PR electronics 5202B User manual

16 17

PULSE ISOLATOR

PRecon 5202B

Contents

Warnings ............................................................................ 18

Safety instructions .............................................................. 19

EC Declaration of Conformity ............................................ 21

How to dismantle SYSTEM 5000 ....................................... 22

Application ......................................................................... 23

Technical characteristics .................................................... 23

Mounting / installation ........................................................ 23

Applications ........................................................................ 24

Order .................................................................................. 25

Electrical specifications ...................................................... 25

Jumper programming ......................................................... 28

Function description........................................................... 29

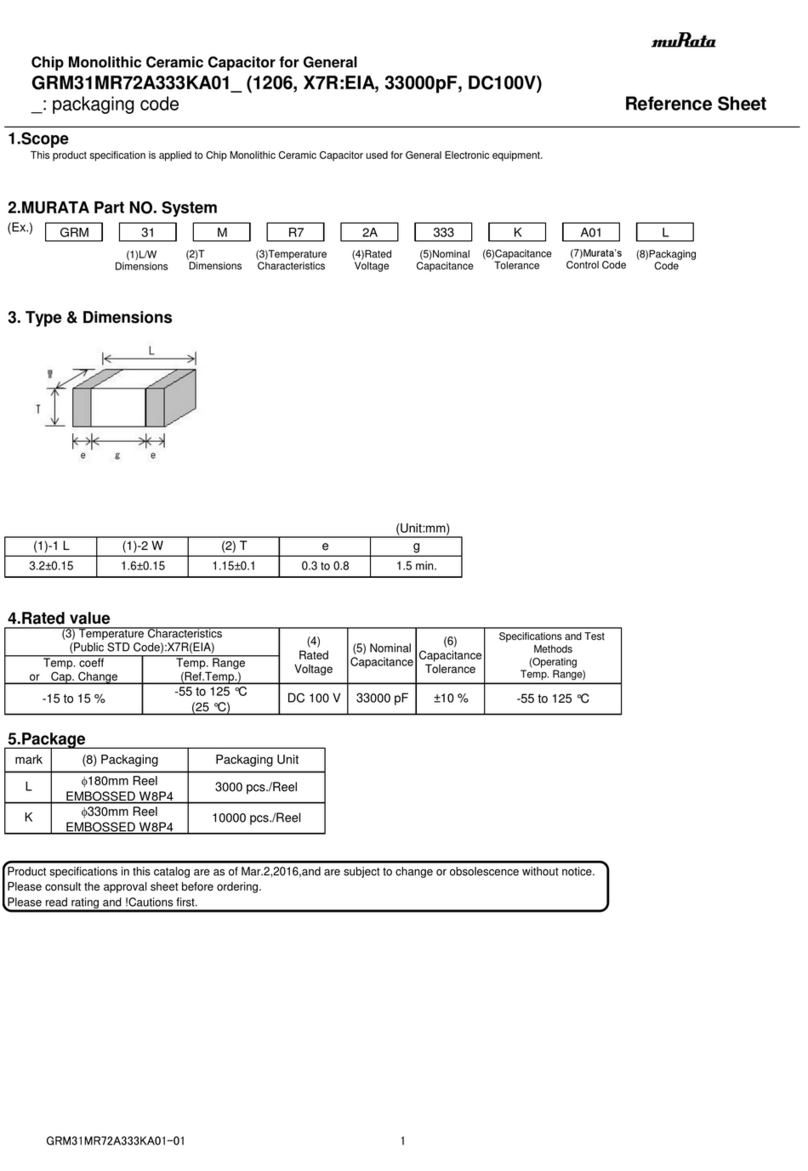

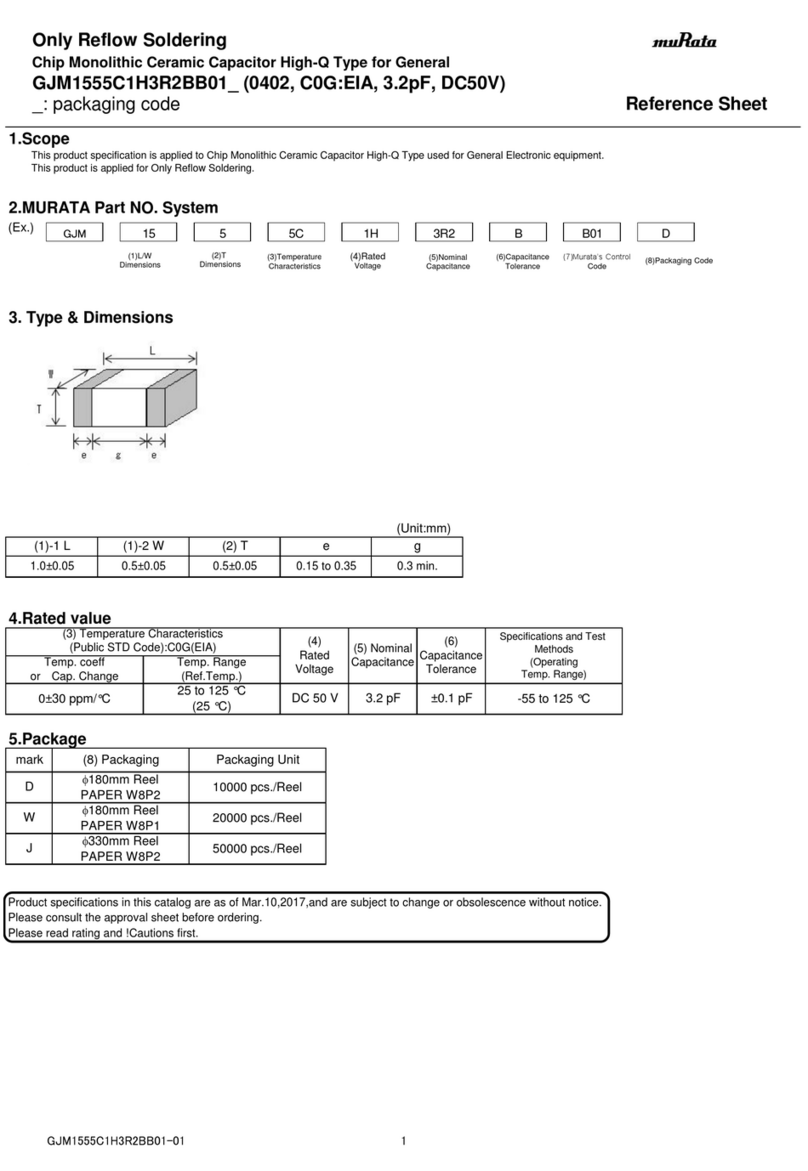

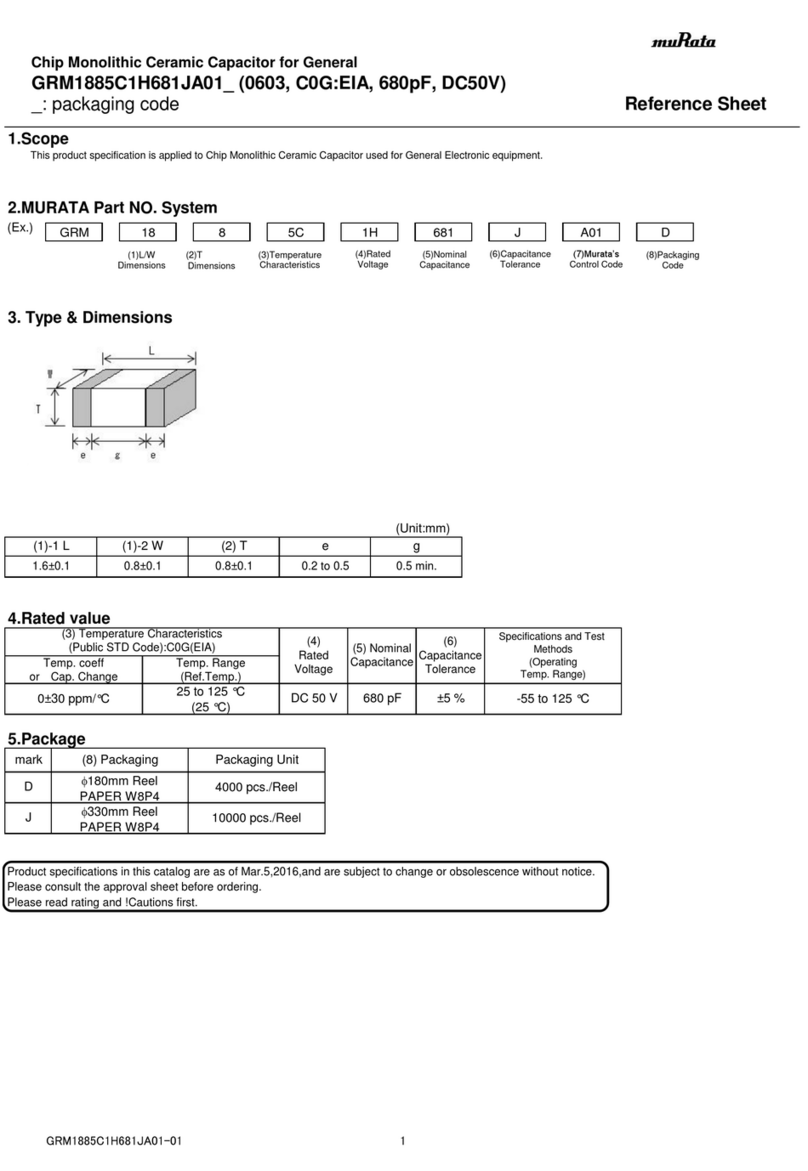

Block diagram 5202B1 and 5202B2 .................................. 30

Block diagram 5202B4 ....................................................... 31

Connections ....................................................................... 32

Appendix:

UL Control Drawing No. 5202QU01................................... 65

31 32 33

43

41 42

Rp

Rs

53

51 52

Rp

Rs

43

41 42

+

-

53

51 52

+

-

43

41 42

53

51 52

53

51 52

Rp

43

41 42

Rp

11 12 13 11 12 13

+

-

Rp = 15 k

Rs = 750

Ω

Ω

Rp = 15 k

Rs = 750

Ω

Ω

11 12 14

13 11 12 14

13

21 22 24

23 21 22 24

23

23

21 22

+

-

23

21 22

Tilslutninger:

Forsyning:

Udgange:

5202B1 og -B2:

Kanal 1Kanal 2 Kanal 2

Indgange:

Kanal 1

Kontakt

Relæ

5202B4:

2 x Relæ N.O. 2 x Relæ N.C.

2 x Relæ N.C.2 x Relæ N.O.

Åben kollektor,

NPN

Åben kollektor,

NPN

NAMUR-føler Kontakt, kabelfejl Kontakt, kabelfejl

Kontakt

Relæ

NAMUR-føler Kontakt, kabelfejl Kontakt, kabelfejl

monteres på

kontakt

monteres på

kontakt

18 19

Symbol identification:

Triangle with an exclamation mark: Warning / demand. Potentially

le thal situations.

The CE mark proves the compliance of the module with the essential

requirements of the directives.

The double insulation symbol shows that the module is protected by

double or reinforced insulation.

Ex modules have been approved acc. to the ATEX directive for use in

connection with installations in explosive areas.

SAFETY INSTRUCTIONS

DEFINITIONS:

Hazardous voltages have been defined as the ranges: 75...1500 Volt DC, and

50...1000 Volt AC.

Technicians are qualified persons educated or trained to mount, operate, and

also troubleshoot technically correct and in accordance with safety regulations.

Operators, being familiar with the contents of this manual, adjust and operate

the knobs or potentiometers during normal operation.

RECEIPT AND UNPACKING:

Unpack the module without damaging it and make sure that the manual always

follows the module and is always available. The packing should always follow

the module until this has been permanently mounted.

Check at the receipt of the module whether the type corresponds to the one

ordered.

ENVIRONMENT:

Avoid direct sunlight, dust, high temperatures, mechanical vibrations and shock,

as well as rain and heavy moisture. If necessary, heating in excess of the stated

limits for ambient temperatures should be avoided by way of ventilation.

All modules fall under Installation Category II, Pollution Degree 1, and Insulation

Class II.

WARNING

This module is designed for connection to hazardous electric

voltages. Ignoring this warning can result in severe personal

injury or mechanical damage.

To avoid the risk of electric shock and fire, the safety instructions

of this manual must be observed and the guidelines followed.

The specifications must not be exceeded, and the module must

only be applied as described in the following.

Prior to the commissioning of the module, this manual must be

examined carefully.

Only qualified personnel (technicians) should install this module.

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

WARNING

Until the module is fixed, do not connect hazardous voltages to

the module. The following operations should only be carried out

on a disconnected module and under ESD-safe conditions:

Dismantlement of the module for setting of dipswitches and

jumpers.

General mounting, connection and disconnection of wires.

Troubleshooting the module.

Repair of the module and replacement of circuit breakers

must be done by PR electronics A/S only.

GENERAL

HAZARD-

OUS

VOLTAGE

WARNING

5202B4:

To keep the safety distances, one relay must not be connected

to hazardous voltage at the same time as the other relay on the

same channel is connected to non-hazardous voltage.

INSTAL-

LATION

20 21

EC DECLARATION OF CONFORMITY

As manufacturer

PR electronics A/S

Lerbakken 10

DK-8410 Rønde

hereby declares that the following product:

Type: 5202B

Name: Pulse isolator

is in conformity with the following directives and

standards:

The EMC Directive 2004/108/EC and later amendments

EN 61326-1 : 2006

For specification of the acceptable EMC performance level, refer to the

electrical specifications for the module.

The Low Voltage Directive 2006/95/EC and later amendments

EN 61010-1 : 2001

The ATEX Directive 94/9/EC and later amendments

EN 50014 : 1997 E incl. A1+A2, EN 50020 : 2002 E and

EN 50281-1-1 : 1998 incl. A1

ATEX certificate: DEMKO 99ATEX127186

No changes are required to enable compliance with the replacement standards:

EN 60079-0 : 2006 and EN 60079-11 : 2007

EN 61241-1 : 2006 and EN 61241-11 : 2007

Notified body

UL International Demko A/S (0539)

Lyskaer 8

P.O. Box 514

DK-2730 Herlev

Rønde, 21 April 2010 Kim Rasmussen

Manufacturer’s signature

MOUNTING:

Only technicians who are familiar with the technical terms, warnings, and

in struc tions in the manual and who are able to follow these should connect the

module.

Should there be any doubt as to the correct handling of the module, please

contact your local distributor or, alternatively,

PR electronics A/S, Lerbakken 10, 8410 Rønde, Danmark tlf: +45 86 37 26 77.

Mounting and connection of the module should comply with national legislation

for mounting of electric materials, i.e. wire cross section, protective fuse, and

location. Descriptions of input / output and supply connections are shown in

the block diagram and on the side label.

The following apply to fixed hazardous voltages-connected modules:

The max. size of the protective fuse is 10 A and, together with a

power switch, it should be easily accessible and close to the module.

The power switch should be marked with a label indicating that it will

switch off the voltage to the module.

Year of manufacture can be taken from the first two digits in the serial number.

CALIBRATION AND ADjUSTMENT:

During calibration and adjustment, the measuring and connection of external

voltages must be carried out according to the specifications of this manual. The

technician must use tools and instruments that are safe to use.

NORMAL OPERATION:

Operators are only allowed to adjust and operate modules that are safely fixed

in panels, etc., thus avoiding the danger of personal injury and damage. This

means there is no electrical shock hazard, and the module is easily accessible.

CLEANING:

When disconnected, the module may be cleaned with a cloth moistened with

distilled water.

LIABILITY:

To the extent the instructions in this manual are not strictly observed, the

customer cannot advance a demand against PR electronics A/S that would

otherwise exist according to the concluded sales agreement.

22 23

PULSE ISOLATOR

PRecon 5202B

• 2 channels - 2 or 4 outputs

• 5-port 3.75 kVAC galvanic isolation

• Dual output

• Cable error detection

• Universal AC or DC supply

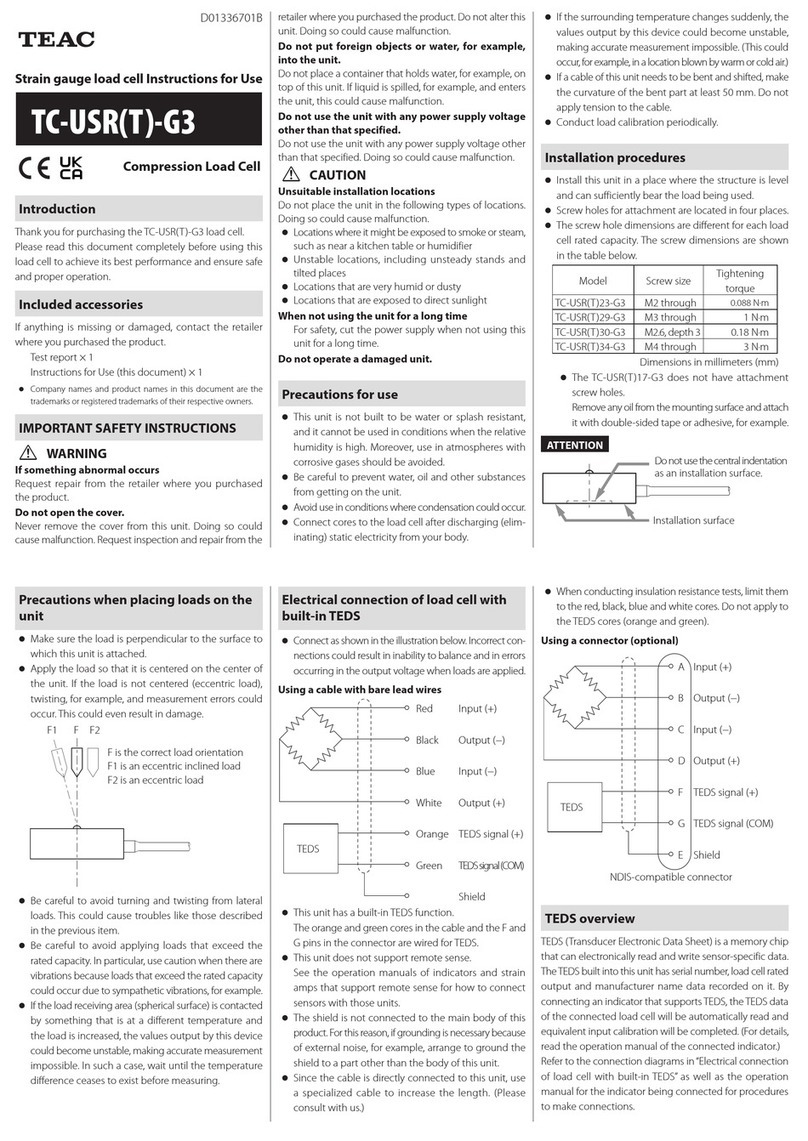

Application:

• Pulse isolator with safety barrier for the supply of NAMUR sensors installed in

the hazardous area.

• Pulse isolator with safety barrier for the detec tion of mechanical contacts

installed in the hazardous area.

• One input signal can be used on two separate outputs.

• A cable error alarm can be detected on a sep arate output.

Technical characteristics:

• PR5202B1 and 5202B2 have relays with change-over contacts or open NPN

collectors available in the safe area.

• PR5202B4 has 4 SPST relays, which are activated simultaneously two and

two, available in the safe area. Each relay can be programmed to the function

N.O. or N.C.

• Inputs, outputs, and supply are floating and galvanically separated.

• The 5202B is designed according to strict safety requirements and is thus

suit able for application in SIL 2 installations.

Mounting / installation:

• Mounted vertically or horizontally on a DIN rail. Up to 84 channels per metre

can be mounted.

HOW TO DISMANTLE SYSTEM 5000

First, remember to demount the connectors with hazardous voltages.

Picture 1:

By lifting the bottom lock, the module

is detached from the DIN rail.

Picture 2:

Then, by lifting the upper lock

and pulling the front plate

simultaneously, the PCB is removed.

Switches and jumpers can now be

adjusted.

24 25

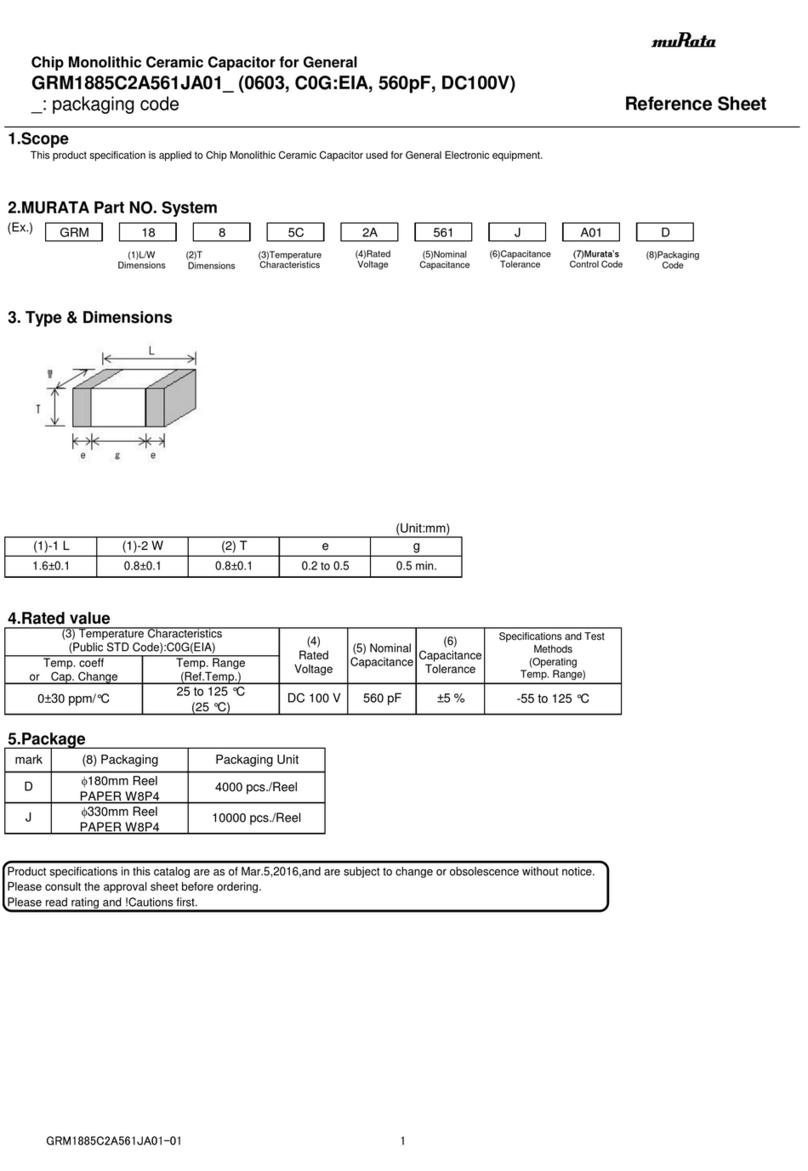

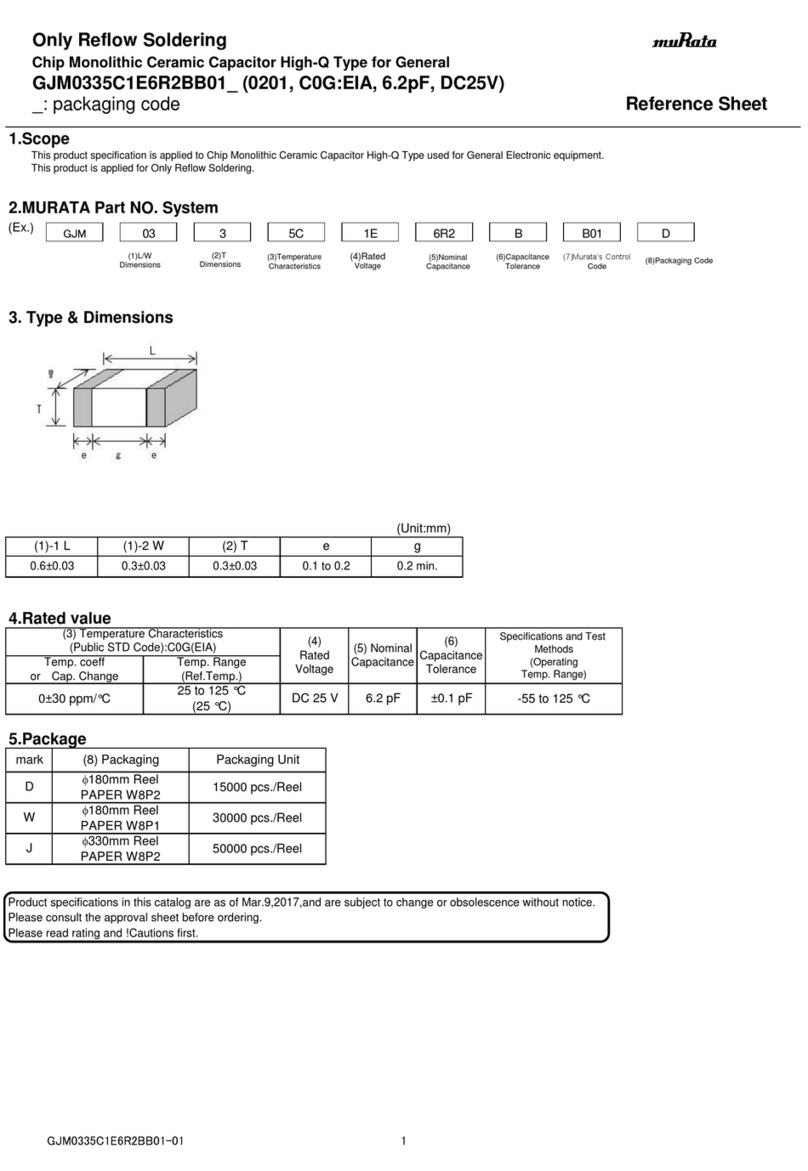

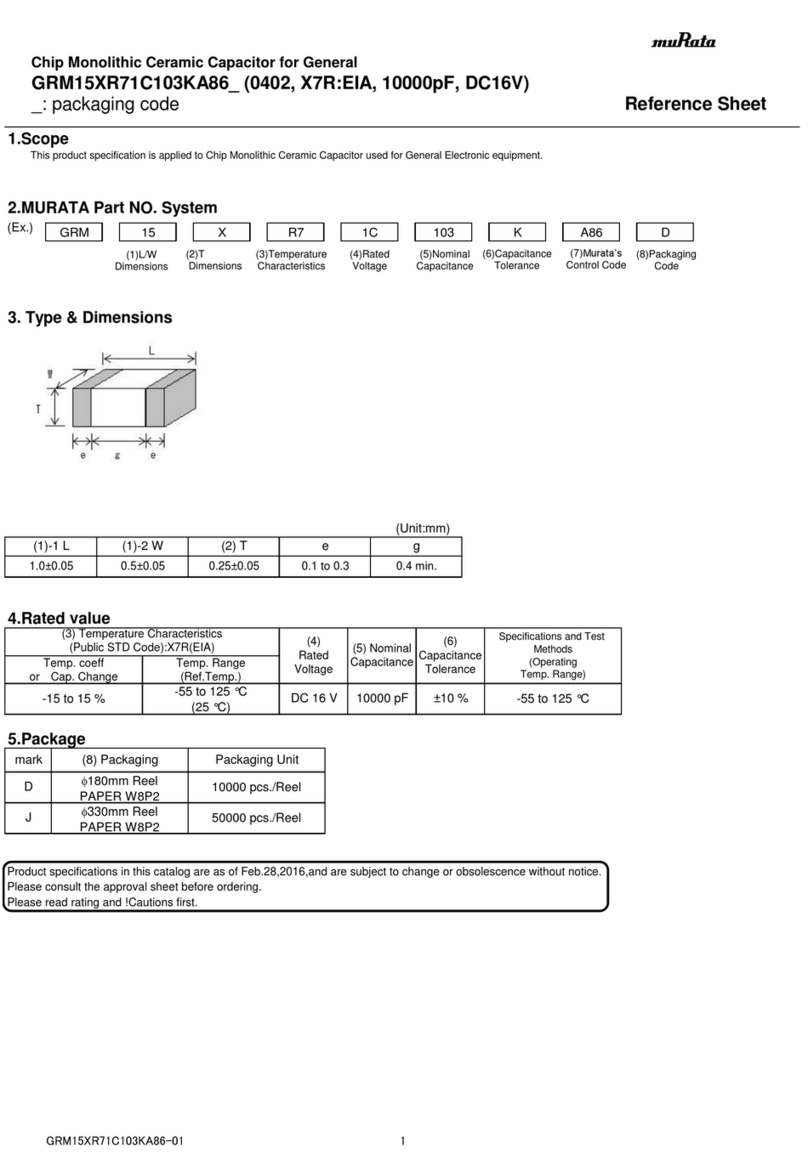

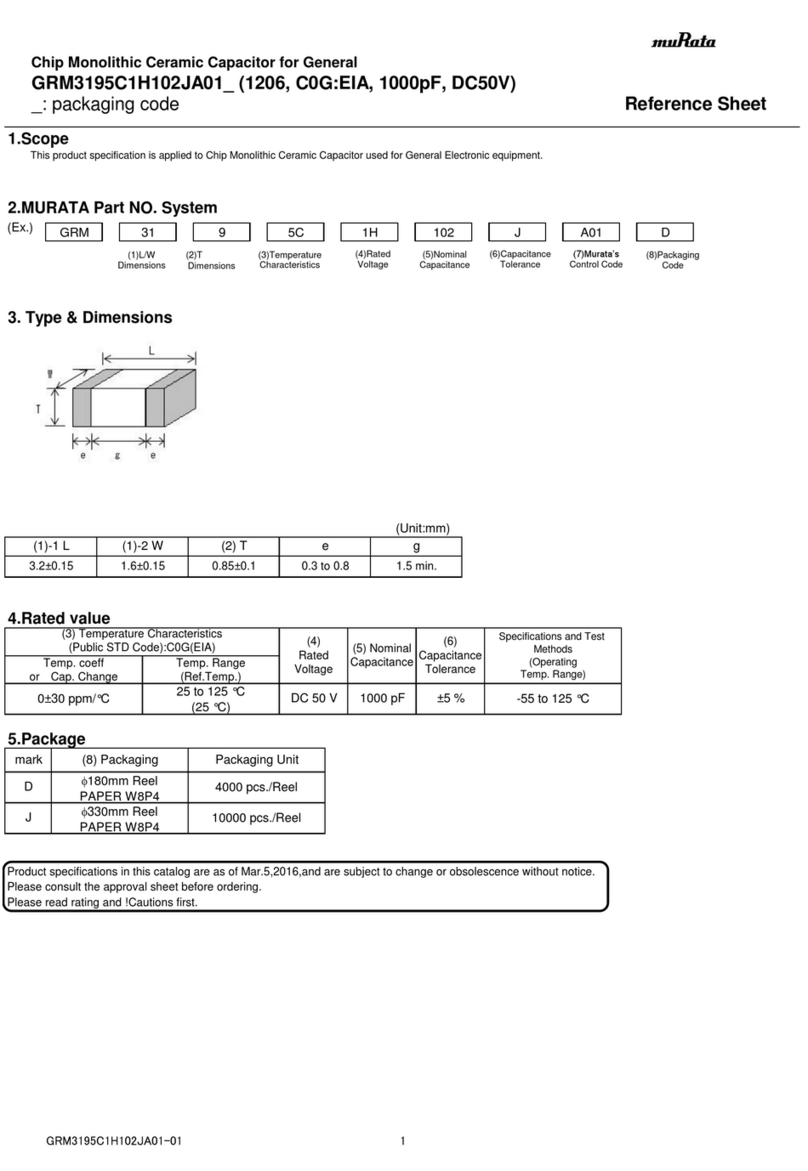

Electrical specifications:

Specifications range:

-20 to +60°C

Common specifications:

Supply voltage universal ............................. 21.6...253 VAC

50...60 Hz

19.2...300 VDC

Internal consumption, 5202B1 and 5202B2 . ≤ 1.5 W (2 channels)

Max. consumption, 5202B1 and 5202B2 ... ≤ 1.5 W (2 channels)

Internal consumption, 5202B4 ..................... ≤ 2.0 W (2 channels)

Max. consumption, 5202B4 ........................ ≤ 2.0 W (2 channels)

Fuse ............................................................. 400 mA T / 250 VAC

Isolation voltage, test / operation ............... 3.75 kVAC / 250 VAC

Calibration temperature............................... 20...28°C

Auxiliary voltage:

NAMUR supply ............................................ 8 VDC / 8 mA

Max. wire size .............................................. 1 x 2.5 mm2 stranded wire

Screw terminal torsion ................................ 0.5 Nm

Relative humidity ......................................... < 95% RH (non-cond.)

Dimensions (HxWxD) ................................... 109 x 23.5 x 130 mm

DIN rail type ................................................. DIN 46277

Protection degree ........................................ IP20

Weight ......................................................... 230 g

EMC immunity influence ..................................... < ±0.5%

Extended EMC immunity:

NAMUR NE 21, A criterion, burst ....................... < ±1%

Rp

Rs

Supply

Supply

Supply

Supply

NAMUR sensors

1 NAMUR sensor

Contact with

cable error detection

Contact

Outputs

Output

Outputs

Cable

error

Signal

2 outputs

26 27

GOST R approval:

VNIIM & VNIIFTRI, Cert. no. ........................ See www.prelectronics.com

Observed authority requirements: Standard:

EMC 2004/108/EC ...................................... EN 61326-1

LVD 2006/95/EC .......................................... EN 61010-1

PELV/SELV ................................................... IEC 364-4-41 and EN 60742

ATEX 94/9/EC .............................................. EN 50014, EN 50020 and

EN 50281-1-1

UL ................................................................ UL 913, UL 508

Inputs:

Sensor types:

NAMUR acc. to ....................................... EN 60947-5-6

Mechanical contact

Frequency range ......................................... 0...5 kHz

Pulse length ................................................. > 0.1 ms

Input resistance ........................................... 1 kΩ

Trig level, signal ........................................... < 1.2 mA, > 2.1 mA

Trig level, cable error ................................... < 0.1 mA, > 6.5 mA

Outputs:

Relay outputs:

Max. frequency ............................................ 20 Hz

Max. voltage ................................................ 250 VRMS

Max. current ................................................ 2 A / AC

Max. AC power ........................................... 100 VA

Max. load at 24 VDC ................................... 1 A

Open NPN collector outputs:

Max. frequency ............................................ 5 kHz

Pulse length ................................................. > 0.1 ms

Load, max. current / voltage ....................... 80 mA / 30 VDC

Voltage drop at 25 mA / 80 mA .................. < 0.75 VDC / < 2.5 VDC

EEx / I.S. approvals:

DEMKO 99ATEX127186 .............................. II (1) GD

[EEx ia] IIC

Applicable for zone ..................................... 0, 1, 2, 20, 21 or 22

Ex / I.S. data:

Terminal 41...43, (51...53)

Um ............................................................... : 250 V

Uo ................................................................ : 10.6 VDC

Io. ................................................................. : 13.8 mADC

Po ................................................................ : 38 mW

Lo ................................................................. : 160 mH

Co ................................................................ : 1.9 µF

UL ................................................................ IS, CL. I, Div. 1, Group A, B, C, D

IS, CL. I, zone 0 and 1, Group IIC

IS, CL. II, Div. 1, Group E, F, G

UL Control Drawing No. .......................... 5202QU01 (see appendix)

28 29

Function description:

Examples of connections on block diagram (1)...(4)

(1) NAMUR sensor with cable error detection in case of cable disconnection or

short-circuit.

(2) Mechanical contact with cable error detection in case of cable disconnection

or short-circuit, when Rs and Rp are mounted on the contact.

(3) Mechanical contact with cable error detection in case of cable disconnection,

when Rp is mounted on the contact.

(4) Mechanical contact without cable error detection.

jumper programming:

• When a channel 1 signal or cable errors are transmitted to channel 2, JP 22

must be in position 2-3, and JP 23 must be in position 1-2.

• Signal transmission to channel 2: If the channel 1 signal is inverted (JP11 in

position 2-3), the channel 2 signal will also be inverted. In this case, the

inversion on channel 2 can be reversed by inverting the channel 2 signal

(JP21 in position 2-3).

• When channel 2 is used individually, input 2 is activated by JP 23 in position

2-3.

30 31

BLOCK DIAGRAM: 5202B4BLOCK DIAGRAM: 5202B1 AND 5202B2

32 33

ISOLATEUR D’IMPULSIONS

PRecon 5202B

Sommaire

Avertissements ................................................................... 34

Consignes de sécurité ....................................................... 35

Déclaration de conformité CE ............................................ 37

Démontage du SYSTEME 5000 ......................................... 38

Application ......................................................................... 39

Caractéristiques techniques............................................... 39

Montage / installation ......................................................... 39

Applications ........................................................................ 40

Référence de commande ................................................... 41

Spécifications électriques .................................................. 41

Programmation des cavaliers ............................................. 44

Déscription des fonctions .................................................. 45

Schéma de principe 5202B1 et 5202B2 ............................ 46

Schéma de principe 5202B4 .............................................. 47

Connexions ........................................................................ 48

Appendice :

UL Control Drawing No. 5202QU01................................... 65

31 32 33

43

41 42

Rp

Rs

53

51 52

Rp

Rs

43

41 42

+

-

53

51 52

+

-

43

41 42

53

51 52

53

51 52

Rp

43

41 42

Rp

11 12 13 11 12 13

+

-

Rp = 15 k

Rs = 750

Ω

Ω

Rp = 15 k

Rs = 750

Ω

Ω

11 12 14

13 11 12 14

13

21 22 24

23 21 22 24

23

23

21 22

+

-

23

21 22

Connections:

Supply:

Outputs:

Channel 1Channel 2 Channel 2

Inputs:

Channel 1

Contact

Relay Open

collector, NPN

Open

collector, NPN

NAMUR sensor Contact, cable error Contact, cable error

Contact

Relay

NAMUR sensor Contact, cable error Contact, cable error

to be mounted

on contact

to be mounted

on contact

5202B4:

2 x Relay N.O. 2 x Relay N.C.

2 x Relay N.C.2 x Relay N.O.

5202B1 and 5202B2:

Table of contents

Other PR electronics Industrial Electrical manuals

PR electronics

PR electronics 9202 Series User manual

PR electronics

PR electronics 9203 Series User manual

PR electronics

PR electronics 9202 Series User manual

PR electronics

PR electronics 3185 User manual

PR electronics

PR electronics 9202 Series User manual

PR electronics

PR electronics 9100 Series User manual

PR electronics

PR electronics 9107B User manual