Table of Contents

Table of Contents

Chapter 1. Introduction

...................................................................................................... 1

1.1 What is CANopen?.......................................................................................................................... 1

1.2 What are the Benefits of Using the CANopen Option Board?......................................................... 1

1.3 Components..................................................................................................................................... 1

Chapter 2. CANopen Communication Option

......................................................................... 2

2.1 Technical Data of CANopen Communication Module ..................................................................... 2

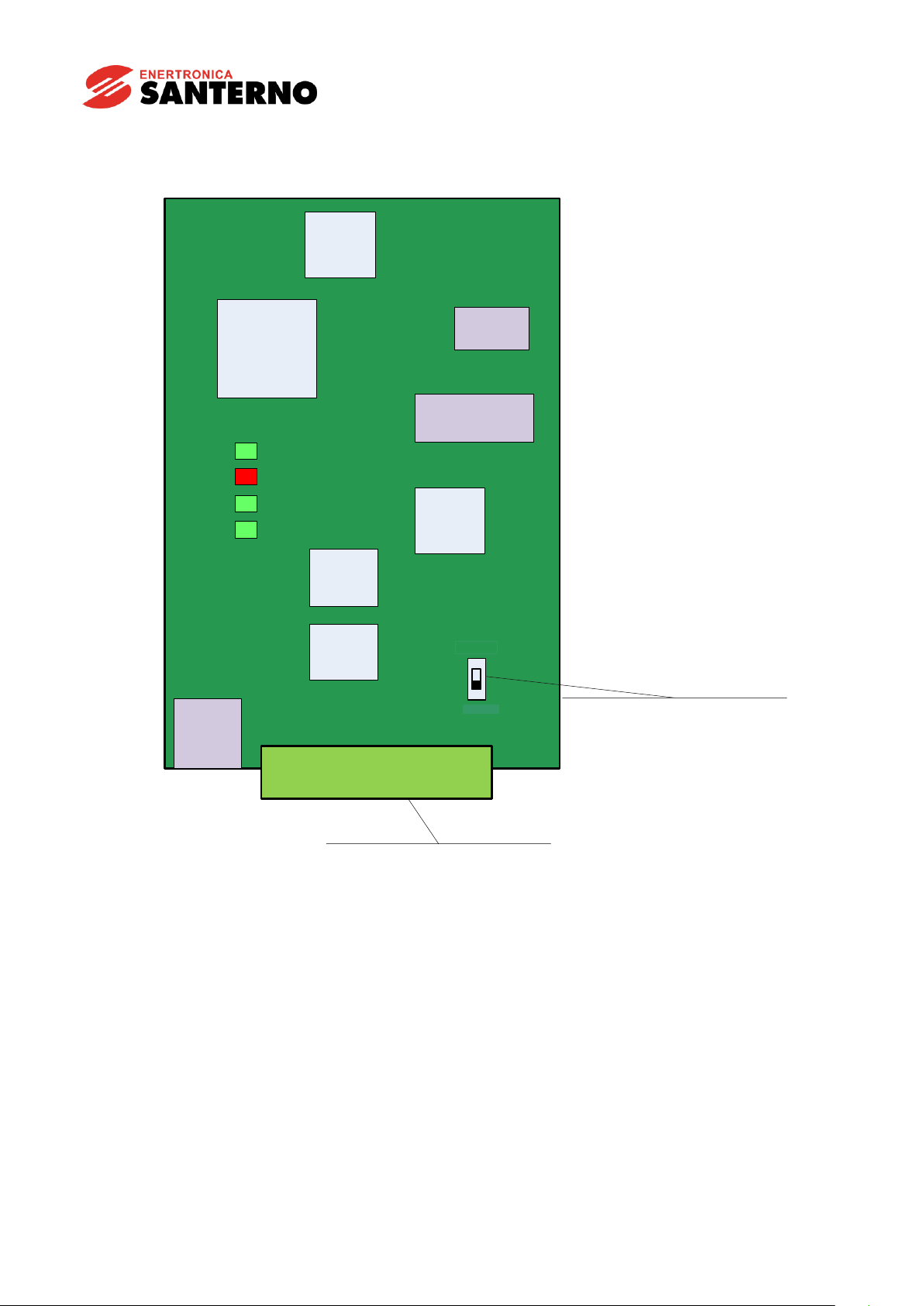

2.2 Layout of CANopen Communication Module .................................................................................. 3

2.3 Installation of CANopen Communication Module............................................................................ 4

2.4 Connection of connector for CANopen signal line........................................................................... 6

2.5 Hardware installation ....................................................................................................................... 7

2.6 Maximum Communication Range according to Baud Rate........................................................... 10

Chapter 3. Diagnosis of the Option Statuses and LED Definition

...............................................11

3.1 Definition of the LED Signal............................................................................................................11

3.2 Diagnosis of Option by LED Signal ................................................................................................11

Chapter 4. Data Communication Protocol of the CANopen

.......................................................17

4.1 Communication Protocol of the CANopen..................................................................................... 17

4.1.1 CAN-ID................................................................................................................................... 17

4.1.2 SDO communication.............................................................................................................. 18

4.1.3 PDO communication.............................................................................................................. 18

4.2 NMT (Network Management) State Machine ................................................................................ 20

4.2.1 NMT state initialization........................................................................................................... 21

4.2.2 NMT state Pre-operational..................................................................................................... 22

4.2.3 NMT state operational............................................................................................................ 22

4.2.4 NMT state stopped................................................................................................................. 22

4.2.5 The frames enabling communication by NMT status............................................................. 23

4.3 Error Control Protocols.................................................................................................................. 23

4.3.1 Protocol node/life guarding .................................................................................................... 23

4.3.2 Protocol heartbeat.................................................................................................................. 24

4.3.3CANopen EDS File ................................................................................................................ 24

Chapter 5. Detailed Specification of Communication Profile Specific Objects

................................25

5.1 Device Type................................................................................................................................... 25

5.2 Error Register ................................................................................................................................ 25

5.3 Pre-defined Error Field .................................................................................................................. 27

5.4 COB-ID SYNC Message................................................................................................................ 28

5.5 Manufacturer Device Name........................................................................................................... 28

5.6 Manufacturer Hardware Version.................................................................................................... 29

5.7 Manufacturer Software Version ..................................................................................................... 29

5.8 Guard Time.................................................................................................................................... 29

5.9 Life Time Factor............................................................................................................................. 30

5.10 COB-ID EMCY............................................................................................................................... 30

5.11 Producer Heartbeat Time............................................................................................................... 30

Chapter 6. Profile

............................................................................................................31

6.1 CiA 402 Drive and Motion Control Device Profile.......................................................................... 31

6.1.1 Finite state automation........................................................................................................... 31

6.1.2 CiA 402 SDO.......................................................................................................................... 33

6.1.3 SDO for Sinus H..................................................................................................................... 40

6.2 PDO............................................................................................................................................... 43

6.2.1 RPDO..................................................................................................................................... 43

6.2.2 RPDO mapping...................................................................................................................... 44

6.2.3 TPDO..................................................................................................................................... 45

6.2.4 TPDO mapping ...................................................................................................................... 46

Chapter 7. Inverter Parameter

............................................................................................47

7.1 Related Parameter List ................................................................................................................ 47