PPM Technology SPC-1 User manual

PPM SPC-1 Operation Manual

1

SPC-1

Single Point Controller

Operation Manual

NOTICE: PPM Technology Limited shall not be liable for errors that may appear herein or for

incidental or consequential damages in connection with or arising from the use of this material

PPM SPC-1 Operation Manual

2

1 INTRODUCTION

1.1 Overview

Thank you for purchasing the SPC-1 (Single Point Controller-1) monitoring

system The SPC-1 is the new interface method between a computer and

the PPM Technology range of hand-held instruments that enables the

discrete-time monitoring of hazardous formaldehyde Monitoring software

used together with its related hardware enables the SPC-1 to allow 8 PPM

Technology hand-held instruments to be automated when connected to

either the COM or USB ports of your PC Through using the SPC-1

programme it will be possible to list the available hand held instruments;

schedule the monitoring; collect and archive data; show graphical

representation of the data collected; set alarm threshold levels; and

generate graphs or reports from the stored data

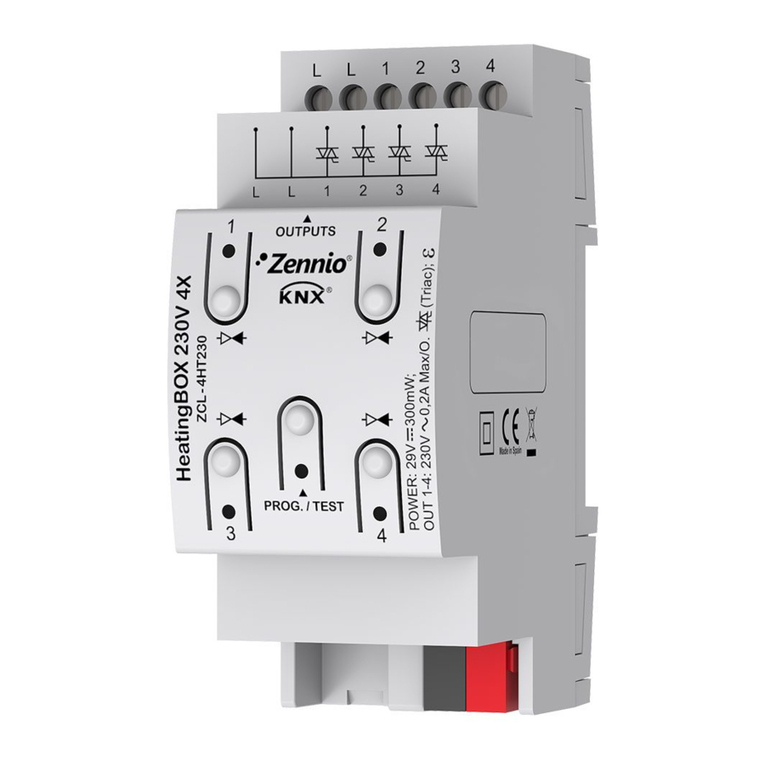

Figure 1.1.1 – Picture of the Single Point Monitor SPC-1 with one

unit connected to a la to .

PPM SPC-1 Operation Manual

3

2 GETTING ST RTED

2.1 Software Installation

Please place the CD into the CD-ROM drive and the software will

automatically run the installation program Clicking on to the “SPC-1 for

Windows XP / 2000” button to launch the installation wizard Using the

installation wizard, complete the installation by following the instructions

onscreen

If the auto run function on your computer is disabled, you can install the

software as follows:

1 From the Start Menu, Select Run

2 Type D:\INSTALL EXE (where D: is you CD-ROM drive)

3 Click on to the “SPC-1 for Windows XP / 2000”

4 Follow the instructions on screen

Your software is now installed To run the software, from the Start menu,

select Programs, PPM Technology and PPMonitor SPC-1 (if default settings

were used) Before running, the system will ask for a software activation

key Visiting htt ://www. m-technology.com/register.shtml can

generate your activation key

2.2 Running the Software

When running the software for the first time, please complete the Company

Information details This information can be used and displayed on various

Reports Information must be entered in the fields without a star in order

to progress to the Main Screen

Figure 2.2.1 – Screenshot of the initial Register Com any

Information screen.

PPM SPC-1 Operation Manual

4

2.3 Hardware Installation

Connect instrument(s) to PC via the SPC-1 box either using Serial or USB

For USB please use supplied USB to Serial adaptor, device drivers and USB

cable For installation instructions for the USB to Serial adaptor see the

included device documentation Please ensure that the battery has been

removed from each instrument before connecting ower to the SPC-1

board.

Figure 2.3.1 – A line drawing of the SPC-1 box.

PPM SPC-1 Operation Manual

5

3 Program Screens

3.1 Main Screen

Once the Company Information has been entered and saved, the main

screen form will be displayed where all functions can be performed and

accessed

Figure 3.1.1 – Screenshot of the main screen.

The main screen of the SPC-1 Single Point monitoring software has eight

buttons, which are:

• Log On / Log Off

• Monitor

• Schedules

• Setup

• Reports

• Admin

• Shutdown

• About

When a button is pressed then the related screen appears These screens

will now be explained:

PPM SPC-1 Operation Manual

6

3.2 Log On / Log Off

The system is password protected and in order to start monitoring or

accessing the data, you need to Log On

The program is supplied with two users already created These are

Administrator (password: letmein) and Guest (password: password)

Access to all areas of the program is given to the Administrator, while the

Guest only has access to the monitoring and reports sections of the

program The Administrator, who can edit user privileges and passwords,

can also create more users

Figure 3.2.1 – Screenshot of the Login screen.

Once Log On is successful the button name changes to Log Off which can be

used to end the users session on the program The availability of some

features will depend on your privileges – if you do not have access then the

button will be grayed out

Figure 3.2.2 - A screenshot of the main screen of the SPC-1 Single

Point monitoring software when logged on as Administrators.

PPM SPC-1 Operation Manual

7

3.3 Monitoring Screen

By clicking the Monitor button, a list of available instruments (units) is shown This

list is common to several screens and will change automatically when units are

connected and disconnected An indicator is situated next to every unit on the list

The indicator shows the status of each unit The table below explains these:

Table 3.3.1 – Table of indicator status colour descri tions.

Status Colour Descri tion

Red

Flashing Red

Amber

Amber (Italic name)

Green

Faulty / Missing

Alarm

Idle

Unit disabled

Sampling

If a schedule is active then by selecting a particular unit, a graphical

representation of results from each of the sensors within that unit is shown, for

example when monitoring using a Formaldemeter

htV

the display will show

graphical representation of Formaldehyde, Temperature and Humidity

Formaldehyde is shown in ppm and mg/m³ A unit is selected by clicking on an

unit button, for instance Figure 3 3 1 is the result of clicking on the F 66 unit

button

Figure 3.3.1 – A screenshot of the Monitor Screen.

PPM SPC-1 Operation Manual

8

3.3 Monitoring Screen

Figure 3.3.2 – A screenshot of the enlarged gra h in the monitor

screen.

By clicking on one of the small graphs in the monitor screen you are able to

view a zoomed version of this graph In Figure 3 3 2, the information at the

right hand side of the graph shows:

Current Schedule: The schedule start and end times are displayed when

scheduling is activated If schedule override is being used, then “n/a” is

displayed in these boxes

Current Axes Settings: These settings allow the user to adjust the values in

the y-axes By entering different values and pressing the Update button, the

graph will resize to the entered values To return to the default size, press

the Reset Ceiling button The values shown in these boxes are for the

primary y-axis That is “ppm” in this case

Graph Printing facility: This button allows you to print out the current graph

with some of the statistics shown under the Sensors tab The current graph

will be printed by the default printer and if no default printer is found then

this button will be disabled

Show all graphs: This button returns to the screen where the three smaller

graphs are shown for the unit

PPM SPC-1 Operation Manual

9

3.3 Monitoring Screen

Figure 3.3.3 – A screenshot of the enlarged gra h in the monitor

screen, sensors section.

By changing to the Sensors tab on the top right hand corner of the Monitor

screen more information about the readings is shown, these include:

Maximum, Minimum and Mean - When a graph is displayed, the highest,

lowest and mean values are displayed here Also shown is the recorded

time when the maximum reading was last taken The values shown in

these boxes are for the primary y-axis That is ppm in this case

Last Readings - These are the last readings collected by the software The

values shown in these boxes are for the primary y-axis That is ppm in this

case

Peak, T.W.A. and S.T.E.L. default values - These are alarm levels set for the

sensors Changes to these alarm levels can be made using the Setup

screen The values shown in these boxes are for the primary y-axis That is

ppm in this case

PPM SPC-1 Operation Manual

10

3.3 Monitoring Screen

Calculated T.W.A. and S.T.E.L. values - These are the calculated values for

Time Waited Average and Short Term Exposure Level based on the current

and previous readings The values shown in these boxes are for the

primary y-axis That is ppm in this case T W A and S T E L are industry

standard measurements for prolonged exposure to environmental

conditions

The T W A is used when both the chemical concentration and exposure

time varies It is usually calculated over 8 hours, which is the standard

daily work shift

Equation 3.3.1 – Equation for T.W.A.

∑

∑

=

=

×

=

n

i

i

n

i

ii

t

tC

TWA

0

0

)(

Figure 3.3.4 – Exam le of a sim le T.W.A. calculation.

S T E L is usually the average concentration for the last 15-minutes

mg/m³ values - These readings are currently only shown against the

Formaldehyde graph The mg/m³ calculation is based upon the

temperature when the reading was taken Because of this the mg/m³ axis

is only relevant for the last reading

Show all graphs: This button returns to the screen where the three smaller

graphs are shown for the unit

Where C = Concentration

t = Duration at level ‘C’

n = Session length

PPM SPC-1 Operation Manual

11

3.4 Schedules Screen

The Schedules Screen allows the user to allocate schedules to individual

units

Figure 3.4.1 – A screenshot of the Schedule Screen.

A Schedule can be set any time during a 24-hour period for each day of the

week In order to create a schedule for a given unit, select the unit using

the unit buttons on the screen, and select the days you wish the unit to be

active by ticking the Enabled checkbox for each day Start Time and End

Time can be entered manually or by using the Preset Times dropdown list at

the bottom of the screen

New Preset Times can be created in the Admin screen described later in the

manual Once the Start Time and End Time have been enter for the Enabled

days, press the Save button These schedules are now bound to the

particular unit To load the same settings for all other units, click on the

Global button There is no need to press Save with the Global button, after

pressing the Global button all available units should have an active

schedule The schedules for one unit can be copied using the Copy button

and reused on another individual unit using the Paste button You will need

to Enable and Save the schedule when using the Copy and Paste function

Schedule Override function: This allows the system to monitor 24 hours a

day without the need to set up existing schedules for each unit This

function can be found in the Admin Screen If the system is sampling

without any enabled schedules then the administrator has enabled the

Schedule Override function The Schedule Override function also takes over

from any schedules that are in place

PPM SPC-1 Operation Manual

12

3.5 Setup Screen

The Setup screen consists of two tabs: Unit and Sensors. The Unit tab is for

general setup options whilst the Sensors tab contains sensor specific

options

The Unit section allows the names of the units to be changed from the

serial number of the unit and to generate a Unit Diagnostic Report, which

gathers information about the unit and prints the results to your default

printer Units can also be enabled or disabled using the Enabled tick-box

All changes need to be saved for them to be affective, this is done by

pressing the Save button

If the Unit Diagnostic Report is grayed out, it is because there is an active

schedule on the system In-order to create a Unit Diagnostic Report, all

schedules for all units need to be disabled The Unit Diagnostic Report

prints one A4 page to your default printer that can be faxed to PPM

Technology if you are encountering any problems (Fax: 44 (0) 1286 671

811) If there is no default printer connected to your PC then the Unit

Diagnostic Report will always be greyed out If problems occur whilst

printing then an error message will be displayed

Figure 3.5.1 – A screenshot of the Setu Screen.

The Unit History automatically gathers information from the program

including unit failures, alarm status and firmware changes Text can be

entered into the right hand box and entered into the unit History by clicking

on the Add Text button; this allows the user to bind free text to a selected

unit Clicking the Clear Text button gets rid of all typed text in the right

hand box

PPM SPC-1 Operation Manual

13

3.5 Setup Screen

Clicking on a Sensor name allows us to view and edit the values for that

sensor The Sensor section allows the names of individual sensor to be

changed from their defaults The sensor can also be disabled from this

screen by using the Disable this sensor checkbox Sensor Ceiling,

Intermediate, T W A and S T E L threshold levels can also be altered from

their default values and changed dependant upon your requirements All

changes need to be saved for them to be affective, this is done by pressing

the Save button

The Sensor History automatically gathers information from the program

including alarm status Text can be entered into the right hand box and

entered into the Sensor History by clicking on the Add Text button; this

allows the user to bind free text to a selected unit Clicking the Clear Text

button gets rid of all typed text in the right hand box

Figure 3.5.2 – A screenshot of the Setu Screen, sensors section.

PPM SPC-1 Operation Manual

14

3.6 Reports Screen

The Reports Screen is used to generate Reports in printed or Coma

Separated Variable ( csv) format The type of reports is selected in the

Output section The information shown in the reports can be filtered by

units or by schedules For each Unit all sensors are selected

Figure 3.6.1 – A screenshot of the Re orts Screen.

A further level of filtering is used for the Date and Time sections Company

Information is included on all the reports generated If Start Date is set to

01/03/2006, End Date is set to 03/03/2006, Start Time is set to 9:00 and

End Time is set to 17:00 then the system does not create a report from

01/03/2006 9:00 to 03/03/2006 17:00 The system will produce a report

that runs from 9:00 to 17:00 on the 1

st

, 2

nd

or 3

rd

of March 2006

When the dates, times, units and type of report have been selected, clicking

the Generate Report button generates the Report Selecting “File.csv” output

causes a “Save As” dialogue to appear but sending output to the Printer

(Graphs) will send the report directly to the default system printer If there

is no default printer connected to your PC then the Printer (Graphs) will

always be greyed out If problems occur whilst printing then an error

message will be displayed

PPM SPC-1 Operation Manual

15

3.7 System dmin Screen

The System Admin Screen allows the Administrator to control the internal

sections of the program The System Admin is split up into 4 sections:

Users/Groups: Groups are used to categorise users By default these are

administrators, users and guests Administrators have access to

everything; Guest can only access monitoring and reports New groups can

be created and existing groups can be changed to suit the needs of the

company Use the tick-boxes to change the access permissions for each

user All changes need to be saved for them to be affective, this is done by

pressing the Save button

Figure 3.7.1 – A screenshot of the System Admin Screen.

Selecting a group will list the users in that group Users can be added,

edited and deleted at any time however the default groups and users

cannot be deleted When creating a new user, they are assigned to the

selected group and this sets their access to the system User Timeout

further restricts access to the system by setting a maximum time a user is

allowed on the system After this time the system will logout the user

automatically The language of the program can also be selected using the

Language section

PPM SPC-1 Operation Manual

16

3.7 System dmin Screen

Preset Times: When scheduling units, the ability to select existing preset

times can save a great deal of set up time Any preset times created here

will appear in the schedule screen

Figure 3.7.2 – A screenshot of the Admin Screen, reset times

section.

PPM SPC-1 Operation Manual

17

3.7 dmin Screen

System Information: The Default Language section takes advantage of the

multilingual functionality of the program The user can create and

download new languages that can be used in this section As well as

individual language settings for each user, the Default Language setting is

the common language used before logging in takes place

Figure 3.7.3 – A screenshot of the Admin Screen, system

information section.

The Schedule Override function allows the system to monitor 24 hours a day

without the need to set up existing schedules for each unit If the Show

Zero Errors checkbox is enabled then a report will be generated when a zero

value of Formaldehyde is detected All changes need to be saved for them

to be affective, this is done by pressing the Save button

The Switch Auto-Run [On/Off] will run the software automatically each time

the Operating System is started (when it is in the On state), preventing the

accidental loss of information by forgetting to start the software manually

Use the Switch Auto-Run [On/Off] button to toggle the state of the Auto-Run

function

Com Port Exclusions let you control which ports are scanned each minute for

units and thus can improve performance Use the Device Manager to check

which Comm Ports are on your systems (in this case COM11 and COM12)

Only enable ports that have SPC-1 devices connected to them

PPM SPC-1 Operation Manual

18

3.7 dmin Screen

Company Information: This section allows the user to make amendments to

the company information should it become necessary The Company

Information is used within the reports section The Fields that are

indicated with a star are required and the Company Information will not Save

without values in these fields All changes need to be saved to be affective,

this is done by pressing the Save button

Figure 3.7.4 – A screenshot of the Admin Screen, com any

information section.

PPM SPC-1 Operation Manual

19

3.8 Shutdown

When a user is Logged In then the Shutdown button is disabled The

Shutdown closes the program and ends the monitoring and archiving of

data In-order to Shutdown the system the user needs to Log Off and then

click the Shutdown button This will bring up a message that asks if we are

sure we want to exit the program, press Yes in order to leave The cross in

the top right hand of the main screen that usually allows the user to close

the program is disabled so that the program cannot mistakenly be closed

3.9 bout Screen

The PPMonitor SPC-1 program version number and release date is given in

the About PPMonitor SPC-1 screen Contact information for PPM

Technology if any problems occur and quote these details If possible

include your registration details too

Figure 3.9.1 – A screenshot of the About PPMonitor SPC-1 Screen.

PPM SPC-1 Operation Manual

20

4 System Operation

4.1 Introduction

In this section we will give examples of how the program can be used To

find all available units Log In as Administrator, go to Admin and select

System Information Let us assume for the purpose of our example that we

have two units F0066 and F0021 connected to our system

Figure 4.1.1 – Screenshot of the System Admin, System Information

screen.

Click on Device Manager and look at ports to find which Comm Port(s) the

instrument(s) have been connected to The two devices connected to the

system are using the USB to Serial adaptors and are listed in Ports as USB

Serial Port (in this case COM11 and COM12) Close the Device Manager,

deselect the corresponding ports on the list and press Save

Table of contents

Popular Controllers manuals by other brands

Wireless Devices

Wireless Devices W1710 POCSAG Airport Operation manual

Sierra

Sierra SmartTrak 50 Series Quick install guide

REGULA

REGULA medius 600 SR Installation and operating instructions

XTA

XTA DP6i Operator's manual

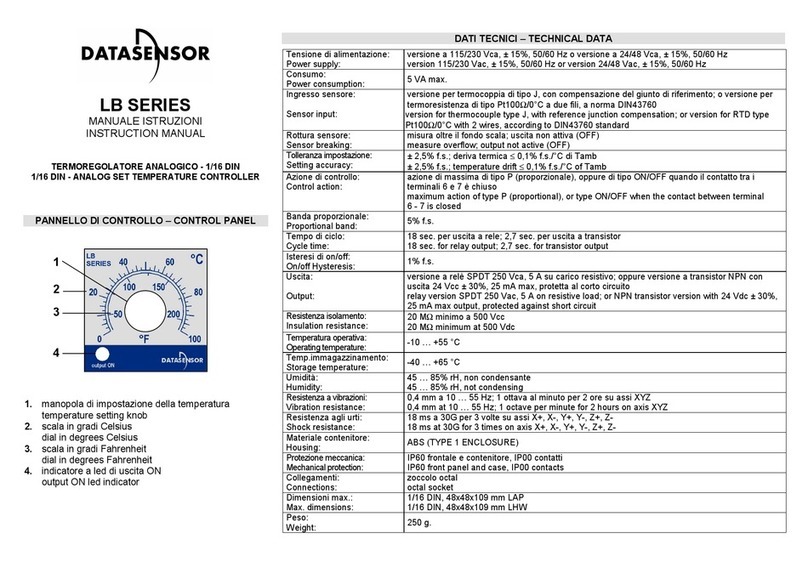

Datasensor

Datasensor LB SERIES instruction manual

TECO

TECO JSDEP Series Simplified manual