Pramac P2000i User manual

INVERTER GENERATOR

P2000i

Operating Manual

INVERTER GENERATOR – P2000i

2

We Appreciate Your Business.

Thank you and congratulations on choosing PRAMAC.

This Operating Manual has been designed to instruct you on the correct use

and operation of your PRAMAC product. Your satisfaction with this product

and its safe operation is our ultimate concern. Therefore please take the time

to read the entire manual, especially the Safety Precautions. They will help

you to avoid potential hazards that may exist when working with this product

.

WARNING

READ AND

UNDERSTAND ALL SAFETY PRECAUTIONS IN THIS MANUAL BEFORE

OPERATING. FAILURE TO COMPLY WITH INSTRUCTIONS IN THIS MANUAL COULD

RESULT IN PERSONAL IN

JURY, PROPERTY DAMAGE, ANDIOR VOIDING OF YOUR

WARRANTY. PRAMAC WILL NOT BE UABLE FOR ANY DAMAGE BEC

AUSE OF FAILURE

TO FOLLOW THESE INSTRUCT/ONS.

INVERTER GENERATOR – P2000i

3

Table of Contents

1SAFETY INSTRUCTIONS AND WARNINGS ......................................... 4

2CONTROLS AND FEATURES.............................................................. 12

2.1 Generator ......................................................................................... 12

2.2 Control Panel .................................................................................... 13

2.3 Control Functions ............................................................................. 14

3GETTING STARTED............................................................................. 18

3.1 Unpack the Generator ...................................................................... 18

3.2 Adding engine Oil ............................................................................. 18

3.3 Adding Fuel ...................................................................................... 20

3.4 Starting the Engine ........................................................................... 21

3.5 Stopping the Engine ......................................................................... 23

4ELECTRICAL CONNECTION............................................................... 24

4.1 Capacity ........................................................................................... 24

4.2 Power Management ......................................................................... 24

4.3 Connecting Electrical Loads ............................................................. 24

4.4 Parellel Connection within 2 generator ............................................. 25

4.5 Battery Charging ............................................................................... 28

4.6 Wattage Reference Guide ................................................................ 29

5MAINTENANCE.................................................................................... 31

5.1 Periodic Maintenance ....................................................................... 31

5.2 Spark Plug Maintenance ................................................................... 32

5.3 Engine Oil Replacement ................................................................... 33

5.4Air Filter Maintenance ....................................................................... 34

5.5 Muffler Screen and Spark Arrestor Maintenance .............................. 35

5.6 Fuel Filter Maintenance .................................................................... 36

6STORAGE............................................................................................. 37

6.1 Long Term Storage ........................................................................... 37

7TROUBLESHOOTING AND SPECIFICATIONS................................... 39

7.1 Troubleshooting Diagram ................................................................. 39

7.2 Fuel Filter Maintenance .................................................................... 40

7.3 Specifications ................................................................................... 41

INVERTER GENERATOR – P2000i

4

1 SAFETY INSTRUCTIONS AND WARNINGS

WARNING

THE ENGINE EXHAUST FROM THIS PRODUCT CONTAINS CHEMICALS TO CAUSE

CANCER, BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

NOTE

Read this manual carefully before operating this machine. This manual should stay with this

machine if it is sold.

INVERTER GENERATOR – P2000i

5

INTRODUCTION

This Operating Manual has been designed to instruct you on the correct

operation of your PRAMAC product. Your satisfaction with this product and its

safe operation is our ultimate concern. Therefore please take the time to read

the entire manual, especially the Safety Precautions. They will help you to

avoid potential hazards that may exist when working with this product.

INVERTER GENERATOR – P2000i

6

IMPORTANT MANUAL INFORMATION

Particulary important information is distinguished in this manual by the

following notes.

Symbol Usage

This manual contains important information that you need to know and

understand in order to assure YOUR SAFETY and PROPER OPERATION

OF EQUIPMENT. The following symbols help you recognize this

information. Please read the manual and pay attention to these

sections.

WARNING

WARNING INDICATE A CERTAINTY OR STRONG POSSIBILITY OF PERSONAL INJURY OR

DEATH IF INSTRUCTIONS ARE NOT FOLLOWED.

NOTICE

CAUTIONS INDICATE A POSSIBILITY ARE NOT FOLLOWED PROPERLY.

TIPS

TIPS GIVE HELPFUL INFORMATION

WARNING

PLEASE READ AND UNDERSTAND THIS MANUAL COMPLETELY BEFORE OPERATING

THE MACHINE.

TIP

Continually seeks advancements in product design and quality. Therefore,

wherein this manual contains the most current product information available

at the time of printing, there may be minor discrepancies between your

engine and this manual. If there is any question cancerning this manual,

please consult a PRAMAC dealer.

This manual should be considered a permanent part of this engine and

should remain with this engine when resod.

Product and specifications are subject to change without notice.

INVERTER GENERATOR – P2000i

7

SAFETY INFORMATION

FUEL IS HIGHLY FLAMMABLE AND POISONOUS

• Always turn off the engine when refueling.

• Never refuel while smoking or in the vicinity of an open flame.

• Take care not to spill any fuel on the engine or muffler when refueling.

• If you swallow any fuel, inhale fuel vapor, or allow

• Any to get in your eye(s), see your doctor immediately. If any fuel spills

on your skin or clothing, immediately wash with soap and water and

change your clothes.

• When operating or transporting the machine, be sure it is kept upright. If

it tilts, fuel may leak from the carburetor or fuel tank.

EXHAUST FUMES ARE POISONOUS

• Never operate the engine in a closed area or it may cause

unconsciousness and death within a short time. Operate the engine in a

well ventilated area.

ENGINE AND MUFFLER MAY BE HOT

• Place the machine in a place where pedestrians or children are not likely

to touch the machine.

• Avoid placing any flammable materials near the exhaust outlet during

operation.

INVERTER GENERATOR – P2000i

8

• Keep the machine at least 1m (3 ft) from buildings or other equipment, or

the engine may overheat @ 1 m (3 ft).

• Do not operate the engine with a dust cover, or other objects covering it.

• When covering the generator, be sure to do so only after the engine and

muffler have completely cooled down.

• Be sure to carry the generator only by its carrying handles.

• Do not place any obstacles on the generator.

ELECTRIC SHOCK PREVENTION

• Never operate the engine in rain or snow.

• Never touch the machine with wet hands or electrical shock will occur.

INVERTER GENERATOR – P2000i

9

• Connect the ground lead of the machine to the ground terminal 1 to

ground the generator to earth (where needed) and connect the end to

the ground electrode buried in the ground.

CONNECTION NOTES

• Avoid connecting the generator to commercial power outlet.

CONNECTION

WARNING

Before the generator can be connected to a building’s electrical system, a licensed

electrician must install an isolation (transfer) switch in the building’s main fuse box. The

switch is the connection point for generator power and allows selec

tion of generator or

main line power to the building. This will prevent the generator from charging the main

power line (back feeding) when the main power supply has failed or has been turned off for

line repair. Back feeding can electrocute or injure line

maintenance personnel. Also,

generator and building electrical system damage can occur when normal operating power

returns if unit is used without an isolation switch.

EXTENSION CORD NOTES

Extension cords should be protected by a tough flexible rubber sheath (I E C

245) or the equivalent to withstand mechanical stress.

INVERTER GENERATOR – P2000i

10

LOCATION OF IMPORTANT LABELS

Please read the following labels carefully before operating this machine.

TIP

Maintain or replace safety and instruction labels, as necessary.

1

INVERTER GENERATOR – P2000i

11

2

3

INVERTER GENERATOR – P2000i

12

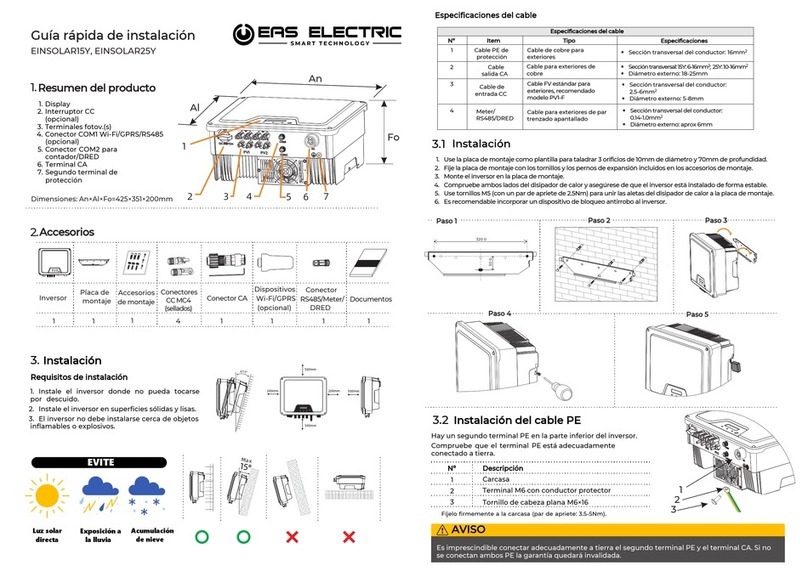

2 CONTROLS AND FEATURES

2.1 Generator

1. Muffler

2. Carrying handle

3. Vented Gas Cap

4. Recoil Starter

5. Control Panel

6. Fuel Gauge

7. Exhaust and Spark Arrestor

8. Oil filter cap

INVERTER GENERATOR – P2000i

13

2.2 Control Panel

AC Pilot Light

1. Engine Switch

2. Economy Throttle (Black)

3. AC Pilot Light

4. Overload Indicator Light

5. Oil Warning Light

6. 12V DC Output

7. 8A DC Circuit Breaker

8. Fuel Petcock

9. Choke

10. 220/230/240V AC Outlets

This socket is only corresponding to a client, the different laws and regulations according to the sales area

changes corresponding to the socket.

11. Ground Terminal

INVERTER GENERATOR – P2000i

14

2.3 Control Functions

ECONOMY THROTTLE

Throttle

When the Throttle switch is in the “I” position the throttle controls the engine

speed according to the connected electrical load. The results are better fuel

consumption and less noise. When the switch is in the “O” position the engine

runs at 4,500 rpm regardless of the electrical load.

NOTE

The Throttle must be “O” when using electrical devices that require a large starting current,

such as a compressor, pump, or refrigenator.

Led Indicators

The LED Indicators assist in communicating proper and improper functions of

the unit.

Output Indicator (Green)

The Output Indicator comes on when the engine starts and produces power.

Overload Alarm (Red)

The Overload Alarm comes on when a connected device requires more

power than the generator is able to produce, the inverter control unit

overheats, or the AC output voltage rises above rated values. The Output

Indicator (Green) will go off and the Overload Alarm (Red) will stay on, but the

engine will continue to run.

When the Overload Alarm Light comes on and power generation stops,

proceed as follows:

INVERTER GENERATOR – P2000i

15

1. Turn off any connected electric devices and stop the

engine.

2. Reduce the

total wattage

of connected electric devices within

the

rated

output.

3. Check for blockages in the cooling air inlet and around

the

contro

l

unit.

lf any

blockages

are found remove

them.

4. After

checking, restart

the

engine.

NOTE

The Overload Alarm may come on for a few seconds when first using electrical devices that

require a large starting current, such as a compressor, pump, or refrigerator.

This is normal

behavior it is not a malfunction.

Low

Oil Alarm

(

Red)

When the engine oil falls below the required

level the

Low

Oi

l

Alar

m

will

come on and the engine will stop automatically. The engine will not restart

until oil is added to the unit to bring it up to the appropriate level.

NOTE

When starting the unit, if the Low Oil Alarm light flickers and the engine will not start, you

will need to add engine oil before attempting to restart the engine.

NOTE

Generator should

only be operated on a level surface. DO NOT operate the generator on

loose ground or obvious inclines. The low oil shutdown feature may be prematurely

activated in these cases causing the engine to not start.

Engine

Switch

The Engine Switch controls the

ignition switch.

Th

e

switch must be in the

“I”

position to start the

generator. Switching

to

the

“O”

position stops the

engine and

will

not allow the engine to be

restarted.

INVERTER GENERATOR – P2000i

16

12V 8A DC Outlet

The 12V 8A DC Outlet is for provided for battery charging. Follow instructions

in the owner’s manual for the battery for charging procedures.

8A DC Circuit Breaker

The 8A DC Circuit Breaker turns off automatically if the current exceeds 8A. If

the circuit breaker turns “O” you will need to push it “in” to turn it “I” again.

Fuel Petcock

The fuel Petcock controls the flow of gasoline from the fuel tank to the

carburetor. The Petcock knob should be in the “I” position when starting and

operating the generator. The Petcock knob should be in the “O” position when

the engine is not running and when storing or transporting the unit.

NOTE

The Fuel Petcock knob helps to prevent stale fuel from remaining in the carburetor while

storing or transporting the unit. Run the fuel out by turning the knob to the “O

” position and

letting the engine run until it stops.

Choke

The Choke is used when starting the engine “cold” (the engine is not hot).

Pull out fully on the choke when starting the engine. Once the engine has

warmed and a steady idle is achieved, push in on the choke. When restarting

a warm engine the choke is not necessary.

INVERTER GENERATOR – P2000i

17

220/230/240V AC Outlets

The Outlets are used to power 220/230/240V Single Phase 50Hz loads

requiring up to 1600W continuous power.

This socket is only corresponding to a client, the different laws and

regulations according to the sales area changes corresponding to the socket.

Ground Terminal

The Ground (Earth) terminal is used to ground the generator when grounded

electrical devices are being used. Consult an electrician for local grounding

regulations.

INVERTER GENERATOR – P2000i

18

3 GETTING STARTED

3.1 Unpack the Generator

Remove the generator from its packaging.

WARNING

Packaging is flammable! Do not attempt to add fuel to this unit before removing it from

packaging.

Inspect the generator to ensure that no damage has occurred in shipping or

handling. If the unit appears to be damaged, DO NOT add fuel or attempt to

start the generator. Please call PRAMAC costumer service.

Check to ensure that you received the following items:

• P 2000i 2000W Generator

• Parallel Cables

• Oil Funnel

If you did not receive any of the above items, please contact PRAMAC

costumer service.

3.2 Adding engine Oil

The generator has been shipped without engine oil. DO NOT add fuel or start

the engine before adding engine oil.

Figure 1

NOTE

In order to add motor oil you will need to remove the side panel from the unit.

INVERTER GENERATOR – P2000i

19

Using a #2 Phillips-head screwdriver remove screws 1 and 2 (seen in figure

1) and lift up and away to remove the side panel.

Figure 2

Place the generator on a level surface. DO NOT tilt the generator while

adding oil. It can cause you to overfill the oil and/or cause the oil to leak into

areas in which it is not intended.

Remove the oil filler cap 1 (seen in figure 2).

Figure 3

Using the funnel (provided) fill with 0.4 L of SAE 10W-30 or 10W-40

(provided) (see figure 3). See figure 4 for proper oil level 1.

Figure 4

Replace oil filler cap and secure side panel with screws.

Recommended engine oil:

A. YAMALUBE4(10W-40)

SAE10W-30or10W-40

B. SAE #30

INVERTER GENERATOR – P2000i

20

C. SAE#20

D. SAE#10W

Recommended engine oil grade: API Service SE type or higher Engine oil

quantity:

0.4L

3.3 Adding Fuel

The fuel tank capacty 4.1 Liter.

DO NOT overfill the tank, otherwise it may overflow when the fuel warms up

and expands.

NOTE

For safety reasons, once fuel has been added to this unit it cannot be returned to the place

of purchase.

1. Use clean, fresh, regular unleaded fuel with a minimum octane rating of

85.

2. DO NOT mix oil with fuel.

3. Clean area around the fuel cap.

4. Remove the fuel cap.

5. Be sure that the fuel strainer is in place.

6. Slowly add fuel to the tank.

7. Do not exceed the red marker position of the fuel filter.

8. Screw on the fuel cap and wipe away and spilled fuel.

NOTE

Use only unleaded gasoline.

The use of leaded gasoline will cause severe damage to internal engine parts.

After filling with fuel, make sure the fuel tank cap is tightened securely.

Table of contents

Other Pramac Inverter manuals

Popular Inverter manuals by other brands

Huawei

Huawei SUN2000-330KTL-H1 user manual

Twin Disc

Twin Disc TECHNODRIVE TM 485-A1 operating manual

SolarEdge

SolarEdge SE2200H Quick installation guide

Soltaro

Soltaro All-In-One ESS user manual

Toshiba

Toshiba VFA7-2370P1 instruction manual

Xantrex

Xantrex XW4024-120/240-60, XW4548-120/240-60,... installation guide