Precision Products SW38PRE User manual

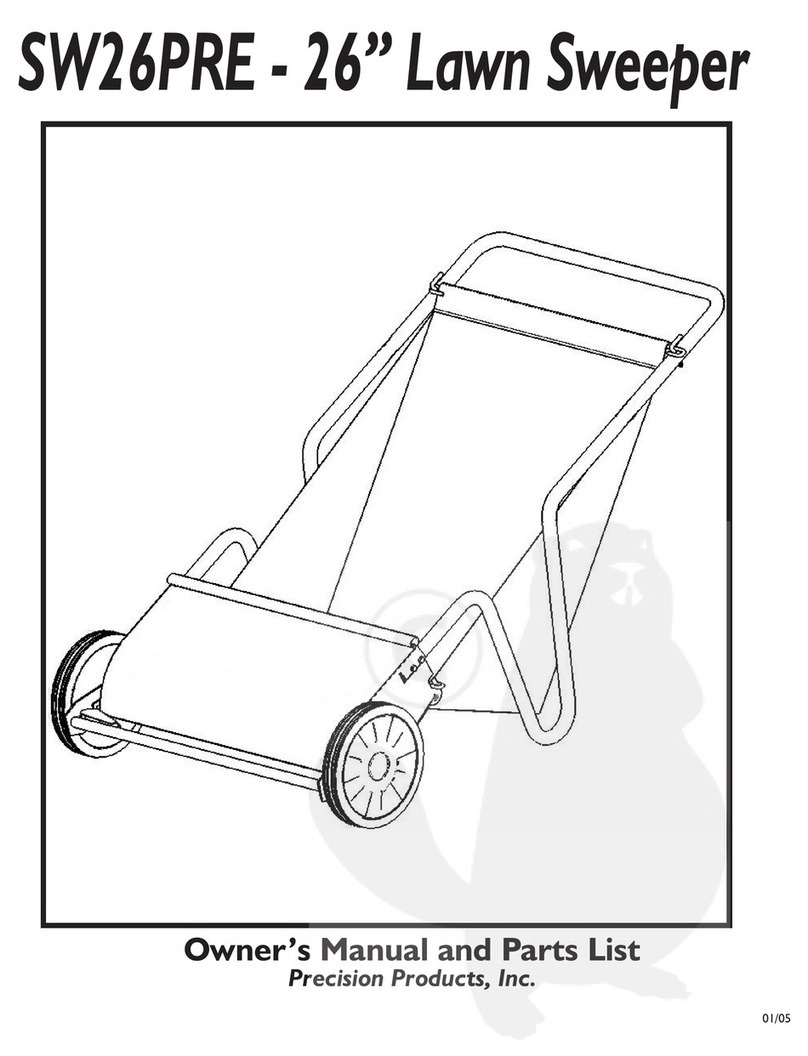

SW38PRE - 38” Tow Behind Lawn Sweeper

Owner’s Manual and Parts List

Precision Products, Inc.

2

1

3

4

6

7

5

8

9

5

10

11

12

13

16

15

14

17

1818

19

20 21

22

28

26

27

25

24

23

30

29

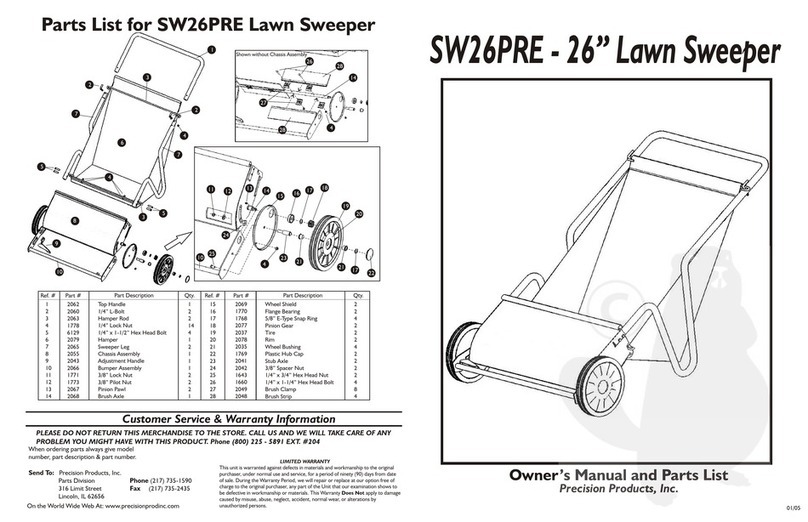

Parts List for SW38PRE

31

32

5

33

36

38

37

39

41

40

43

42

44

45

46

23

35

47

48

49

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

**

**

**

**

Height Adjustment Tube

Handle Grip

Caster Assembly

Sweeper Chassis

5/16” Lock Nut

5/16” x 2” Hex Head Bolt

Bumper Assembly

Hitch Arms

5/16” x 2 1/4” Hex Head Bolt

Clevis Plate

5/16” x 3-1/4” Hex Head Bolt

Hamper Pivot Bracket Assembly

Top Hamper Cross Tube

Bottom Hamper Cross Tube

Hamper Support Rod

Bottom Hamper Side Tube

Top Side Hamper Tube

Tie Rod

5/16” x 5/8” Hex Head Bolt

1/4” x 1-3/4” Hex Head Bolt

5/16” x 3/4” Hex Head Bolt

1/4” x 1/2” Hex Head Bolt

5/16” x 1/2” Hex Head Bolt

Wheel Shield

Stub Axle

Pinion Gear

10” Tire

10” Die Cast Wheel

5/8” E Type Snap Ring

Plastic Hub Cap

Flange Bearing

3/8” Lock Nut

Pinion Pawl

3/8” Pilot Nut

RH Hamper Pivot Bracket

Top Pivot Cross Tube

1/4” x 1-1/2” Hex Head Bolt

LH Hamper Pivot Bracket

LH Cross Tube Lock

1/4” Lock Nut

RH Cross Tube Lock

Plastic Hamper Hinge

Vertical Pivot Tube

Pivot Support Tube

Pivot Stand Tube

Pivot Stand Brace

Brush Strip

Brush Spring

Bush/Axle/Disc Assembly

Catch Bracket

**PARTS NOT ILLUSTRATED

Hamper (Material)

Wind Apron

Hamper Dump Rope

Spring

20

Ref # Part Description Qty.

34

Part # Ref # Part Description Qty.

Part #

LIMITED WARRANTY

This unit is warranted against defects in materials and workmanship to the original

purchaser, under normal use and service, for a period of ninety (90) days from date

of sale. During the Warranty Period, we will repair or replace at our option free of

charge to the original purchaser, any part of the Unit that our examination shows to

be defective in workmanship or materials. This Warranty Does Not apply to damage

caused by misuse, abuse, neglect, accident, normal wear, or alterations by

unauthorized persons.

Customer Service & Warranty Information

PLEASE DO NOT RETURN THIS MERCHANDISE TO THE STORE. CALL US AND WE WILL TAKE CARE OF ANY

PROBLEM YOU MIGHT HAVE WITH THIS PRODUCT. Phone (800) 225 - 5891 EXT. #204

When ordering parts always give model

number, part description & part number.

Send To: Precision Products, Inc.

Parts Division Phone (217) 735-1590

316 Limit Street Fax (217) 735-2435

Lincoln, IL 62656

Parts list on back page

1

1

2

1

19

1

1

2

2

2

1

2

1

1

2

2

2

1

4

2

2

2

8

2

2

2

2

2

2

2

2

2

2

2

1

1

3

1

1

13

1

2

2

2

2

2

6

18

1

1

1

1

1

1

01/04

1745

1746

1747

3230

1749

4041

3231

3232

1752

1753

1754

1755

3233

3234

1758

1792

1759

3235

1761

1065

1248

1647

1762

1763

1764

1765

1766

1767

1768

1769

1770

1771

1772

1773

1774

3236

6129

1776

1777

1778

1779

1780

1781

1782

1783

1784

3237

1786

3238

1795

3239

3240

1790

1282

37

40

50

Your new SW38PRE lawn sweeper is precision manufactured using the finest in tools and materials. Although it is

ruggedly constructed, do not subject this unit to misuse. Be sure to wipe off your unit after each use. Store in a

dry place out of direct sunlight. Do not permit the lawn sweeper to stand in the hot sun, unless it is in actual use.

You will find many work saving uses for your lawn sweeper. Use it early in the spring to give your lawn a good healthy

scrubbing. Use it throughout spring and summer before and after mowing. Sweeping your lawn before mowing stands

the grass up for a clean, even cut. It also allows increased protection to your mower by removing sticks, stones and

nuts, which might damage the blade(s) on your mower. Sweeping your lawn after mowing will whisk away unsightly

grass clippings - leaving your lawn velvety smooth.

Tools Required For Assembly:

Assembly Parts List Description

One (1) - Pair Pliers (Needle Nose)

Two (2) - 7/16” Wrenches

Two (2) - ½” Wrenches

Prior To Assembly:

Remove all Sweeper Parts from carton. Make sure all parts and assemblies are

present before assembly. If any parts are missing, contact Customer Service

(contact information on back sheet) immediately for assistance.

Lay out all parts and have tools ready.

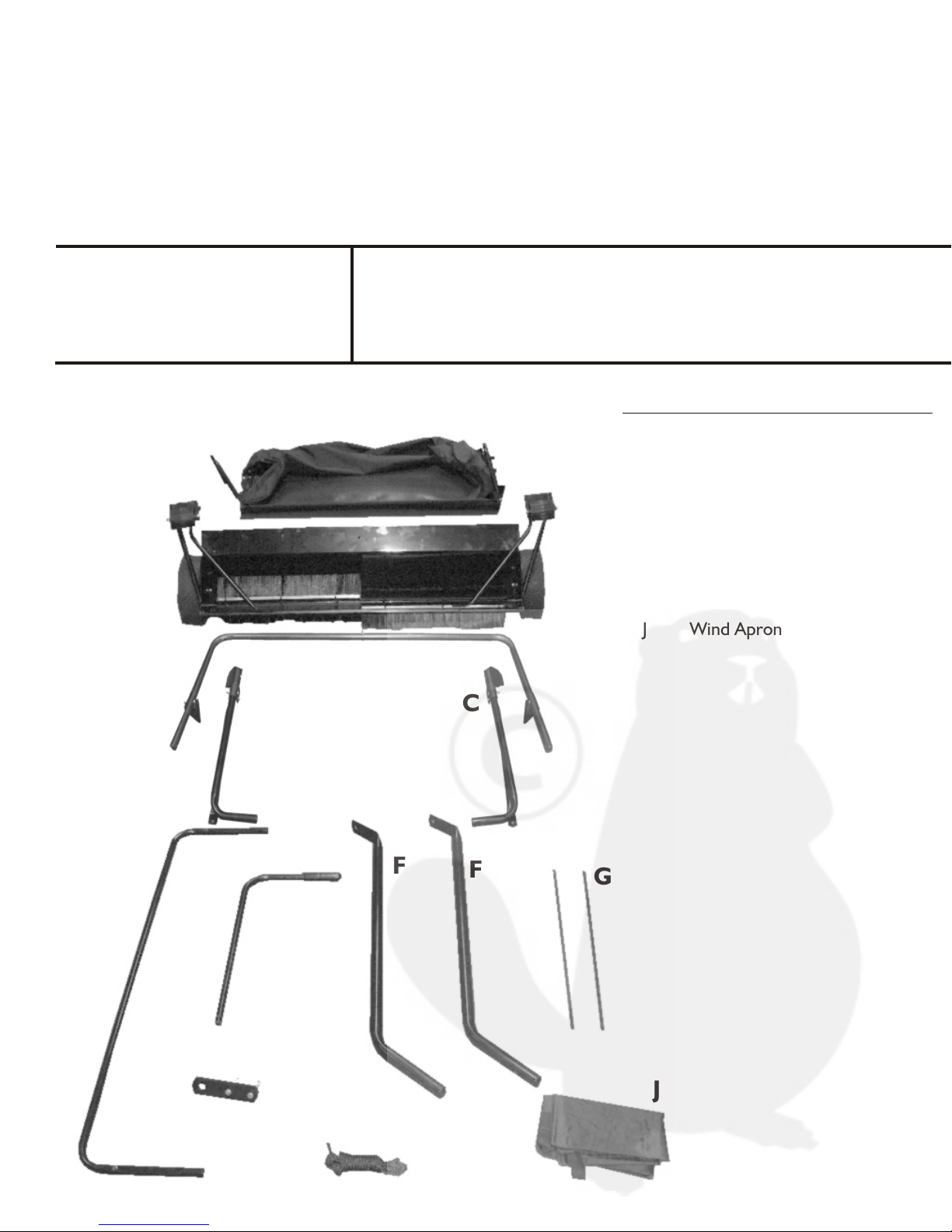

Hamper Assembly

Chassis Assembly

Pivot Frame Assembly

Bottom Hamper Cross Tube

Height Adjustment Tube

Hitch Arms

Hamper Support Rods

Clevis Plates

Hamper Dump Rope

Wind Apron

1

1

1

1

1

2

2

2

1

1

Ref. Description Qty.

Parts List Of SW38PRE

A

B

C

D

E

FG

H

I

J

A

B

C

D

E

F

G

H

I

J

Ref.

F

CC

OPERATION:

Brush Adjustment: Your new trailer-sweeper is

equipped with a handy, “From Your Seat” brush

adjustment. To raise, push Height Adjustment Tube

back and down until desired sweeping height is

attained. To lower, push Height Adjustment Tube

back and pull up to desired sweeping height (See Fig 18).

For best results, brushes should barely touch the top

of the grass blades. Brushes should be raised when

transporting the unit to and from sweeping area.

Sweeping Speed: For best results, rider/tractor

should travel at a 3 to 5 M.P.H. range.

Dumping: Simply pull the Hamper Dump Rope

forward to empty debris (See Fig. 19). Slowly ease

the Hamper Dump Rope back, keeping even

pressure, until the Hamper returns back down.

CAUTION: DO NOT ALLOW THE HAMPER DUMP

ROPE TO HAVE TOO MUCH SLACK IN IT WHEN

OPERATING. THE ROPE CAN GET CAUGHT IN

THE BRUSHES CAUSING INJURIES.

Pull Hamper

Dump Rope

Low

High

Fig. 18

Fig. 19

Height

Adjustment

Tube

MAINTENANCE:

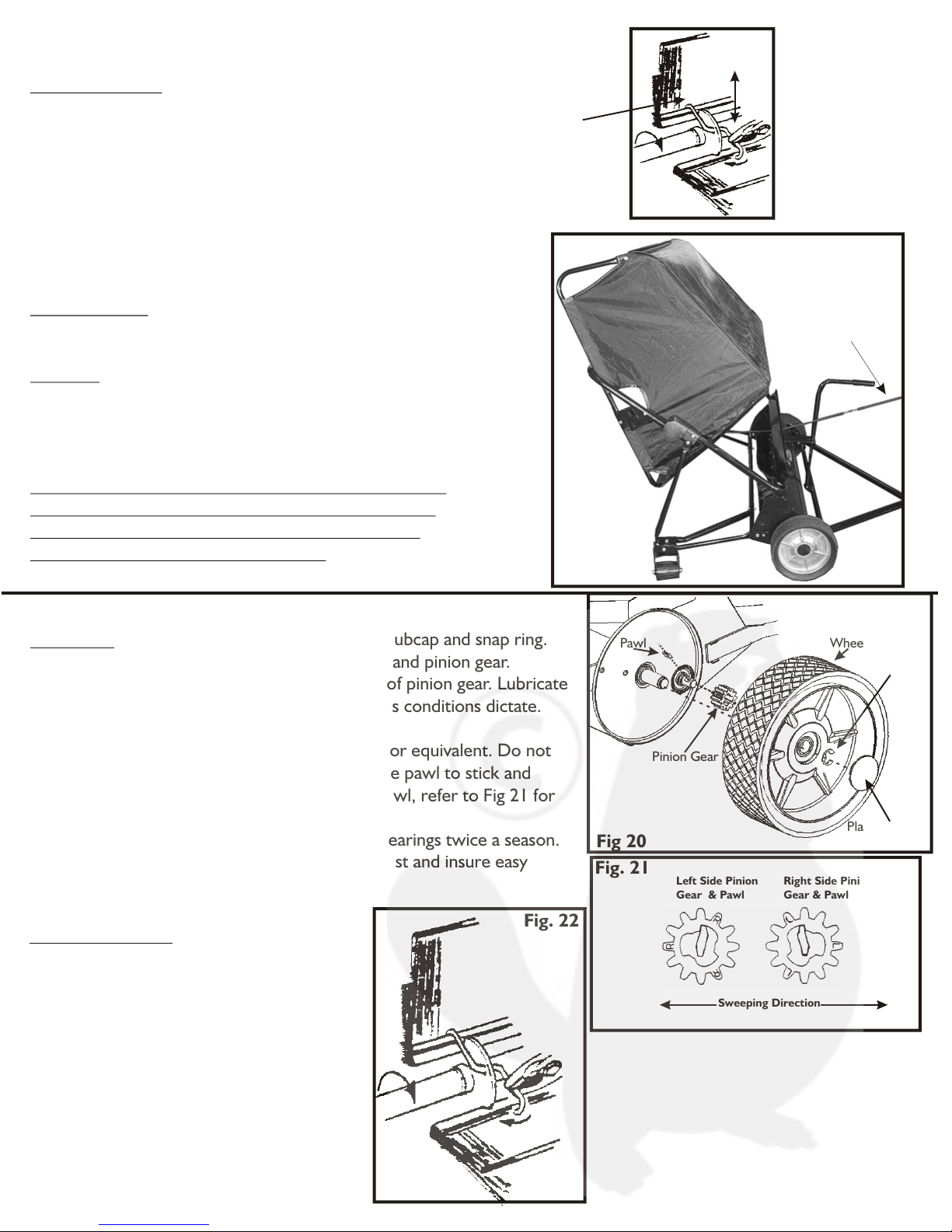

Lubrication: Remove wheel by removing plastic hubcap and snap ring.

Apply a light multipurpose grease to wheel gear and pinion gear.

NOTE: DO NOT allow grease to enter center of pinion gear. Lubricate

at the beginning of each season or more often as conditions dictate.

See Fig. 20.

Remove pinion gear and oil pawl with SAE #20 or equivalent. Do not

apply grease or heavy oil to pawl. This causes the pawl to stick and

operate erratically. When installing pinion and pawl, refer to Fig 21 for

correct position.

Apply SAE #20 oil or equivalent to brush axle bearings twice a season.

Oil Hamper pivot pins occasionally to prevent rust and insure easy

dumping.

Fig 20 Plastic Hubcap

Wheel

Snap Ring

Pinion Gear

Pawl

Sweeping Direction

Left Side Pinion

Gear & Pawl

Right Side Pinion

Gear & Pawl

Fig. 21

Brush Replacement:

Place brush strips in slots of brush disc so

shorter supporting bristles are away from

brush sweeping rotation. Secure at each

disc with three holder springs. Feed spring

through hole in disc. Place upper point into

bristles with point next to disc. With pliers,

grasp springs, turn and raise upward so lower

point is secured on backing of second brush.

Tap each end of spring with pliers to make

certain that the points are completely down

into bristles. See Fig. 22

Fig. 22

Step 1

Attach the Pivot Stand Brace (pre-attached to Sweeper Chassis)

to the Sweeper Chassis using a 1/4” x 1-1/4” Bolt. Repeat this step

for the other Pivot Stand Brace. Fig. 1

Lock the Pivot Stand Tube in place by inserting a 1/4” x 1/2”

Bolt through the Pivot Stand Tube and Sweeper Assembly and

securing it with a 1/4” Lock Nut. Fig.1

Tighten the nut on the pre-attached 5/16” Bolt if needed. Pivot Stand

Brace

Sweeper

Chassis

1/4 x 1-1/4”

Bolt

Step 2

Attach both Bottom Pivot Frame Assemblies to both right and left

sides on the front of the Sweeper Chassis using two 1/4” x 1-1/2”

Hex Head Bolts and two 1/4” Lock Nuts. Fig.2 (Right Bottom Pivot

Frame Assembly Shown) Next, bolt the Vertical Pivot Tube on the

Pivot Frame Assembly to the Caster Assembly using two

5/16” x 1/2” Bolts and two 5/16” Lock Nuts. Fig.2

Remove the bottom 1/4” x 1-1/2” Bolts (on both Bottom Pivot Frame

Assemblies, Fig. 3) and insert the Top Pivot Frame Assembly into both sides. Fig.4

The tube ends will attach inside the Plastic Hamper Hinge. Re-insert

the removed 1/4” x 1-1/2” Bolts to secure the Top Pivot Frame Assembly.

Attach the Catch Bracket on top of the Top Pivot Frame Assembly Tube

using the (pre-attached) 1/4” x 1-1/2” Bolt and 1/4” Lock Nut. Fig 5

Top Pivot Frame Assembly

Sweeper Chassis

Pivot Frame Brackets

under the Pivot Frame

Assembly and gaps

opening towards the

rear of the unit

Caster

Assembly

Vertical

Pivot

Tube

5/16” x 1/2”

Bolt

Step 7

Insert the Hamper Dump Rope through

center hole on the Sweeper Chassis Assembly.

Next, lay the Hamper Dump Rope behind the

sweeper. Fig. 15

Loosen the bolts holding both right and left

Hamper Pivot Bracket Assemblies. Fig. 14

Install the Hamper Assembly onto the Pivot Frame

Assembly. The Hamper Pivot Bracket Assemblies

fit inside the slots on both Frame Pivot Brackets.

Tighten both bolts after Hamper installation. Fig. 16

The Hamper Dump Rope needs to go under

and up the back side of the Hamper Assembly

for proper dumping operation. Tie the Hamper

Dump Rope end to the center of the Top Hamper

Cross Brace. Fig. 17

Hamper Dump

Rope

Hamper Pivot

Bracket & Bolt

Hamper Dump

Rope

Top Hamper

Cross Tube

STORAGE:

Remove both Hamper Support Rods

on the inside of the Hamper.

Next, simply release both Cross Tube

Locks and fold the Hamper down.

You can also pull the Hitch

Arm Assembly up and tie

it off through the Clevis

Plates with the Hamper

Dump Rope.

Cross Tube Lock

1/4” x 1-1/2”

Bolt

1/4” x 1/2”

Bolt

Pivot Stand

Tube

NOTE: ALL REFERENCES TO “RIGHT” AND “LEFT” DIRECTIONS

ARE IN REFERENCE TO POSITION BEHIND SWEEPER.

Pre-Attached

5/16” Bolt

Fig. 1

Fig. 2

Sweeper Chassis

Fig. 3

Fig. 15

Fig. 16

Fig. 17

Vertical

Pivot

Tube

1/4” x 1-1/2”

Bolt

Right-Bottom Pivot

Frame Assembly

Top Pivot Frame

Assembly Tube

Right-Bottom

Pivot Frame Assembly

Left-Bottom

Pivot Frame Assembly

Catch Bracket

1/4” x 1-1/2” Bolt

1/4” Lock Nut

Plastic Hamper

Hinge

Plastic Hamper

Hinge

Bolt, inside

to out

1/4” Lock Nut

Fig. 4

Fig. 5

Step 4

Attach the hitch arm assembly to the front of the

Sweeper Chassis Assembly using two 5/16” x 3/4”

Hex Head Bolts and two 5/16” Lock Nuts. Fig. 8

If you have trouble attaching the Hitch Arm Assembly,

try loosening the 5/16” x 3-1/4” Hex Head Bolt in order

for the Hitch Arms to spread apart easier.

Sweeper

Chassis

Assembly

Hitch Arm

Assembly

5/16” x 3/4”

Hex Head Bolt

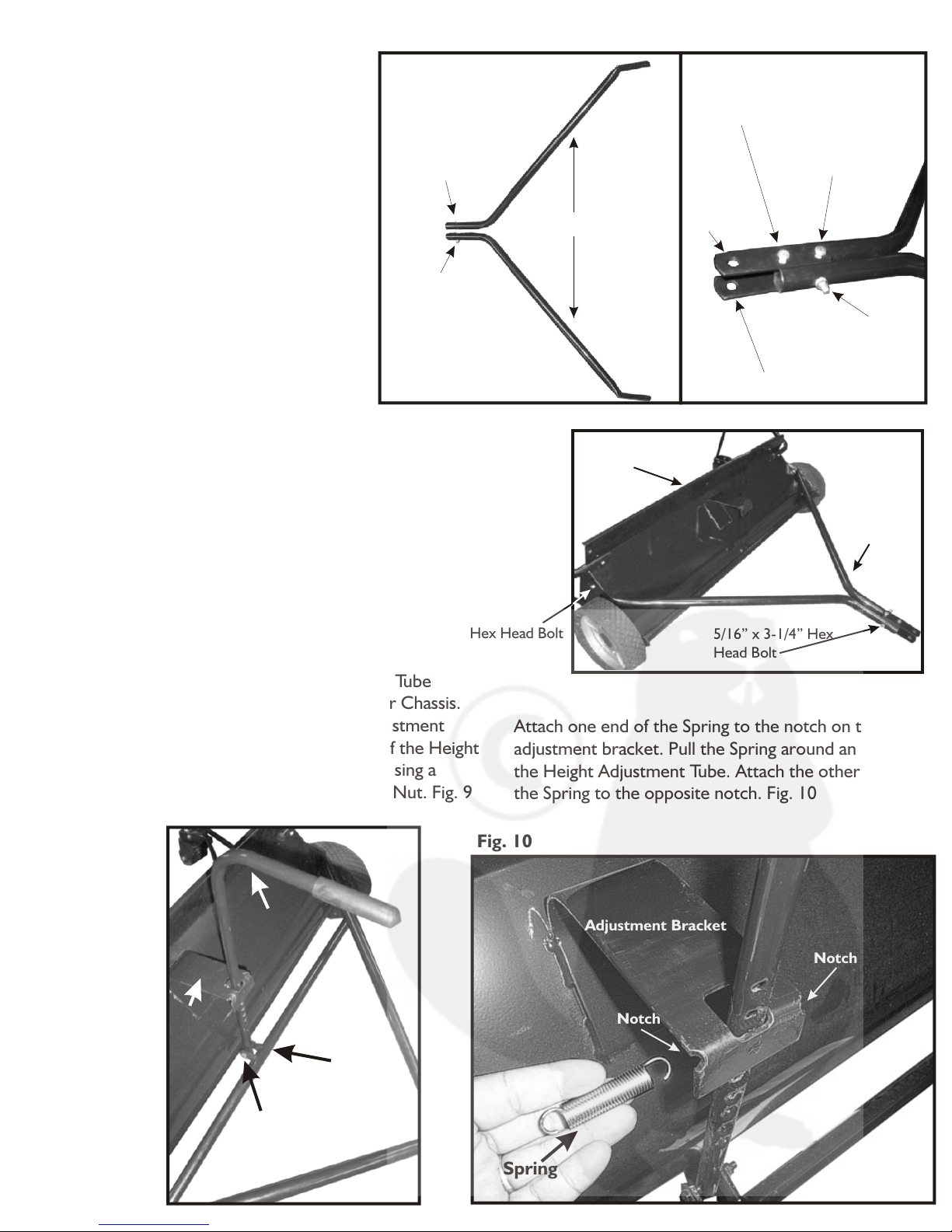

Step 5

Insert the bottom of the Height Adjustment Tube

through the hole in the front of the Sweeper Chassis.

Be sure the Handle Grip on the Height Adjustment

Tube is facing forward. Attach the bottom of the Height

Adjustment Tube to the Bumper Assembly using a

5/16” x 2” Hex Head Bolt and a 5/16” Lock Nut. Fig. 9

Height

Adjustment

Tube

Bumper

Assembly

5/16” x 2”

Hex Head Bolt

Height

Adjustment

Bracket

Notch

Spring

Step 6

For Packaging purposes the Top Side Hamper

Tubes (2 - one each side) are put on upside-down.

Remove the nut on each end of the Tie Rod and

re-attach the Top Side Hamper Tubes as shown

in illustration. Fig. 11

Insert The Top Side Hamper Tube into the

end of the Top Hamper Cross Tube. There is

a spring button lock on the Top Side Hamper

Tube that will secure these two tube assemblies

together. Fig. 11

Top Side Hamper Tube

Assembled Correctly

Tie Rod

Attach these

two tube

assemblies

together

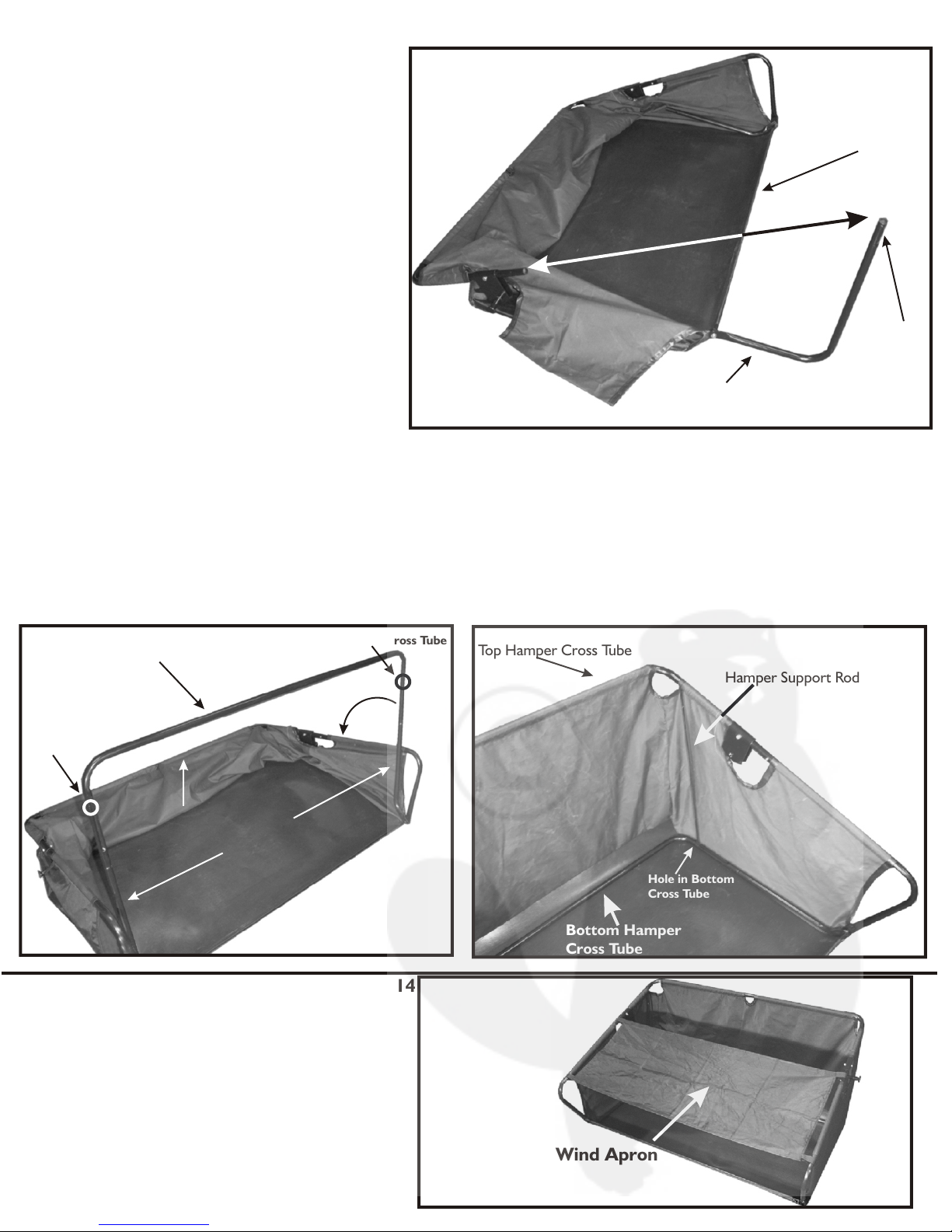

Attach the Bottom Hamper Cross Tube to the

two (one each side) Bottom Side Hamper Tubes.

The two holes in the Bottom Hamper Cross

Tube need to face out as shown in the illustration.

Fig. 12 These holes are for the Hamper Support

Rods, attached later in this assembly.

Push the Bottom Hamper Cross Tube down while

pulling up on the Top Hamper Cross Tube, this

creates the extended Hamper Assembly. Fig. 12

Finally, insert one end of the Hamper Support Rod

into the Top Hamper Cross Tube hole and the

other end of the Hamper Support Rod into the Bottom

Hamper Cross Tube hole. Fig. 13 Repeat this process for

the other Hamper Support Rod on the other side of

the Hamper Assembly.

Bottom Hamper Cross Tube

Side Hamper

Tubes

Top Hamper Cross Tube

Bottom Hamper

Cross Tube

Hamper Support Rod

Attach the optional Wind Apron to the

outside tubes towards the front of the

Hamper Assembly. Fig. 14

The Wind Apron helps keep debris from

blowing out of the Hamper Assembly while

the unit is in use.

Wind Apron

5/16” x 3-1/4” Hex

Head Bolt

Fig. 8

Fig. 9

Fig. 10

Notch

Adjustment Bracket

Fig. 11

Spring

Button

Lock

Fig. 12

Hole in Bottom

Cross Tube

Hole in Bottom Cross Tube

Push

Down

lPu l Up

Hole in Bottom

Cross Tube

Fig. 13

Fig. 14

Attach one end of the Spring to the notch on the height

adjustment bracket. Pull the Spring around and behind

the Height Adjustment Tube. Attach the other end of

the Spring to the opposite notch. Fig. 10

Step 3

Attach both Hitch Arms together using

one 5/16” x 3-1/4” Hex Head Bolt and

one 5/16” Lock Nut. Fig. 6 Do not tighten

this bolt yet.

Attach both Clevis Plates to the end of

the Hitch Arms. One 5/16” x 2-1/4”

Hex Head Bolt is attached in front

of the 5/16” x 3-1/4” Hex Head Bolt that

was used to connect the Hitch Arms.

The other 5/16” x 2-1/4” Hex Head Bolt

needs to be behind the Hitch Arm Bolt.

Tighten the Hitch Arm bolt then the two

Clevis Plate Bolts. Fig. 7 This arrangement

keeps the Clevis Plates from slipping off

the end of the Hitch Arms while in use.

Hitch Arms

5/16” x 3-1/4”

Hex Head Bolt

5/16” Lock Nut

Clevis Plate

5/16” x 3-1/4”

Hitch Arm

Bolt

Clevis Plate

FRONT 5/16” x 2-1/4”

Hex Head Bolt

BACK 5/16” x 2-1/4”

Hex Head Bolt

Fig. 6

Fig. 7

Step 4

Attach the hitch arm assembly to the front of the

Sweeper Chassis Assembly using two 5/16” x 3/4”

Hex Head Bolts and two 5/16” Lock Nuts. Fig. 8

If you have trouble attaching the Hitch Arm Assembly,

try loosening the 5/16” x 3-1/4” Hex Head Bolt in order

for the Hitch Arms to spread apart easier.

Sweeper

Chassis

Assembly

Hitch Arm

Assembly

5/16” x 3/4”

Hex Head Bolt

Step 5

Insert the bottom of the Height Adjustment Tube

through the hole in the front of the Sweeper Chassis.

Be sure the Handle Grip on the Height Adjustment

Tube is facing forward. Attach the bottom of the Height

Adjustment Tube to the Bumper Assembly using a

5/16” x 2” Hex Head Bolt and a 5/16” Lock Nut. Fig. 9

Height

Adjustment

Tube

Bumper

Assembly

5/16” x 2”

Hex Head Bolt

Height

Adjustment

Bracket

Notch

Spring

Step 6

For Packaging purposes the Top Side Hamper

Tubes (2 - one each side) are put on upside-down.

Remove the nut on each end of the Tie Rod and

re-attach the Top Side Hamper Tubes as shown

in illustration. Fig. 11

Insert The Top Side Hamper Tube into the

end of the Top Hamper Cross Tube. There is

a spring button lock on the Top Side Hamper

Tube that will secure these two tube assemblies

together. Fig. 11

Top Side Hamper Tube

Assembled Correctly

Tie Rod

Attach these

two tube

assemblies

together

Attach the Bottom Hamper Cross Tube to the

two (one each side) Bottom Side Hamper Tubes.

The two holes in the Bottom Hamper Cross

Tube need to face out as shown in the illustration.

Fig. 12 These holes are for the Hamper Support

Rods, attached later in this assembly.

Push the Bottom Hamper Cross Tube down while

pulling up on the Top Hamper Cross Tube, this

creates the extended Hamper Assembly. Fig. 12

Finally, insert one end of the Hamper Support Rod

into the Top Hamper Cross Tube hole and the

other end of the Hamper Support Rod into the Bottom

Hamper Cross Tube hole. Fig. 13 Repeat this process for

the other Hamper Support Rod on the other side of

the Hamper Assembly.

Bottom Hamper Cross Tube

Side Hamper

Tubes

Top Hamper Cross Tube

Bottom Hamper

Cross Tube

Hamper Support Rod

Attach the optional Wind Apron to the

outside tubes towards the front of the

Hamper Assembly. Fig. 14

The Wind Apron helps keep debris from

blowing out of the Hamper Assembly while

the unit is in use.

Wind Apron

5/16” x 3-1/4” Hex

Head Bolt

Fig. 8

Fig. 9

Fig. 10

Notch

Adjustment Bracket

Fig. 11

Spring

Button

Lock

Fig. 12

Hole in Bottom

Cross Tube

Hole in Bottom Cross Tube

Push

Down

lPu l Up

Hole in Bottom

Cross Tube

Fig. 13

Fig. 14

Attach one end of the Spring to the notch on the height

adjustment bracket. Pull the Spring around and behind

the Height Adjustment Tube. Attach the other end of

the Spring to the opposite notch. Fig. 10

Step 3

Attach both Hitch Arms together using

one 5/16” x 3-1/4” Hex Head Bolt and

one 5/16” Lock Nut. Fig. 6 Do not tighten

this bolt yet.

Attach both Clevis Plates to the end of

the Hitch Arms. One 5/16” x 2-1/4”

Hex Head Bolt is attached in front

of the 5/16” x 3-1/4” Hex Head Bolt that

was used to connect the Hitch Arms.

The other 5/16” x 2-1/4” Hex Head Bolt

needs to be behind the Hitch Arm Bolt.

Tighten the Hitch Arm bolt then the two

Clevis Plate Bolts. Fig. 7 This arrangement

keeps the Clevis Plates from slipping off

the end of the Hitch Arms while in use.

Hitch Arms

5/16” x 3-1/4”

Hex Head Bolt

5/16” Lock Nut

Clevis Plate

5/16” x 3-1/4”

Hitch Arm

Bolt

Clevis Plate

FRONT 5/16” x 2-1/4”

Hex Head Bolt

BACK 5/16” x 2-1/4”

Hex Head Bolt

Fig. 6

Fig. 7

Step 1

Attach the Pivot Stand Brace (pre-attached to Sweeper Chassis)

to the Sweeper Chassis using a 1/4” x 1-1/4” Bolt. Repeat this step

for the other Pivot Stand Brace. Fig. 1

Lock the Pivot Stand Tube in place by inserting a 1/4” x 1/2”

Bolt through the Pivot Stand Tube and Sweeper Assembly and

securing it with a 1/4” Lock Nut. Fig.1

Tighten the nut on the pre-attached 5/16” Bolt if needed. Pivot Stand

Brace

Sweeper

Chassis

1/4 x 1-1/4”

Bolt

Step 2

Attach both Bottom Pivot Frame Assemblies to both right and left

sides on the front of the Sweeper Chassis using two 1/4” x 1-1/2”

Hex Head Bolts and two 1/4” Lock Nuts. Fig.2 (Right Bottom Pivot

Frame Assembly Shown) Next, bolt the Vertical Pivot Tube on the

Pivot Frame Assembly to the Caster Assembly using two

5/16” x 1/2” Bolts and two 5/16” Lock Nuts. Fig.2

Remove the bottom 1/4” x 1-1/2” Bolts (on both Bottom Pivot Frame

Assemblies, Fig. 3) and insert the Top Pivot Frame Assembly into both sides. Fig.4

The tube ends will attach inside the Plastic Hamper Hinge. Re-insert

the removed 1/4” x 1-1/2” Bolts to secure the Top Pivot Frame Assembly.

Attach the Catch Bracket on top of the Top Pivot Frame Assembly Tube

using the (pre-attached) 1/4” x 1-1/2” Bolt and 1/4” Lock Nut. Fig 5

Top Pivot Frame Assembly

Sweeper Chassis

Pivot Frame Brackets

under the Pivot Frame

Assembly and gaps

opening towards the

rear of the unit

Caster

Assembly

Vertical

Pivot

Tube

5/16” x 1/2”

Bolt

Step 7

Insert the Hamper Dump Rope through

center hole on the Sweeper Chassis Assembly.

Next, lay the Hamper Dump Rope behind the

sweeper. Fig. 15

Loosen the bolts holding both right and left

Hamper Pivot Bracket Assemblies. Fig. 14

Install the Hamper Assembly onto the Pivot Frame

Assembly. The Hamper Pivot Bracket Assemblies

fit inside the slots on both Frame Pivot Brackets.

Tighten both bolts after Hamper installation. Fig. 16

The Hamper Dump Rope needs to go under

and up the back side of the Hamper Assembly

for proper dumping operation. Tie the Hamper

Dump Rope end to the center of the Top Hamper

Cross Brace. Fig. 17

Hamper Dump

Rope

Hamper Pivot

Bracket & Bolt

Hamper Dump

Rope

Top Hamper

Cross Tube

STORAGE:

Remove both Hamper Support Rods

on the inside of the Hamper.

Next, simply release both Cross Tube

Locks and fold the Hamper down.

You can also pull the Hitch

Arm Assembly up and tie

it off through the Clevis

Plates with the Hamper

Dump Rope.

Cross Tube Lock

1/4” x 1-1/2”

Bolt

1/4” x 1/2”

Bolt

Pivot Stand

Tube

NOTE: ALL REFERENCES TO “RIGHT” AND “LEFT” DIRECTIONS

ARE IN REFERENCE TO POSITION BEHIND SWEEPER.

Pre-Attached

5/16” Bolt

Fig. 1

Fig. 2

Sweeper Chassis

Fig. 3

Fig. 15

Fig. 16

Fig. 17

Vertical

Pivot

Tube

1/4” x 1-1/2”

Bolt

Right-Bottom Pivot

Frame Assembly

Top Pivot Frame

Assembly Tube

Right-Bottom

Pivot Frame Assembly

Left-Bottom

Pivot Frame Assembly

Catch Bracket

1/4” x 1-1/2” Bolt

1/4” Lock Nut

Plastic Hamper

Hinge

Plastic Hamper

Hinge

Bolt, inside

to out

1/4” Lock Nut

Fig. 4

Fig. 5

Your new SW38PRE lawn sweeper is precision manufactured using the finest in tools and materials. Although it is

ruggedly constructed, do not subject this unit to misuse. Be sure to wipe off your unit after each use. Store in a

dry place out of direct sunlight. Do not permit the lawn sweeper to stand in the hot sun, unless it is in actual use.

You will find many work saving uses for your lawn sweeper. Use it early in the spring to give your lawn a good healthy

scrubbing. Use it throughout spring and summer before and after mowing. Sweeping your lawn before mowing stands

the grass up for a clean, even cut. It also allows increased protection to your mower by removing sticks, stones and

nuts, which might damage the blade(s) on your mower. Sweeping your lawn after mowing will whisk away unsightly

grass clippings - leaving your lawn velvety smooth.

Tools Required For Assembly:

Assembly Parts List Description

One (1) - Pair Pliers (Needle Nose)

Two (2) - 7/16” Wrenches

Two (2) - ½” Wrenches

Prior To Assembly:

Remove all Sweeper Parts from carton. Make sure all parts and assemblies are

present before assembly. If any parts are missing, contact Customer Service

(contact information on back sheet) immediately for assistance.

Lay out all parts and have tools ready.

Hamper Assembly

Chassis Assembly

Pivot Frame Assembly

Bottom Hamper Cross Tube

Height Adjustment Tube

Hitch Arms

Hamper Support Rods

Clevis Plates

Hamper Dump Rope

Wind Apron

1

1

1

1

1

2

2

2

1

1

Ref. Description Qty.

Parts List Of SW38PRE

A

B

C

D

E

FG

H

I

J

A

B

C

D

E

F

G

H

I

J

Ref.

F

CC

OPERATION:

Brush Adjustment: Your new trailer-sweeper is

equipped with a handy, “From Your Seat” brush

adjustment. To raise, push Height Adjustment Tube

back and down until desired sweeping height is

attained. To lower, push Height Adjustment Tube

back and pull up to desired sweeping height (See Fig 18).

For best results, brushes should barely touch the top

of the grass blades. Brushes should be raised when

transporting the unit to and from sweeping area.

Sweeping Speed: For best results, rider/tractor

should travel at a 3 to 5 M.P.H. range.

Dumping: Simply pull the Hamper Dump Rope

forward to empty debris (See Fig. 19). Slowly ease

the Hamper Dump Rope back, keeping even

pressure, until the Hamper returns back down.

CAUTION: DO NOT ALLOW THE HAMPER DUMP

ROPE TO HAVE TOO MUCH SLACK IN IT WHEN

OPERATING. THE ROPE CAN GET CAUGHT IN

THE BRUSHES CAUSING INJURIES.

Pull Hamper

Dump Rope

Low

High

Fig. 18

Fig. 19

Height

Adjustment

Tube

MAINTENANCE:

Lubrication: Remove wheel by removing plastic hubcap and snap ring.

Apply a light multipurpose grease to wheel gear and pinion gear.

NOTE: DO NOT allow grease to enter center of pinion gear. Lubricate

at the beginning of each season or more often as conditions dictate.

See Fig. 20.

Remove pinion gear and oil pawl with SAE #20 or equivalent. Do not

apply grease or heavy oil to pawl. This causes the pawl to stick and

operate erratically. When installing pinion and pawl, refer to Fig 21 for

correct position.

Apply SAE #20 oil or equivalent to brush axle bearings twice a season.

Oil Hamper pivot pins occasionally to prevent rust and insure easy

dumping.

Fig 20 Plastic Hubcap

Wheel

Snap Ring

Pinion Gear

Pawl

Sweeping Direction

Left Side Pinion

Gear & Pawl

Right Side Pinion

Gear & Pawl

Fig. 21

Brush Replacement:

Place brush strips in slots of brush disc so

shorter supporting bristles are away from

brush sweeping rotation. Secure at each

disc with three holder springs. Feed spring

through hole in disc. Place upper point into

bristles with point next to disc. With pliers,

grasp springs, turn and raise upward so lower

point is secured on backing of second brush.

Tap each end of spring with pliers to make

certain that the points are completely down

into bristles. See Fig. 22

Fig. 22

SW38PRE - 38” Tow Behind Lawn Sweeper

Owner’s Manual and Parts List

Precision Products, Inc.

2

1

3

4

6

7

5

8

9

5

10

11

12

13

16

15

14

17

1818

19

20 21

22

28

26

27

25

24

23

30

29

Parts List for SW38PRE

31

32

5

33

36

38

37

39

41

40

43

42

44

45

46

23

35

47

48

49

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

**

**

**

**

Height Adjustment Tube

Handle Grip

Caster Assembly

Sweeper Chassis

5/16” Lock Nut

5/16” x 2” Hex Head Bolt

Bumper Assembly

Hitch Arms

5/16” x 2 1/4” Hex Head Bolt

Clevis Plate

5/16” x 3-1/4” Hex Head Bolt

Hamper Pivot Bracket Assembly

Top Hamper Cross Tube

Bottom Hamper Cross Tube

Hamper Support Rod

Bottom Hamper Side Tube

Top Side Hamper Tube

Tie Rod

5/16” x 5/8” Hex Head Bolt

1/4” x 1-3/4” Hex Head Bolt

5/16” x 3/4” Hex Head Bolt

1/4” x 1/2” Hex Head Bolt

5/16” x 1/2” Hex Head Bolt

Wheel Shield

Stub Axle

Pinion Gear

10” Tire

10” Die Cast Wheel

5/8” E Type Snap Ring

Plastic Hub Cap

Flange Bearing

3/8” Lock Nut

Pinion Pawl

3/8” Pilot Nut

RH Hamper Pivot Bracket

Top Pivot Cross Tube

1/4” x 1-1/2” Hex Head Bolt

LH Hamper Pivot Bracket

LH Cross Tube Lock

1/4” Lock Nut

RH Cross Tube Lock

Plastic Hamper Hinge

Vertical Pivot Tube

Pivot Support Tube

Pivot Stand Tube

Pivot Stand Brace

Brush Strip

Brush Spring

Bush/Axle/Disc Assembly

Catch Bracket

**PARTS NOT ILLUSTRATED

Hamper (Material)

Wind Apron

Hamper Dump Rope

Spring

20

Ref # Part Description Qty.

34

Part # Ref # Part Description Qty.

Part #

LIMITED WARRANTY

This unit is warranted against defects in materials and workmanship to the original

purchaser, under normal use and service, for a period of ninety (90) days from date

of sale. During the Warranty Period, we will repair or replace at our option free of

charge to the original purchaser, any part of the Unit that our examination shows to

be defective in workmanship or materials. This Warranty Does Not apply to damage

caused by misuse, abuse, neglect, accident, normal wear, or alterations by

unauthorized persons.

Customer Service & Warranty Information

PLEASE DO NOT RETURN THIS MERCHANDISE TO THE STORE. CALL US AND WE WILL TAKE CARE OF ANY

PROBLEM YOU MIGHT HAVE WITH THIS PRODUCT. Phone (800) 225 - 5891 EXT. #204

When ordering parts always give model

number, part description & part number.

Send To: Precision Products, Inc.

Parts Division Phone (217) 735-1590

316 Limit Street Fax (217) 735-2435

Lincoln, IL 62656

Parts list on back page

1

1

2

1

19

1

1

2

2

2

1

2

1

1

2

2

2

1

4

2

2

2

8

2

2

2

2

2

2

2

2

2

2

2

1

1

3

1

1

13

1

2

2

2

2

2

6

18

1

1

1

1

1

1

01/04

1745

1746

1747

3230

1749

4041

3231

3232

1752

1753

1754

1755

3233

3234

1758

1792

1759

3235

1761

1065

1248

1647

1762

1763

1764

1765

1766

1767

1768

1769

1770

1771

1772

1773

1774

3236

6129

1776

1777

1778

1779

1780

1781

1782

1783

1784

3237

1786

3238

1795

3239

3240

1790

1282

37

40

50

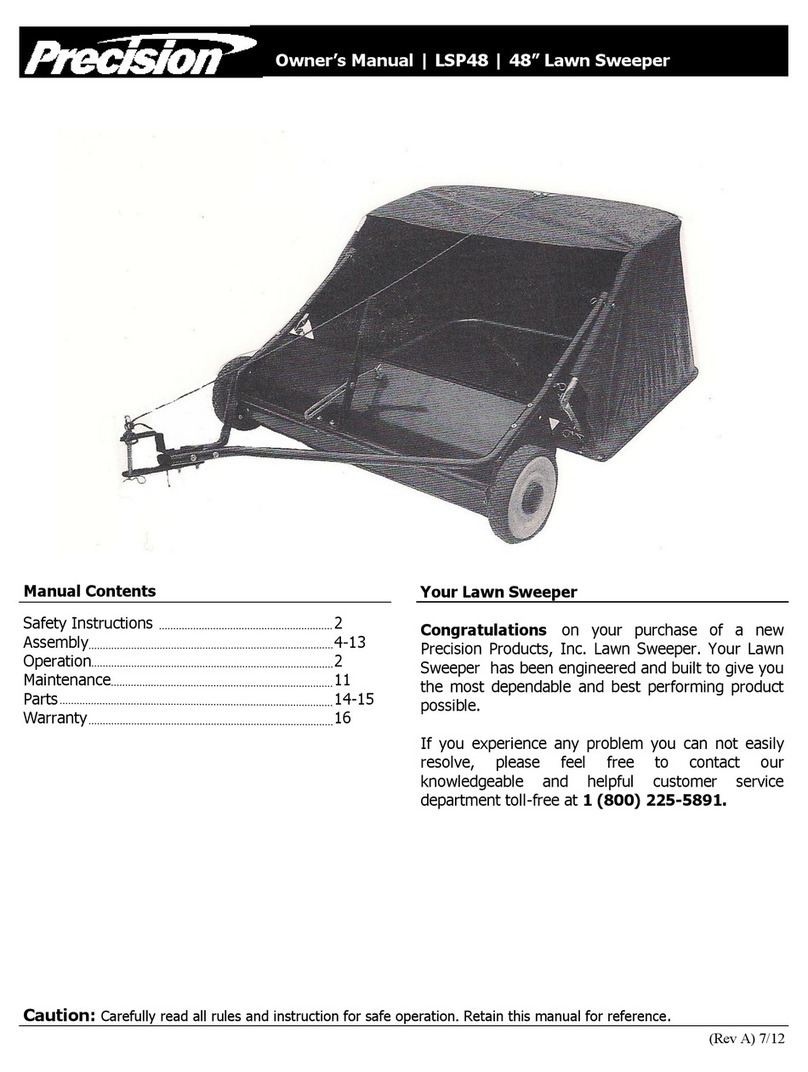

Table of contents

Other Precision Products Lawn Sweeper manuals