PPI QD User manual

INSTALLATION

Follow all instructions carefully. This is necessary to insure satisfactory performance

of both pulley and bushings. For units that have had the shaft installed at the factory,

retighten the capscrews with a torque wrench set at the proper value, as state in

Table 1.

1. Before installing the bushing, polish the following components:

• Surface of shaft.

• Bore of the bushing.

• Tapered inside diameter of the QD hub.

• Tapered outside diameter of the QD bushing.

Remove all burrs and foreign material; any particles left on the mating surfaces may

cause improper installation. Do not lubricate mating surfaces.

2. If pulley is to be keyed to shaft, make sure both shaft and bushing keyways are clean,

smooth, and free from burrs. Check key size with both shaft and bushing keyways.

Keys should be placed into the shaft keyways at this time. Pulley bushing keyways

require alignment of both shaft keyways for proper bushing to hub installation.

3. Place shaft into pulley and located in the desire position. Be careful not to damage the

bore of the hubs.

4. Carefully insert a wedge in the bushing split and tap lightly to expand the bushing. Use

caution as excessive expansion will cause the bushing to split. Slip bushings

onto shaft and into hubs with the drilled holes of the bushings lined up with the

threaded holes of the hub.

5. Place capscrews, including locking washers, into the unthreaded holes of each

bushing and hand tighten capscrews into the threaded holes of the hub.

6. Remove the wedge from the bushing split.

7. Tighten capscrews in each bushing slightly so that bushings are snug in hubs.

8. Using an accurate torque wrench and the recommended torque from Table 1, tighten

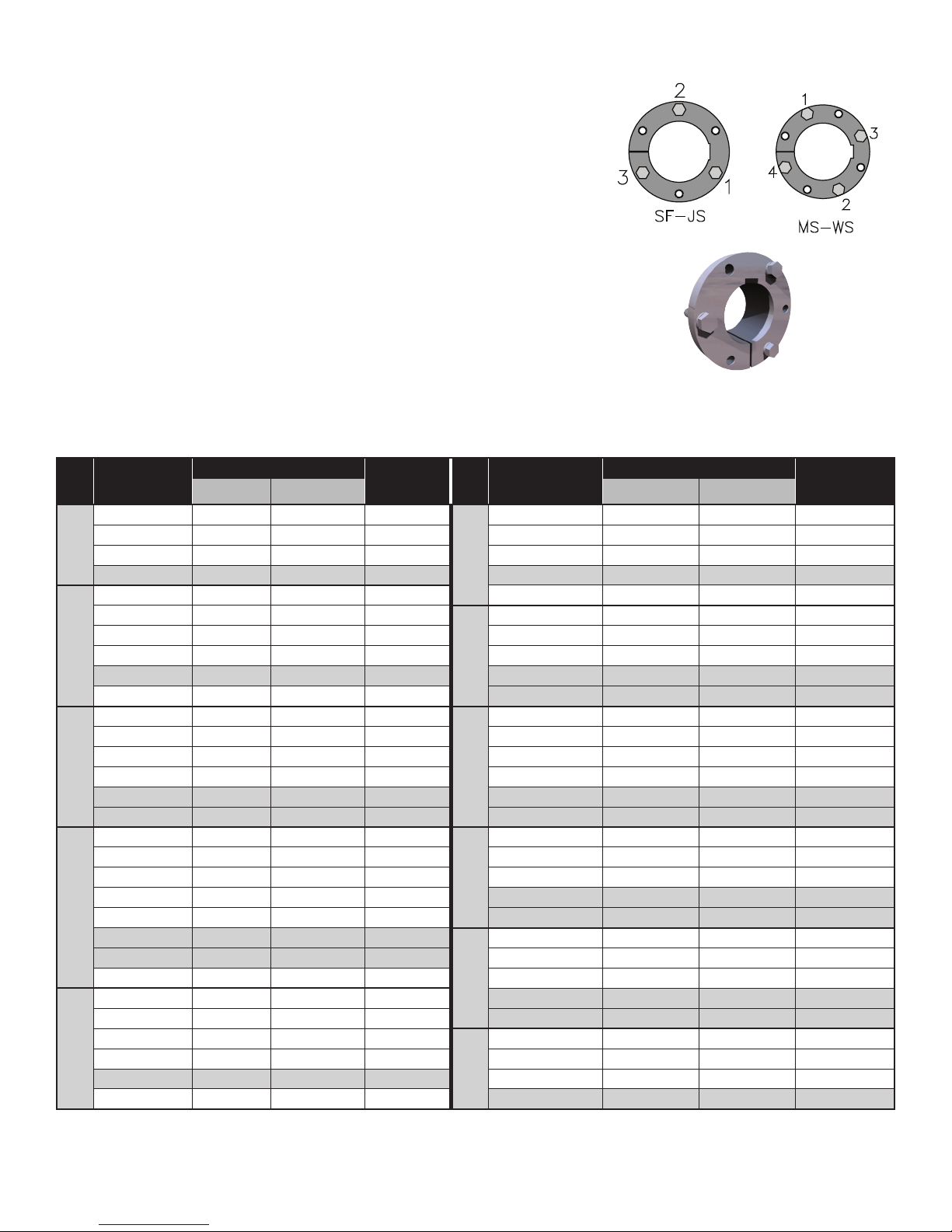

capscrews alternately and evenly in one bushing only. Use the numbered sequence

on the bushing flange capscrew heads in the Diagrams, starting with 1 first, 2 second,

etc., with all capscrews being used until the specified torque no longer turns the capscrews.

It is recommended to use a hammer and a heavy steel or bronze bar, drift on the face of the bushing, starting opposite the split. Avoid

drifting outside of the bolt circle. This will aid in seating of the shallow taper of a QD bushing.

Do not exceed recommended torque from Table 1 in attempt to pull bushing flange flush with hub face – there should be clearance when

tightened. If bushing flange is pulled flush with hub face while tightening capscrews to recommended torque, check for undersized shaft.

9. Repeat for the second bushing.

OPERATION & MAINTENANCE

QD®BUSHING

INSTALLATION INSTRUCTIONS

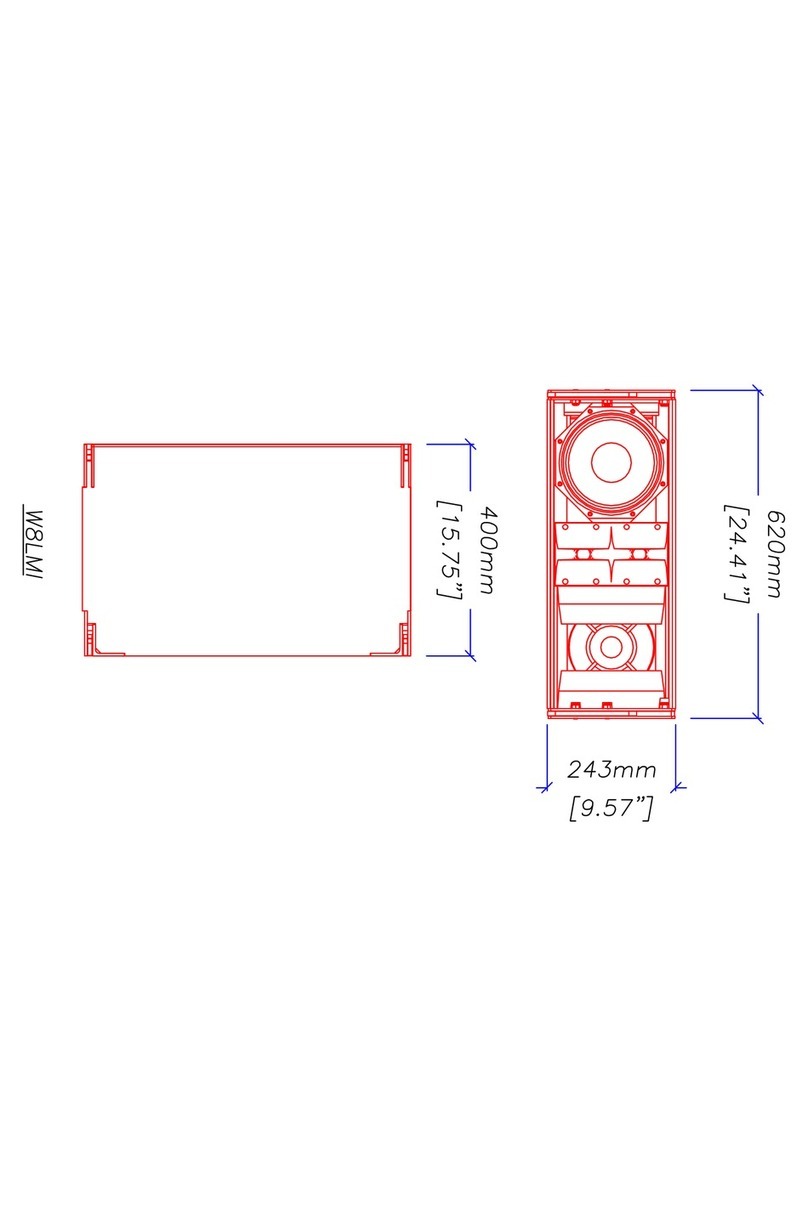

Diagram A

Table 1

Recommended QD Capscrew Torque

HUB # Diameter

(UNRC) Length Torque

(in lbs)

Torque

(N - M)

SH 31/4 1 1/4 108 12

SDS 31/4 1 1/4 108 12

SK 35/16 1 1/2 200 23

SF 33/8 2 360 41

E31/2 2 1/2 720 81

F39/16 2 1/2 900 102

JS 35/8 2 1/2 1,620 183

MS 43/4 3 2,700 305

NS 47/8 3 1/2 3,600 407

PS 4 1 3 1/2 5,400 610

WS 41 1/8 4 7,200 814

READ THESE INSTRUCTIONS CAREFULLY BEFORE STARTING INSTALLATION

Diagram B Diagram C

MAINTENANCE

During the first month of operation, inspect bushings and capscrews for proper seating

at least once a week and re-torque as necessary. Thereafter inspect the bushings during

periodic shutdowns.

REMOVAL

1. Remove all capscrews.

2. Insert the capscrews into all threaded removal holes on bushings.

3. Tighten capscrews alternately and evenly in one bushing only until bushing

is loosened in hub. If bushing does not loosen immediately, tap on hub with

a soft hammer.

4. Remove bushing from the shaft. The use of a wedge carefully inserted in the split of

the flange will expand the bushing to make it easier to slide off the the shaft.

5. Remove the second bushing per steps 1-4.

QD®KEY SIZES

HUB Bore Range

Keyway

Keystock HUB Bore Range

Keyway

Keystock

Shaft Bushing Shaft Bushing

SH

5/8-7/8 3/16 x 3/32 3/16 x 3/32 3/16 x 3/16

F

1 15/16 - 2 1/4 1/2 x 1/4 1/2 x 1/4 1/2 x 1/2

15/16 - 1 1/4 1/4 x 1/8 1/4 x 1/8 1/4 x 1/4 2 5/16 - 2 3/4 5/8 x 5/16 5/8 x 5/16 5/8 x 5/8

1 5/16 - 1 3/8 5/16 x 5/32 5/16 x 5/32 5/16 x 5/16 2 13/16 - 3 1/4 3/4 x 3/8 3/4 x 3/8 3/4 x 3/4

1 7/16 - 1 5/8 3/8 x 3/16 3/8 x 1/16 3/8 x 1/4 3 5/16 - 3 3/4 7/8 x 7/16 7/8 x 3/16 7/8 x 5/8

SDS

5/8-7/8 3/16 x 3/32 3/16 x 3/32 3/16 x 3/16 3 13/16 - 4 NONE NONE NONE

15/16 - 1 1/4 1/4 x 1/8 1/4 x 1/8 1/4 x 1/4

JS

2 15/16 - 3 1/4 3/4 x 3/8 3/4 x 3/8 3/4 x 3/4

1 5/16 - 1 3/8 5/16 x 5/32 5/16 x 5/32 5/16 x 5/16 3 5/16 - 3 3/4 7/8 x 7/16 7/8 x 7/16 7/8 x 7/8

1 7/16 - 1 5/8 3/8 x 3/16 3/8 x 3/16 3/8 x 3/8 3 13/16 1 x 1/2 1 x 1/2 1 x 1

1 11/16 - 1 3/4 3/8 x 3/16 3/8 x 1/8 3/8 x 5/16 3 7/8 - 4 1 x 1/2 1 x 1/4 1 x 3/4

1 13/16 - 2 NONE NONE NONE 4 1/16 - 4 1/2 1 x 1/2 1 x 1/8 1 x 5/8

SK

15/16 - 1 1/4 1/4 x 1/8 1/4 x 1/8 1/4 x 1/4

MS

2 15/16 - 3 1/4 3/4 x 3/8 3/4 x 3/8 3/4 x 3/4

1 5/16 - 1 3/8 5/16 x 5/32 5/16 x 5/32 5/16 x 5/16 3 5/16 - 3 3/4 7/8 x 7/16 7/8 x 7/16 7/8 x 7/8

1 7/16 - 1 3/4 3/8 x 3/16 3/8 x 3/16 3/8 x 3/8 3 13/16 - 4 1/2 1 x 1/2 1 x 1/2 1 x 1

1 13/16 - 2 1/8 1/2 x 1/4 1/2 x 1/4 1/2 x 1/2 4 9/16 - 4 3/4 1 1/4 x 5/8 1 1/4 x 5/8 1 1/4 x 1 1/4

2 3/16 - 2 1/4 1/2 x 1/4 1/2 x 1/8 1/2 x 3/8 4 13/16 - 5 1/4 1 1/4 x 5/8 1 1/4 x 3/8 1 1/4 x 1

2 5/16 - 2 1/2 5/8 x 5/16 5/8 x 1/16 5/8 x 3/8 5 5/16 - 5 1/2 1 1/4 x 5/8 1 1/4 x 1/4 1 1/4 x 7/8

SF

15/16 - 1 1/4 1/4 x 1/8 1/4 x 1/8 1/4 x 1/4

NS

3 7/16 - 3 3/4 7/8 x 7/16 7/8 x 7/16 7/8 x 7/8

1 5/16 - 1 3/8 5/16 x 5/32 5/16 x 5/32 5/16 x 5/16 3 13/16 - 4 1/2 1 x 1/2 1 x 1/2 1 x 1

1 7/16 - 1 3/4 3/8 x 3/16 3/8 x 3/16 3/8 x 3/8 4 9/16 - 5 1/4 1 1/4 x 5/8 1 1/4 x 5/8 1 1/4 x 1 1/4

1 13/16 - 2 1/4 1/2 x 1/4 1/2 x 1/4 1/2 x 1/2 5 5/16 - 5 1/2 1 1/4 x 5/8 1 1/4 x 3/8 1 1/4 x 1

2 5/16 5/8 x 5/16 5/8 x 5/16 5/8 x 5/8 5 9/16 - 6 1 1/2 x 3/4 1 1/2 x 1/4 1 1/2 x 1

2 3/8 - 2 1/2 5/8 x 5/16 5/8 x 3/16 5/8 x 1/2

PS

3 15/16 - 4 1/2 1 x 1/2 1 x 1/2 1 x 1

2 9/16 - 2 3/4 5/8 x 5/16 5/8 x 1/16 5/8 x 3/8 4 9/16 - 5 1/2 1 1/4 x 5/8 1 1/4 x 5/8 1 1/4 x 1 1/4

2 13/16 - 2 15/16 NONE NONE NONE 5 9/16 - 6 1/4 1 1/2 x 3/4 1 1/2 x 3/4 1 1/2 x 1 1/2

E

1 7/16 - 1 3/4 3/8 x 3/16 3/8 x 3/16 3/8 x 3/8 6 5/16-6 1/2 1 1/2 x 3/4 1 1/2 x 1/2 1 1/2 x 1 1/4

1 13/16 - 2 1/4 1/2 x 1/4 1/2 x 1/4 1/2 x 1/2 6 9/16-7 1 3/4 x 3/4 1 3/4 x 1/4 1 3/4 x 1

2 5/16 - 2 3/4 5/8 x 5/16 5/8 x 5/16 5/8 x 5/8

WS

5 15/16 - 6 1/2 1 1/2 x 3/4 1 1/2 x 3/4 1 1/2 x 1 1/2

2 13/16 - 2 7/8 3/4 x 3/8 3/4 x 3/8 3/4 x 3/4 6 9/16 - 7 1/2 1 3/4 x 3/4 1 3/4 x 3/4 1 3/4 x 1 1/2

2 15/16 - 3 1/4 3/4 x 3/8 3/4 x 1/8 3/4 x 1/2 7 9/16 - 8 1/8 2 x 3/4 2 x 3/4 2 x 1 1/2

3 5/16 - 3 1/2 NONE NONE NONE 8 3/16 - 8 1/2 2 x 3/4 2 x 1/4 2 x 1

Keys are provided for shaded cells only, (non-standard key sizes)

Unshaded keysizes are FULL Depth Keys

QD®METRIC KEY SIZES

METRIC DIMENSIONS (mm) DIMENSIONS CONVERTED TO ENGLISH UNITS (in)

HUB Bore Shaft Bushing Keystock Length HUB Bore Key Width Key Height Length

SF

20 6 x 3.5 6 x 2.8 6 x 6

53 SF

0.787 0.236 0.236

2 1/16

25 - 30 8 x 4 8 x 3.3 8 x 7 0.984 - 1.181 0.315 0.276

35 10 x 5 10 x 3.3 10 x 8 1.378 0.394 0.315

40 12 x 5 12 x 3.3 12 x 8 1.575 0.472 0.315

45 - 50 14 x 5.5 14 x 3.8 14 x 9 1.772 - 1.969 0.551 0.354

55 16 x 6 16 x 4.3 16 x 10 2.165 0.63 0.394

60 18 x 7 18 x 4.4 18 x 11 2.362 0.709 0.433

65 - 75 None None None 2.559 - 2.953 None None

E

20 6 x 3.5 6 x 2.8 6 x 6

70 E

0.787 0.236 0.236

2 3/4

25 - 30 8 x 4 8 x 3.3 8 x 7 0.984 - 1.181 0.315 0.276

35 10 x 5 10 x 3.3 10 x 8 1.378 0.394 0.315

40 12 x 5 12 x 3.3 12 x 8 1.575 0.472 0.315

45 - 50 14 x 5.5 14 x 3.8 14 x 9 1.772 - 1.969 0.551 0.354

55 16 x 6 16 x 4.3 16 x 10 2.165 0.63 0.394

60 - 65 18 x 7 18 x 4.4 18 x 11 2.362 - 2.559 0.709 0.433

70 20 x 7.5 20 x 4.9 20 x 12 2.756 0.787 0.472

75 -90 None None None 2.953 - 3.543 None None

F

25 - 30 8 x 4 8 x 3.3 8 x 7

95 F

0.984 - 1.181 0.315 0.276

3 3/4

35 10 x 5 10 x 3.3 10 x 8 1.378 0.394 0.315

40 12 x 5 12 x 3.3 12 x 8 1.575 0.472 0.315

45 - 50 14 x 5.5 14 x 3.8 14 x 9 1.772 - 1.969 0.551 0.354

55 16 x 6 16 x 4.3 16 x 10 2.165 0.63 0.394

60 - 65 18 x 7 18 x 4.4 18 x 11 2.362 - 2.559 0.709 0.433

70 - 75 20 x 7.5 20 x 4.9 20 x 12 2.756 - 2.953 0.787 0.472

80 - 85 22 x 9 22 x 5.4 22 x 14 3.150 - 3.346 0.866 0.551

90 25 x 9 25 x 5.4 25 x 14 3.543 0.984 0.551

95 - 100 None None None 3.740 - 3.937 None None

JS

35 10 x 5 10 x 3.3 10 x 8

85 JS

1.378 0.394 0.315

3 3/8

40 12 x 5 12 x 3.3 12 x 8 1.575 0.472 0.315

45 - 50 14 x 5.5 14 x 3.8 14 x 9 1.772 - 1.969 0.551 0.354

55 16 x 6 16 x 4.3 16 x 10 2.165 0.63 0.394

60 - 65 18 x 7 18 x 4.4 18 x 11 2.362 - 2.559 0.709 0.433

70 - 75 20 x 7.5 20 x 4.9 20 x 12 2.756 - 2.953 0.787 0.472

80 - 85 22 x 9 22 x 5.4 22 x 14 3.150 - 3.346 0.866 0.551

90 - 95 25 x 9 25 x 5.4 25 x 14 3.543 - 3.740 0.984 0.551

100 - 110 28 x 10 28 x 6.4 28 x 16 3.937 - 4.331 1.102 0.63

MS

65 18 x 7 18 x 4.4 18 x 11

122 MS

2.559 0.709 0.433

4 13/16

70 - 75 20 x 7.5 20 x 4.9 20 x 12 2.756 - 2.953 0.787 0.472

80 - 85 22 x 9 22 x 5.4 22 x 14 3.150 - 3.346 0.866 0.551

90 - 95 25 x 9 25 x 5.4 25 x 14 3.543 - 3.740 0.984 0.551

100 - 110 28 x 10 28 x 6.4 28 x 16 3.937 - 4.331 1.102 0.63

115 -130 32 x 11 32 x 7.4 32 x 18 4.528 - 5.118 1.26 0.709

NS

100 - 110 28 x 10 28 x 6.4 28 x 16

152 NS

3.937 - 4.331 1.102 0.63

6115 -130 32 x 11 32 x 7.4 32 x 18 4.528 - 5.118 1.26 0.709

135-140 36 x 12 36 x 8.4 36 x 20 5.312 - 5.512 1.417 0.787

PS 150 36 x 12 36 x 8.4 36 x 20 165 PS 5.906 1.417 0.787 6 1/2

160 40 x 13 40 x 9.4 40 x 22 6.299 1.575 0.866

WS 170 40 x 13 40 x 9.4 40 x 22 184 WS 6.693 1.575 0.866 7 1/4

180 45 x 15 45 x 10.4 45 x 25 7.087 1.772 0.984

OM 010 Contact your sales representative for more information 03/14

©2014 | Precision Pulley & Idler | All Rights Reserved

CORpORATe OffICe • P.O. Box 287 • Pella, IA 50219

800.247.1228 • 641.628.3115 • 641.628.3658 FAX