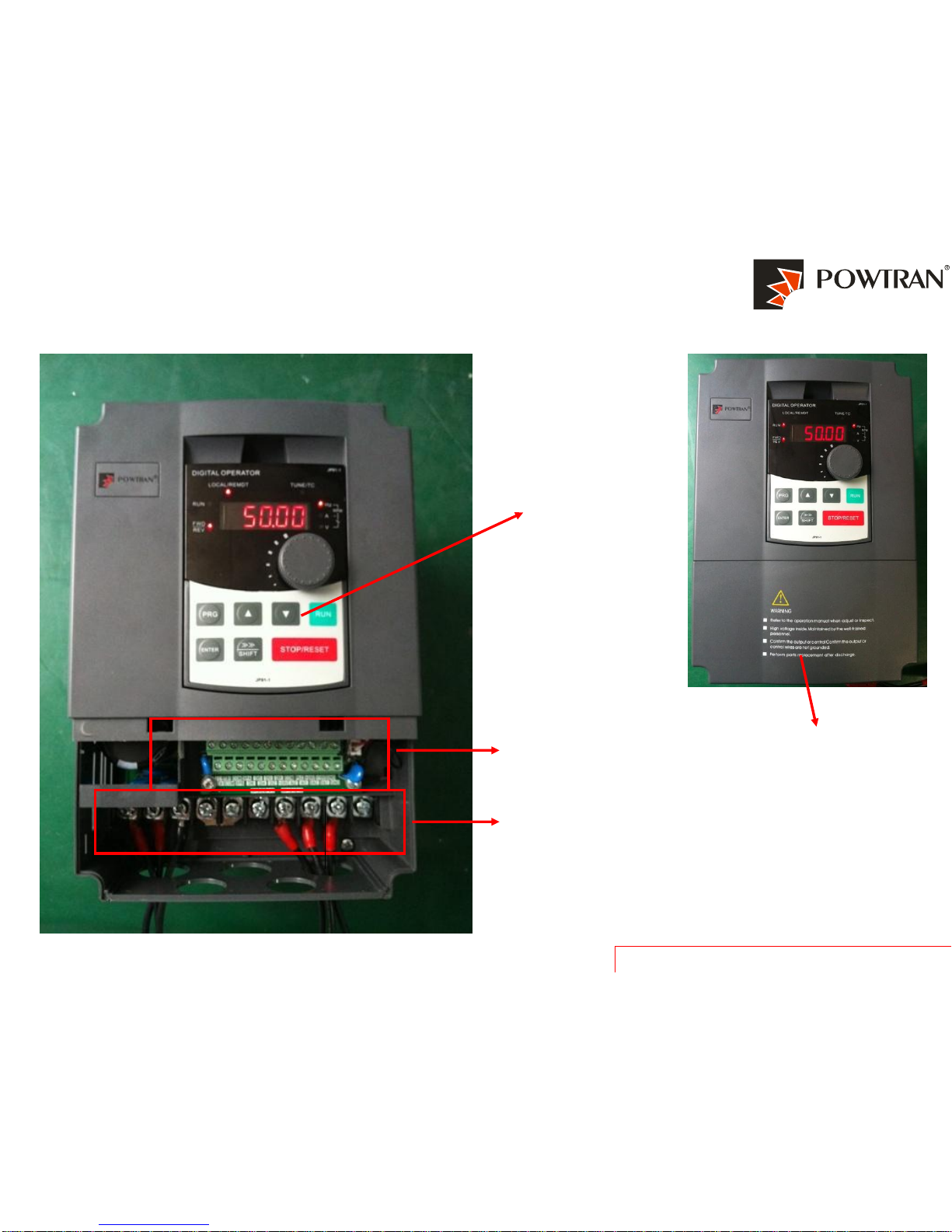

3. Installation of PI9000 procedure :

Install show picture -1

Service center of POWTRAN technology company

My future ,drive and control

Install show picture -2

Service center of POWTRAN technology company

My future ,drive and control

keyboard

Main Terminal cover

I/O control terminal Front cover

Power on inverter

Service center of POWTRAN technology company

My future ,drive and control

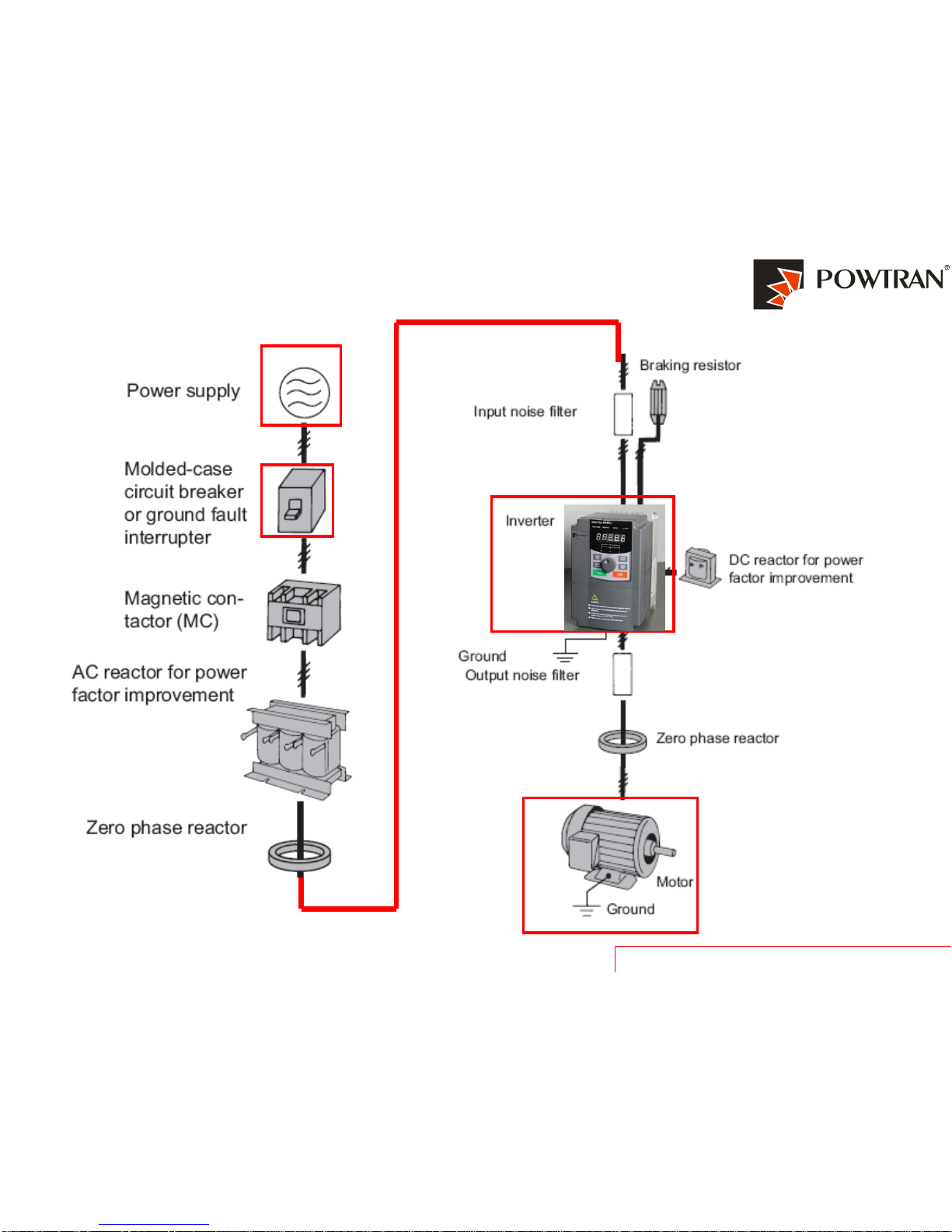

4.Examples of connections between the Inverter typical peripheral

devices are shown.

Please refer to “APPLICATION OF

OPTIONAL EQUIPMENT ”.

Service center of POWTRAN technology company

My future ,drive and control

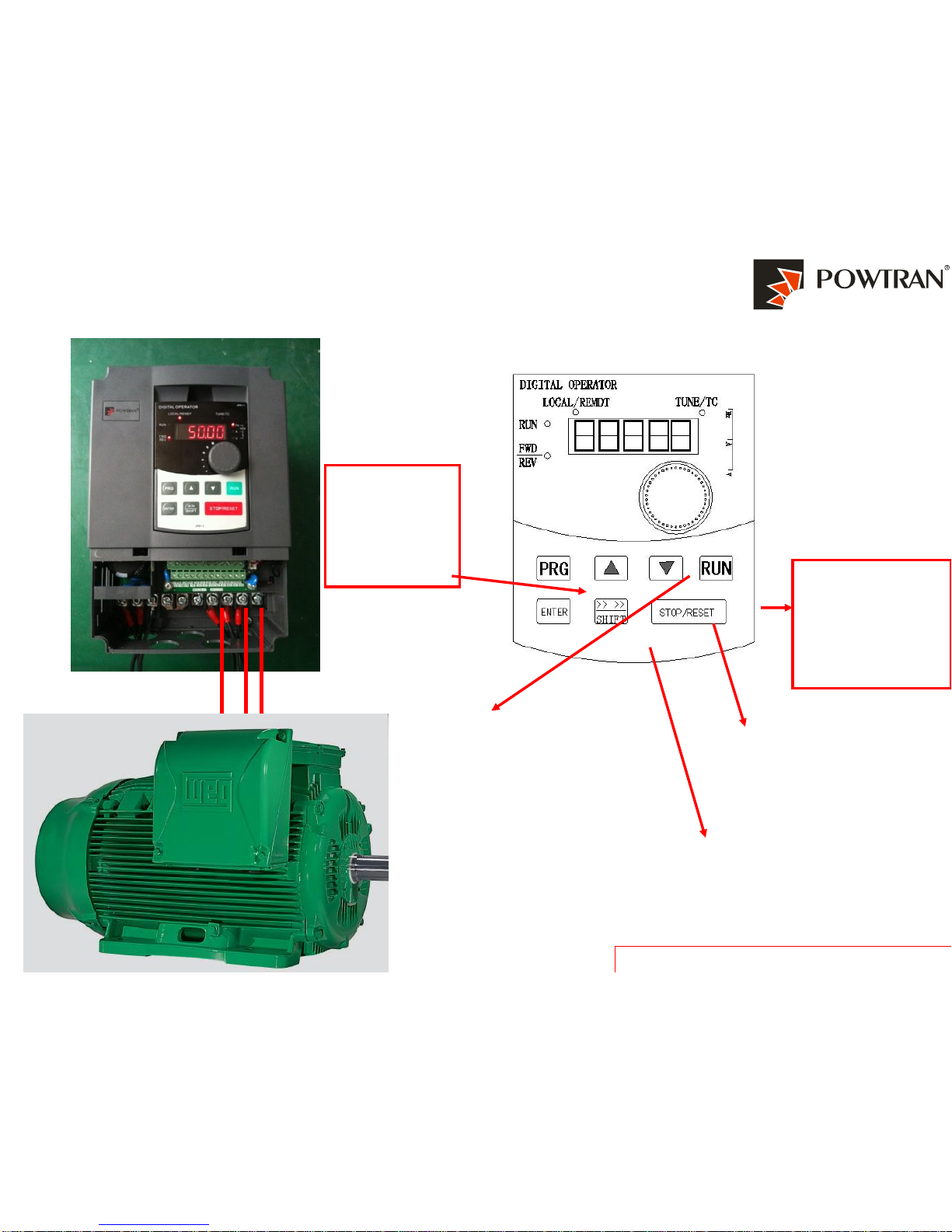

5.Keyboard operating instruction._1

The operator interface provides a means for an operator to start and stop the

motor and adjust the operating speed.

Escape key :enter into function parameters

list or escape it .

1.Shift the data bit when do a modification .

2:shift the monitor parameters in the stop mode

Date or Function code

increase/decrease

Enters menus and parameters, and set validates

parameter changes.

Starts the Inverter operation

1.Stop inverter operation

2.Also acts as the Reset key

when a fault has occurred.

1.Change the U0-UP,E0-E5 in the first Menu

2.Change the function code in the second menu

3.Change the value of function code in the third menu

4.Frequency setting in the run or stop mode.

Service center of POWTRAN technology company

My future ,drive and control

5.Keyboard operating instruction. _2

1.The first menu F0 2.The second menu:F0.01 3.The third menu:50.00

50.00

Press PRG

y0 y0.00

Press ENTER

Press ENTER

000001y0.01y0 flash

Press UP

Press ENTER

Press PRG

2. Reset parameters to factory setting

50.00

Press PRG

F0

Press ENTER

F0.00 F0.01 050.00

Press UP

Press SHIFT

50.00

Press ENTER

25.00F0.0225.00 flash

Press DOWN

Press ENTERPress PRG

flash

F0

Press PRG

3. Parameters setting

Press PRG

Service center of POWTRAN technology company

My future ,drive and control

6.Trial operation follow chart

Trail

operat

ion

Control mode

Selection

(F0.00)

F0 00 Motor parameters

Setting b0.00-

b0.05 para

Accel. /Decel .time

setting

(F0.13、F0.14)

Motor auto-turning

(b0.27)

command source

selection

F0.11

Frequency setting

(F0.03,F0.04,F0.07)

Motor Startup mode

(F3.00)

Proper accel. and

Decel. time

(F0.13,F0.14)

Motor stop mode

(F3.07)

If has any abnormal

Problem, Refer to

troubleshooting list

OK

The

END

1/0 vector

control

2 V/F

control

Yes

NO

To Command

source

Selection

U0.01

PI9000 has a good vector

control Performance .

we suggestion you select

Vector control mode .

Service center of POWTRAN technology company

My future ,drive and control

7.Wiring

Service center of POWTRAN technology company

My future ,drive and control

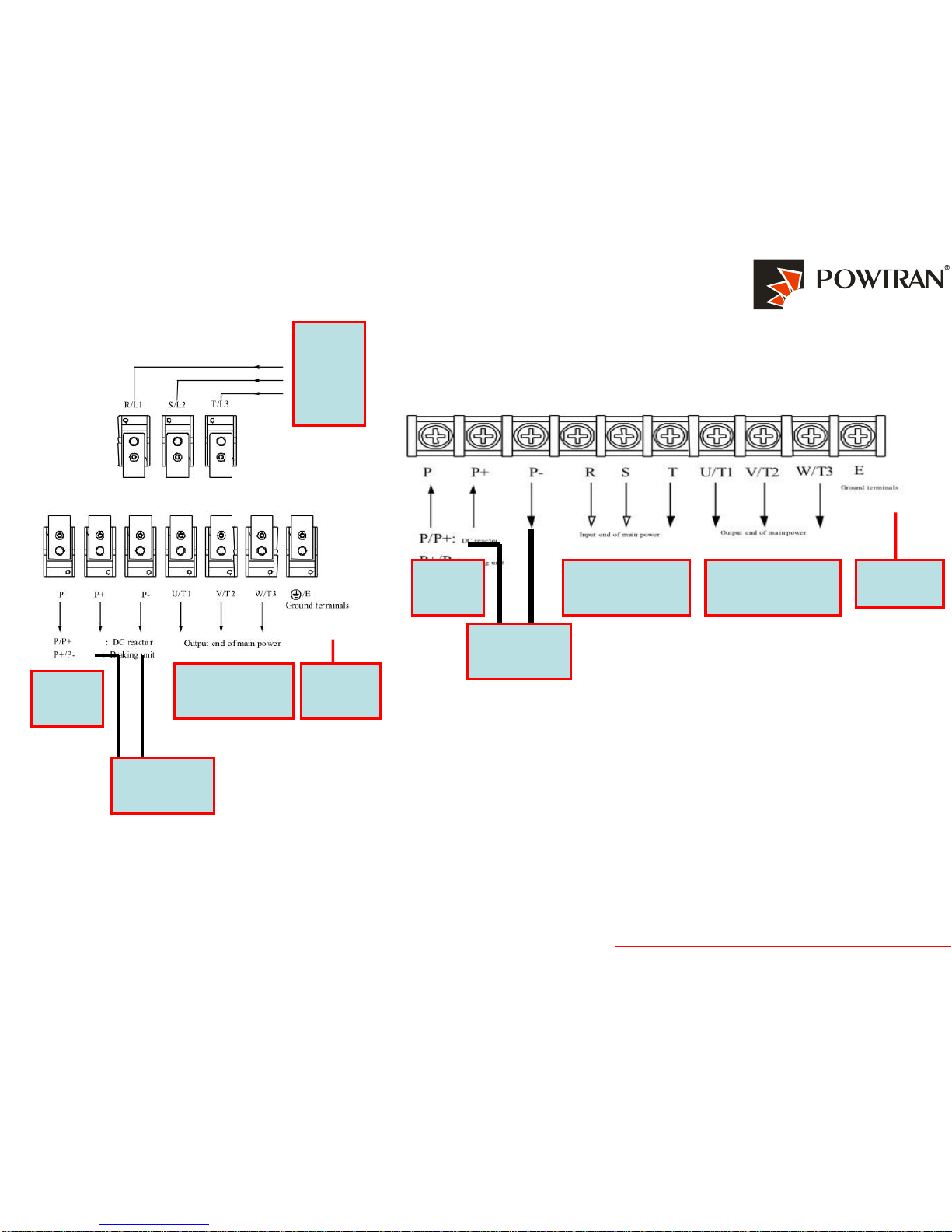

. Main terminal

Main circuit terminal(<7.5KW, 380V):

Input power

Supply DC

reactor

Braking resistor

Motor

Main circuit terminal(11kW to 15kW, 380V):

Input power

Supply DC

reactor Braking

resistor Motor

Service center of POWTRAN technology company

My future ,drive and control

The main terminal of 45~220kW(380V)inverter

Power

Supply

input

DC

reactor

Braking

Unit

Motor ground

Ground

To earth

DC

reactor

Braking

Unit

Power

supply Motor Ground

To earth

The main terminal of 18.5~355kW(380V)inverter

Service center of POWTRAN technology company

My future ,drive and control

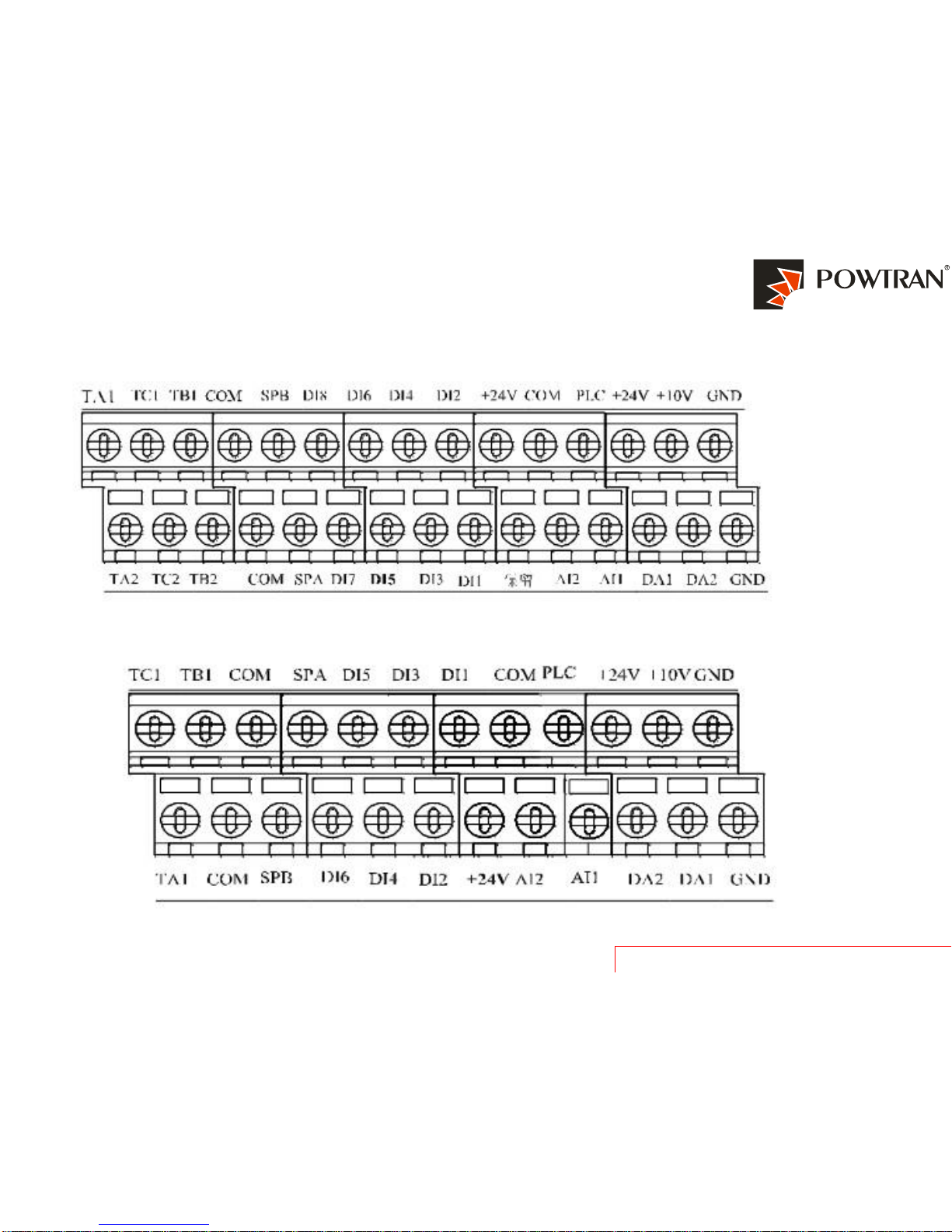

I/O control terminal of PI9000.

There are two type of controller board of PI9000.

The I/O terminal of 9KLCB controller board

The I/O terminal of 9KSCB controller board

Service center of POWTRAN technology company

My future ,drive and control

Performing motor auto-turning to get the motor parameters

Automatically for vector control application .

8.How to perform motor auto-turning ?

1. Set F0.00=1 or 2 refer to whether you have PG card or not . (set corresponding

value in parameter b0.28 and b0.29 according to your encoder )

2. Typing motor parameters in parameter b.00-b0.05 according to your motor nameplate.

3. Disconnect load from motor for performing complete rotational auto-turning.

b0.00 motor type 0:General asynchronous motor

1:Asynchronous frequency conversion motor

2:permanent magnet synchronous motor

b0.01 rated power 0.1~1000.0KW

b0.02 rated voltage 1~2000V

b0.03 rated current 0.01A~655.35A(rated power <=55KW)

0.1A~6553.5A (rated power >55KW)

b0.04 rated frequency 0.01~F0.19 (maximum frequency )

b0.05 rated rotation speed 0~36000RPM

b0.27 motor auto-turning

selection 0:no operation

1,Asynchronous motor parameters still auto tunning.

2.Asynchronous motor parameters comprehensive

auto tunning.

Service center of POWTRAN technology company

My future ,drive and control

4. Program b0.27=2 and press RUN key ,the auto-turning is going to start.

(If the load can’t take away from the motor ,please set b0.27 to 1 to perform

stationary auto-turning )

5. The time of auto-turning is depended on the parameter F0.13 and F0.14.

6. You can test whether the PG card is OK or not in the parameter d0.33 (ABZ

position),Also you can monitor the encoder feedback speed in parameter d0.26.

8.Motor auto turning _1

Motor basic

Parameter

setting Going to Auto-turning Auto-turning Finish auto-turning

Service center of POWTRAN technology company

My future ,drive and control

F0.00 Control Mode Sensor feedback close loop vector control 1

b0.27 motor auto-turning

selection

0:no operation

1,Asynchronous motor parameters still auto tunning.

2.Asynchronous motor parameters comprehensive

auto tunning.

2

b0.29 PG Pulse 1~65535 2500

b0.28 PG Type ABZ incremental encoder 0

b0.34 PG Dropped Inspection

Time 0.1S-10S 0.0

8.1 PG feedback close loop vector control

Before use close loop vector

control with PG card, first of

all ,motor must auto-turning refer

to point 8.

Service center of POWTRAN technology company

My future ,drive and control

9. Apply the braking unit and braking resistor .

The HP of 22kW of 220V and below and HP of 15 and it is below has built

In braking unit inside of inverter ,it can provide maximum of 50% of braking

Torque ,if connect to braking unit ,it can provide maximum of 150% torque .

It is no need to set any parameters for connecting the

braking unit .

The braking function is activated in default ! The activated of DC braking

Voltage is 130% UDC

The wires of braking

unit connect to B1

and B2 terminal

Service center of POWTRAN technology company

My future ,drive and control

10.1. Operating the VFD with keyboard

Frequency setting

F0.03=4 (keyboard in default)

Run command by key

board F0.11=0 ,

Change the

Display

content

With SHIFT

button

Stop motor

F0.11=0

F0.24=1 For

switchover

FWD and REV

Running

direction

Service center of POWTRAN technology company

My future ,drive and control

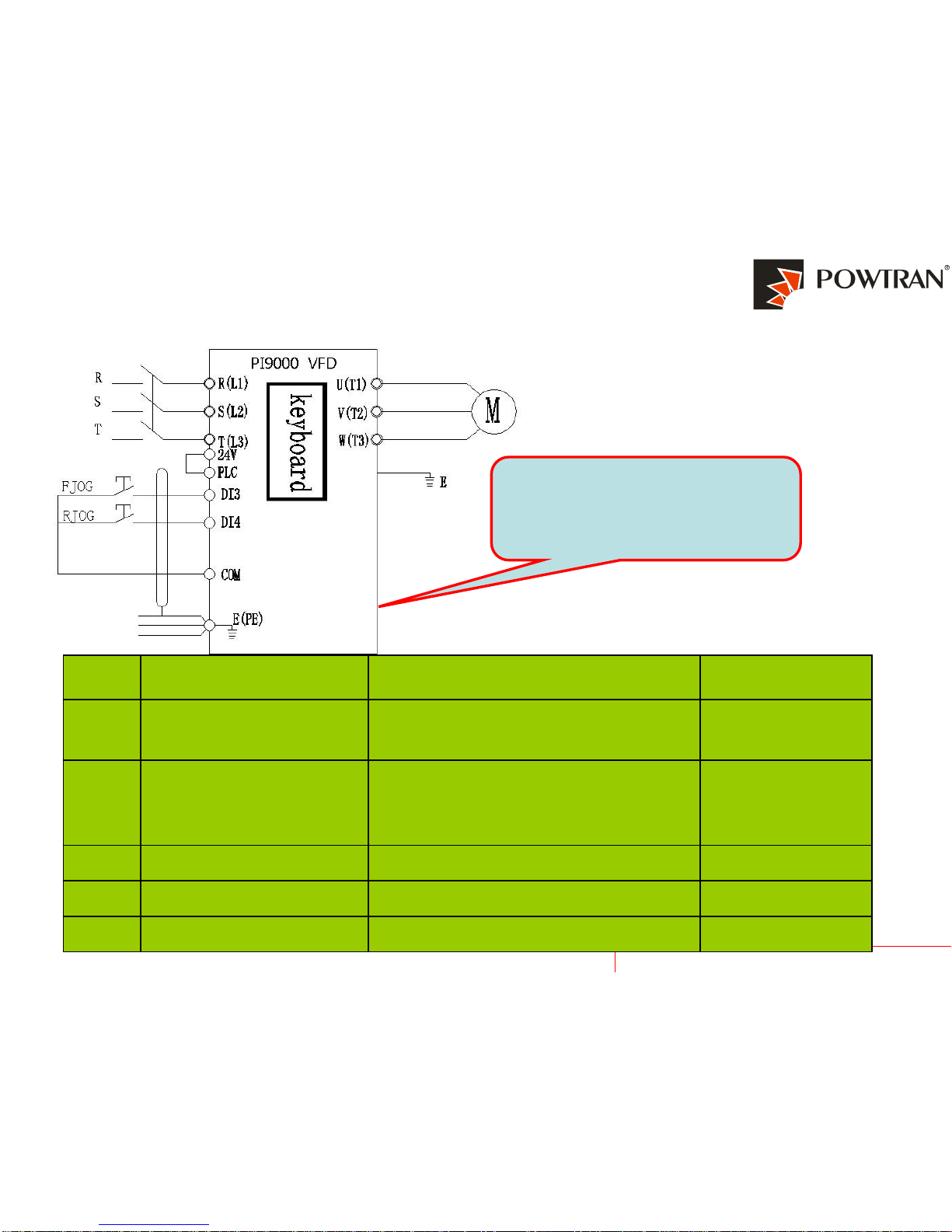

10.2 Operating Forward and reverse terminal

for JOG running

FJOG/RJOG

running :DI3 ,DI4 with

COM

F0.11 Running Control Mode 1:Terminal control 1

F1.02 (DI3 )Input Terminal

Function Selection FWD JOG command 4

F1.03 (DI4) Input Terminal

Function Selection

REV JOG command 5

F7.00 Jog running frequency 0.00~F0.19(Maximum frequency) 2.00Hz

F7.01 Jog acceleration time 0.1~3600.0S 20.0S

F7.02 Jog deceleration time 0.1~3600.0S 20.0S

Other manuals for PI9000 series

1

Table of contents

Other Powtran DC Drive manuals

Popular DC Drive manuals by other brands

Danfoss

Danfoss VLT AQUA Drive FC 200 operating instructions

SOMFY

SOMFY S&SO-RS100 io instructions

Twin Disc

Twin Disc AM080 Operator's manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 7000 Series user manual

Santerno

Santerno SINUS H Series user manual

SEW-Eurodrive

SEW-Eurodrive Movigear Performance MGF**-DFC-C Series operating instructions