CONTENTS

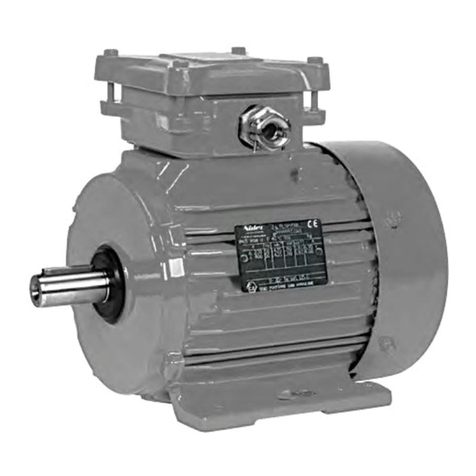

1 - RECEIPT ............................................................... 5

1.1 - Identication............................................................5

1.2 - Storage ...................................................................6

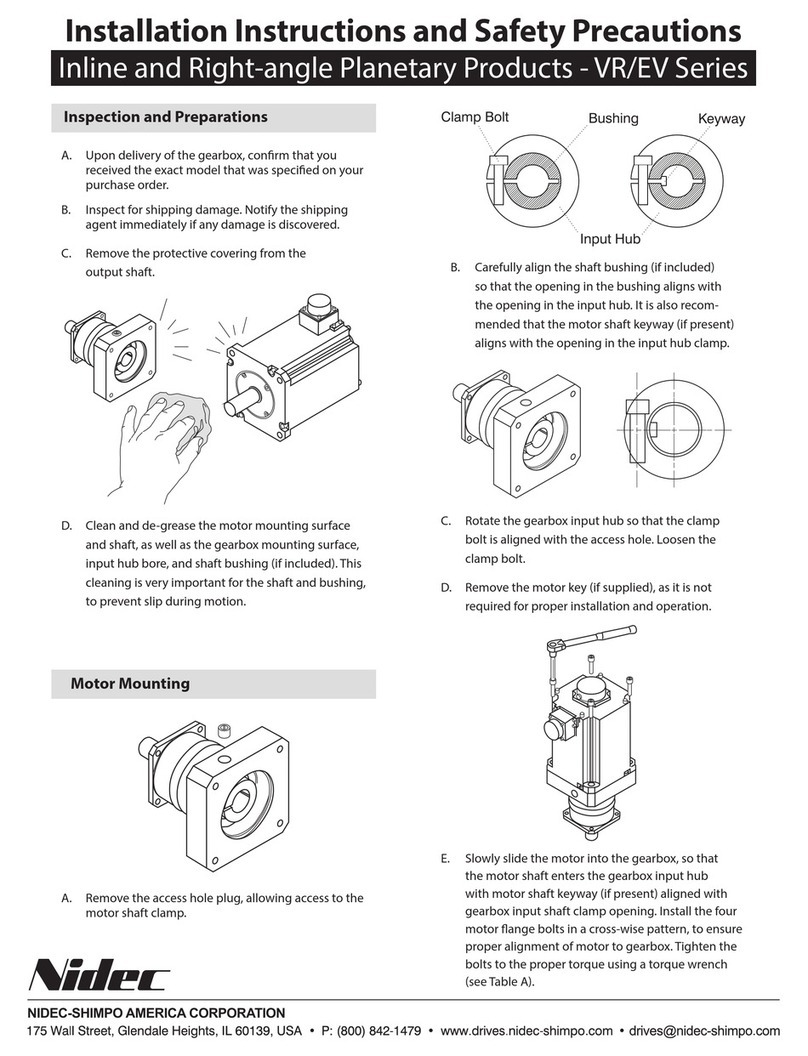

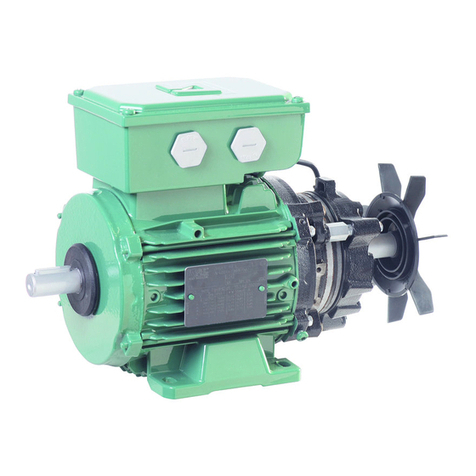

2 - ASSEMBLY ........................................................... 6

2.1 - Checking the insulation ...........................................6

2.2 - Location - ventilation ...............................................7

2.3 - Coupling..................................................................7

2.4 - Electrical guidelines ..............................................10

2.5 - Mains connection ..................................................13

3 - ROUTINE MAINTENANCE ................................. 16

3.1 - Lubrication ............................................................16

3.2 - Bearing maintenance ............................................20

4 - PREVENTIVE MAINTENANCE........................... 20

5 - TROUBLESHOOTING GUIDE............................ 21

6 - CORRECTIVE MAINTENANCE: GENERAL ...... 22

6.1 - Dismantling the motor ...........................................22

6.2 - Checks before reassembly....................................22

6.3 - Mounting the bearings on the shaft........................22

6.4 - Reassembling the motor........................................22

6.5 - Reassembling the terminal box .............................22

7 - POSITION OF LIFTING RINGS........................... 23

8 - SPARE PARTS.................................................... 24

9 - RECYCLING........................................................ 24

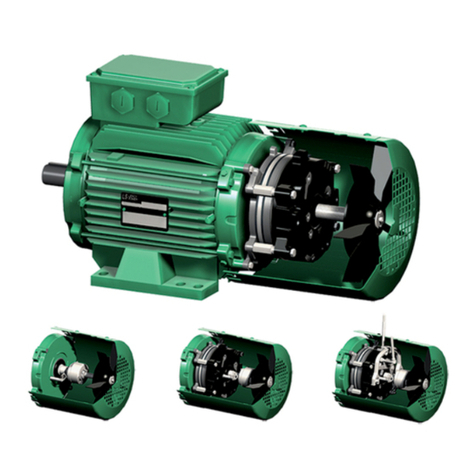

DISMANTLING AND REASSEMBLY

PROCEDURES

10 - LS/LSES MOTORS ........................................... 26

10.1 - 71 to 160 MP/LR motors......................................26

10.2 - 160 M/L/LU, 180 MT/LR motors ..........................28

10.3 - 180 L/LUR, 200 L/LR/LU, 225 ST/MT/MR,

250 MZ motors ....................................................30

10.4 - 225 MG, 250 ME/MF, 280 SC/MC/SD/MD,

315 SN motors.....................................................32

10.5 - 280 SU/SK/MK, 315 (except SN) motors.............34

11 - FLS/FLSES MOTORS....................................... 36

11.1 - 80 to 132 motors..................................................36

11.2 - 160, 180 MR motors ............................................38

11.3 - 180 M/L/LUR, 200 LU, 225 MR/SR motors ..........40

11.4 - 225 M to 280 motors ............................................42

11.5 - 315 to 355 LD motors...........................................44

12 - PLS/PLSES MOTORS ...................................... 46

12.1 - 180 LG/LGU, 200 M/L/LP/LU/LR,

225 MR motors ....................................................46

12.2 - 225 MG, 250, 280 SC/SD/MC/MD motors ...........48

12.3 - 280 MG, 315 motors............................................50

INDEX

Adjustment ...........................................................................8

Alarms - early warning ........................................................12

Assembly..............................................................................6

Balancing..............................................................................7

Belts......................................................................................9

Built-in thermal protection ...................................................12

Cable gland.........................................................................13

Cables: cross-section .................................................. 14 - 15

Capacitors .......................................................................... 11

Connection .........................................................................15

Connection diagrams..........................................................15

Corrective maintenance......................................................22

Coupling .......................................................................... 7 - 8

Coupling sleeves ..................................................................8

Digistart ..............................................................................10

Direction of rotation.............................................................15

Draining condensation .......................................................16

Earth terminal .....................................................................15

Earthing .............................................................................. 11

European directives..............................................................5

Frequency inverter.............................................................. 11

Greasing - Grease nipples ...................................... 6 - 16 - 20

Handling ...............................................................................7

Identication .........................................................................5

Inertia ywheel......................................................................8

Insulation .............................................................................6

Lifting rings .........................................................................23

Location ...............................................................................7

Logos ...................................................................................5

Lubrication..........................................................................16

Mains connection................................................................13

Nameplate ............................................................................5

Power .................................................................................10

Power supply ......................................................................15

Preventive maintenance .................................................... 20

Protection ...........................................................................12

Pulleys..................................................................................9

Receipt .................................................................................5

Routine maintenance......................................................... 20

Shields......................................................................... 16 - 20

Slide rails ..............................................................................9

Space heaters.....................................................................12

Spare parts ........................................................................ 24

Starting ...............................................................................10

Storage.................................................................................6

Terminal box ......................................................................13

Terminal box: tightening the nuts.........................................15

Tie rods: tightening .............................................................22

Tolerances ............................................................................8

Troubleshooting..................................................................21

Ventilation.............................................................................7