www.prattsafety.com

INTERNATIONAL

info@prattsafety.com

AUSTRALIA

1300 133 226

info@prattsafety.com.au

NEW ZEALAND

0800 133 226

info@prattsafety.co.nz

PRODUCT DATA SHEET

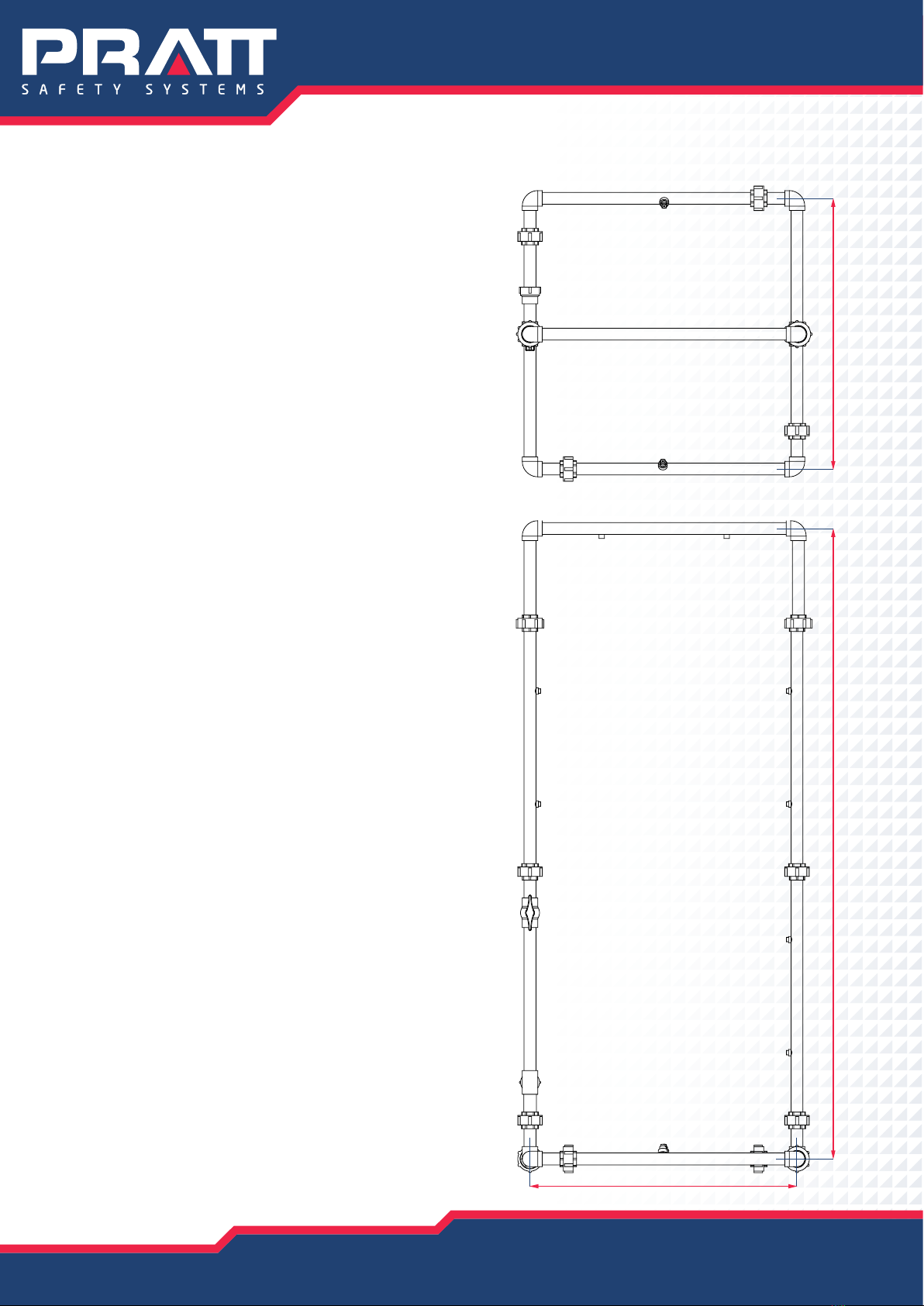

Model No: PSPCS

PRATT PORTABLE DECONTAMINATION SHOWER

SHOWER SET UP OPERATION & TAKE DOWN:

1. Attach water supply hose to inlet hose nozzle.

Minimum water pressure should be 210kPa.

2. Ensure shower valve is turned off (T handle

is horizonal).

3. Turn water supply on.

4. Test shower by turning on shower valve (T handle

is vertical) and operate for 15-30 seconds to ensure

correct operation.

5. Turn shower valve off. Shower is now ready for use

when required.

6. After use, shower should be fully de-contaminated,

cleaned and dried.

7. Shower should also be inspected for damage,

or missing parts and should be completely

dry before storage.

8. Disassemble and store in carry bag to protect shower

from sunlight and other environmental conditions.

HOW TO USE THE SHOWER:

1. Open the shower valve (T handle is vertical). Allow about

10 seconds to reach full spray pattern.

2. Stand within water spray pattern and rotate body slowly

to receive full benefit of decontamination spray.

3. Remove any contaminated clothing.

4. Continue to rotate body and remain within shower for

at least 15 minutes.

5. Seek further medical attention.

EFFECTIVE SPRAY PATTERN:

1. The most effective spray pattern creates a wall of water

by overlapping the spray and keeping the spray

in a vertical plain with the upright portion of the shower.

2. All shower spray nozzles should be facing inward

so that the water sprays meet at the centre.

3. The optimum spray pattern can be attained with

a minimum pressure of 210kPa.

SHOWER INSPECTION & MAINTENANCE:

1. As with all emergency equipment this shower unit

should be inspected regularly to ensure all components

are included in the carry bag.

2. Also conduct a visual inspection of the components

to ensure there is no damage or missing parts or affect

from other contaminants.

3. It is recommended the shower unit is assembled and

operated on a regular basis to ensure proper operation

and that the connectors and seals are in good condition.

4. Occasional coating of a silicone based lubricant on the

connectors will ensure they function smoothly. 850mm

2005mm 860mm