Pratt & Whitney Canada PT6A Turboprop User manual

Key

NeW

OWNeR

WISDOm

YOUR PT6A

TURbOPROP

Key

NeW

OWNeR

WISDOm

YOUR PT6A

TURbOPROP

11 1

Congratulations on your acquisition of an aircraft powered by the

Pratt & Whitney Canada Corp. (P&WC) dependable PT6A Turboprop

Engine! Just like you, operators around the globe have made the

PT6A engines their choice in the business and general aviation

market – engines known to provide exceptional power, performance

and peace of mind. By making this wise choice, you are benefiting

from 45 years and 300 million hours of in-service experience

resulting in unmatched reliability.

This handbook has been designed to give you a brief overview

of the PT6A engine as well as some maintenance and power

management recommendations. Always refer to the Pilots Operating

Handbook (POH), Aircraft Flight Manual (AFM), Engine Maintenance

Manual (EMM), Service Bulletin’s (SB) or other service information

documentation for a complete text of the approved / recommended

procedures and latest information.

Know your pt6A turboprop

Congratulations on your acquisition of an aircraft powered by the

Pratt & Whitney Canada Corp. (P&WC) dependable PT6A Turboprop

Engine! Just like you, operators around the globe have made the

PT6A engines their choice in the business and general aviation

market – engines known to provide exceptional power, performance

and peace of mind. By making this wise choice, you are benefiting

from 45 years and 300 million hours of in-service experience

resulting in unmatched reliability..

This handbook has been designed to give you a brief overview

of the PT6A engine as well as some maintenance and power

management recommendations. Always refer to the Pilots Operating

Handbook (POH), Aircraft Flight Manual (AFM), Engine Maintenance

Manual (EMM), Service Bulletin’s (SB) or other service information

documentation for a complete text of the approved / recommended

procedures and latest information.

Know your pt6A turboprop

22 2

Should you require additional information related to:

AOG / critical emergency services

Technical / maintenance consultation

Warranty

Publications

Field Service Representative (FSR) contact info

Rental Engines

Engine status in any P&WC Service Centre

Eagle Service Plan®(ESP®)

AOG Parts After Hours,

our Customer FIRST Centre is available 24 hours a day,

7 days a week to assist you.

In Canada and the United States:

Tel: 1-800-268-8000

International:

Tel: International Access Code + 8000-268-8000

Other Numbers:

Tel: (450) 647-8000 Fax: (450) 647-2888

Email:

Visit our website at:

www.pwc.ca

Know your pt6A turboprop

Should you require additional information related to:

AOG / critical emergency services

Technical / maintenance consultation

Warranty

Publications

Field Service Representative (FSR) contact info

Rental Engines

Engine status in any P&WC Service Centre

Eagle Service Plan®(ESP®)

AOG Parts After Hours,

our Customer FIRST Centre is available 24 hours a day,

7 days a week to assist you.

In Canada and the United States:

Tel: 1-800-268-8000

International:

Tel: International Access Code + 8000-268-8000

Other Numbers:

Tel: (450) 647-8000 Fax: (450) 647-2888

Email:

Visit our website at:

www.pwc.ca

Know your pt6A turboprop

33 3

Know your pt6A turboprop

Take note of your PT6A engine model and serial number.

This will help us to coordinate our support in a timely manner.

Engine Model:

Engine Serial Number:

Engine Logbook:

Each engine is supplied with a logbook(s) to record all maintenance

actions as well as engine running times and cycles. The logbook(s)

must accompany the engine or module each time they are sent to an

approved service or overhaul facility.

Know your pt6A turboprop

Take note of your PT6A engine model and serial number.

This will help us to coordinate our support in a timely manner.

Engine Model:

Engine Serial Number:

Engine Logbook:

Each engine is supplied with a logbook(s) to record all maintenance

actions as well as engine running times and cycles. The logbook(s)

must accompany the engine or module each time they are sent to an

approved service or overhaul facility.

55 5

DisclAimer

Disclaimer

The information contained herein has been set out in summary

form and is provided for general reference purposes only and may

be changed without prior notice. It should not be construed as

creating any obligation on the part of Pratt & Whitney Canada Corp.

While every care has been taken to avoid errors, Pratt & Whitney

Canada Corp. makes no representations about the accuracy of

these guidelines and accepts no responsibility for any error herein.

In no event shall P&WC be liable for any damages whatsoever

resulting from the misuse, misinterpretation, analysis,

interpretation or application of any of the guidelines contained

herein. The information contained herein does not replace or

supersede the information contained in the appropriate airframe or

engine maintenance manuals or other official publications.

Always refer to the Pilot’s Operating Handbooks (POH), Aircraft

Flight Manuals (AFM), Engine Maintenance Manuals (EMM),

Service Bulletins (SB) or other Service Information documentation

for a complete text of the approved / recommended procedures

and latest information.

PT6 and PT6A are trademarks of Pratt & Whitney Canada Corp.

© Copyright Pratt & Whitney Canada Corp. May not be reproduced, in whole

or in part, without prior written consent

DisclAimer

Disclaimer

The information contained herein has been set out in summary

form and is provided for general reference purposes only and may

be changed without prior notice. It should not be construed as

creating any obligation on the part of Pratt & Whitney Canada Corp.

While every care has been taken to avoid errors, Pratt & Whitney

Canada Corp. makes no representations about the accuracy of

these guidelines and accepts no responsibility for any error herein.

In no event shall P&WC be liable for any damages whatsoever

resulting from the misuse, misinterpretation, analysis,

interpretation or application of any of the guidelines contained

herein. The information contained herein does not replace or

supersede the information contained in the appropriate airframe or

engine maintenance manuals or other official publications.

Always refer to the Pilot’s Operating Handbooks (POH), Aircraft

Flight Manuals (AFM), Engine Maintenance Manuals (EMM),

Service Bulletins (SB) or other Service Information documentation

for a complete text of the approved / recommended procedures

and latest information.

PT6 and PT6A are trademarks of Pratt & Whitney Canada Corp.

© Copyright Pratt & Whitney Canada Corp. May not be reproduced, in whole

or in part, without prior written consent

66 6

nomenclAture

ADAS Aircraft Data Acquisition System

AFM Aircraft Flight Manual

AGB Accessory Gearbox

AOG Aircraft On Ground

CT Compressor Turbine

ECTM®Engine Condition Trend Monitoring®

EESP Extended Engine Service Policy

EPL Emergency Power Lever

ESP®Eagle Service Plan®

FOD Foreign Object Damage

FSR Field Service Representative

HSI Hot Section Inspection

ITT Interturbine Temperature

LCF Low Cycle Fatigue

MOR Manual Override

Ng Gas Generator Speed

nomenclAture

ADAS Aircraft Data Acquisition System

AFM Aircraft Flight Manual

AGB Accessory Gearbox

AOG Aircraft On Ground

CT Compressor Turbine

ECTM®Engine Condition Trend Monitoring®

EESP Extended Engine Service Policy

EPL Emergency Power Lever

ESP®Eagle Service Plan®

FOD Foreign Object Damage

FSR Field Service Representative

HSI Hot Section Inspection

ITT Interturbine Temperature

LCF Low Cycle Fatigue

MOR Manual Override

Ng Gas Generator Speed

77 7

Np Propeller Speed

PPSP Primary Parts Service Policy

PLA Power Lever Assembly

POH Pilot’s Operating Handbook

PT Power Turbine

RPM Rotations Per Minute

SB Service Bulletin

SHP Shaft Horsepower

SIL Service Information Letter

STOL Short Takeoff and Landing

TBO Time Between Overhaul

TSO Time Since Overhaul

TTSN Total Time Since New

TCSN Total Cycles Since New

UAC United Aircraft Corporation

Wf Fuel Flow Rate

nomenclAture

Np Propeller Speed

PPSP Primary Parts Service Policy

PLA Power Lever Assembly

POH Pilot’s Operating Handbook

PT Power Turbine

RPM Rotations Per Minute

SB Service Bulletin

SHP Shaft Horsepower

SIL Service Information Letter

STOL Short Takeoff and Landing

TBO Time Between Overhaul

TSO Time Since Overhaul

TTSN Total Time Since New

TCSN Total Cycles Since New

UAC United Aircraft Corporation

Wf Fuel Flow Rate

nomenclAture

88 8

Initial Customer Support Presentation

P&WC offers a three-part introduction to the company, engine maintenance

and our aftermarket support logistics. You have the option of scheduling a

meeting at your convenience or we will be happy to send you an information

kit with brochures and a copy of the presentation that you may review at

your leisure. When the time comes, your local FSR can provide guidance

on such things as fuel nozzle exchange, boroscope inspection of the hot

section or other maintenance areas.

Publications

P&WC offers a package of high-quality technical publications for new

aircraft operators. Moreover, a free two-year revision service is provided

for each new publications subscription. Additional publications may also

be purchased. The price list for commercial publications is available upon

request by contacting Publications Customer Services.

For additional details on our Technical Publications, including contact info,

please visit us at our website, www.pwc.ca

Warranty

P&WC prides itself in offering transferable warranty coverage that is

amongst the best in the aerospace business. The new engine warranty is

comprised of the Basic Coverage Period and may be supplemented by one

or both of the following available service policies:

·The Primary Parts Service Policy (PPSP) is a renewable pro-rata warranty

coverage for the repair or replacement of specific engine parts damaged

due to a defect in material or manufacturing workmanship during their

P&WC commercially-supported class life.

·The Extended Engine Service Policy (EESP) applies for a premature,

engine-chargeable event when an overhaul is required.

Know your pt6A turboprop

Initial Customer Support Presentation

P&WC offers a three-part introduction to the company, engine maintenance

and our aftermarket support logistics. You have the option of scheduling a

meeting at your convenience or we will be happy to send you an information

kit with brochures and a copy of the presentation that you may review at

your leisure. When the time comes, your local FSR can provide guidance

on such things as fuel nozzle exchange, boroscope inspection of the hot

section or other maintenance areas.

Publications

P&WC offers a package of high-quality technical publications for new

aircraft operators. Moreover, a free two-year revision service is provided

for each new publications subscription. Additional publications may also

be purchased. The price list for commercial publications is available upon

request by contacting Publications Customer Services.

For additional details on our Technical Publications, including contact info,

please visit us at our website, www.pwc.ca

Warranty

P&WC prides itself in offering transferable warranty coverage that is

amongst the best in the aerospace business. The new engine warranty is

comprised of the Basic Coverage Period and may be supplemented by one

or both of the following available service policies:

·The Primary Parts Service Policy (PPSP) is a renewable pro-rata warranty

coverage for the repair or replacement of specific engine parts damaged

due to a defect in material or manufacturing workmanship during their

P&WC commercially-supported class life.

·The Extended Engine Service Policy (EESP) applies for a premature,

engine-chargeable event when an overhaul is required.

Know your pt6A turboprop

99 9

Once we have been informed of a new PT6A engine delivery to an aircraft

operator, a copy of the applicable new engine warranty will be sent

to the new owner by the P&WC Warranty Administration department.

Notification of new aircraft sales is normally received directly from aircraft

manufacturers, their licensed dealers or directly from the owner. Note

that warranty coverage is attached to the engine serial number, not to

the owner. For any warranty questions, please feel free to email us at

If your aircraft is involved in an incident which affects the engine (e.g. prop

strike, hard landing), you must inform P&WC Warranty by filling out the

form included in SIL GEN-039. This will ensure that your warranty policy is

reinstated following the corrective maintenance actions.

Customer Portal

Pratt & Whitney Canada is committed to providing global support services

that delights our customers. The P&WC Customer portal is just one of the

many ways in which we collaborate with our customers. The portal will give

access to an increasing list of on-line services and information.

Register today on our website, www.pwc.ca, free of charge, to receive

the P&WC Extranet Application URL, username and password once the

registration request has been approved and processed.

Know your pt6A turboprop

Once we have been informed of a new PT6A engine delivery to an aircraft

operator, a copy of the applicable new engine warranty will be sent

to the new owner by the P&WC Warranty Administration department.

Notification of new aircraft sales is normally received directly from aircraft

manufacturers, their licensed dealers or directly from the owner. Note

that warranty coverage is attached to the engine serial number, not to

the owner. For any warranty questions, please feel free to email us at

If your aircraft is involved in an incident which affects the engine (e.g. prop

strike, hard landing), you must inform P&WC Warranty by filling out the

form included in SIL GEN-039. This will ensure that your warranty policy is

reinstated following the corrective maintenance actions.

Customer Portal

Pratt & Whitney Canada is committed to providing global support services

that delights our customers. The P&WC Customer portal is just one of the

many ways in which we collaborate with our customers. The portal will give

access to an increasing list of on-line services and information.

Register today on our website, www.pwc.ca, free of charge, to receive

the P&WC Extranet Application URL, username and password once the

registration request has been approved and processed.

Know your pt6A turboprop

1010 10

PT6A Engine Overview

Unmatched versatility, dependability and performance have made the PT6A

engine the most thoroughly proven and popular turboprop engine family

in the 500- to 1,700-shp class, covering a diverse range of applications

across all aircraft markets. We continually invest in technology to make our

engines the most environmentally friendly and to offer even greater value in

the form of higher performance and digital engine control.

The PT6 engine, a lightweight free turbine engine incorporating a reverse

flow combustion path, is designed for aircraft propulsion use. It utilizes two

counter-rotating turbines; one driving the compressor and the other driving

the propeller through a reduction gearbox. The latter turbine is “free”

or independent of the compressor turbine. More recent, higher powered

models incorporate a two-stage power turbine.

Over the years, the PT6 engine has evolved and adapted to a multitude of

uses. The PT6A engine is the turboprop designation, powering commuter,

corporate and utility aircraft, aerobatic trainers, agricultural aircraft, short

takeoff and landing (STOL) aircraft and water bombers. This handbook is

dedicated to the PT6A variant.

The PT6B, C & T (Twin-Pac®) engines are turboshaft variants, providing

reliable power to many of the worlds helicopters and more recently to

tiltrotors.

The ST6 engine is an industrial variant of the PT6 engine, originally

developed for the United Aircraft Corporation (UAC) TurboTrain and

intended for stationary application.

pt6A engine generAl

PT6A Engine Overview

Unmatched versatility, dependability and performance have made the PT6A

engine the most thoroughly proven and popular turboprop engine family

in the 500- to 1,700-shp class, covering a diverse range of applications

across all aircraft markets. We continually invest in technology to make our

engines the most environmentally friendly and to offer even greater value in

the form of higher performance and digital engine control.

The PT6 engine, a lightweight free turbine engine incorporating a reverse

flow combustion path, is designed for aircraft propulsion use. It utilizes two

counter-rotating turbines; one driving the compressor and the other driving

the propeller through a reduction gearbox. The latter turbine is “free”

or independent of the compressor turbine. More recent, higher powered

models incorporate a two-stage power turbine.

Over the years, the PT6 engine has evolved and adapted to a multitude of

uses. The PT6A engine is the turboprop designation, powering commuter,

corporate and utility aircraft, aerobatic trainers, agricultural aircraft, short

takeoff and landing (STOL) aircraft and water bombers. This handbook is

dedicated to the PT6A variant.

The PT6B, C & T (Twin-Pac®) engines are turboshaft variants, providing

reliable power to many of the worlds helicopters and more recently to

tiltrotors.

The ST6 engine is an industrial variant of the PT6 engine, originally

developed for the United Aircraft Corporation (UAC) TurboTrain and

intended for stationary application.

pt6A engine generAl

1111 11

moDulArity

The design of the PT6A engine allows it to be split into two major parts

called the power section assembly and the gas generator assembly. Only

certain engine models are defined as being modular, which allows the

interchange and tracking of each module. Three criteria must be met for the

engine to be modular.

1. Each major assembly is equipped with a data plate and a third data

plate is located on the inlet case for the complete engine assembly.

2. There is a logbook for each module.

3. In the appropriate SB on service lives, there will be an overhaul interval

quoted for each module and the engine assembly.

On non-modular PT6A engines, the power section assembly can be removed

and sent for service, but must be returned and installed on the same gas

generator assembly.

Small PT6A Engine

moDulArity

The design of the PT6A engine allows it to be split into two major parts

called the power section assembly and the gas generator assembly. Only

certain engine models are defined as being modular, which allows the

interchange and tracking of each module. Three criteria must be met for the

engine to be modular.

1. Each major assembly is equipped with a data plate and a third data

plate is located on the inlet case for the complete engine assembly.

2. There is a logbook for each module.

3. In the appropriate SB on service lives, there will be an overhaul interval

quoted for each module and the engine assembly.

On non-modular PT6A engines, the power section assembly can be removed

and sent for service, but must be returned and installed on the same gas

generator assembly.

Small PT6A Engine

1212 12

ADvAntAges of the pt6A engine Design

A number of advantages are derived from the design of the PT6A engine

which have proven valuable in routine field operation.

During an engine start, only the compressor section of the PT6A engine

needs be rotated by the starter-generator. By comparison, a fixed-shaft

engine must spin all rotating components including the reduction gearbox

and propeller during an engine start, resulting in a requirement for heavier

starting systems.

The PT6A engine free turbine design allows the propeller RPM to be reduced

and the propeller feathered during ground operation without shutting

down the engine. This facilitates fast passenger loading and permits very

quiet ground operation. Propeller RPM can also be varied in flight (on most

applications) permitting propeller RPM to be set for quieter cruise and

optimum efficiency.

ADvAntAges of the pt6A engine Design

A number of advantages are derived from the design of the PT6A engine

which have proven valuable in routine field operation.

During an engine start, only the compressor section of the PT6A engine

needs be rotated by the starter-generator. By comparison, a fixed-shaft

engine must spin all rotating components including the reduction gearbox

and propeller during an engine start, resulting in a requirement for heavier

starting systems.

The PT6A engine free turbine design allows the propeller RPM to be reduced

and the propeller feathered during ground operation without shutting

down the engine. This facilitates fast passenger loading and permits very

quiet ground operation. Propeller RPM can also be varied in flight (on most

applications) permitting propeller RPM to be set for quieter cruise and

optimum efficiency.

1313 13

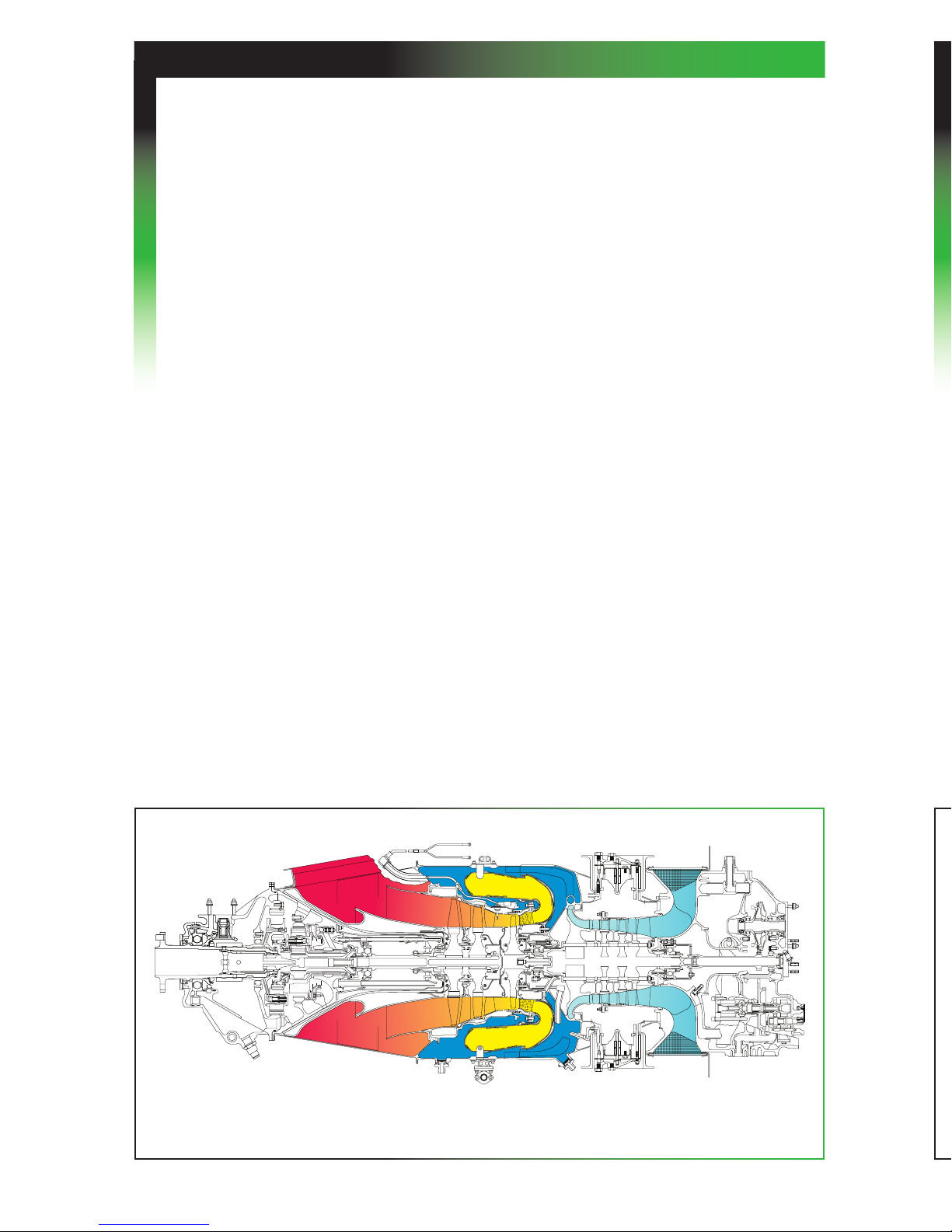

principles of operAtion

The PT6A engine consists of two main sections, the gas generator section

and the power section.

The gas generator section compresses and delivers air to the combustion

chamber where it is mixed with fuel and ignited. The resulting hot gases

turn the compressor turbine which provides the power to run the compressor

and the accessory gearbox located at the rear of the engine. The hot gases

continue on to the power turbine where the remaining energy is extracted to

turn the propeller.

Np Nf T5 (ITT) Ng

Wf

FCU

Tq

principles of operAtion

The PT6A engine consists of two main sections, the gas generator section

and the power section.

The gas generator section compresses and delivers air to the combustion

chamber where it is mixed with fuel and ignited. The resulting hot gases

turn the compressor turbine which provides the power to run the compressor

and the accessory gearbox located at the rear of the engine. The hot gases

continue on to the power turbine where the remaining energy is extracted to

turn the propeller.

Np Nf T5 (ITT) Ng

Wf

FCU

Tq

1414 14

Air is directed to a compressor consisting of three axial stages (Four

axial stages on large PT6A engine models) and one centrifugal stage.

Compressed air leaving the compressor passes through diffuser pipes

which turn the flow 90 degrees, reduce its speed and direct the air into the

combustion chamber.

In the annular combustion chamber the air is mixed with fuel and burned.

Two igniter plugs are used to light the fuel/air mixture when the engine is

started. They are not required to maintain the combustion process and can

be shut off once the engine has reached idle speed.

The expanding hot gases are directed first through the compressor turbine

and then through the power turbine. After passing through the power

turbine, the gases are exhausted through ports on each side of the engine.

(Some engines are fitted with a single-port exhaust.) The exhaust stubs

fitted to the engine are normally directed to utilize the remaining energy of

the gases in the form of thrust for additional aircraft propulsion.

Two bleed air systems are incorporated in the PT6A engine. Automatic bleed

air from the compressor prevents compressor stall during acceleration from

low engine speeds or deceleration from high engine speeds. For aircraft

use, air may be bled for heating or pressurizing aircraft cabins.

Airflow

Medium PT6A Engine

Air is directed to a compressor consisting of three axial stages (Four

axial stages on large PT6A engine models) and one centrifugal stage.

Compressed air leaving the compressor passes through diffuser pipes

which turn the flow 90 degrees, reduce its speed and direct the air into the

combustion chamber.

In the annular combustion chamber the air is mixed with fuel and burned.

Two igniter plugs are used to light the fuel/air mixture when the engine is

started. They are not required to maintain the combustion process and can

be shut off once the engine has reached idle speed.

The expanding hot gases are directed first through the compressor turbine

and then through the power turbine. After passing through the power

turbine, the gases are exhausted through ports on each side of the engine.

(Some engines are fitted with a single-port exhaust.) The exhaust stubs

fitted to the engine are normally directed to utilize the remaining energy of

the gases in the form of thrust for additional aircraft propulsion.

Two bleed air systems are incorporated in the PT6A engine. Automatic bleed

air from the compressor prevents compressor stall during acceleration from

low engine speeds or deceleration from high engine speeds. For aircraft

use, air may be bled for heating or pressurizing aircraft cabins.

Airflow

Medium PT6A Engine

1515 15

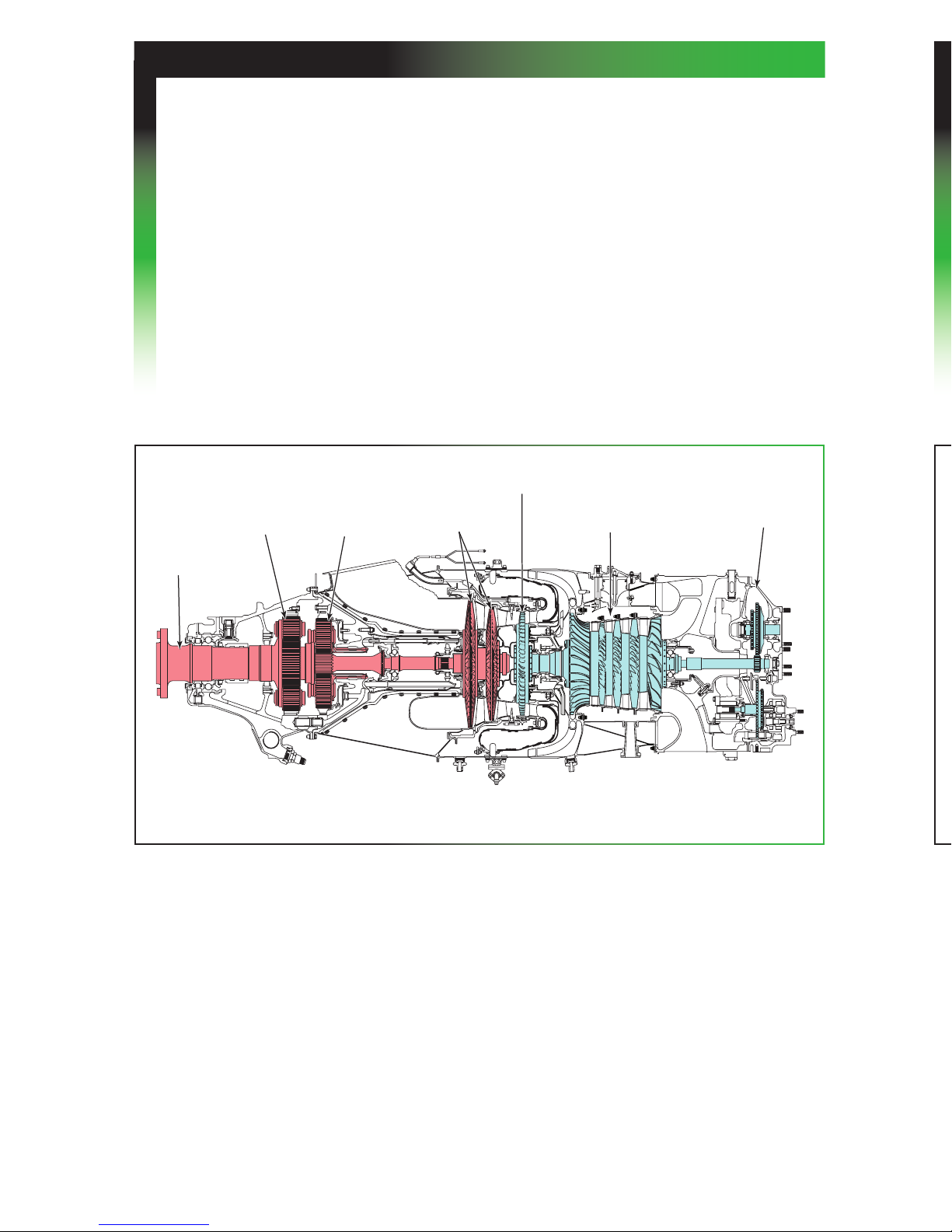

A shaft connects the power turbine to the two-stage planetary reduction

gearbox. The first stage reduction ring gear floats axially against a hydraulic

torquemeter cylinder. The oil pressure in this cylinder is proportional to

output torque which is displayed on the torque indicator in the cockpit.

Bevel gears located forward of the second stage planetary gears drive the

following accessories mounted on the forward reduction gearbox case:

·propeller governor or constant speed unit

· propeller overspeed governor

· tachometer-generator

The accessory gearbox, mounted on the rear of the engine, is used to drive

the following engine accessories:

· High-pressure fuel pump

· Fuel control unit

· Oil scavenge and oil pressure pumps.

Space is also provided for aircraft manufacturer provided accessories such

as the starter-generator, gas generator tachometer-generator, fuel boost

pumps or hydraulic pumps.

power trAin

1 ST STAGE

REDUCTION

GEAR

PROPELLER

SHAFT

2 ND STAGE

REDUCTION

GEAR

POWER

TURBINES

COMPRESSOR

TURBINE

ACCESSORY

GEARBOX

COMPRESSOR

Large PT6A Engine

A shaft connects the power turbine to the two-stage planetary reduction

gearbox. The first stage reduction ring gear floats axially against a hydraulic

torquemeter cylinder. The oil pressure in this cylinder is proportional to

output torque which is displayed on the torque indicator in the cockpit.

Bevel gears located forward of the second stage planetary gears drive the

following accessories mounted on the forward reduction gearbox case:

·propeller governor or constant speed unit

· propeller overspeed governor

· tachometer-generator

The accessory gearbox, mounted on the rear of the engine, is used to drive

the following engine accessories:

· High-pressure fuel pump

· Fuel control unit

· Oil scavenge and oil pressure pumps.

Space is also provided for aircraft manufacturer provided accessories such

as the starter-generator, gas generator tachometer-generator, fuel boost

pumps or hydraulic pumps.

power trAin

1 ST STAGE

REDUCTION

GEAR

PROPELLER

SHAFT

2 ND STAGE

REDUCTION

GEAR

POWER

TURBINES

COMPRESSOR

TURBINE

ACCESSORY

GEARBOX

COMPRESSOR

Large PT6A Engine

1616 16

Support of the main shafts in the PT6A engine is accomplished by a

combination of ball and roller bearings. Ball bearings support axial and

radial loading, while the roller bearings support only radial loads, allowing

for thermal expansion.

Propeller Shaft Power Turbine Compressor

No. 5: Roller No. 3: Roller No. 1: Ball

No. 6: Ball No. 4: Ball No. 2: Roller

No. 7: Roller**

** Smaller reduction gearboxes do not utilize a No. 7 bearing.

beArings

A-52

A-61

A-64

A-66

A-60

A-65

A-67

765

65

4321

Support of the main shafts in the PT6A engine is accomplished by a

combination of ball and roller bearings. Ball bearings support axial and

radial loading, while the roller bearings support only radial loads, allowing

for thermal expansion.

Propeller Shaft Power Turbine Compressor

No. 5: Roller No. 3: Roller No. 1: Ball

No. 6: Ball No. 4: Ball No. 2: Roller

No. 7: Roller**

** Smaller reduction gearboxes do not utilize a No. 7 bearing.

beArings

A-52

A-61

A-64

A-66

A-60

A-65

A-67

765

65

4321

1717 17

foD protection

Inertial Separator

The nacelle inlet of many aircraft models includes an inertial separator

provided by the aircraft manufacturer to prevent heavy particles from

entering the engine inlet. Most installations incorporate two moveable

vanes, one upstream of the engine inlet and the other blocking the bypass

duct. For bypass operation, the inlet vane is lowered and the bypass

duct vane is opened permitting maximum separating efficiency. In some

installations, the vanes are fixed in the bypass mode.

As shown in the sketch, air entering the engine inlet must turn sharply past

the inlet vane (shown in the lowered position). Particles heavier than air

are carried straight through, by their own inertia, into the bypass duct and

dumped overboard.

The aft radial inlet design provides many advantages such as superior

anti-icing utilizing the principle of inertial separation, low noise levels and

unequalled protection from FOD.

BYPASS (ICING)

POSITION

NORMAL

POSITION

foD protection

Inertial Separator

The nacelle inlet of many aircraft models includes an inertial separator

provided by the aircraft manufacturer to prevent heavy particles from

entering the engine inlet. Most installations incorporate two moveable

vanes, one upstream of the engine inlet and the other blocking the bypass

duct. For bypass operation, the inlet vane is lowered and the bypass

duct vane is opened permitting maximum separating efficiency. In some

installations, the vanes are fixed in the bypass mode.

As shown in the sketch, air entering the engine inlet must turn sharply past

the inlet vane (shown in the lowered position). Particles heavier than air

are carried straight through, by their own inertia, into the bypass duct and

dumped overboard.

The aft radial inlet design provides many advantages such as superior

anti-icing utilizing the principle of inertial separation, low noise levels and

unequalled protection from FOD.

BYPASS (ICING)

POSITION

NORMAL

POSITION

1818 18

The fuel system is designed to deliver clean fuel to the engine at the

pressure and flow that are necessary for all engine operating conditions.

The airframe fuel system contains the necessary boost pumps, transfer

pumps, selector/shutoff valves, strainers and filters required to supply fuel

to the engine(s) and to manage the fuel load distribution in the airplane.

The engine is equipped with a fuel system which consists of a fuel heater,

high-pressure fuel pump, fuel filter, fuel control unit, start control or flow

divider unit and a manifold with fuel injection nozzles.

The fuel control unit is either a hydro-pneumatic or a hydro-mechanical

system which meters the correct amount of fuel to the engine to maintain

the gas generator speed selected by the pilot via the power control lever. It

also controls fuel flow scheduling during engine starting, acceleration and

deceleration.

The PT6A engine is approved for operation with all commercial jet fuels,

JP-4, JP-5 and for a maximum of 150 hours during any overhaul period with

all grades of aviation gasoline. Specific grades of diesel fuel are approved

as alternate fuels for restricted use. No engine adjustments are required

in changing from one fuel to another, nor is it necessary to purge the fuel

system when changing fuels, except when using alternate fuels.

For listings of approved fuels and fuel additives refer to the appropriate

Service Bulletins for each PT6A engine model.

fuel system

The fuel system is designed to deliver clean fuel to the engine at the

pressure and flow that are necessary for all engine operating conditions.

The airframe fuel system contains the necessary boost pumps, transfer

pumps, selector/shutoff valves, strainers and filters required to supply fuel

to the engine(s) and to manage the fuel load distribution in the airplane.

The engine is equipped with a fuel system which consists of a fuel heater,

high-pressure fuel pump, fuel filter, fuel control unit, start control or flow

divider unit and a manifold with fuel injection nozzles.

The fuel control unit is either a hydro-pneumatic or a hydro-mechanical

system which meters the correct amount of fuel to the engine to maintain

the gas generator speed selected by the pilot via the power control lever. It

also controls fuel flow scheduling during engine starting, acceleration and

deceleration.

The PT6A engine is approved for operation with all commercial jet fuels,

JP-4, JP-5 and for a maximum of 150 hours during any overhaul period with

all grades of aviation gasoline. Specific grades of diesel fuel are approved

as alternate fuels for restricted use. No engine adjustments are required

in changing from one fuel to another, nor is it necessary to purge the fuel

system when changing fuels, except when using alternate fuels.

For listings of approved fuels and fuel additives refer to the appropriate

Service Bulletins for each PT6A engine model.

fuel system

1919 19

oil system

The PT6A engine has a self-contained oil system with the exception of the

oil cooler, air duct and associated plumbing. The oil level should be verified

after engine shutdown and while the oil is still hot, using either a dipstick

or a sightglass.

For more information related to the oil system, please refer to page 29.

oil system

The PT6A engine has a self-contained oil system with the exception of the

oil cooler, air duct and associated plumbing. The oil level should be verified

after engine shutdown and while the oil is still hot, using either a dipstick

or a sightglass.

For more information related to the oil system, please refer to page 29.

Table of contents

Popular Engine manuals by other brands

O.S. Speed

O.S. Speed B21 ADAM DRAKE EDITION instruction manual

ZF Marine

ZF Marine W23100 Series operating manual

Sumitomo Drive Technologies

Sumitomo Drive Technologies IB Series Maintenance manual

Kipor

Kipor KD388 Operation manual

MerCruiser

MerCruiser QSD 2.0 manual

Cobra

Cobra DG350 Original instructions