TAB TEXT HERETAB TEXT HERE TAB TEXT HERE TAB TEXT HERE TAB TEXT HERE

REPAIRS

SERVICE TRAINING MANUAL

14.1 REV 11/19/04

RELAY REPLACEMENT CONTINUED

Page 2

RELAY INSTALLATION

1. Inspect the orientation of the new relays, wiring and metal

adapter plate in its shipping cardboard. The relays will be

installed in the control box with the same orientation. Remove

the new relays, wiring and metal adapter place from its packing

material. Take care to keep the orientation of the new relays as

packed to avoid twisting the wires. Locate the metal adapter

plate; it will be installed first.

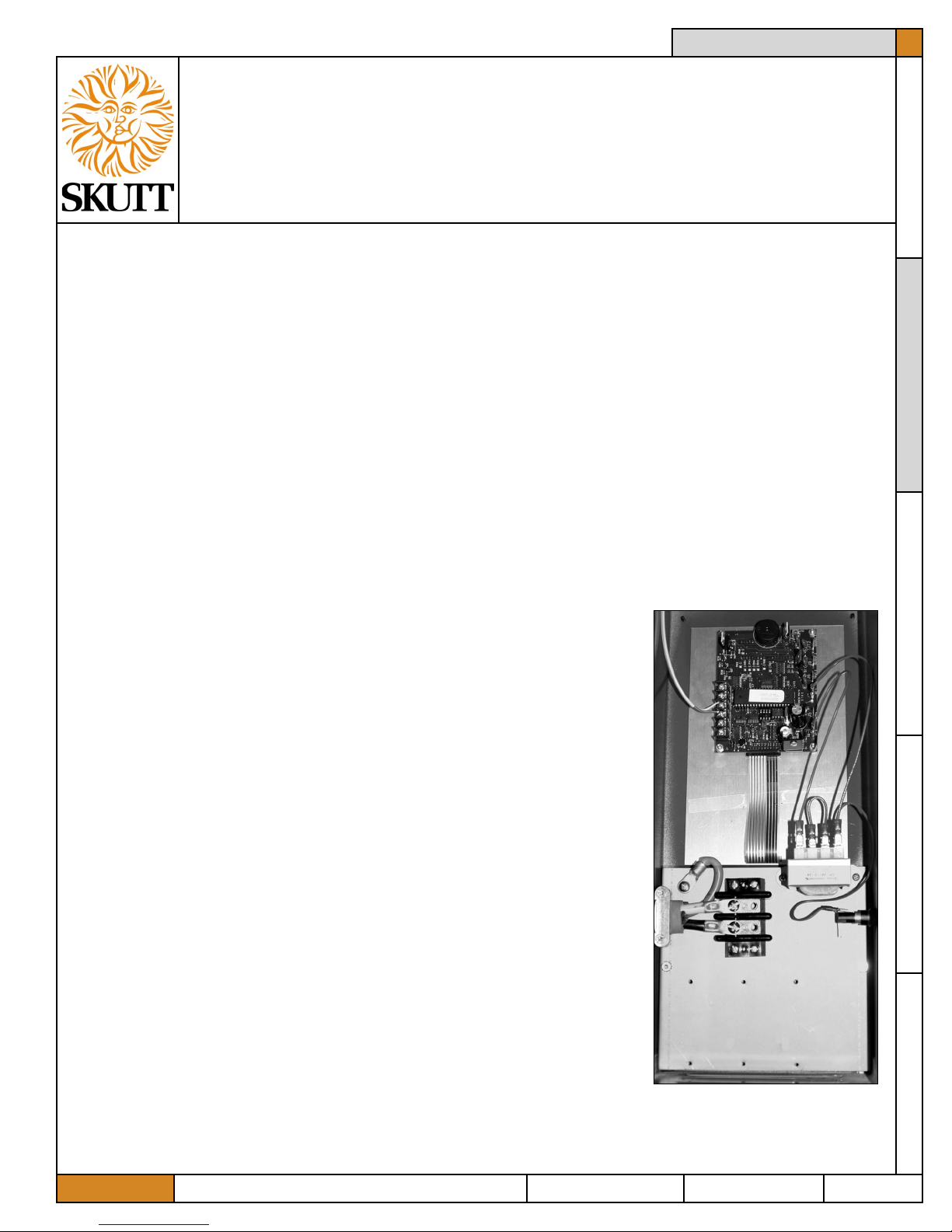

2. Install the metal relay adapter plate in the control box using 3 of

the old relay screws. The silver colored spacers on the adapter

plate should be placed directly against the metal chassis and

screwed down lightly. Use the bottom set of existing holes in the

metal chassis for mounting the adapter plate. Refer to photo #2

for the proper orientation of the metal adapter plate.

3. Place the 3 new relays and wiring harnesses in place on the

metal chasses. Slide the bottom lip of each relay in its proper place. The plastic lip of

the relays should slide underneath the top notched portion of the metal relay adapter

plate.

4. Using the remaining 3 old relay screws, fasten down the remaining lips of the new

relays using the existing holes in the metal chassis. Lightly tighten down all six screws

holding the relays in place. Do not overtighten the screws as they may strip out.

5. Locate the two large silver ring tongue connectors that contain 3 white wires and one

small red wire each and fasten to the terminal block securely. It makes no difference

if the ring tongue connectors are switched in position on the terminal block. Tighten

these screws VERY tight.

6. Locate the two small red wires mentioned above in step #5. Plug one red wire into the

vacant bottom tab of the transformer and the other red wire into the fuse holder.

7. Locate the two long red wires attached to the black relays. One wire will have a double

end. Plug the wire with the double lead into the circuit board in the position labeled

center tap. Plug the loose end of this wire into the top center tab of the transformer.

Plug the other single long red wire into the circuit board on the tab labeled output 2.

8. Find the six, white, ten inch long wires attached to the relays. Attach these six wires

to the heat baffle terminal strip using the old screws. Attach wire #1 (wires designa-

tions are labled on each relay) to position #1 on the terminal strip. Ensure that these

connectors are lined up nicely and securely tightened. Refer to the numbered strip on

the other side of the heat baffle for proper wire position. Reconnect the red and yellow

thermocouple wire if necessary. Make sure the red thermocouple wire is connected to

the negative position of the terminal strip. This would be the end (or bottom) connec-

tor on the terminal strip. It is labeled “-” on the other side.

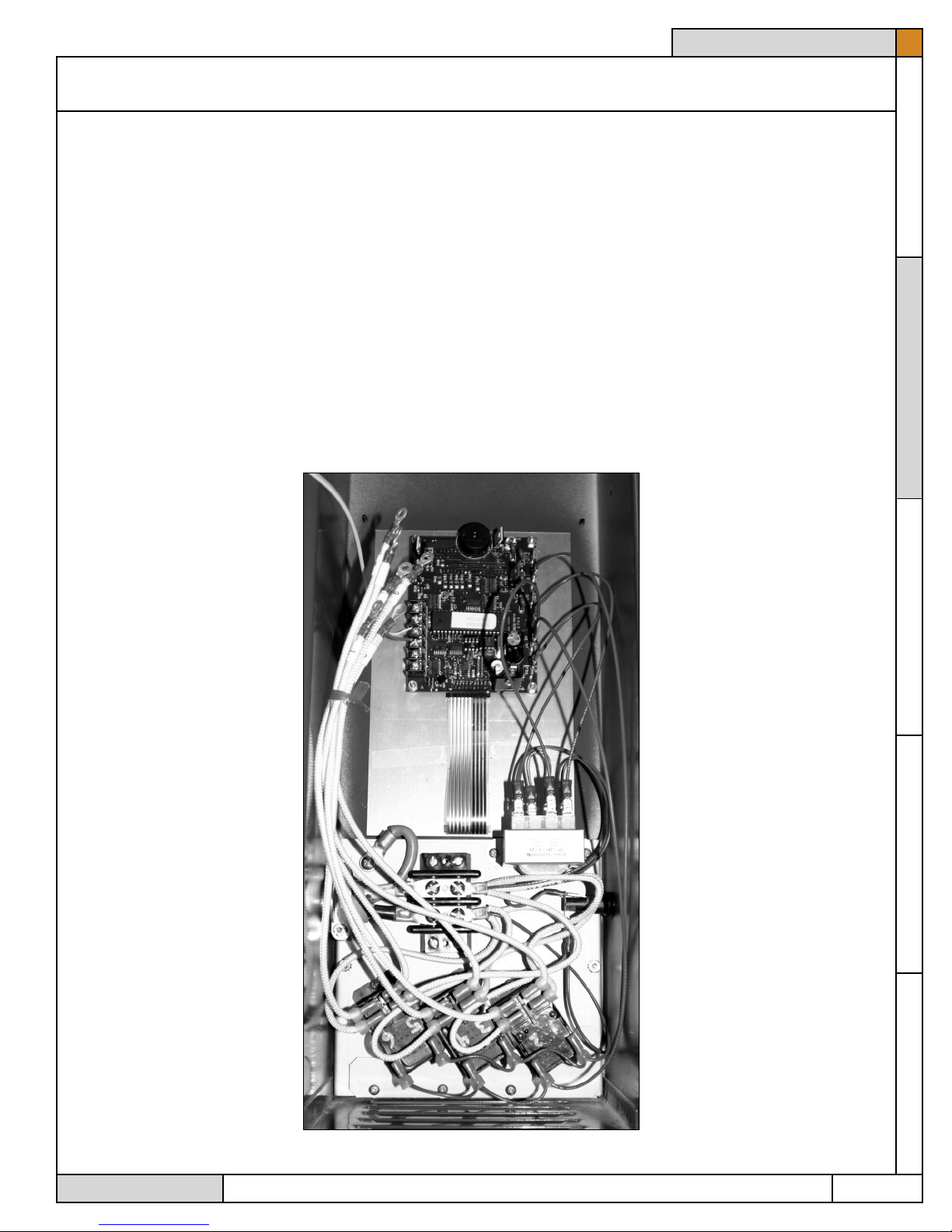

9. All of the wiring should be connected now. Check all wiring for any loose ends or

unattached connectors. Refer to the photo #3, finished wiring, if necessary to determine

proper connection points. Ensure that all wiring is neatly routed around components

such as the transformer. Reroute the wiring as necessary to eliminate kinks or pinch