www.balluff.com 7english

Ignition protection

“nA” and “tb”

2.4 Use and inspection

2.4.1 Device category and suitability

The transducer has been classified as electrical equipment

in device group II, i.e. it is suitable for all explosive areas,

with the exception of fire damp-prone mines. It may be

used in gas and dust explosive areas in accordance with

the following descriptions.

Gas explosion protection

Device category II3G covers devices that have been

designed to ensure a normal level of safety during normal

operation within the operational parameters stated by the

manufacturer. Devices in the category may be used in

zone2, i.e. in areas in which an explosive atmosphere

caused by gases, vapors, or mist is not expected. If such

an atmosphere develops, this is very likely to occur only

seldom and for a short period.

The ignition protection type nA ensures that the electrical

equipment is unable to ignite a surrounding explosive

atmosphere during normal operation and under specific

abnormal conditions.

The risk of sparks is minimized.

Gas group IIC indicates that the transducer can be used in

all gases in compliance with the temperature class.

Temperature class T4 indicates that the outer surface

temperature of the transducer is below 135°C, even if the

permissible operating conditions are unfavorable. As a

result, an explosive gas atmosphere with an ignition

temperature of over 135°C cannot be ignited.

Dust explosion protection

Device category II 2 D covers devices that have been

designed to ensure the required amount of safety, even in

case of frequent device malfunctions or error states which

are generally to be expected. Devices in this category may

be used in zone21 in which an explosive atmosphere

caused by dust/air mixtures may occasionally occur.

The ignition protection type tb indicates that the electrical

equipment is protected against dust entry by housing.

Dust group IIIC covers possible use in all areas with an

explosive dust atmosphere, both with conductive and

non-conductive dusts and flammable fibers.

The temperature specification T135°C indicates that the

external surface temperature of the transducer is below

135°C under all conditions of the device category.

IP6x confirms the dust resistance of the housing.

2.4.2 Special conditions (“X” symbol)

The “X” symbol indicates special conditions that must be

noted for safe operation:

– The permissible ambient temperature is limited to

−40°C to +60°C.

– The impact resistance test was done in accordance

with a low degree of mechanical risk.

– Cable and line inlets were tested with reduced tensile

force in accordance with EN60079-0. This is why the

connection cable must be routed in a permanent

location and protected against tension and rotary loads

using an additional clamp. Drag chains may not be

used.

2.4.3 Operator documents

Zone classification in the system is the responsibility of the

operator and must be documented in an explosion

protection document. This document must also contain

the hazard analysis and assessment, proof of training,

maintenance plans and other documents as required

under Directive 1999/92/EC.

We expressly recommend including the user’s guide in the

operator’s documentation. For safety reasons, it must be

taken over completely and without any changes.

2.5 Assembly, installation, and setup

Assembly, installation, and setup of the transducer must

not be done in an explosive atmosphere.

Protect the transducer from damage and wear. In addition

to mechanical protection, this also includes precautions to

prevent non-permissible operating conditions and damage

due to environmental influences.

Note that the position measuring system must be

connected to the potential compensation system in

accordance with the requirements in EN60079-14. The

external connection for the transducer is accomplished by

means of metallic conducting installation in a grounded

area. The flange and housing are mechanically fixed with

electrically conductive connections, so that no potential

differences can occur between them. The cable shield is

connected to the housing and must be connected to the

potential of the system’s control cabinet.

2ATEX safety notes (continued)

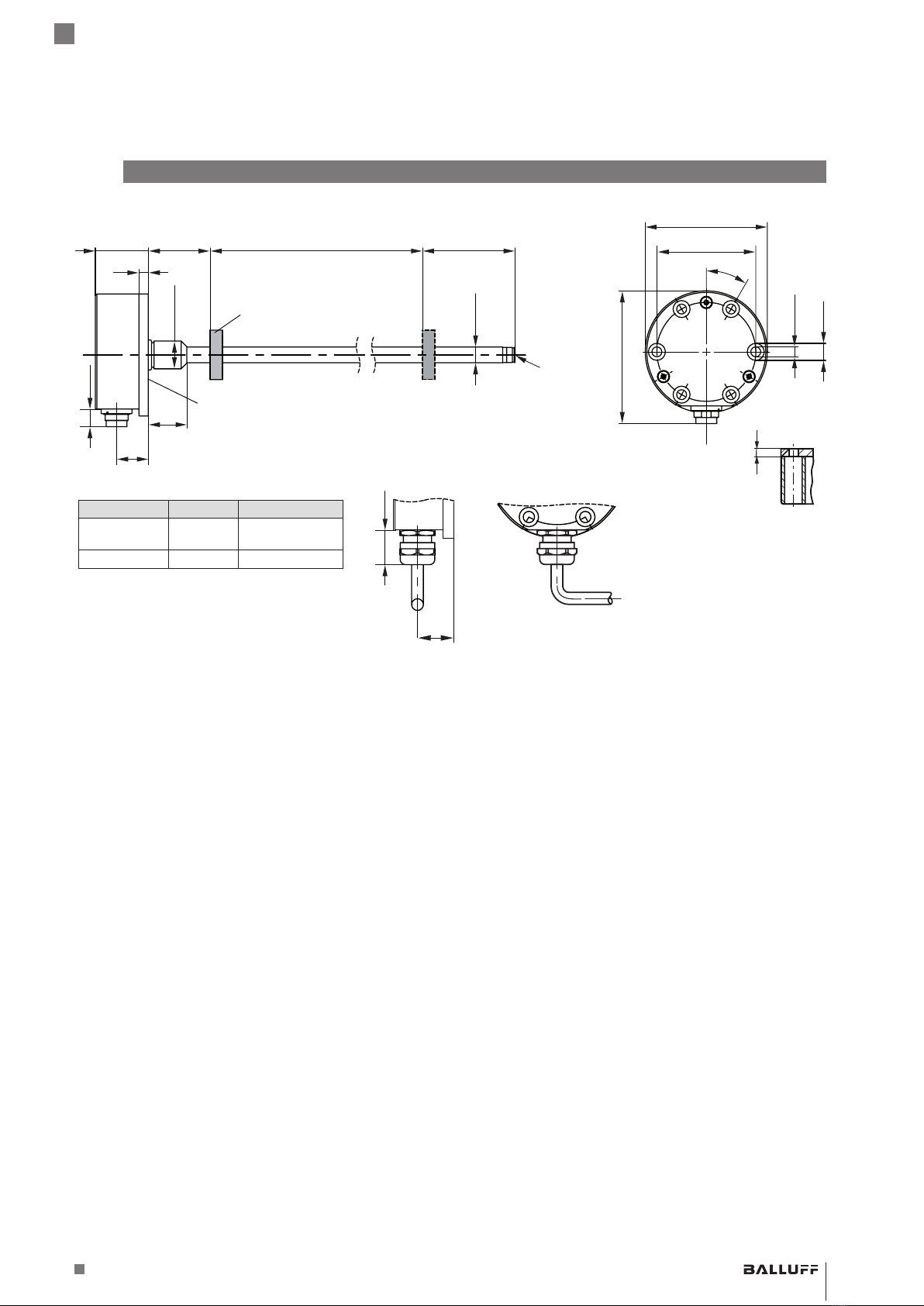

BTL7-A/C/E/G5__-M____-K(8)-NEX-SR32/K___

Micropulse Transducer - Rod Style