Precision Products TCT15 Datasheet

Fig. 3

3/4” Flat Washer

Cotter Pin

Axle Slot

Fig. 1

Ref.

No.

Part

No.

1 1840 1/2”x 1-3/4” Clevis Pin

2 1248 5/16” x 3/4” Hex Head Bolt

3 1042 #14 Hitch Pin Clip

4 1044 5/16” Flat Washer

5 1276 5/16” Lock Washer

6 1275 5/16” Hex Head Nut

7 3739 3/4” In Diam. x 2” Flat Washer

8 1264 3/4” Flat Washer

9 1262 1/8” x 1-1/4” Cotter Pin

1

6

1

6

6

6

4

2

2

Part Description

Hardware

Sack Qty.

Trailer Sprayer

ASSEMBLY INSTRUCTIONS & PARTS LIST 03/05

PRECISION PRODUCTS, INC.

3736-6

Assembly Hardware

Assembly Instructions

Cart Body Assembly Parts

LIMITED WARRANTY

This unit is warranted against defects in materials and workmanship to the original

purchaser, under normal use and service, for a period of ninety (90) days from date

of sale. During the Warranty Period, we will repair or replace at our option free of

charge to the original purchaser, any part of the Unit that our examination shows to

be defective in workmanship or materials. This Warranty apply to damage

caused by misuse, abuse, neglect, accident, normal wear, or alterations by

unauthorized persons.

Does Not

The electric pump on this model has its own warranty. Precision Products, Inc. does not carry

a warranty on the pump. Please refer to the parts list and operation manual for the pump

included with this model.

PRECISION PRODUCTS, INC.

Fig.3

Tools needed for assembly:

Two 1/2” Wrenches

1 Pair Needle Nose Pliers

123

5

8

9

7

6

4

Fig. 2

3/4” Diameter x 2”

Flat Washers

Axle

1/2”x 1-3/4” Clevis Pin

5/16” x 3/4” Hex Head Bolt

#14 Hitch Pin Clip

5/16” Flat Washer

5/16” Lock Washer

5/16” Hex Head Nut

3/4” Diameter x 2” Flat Washer

3/4” Flat Washer

1/8” x 1-1/4” Cotter Pin

5/16” x 1/2” Hex Head Bolt

1

2

4

42

6

3

43

44

7

10

5

8

9

2

4

45

47

5

6

5

6

62

4

5/16” Lock

Washers

Fig. 4

5/16” x 1” Hex

Head Bolts

5/16” Flat

Washers

Clevis

5/16” Hex

Head Nuts

46

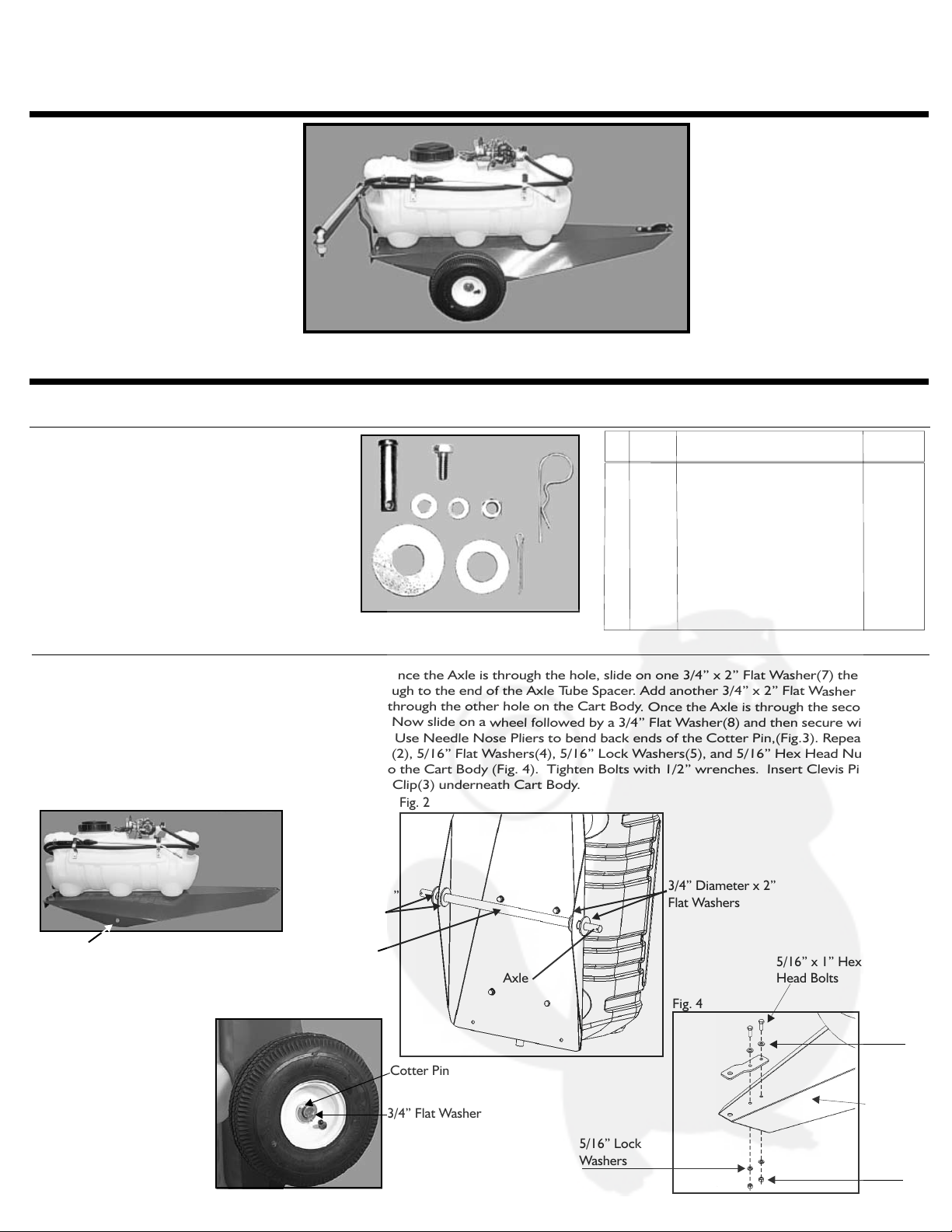

STEP 1 Insert Axle through Axle Slot on Cart Body. Once the Axle is through the hole, slide on one 3/4” x 2” Flat Washer(7) then the

Axle Tube Spacer(44), then slide the Axle through to the end of the Axle T

ube Spacer. Add another 3/4” x 2” Flat Washer (inside

of the Sprayer Cart body) and push the Axle through the other hole on the Cart Body. Once the Axle is through the second hole,

slide on a 3/4” ID x 2” Flat Washer(7), (Fig.2). Now slide on a wheel followed by a 3/4” Flat Washer(8) and then secure with

a Cotter Pin(9). Repeat this for both Wheels. Use Needle Nose Pliers to bend back ends of the Cotter Pin,(Fig.3). Repeat for

other side. Using 5/16” x 3/4” Hex Head Bolts(2), 5/16” Flat Washers(4), 5/16” Lock Washers(5), and 5/16” Hex Head Nuts(6)

attach Clevis, (42),(on topside of Cart Body) to the Cart Body (Fig. 4). Tighten Bolts with 1/2” wrenches. Insert Clevis Pin(1)

through Clevis and secure with #14 Hitch Pin Clip(3) underneath Cart Body.

1

2

3

4

5

6

7

8

9

10

Ref. Part Description Part Number

Qty.

1840

1248

1042

1044

1276

1275

3739

1264

1262

1249

1

6

1

6

10

6

4

2

2

4

42

43

44

45

46

47

Ref. Part Description Part Number

Qty.

Clevis

Axle

Axle Tube Spacer

10” Pneumatic Wheel for TCT

TCT Cart Body

Boom Mount

1243P

3769

3767

3768

3740R

3766R

1

1

1

2

1

1

**Part quantities includes pieces assembled at factory

and those in hardware sack.

TCT15

TCT15RT

Cart Body

3/4” Diameter x 2”

Flat Washers

Axle Spacer

5

When ordering parts, always give model number,

part description, & part number.

Precision Products, Inc.

Parts Division (217)735-1590

316 Limit Street (217)735-2435

Lincoln, IL 62656

or visit us on the world wide web :www.precisionprodinc.com

Send To:

Phone

Fax

Customer Service

CUSTOMER SUPPORT

At Precision Products, Inc. delivering quality, value and outstanding service is our goal.

However, sometimes parts do become damaged or lost during transport from our facilities to

the store. If you have any problems, please do not return this merchandise to the store.

Call us and we will take care of any problem you may have with this unit.

Rear View

5/16” Hex Head Bolts

5/16” Flat Washer

Fig. 5

Boom Mount

Assembly Instructions Continued

Ref. Part Description Part Number

6

4

8

8

1

1

2

3

3

1

2

4

1

1

1

1

1

1

4

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Part Description

Ref. Part Number Qty.

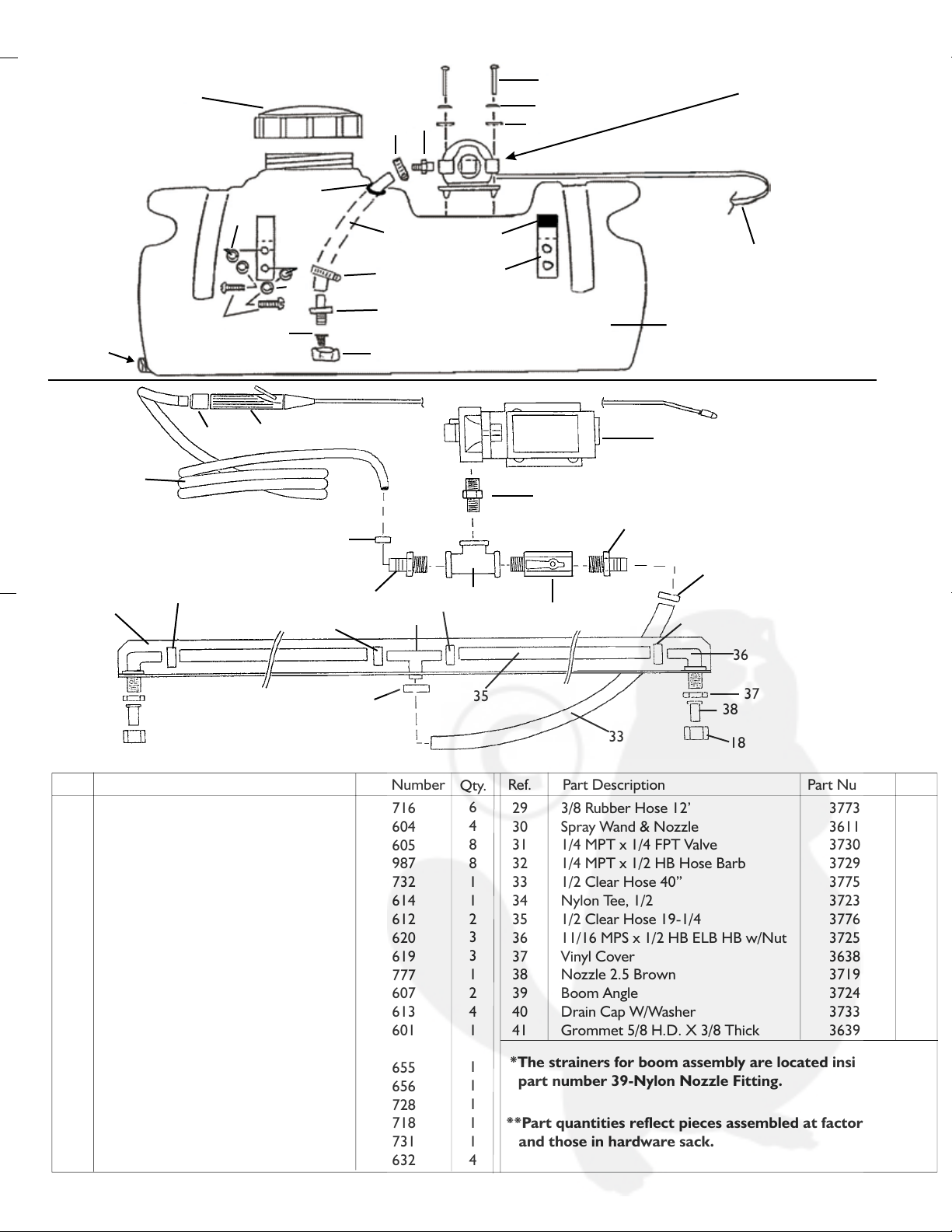

Hose Clamp .702 - .801 Plastic

10-24 x 1-1/4 Round Head Screw

#10 Flat Washer (10FWZP)

3/16” Lock Washer

Wire Harness

15 Gallon Sprayer Tank

Wand Holder

Nozzle Cap

Suction Strainer*

3/8 Rubber Hose 24”

Hose Barb 3/8 MPT x 3/8 HB

10-24 x 1/2 Bolt

Tank Lid

Pump Electric: Check Model Number

Models TCT15-12V (1.0 W/O Switch)

Models TCT15RT-12V (1.0 W/ Switch)

3/8” MPT x 1/4” MPT Nipple

Nylon Tee, 1/4”

1/4 MPT x 3/8 HB

1/2” Stainless Steel Clamp

3716

3604

3605

2987

3732

3614

3612

3620

3619

3777

3607

3613

3601

3655

3656

3728

3718

3731

3632

Qty.

29

30

31

32

33

34

35

36

37

38

39

40

41

3/8 Rubber Hose 12’

Spray Wand & Nozzle

1/4 MPT x 1/4 FPT Valve

1/4 MPT x 1/2 HB Hose Barb

1/2 Clear Hose 40”

Nylon Tee, 1/2

1/2 Clear Hose 19-1/4

11/16 MPS x 1/2 HB ELB HB w/Nut

Vinyl Cover

Nozzle 2.5 Brown

Boom Angle

Drain Cap W/Washer

Grommet 5/8 H.D. X 3/8 Thick

3773

3611

3730

3729

3775

3723

3776

3725

3638

3719

3724B

3733

3639

1

1

1

1

1

1

2

2

2

2

1

1

1

PLUMBING ASSEMBLY

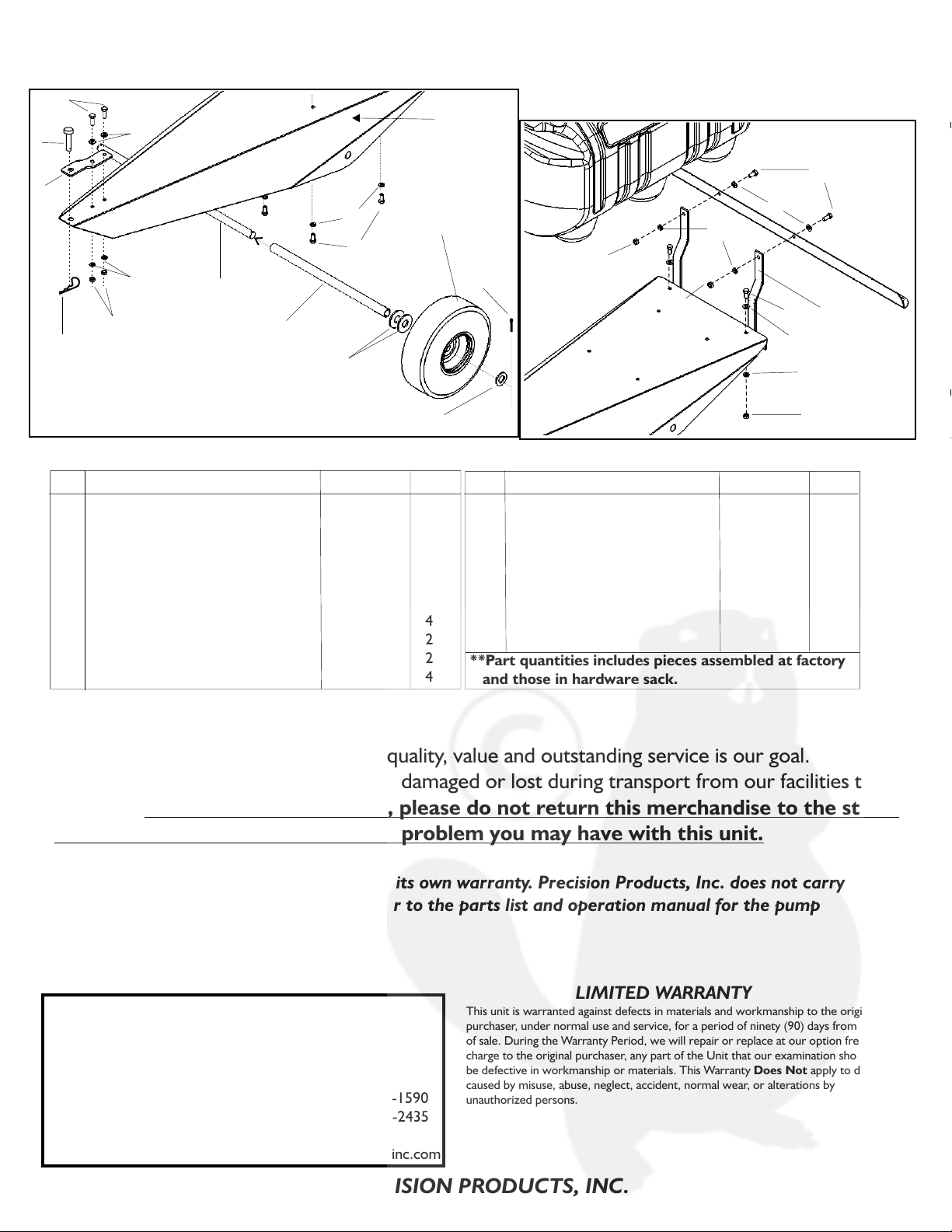

STEP 2 Attach Boom Mount to Cart Body using 5/16” x 3/4” Hex Head Bolts(2), 5/16” Flat Washers(4), 5/16” Lock Washers(5)

and 5/16” Hex Head Nuts (6),(Fig.5). Attach Boom Arm Assembly to Boom Mount using 5/16” x 3/4” Hex Head Bolts(2),

5/16” Flat Washers(4), 5/16” Lock Washers(5) and 5/16” Hex Head Nuts(6), (Fig. 6). Tighten all four Bolts with the 1/2”

wrenches.

Parts List for Pump Assembly

SEE BELOW FOR PLUMBING

ASSEMBLY

12

13

15

16

17

18

19

21

28

28

20

13

14

21

22

23

24

28

27

28

26

25

29

30

31

11

32

11

11 11

33

34

35

36

37

18

38

11

5/16” Hex Head Nut

5/16” Lock Washer

Fig. 6

14

Hose from Ball

Valve off of Pump

11

40

39

**Part quantities reflect pieces assembled at factory

and those in hardware sack.

Boom Arm

Assembly

Drain Cap

*The strainers for boom assembly are located inside

part number 39-Nylon Nozzle Fitting.

Introduction

Your sprayer has been manufactured to provide the maximum

in dependable efficient use. Proper operation and maintenance

will ensure long satisfactory service. Study this manual carefully

to become familiar with the operation and maintenance

instructions.

Keep your manual in a safe, convenient place for future

reference. Always mention the model and part number in any

correspondence. To insure correct parts service be sure to

use part number and description when ordering.

Operation

Operating power is obtained from a 12 volt direct source or

cigarette lighter plug. Be sure to connect the red to the

positive (+) source and attach the black to the negative ( - )

source.

Before spraying chemicals, fill the tank full

of plain water to allow familiarization with the sprayer and to

prevent waste of expensive chemicals.

IMPORTANT:

Sprayer Maintenance

.

A sprayer is a carefully designed and built machine that should

provide many years of reliable service if properly cared for.

The main rule in caring for any sprayer is:

Neglect costs dollars in repairs, wasted spray material and

premature replacement of the sprayer.

KEEP IT CLEAN

Cleaning & Storage

Most spray materials are highly corrosive. The most important

aspect of long dependable service from the sprayer is a thorough

cleaning immediately following each use. In addition, the residue

of one type of chemical could cause an undesirable effect when a

different chemical is used for a different purpose.

The most effective cleaning method is to pump several rinses of

clean water through the tank, pump, hoses, boom, spray gun, etc.

A neutralizing agent such as a solution of Nutra-Sol, a detergent or

household ammonia as recommended by the chemical manufacturer

can assist in removal of a persistent chemical. When the system is

thoroughly cleaned drain the tank, suction line, pump, hoses, etc.

The following steps should be followed for the maintenance and

storage of your sprayer.

1. Wash and flush out sprayer after completion of each phase

of your program. Flush out sprayer when changing chemicals if

there is a possibility of the chemicals being incompatible. Use of a

detergent is advisable if the chemical manufacturer does not make

specific cleaning recommendations. Flush system completely,

including nozzles. Never use metal objects to open clogged

nozzles.

2. Clean sprayer thoroughly before storing at the end of the

spraying season. Permanent type anti-freeze added to the final

rinse will leave a rust inhibiting film in parts of the sprayer.

37

41

Rear View

5/16” Hex Head Bolts

5/16” Flat Washer

Fig. 5

Boom Mount

Assembly Instructions Continued

Ref. Part Description Part Number

6

4

8

8

1

1

2

3

3

1

2

4

1

1

1

1

1

1

4

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Part Description

Ref. Part Number Qty.

Hose Clamp .702 - .801 Plastic

10-24 x 1-1/4 Round Head Screw

#10 Flat Washer (10FWZP)

3/16” Lock Washer

Wire Harness

15 Gallon Sprayer Tank

Wand Holder

Nozzle Cap

Suction Strainer*

3/8 Rubber Hose 24”

Hose Barb 3/8 MPT x 3/8 HB

10-24 x 1/2 Bolt

Tank Lid

Pump Electric: Check Model Number

Models TCT15-12V (1.0 W/O Switch)

Models TCT15RT-12V (1.0 W/ Switch)

3/8” MPT x 1/4” MPT Nipple

Nylon Tee, 1/4”

1/4 MPT x 3/8 HB

1/2” Stainless Steel Clamp

3716

3604

3605

2987

3732

3614

3612

3620

3619

3777

3607

3613

3601

3655

3656

3728

3718

3731

3632

Qty.

29

30

31

32

33

34

35

36

37

38

39

40

41

3/8 Rubber Hose 12’

Spray Wand & Nozzle

1/4 MPT x 1/4 FPT Valve

1/4 MPT x 1/2 HB Hose Barb

1/2 Clear Hose 40”

Nylon Tee, 1/2

1/2 Clear Hose 19-1/4

11/16 MPS x 1/2 HB ELB HB w/Nut

Vinyl Cover

Nozzle 2.5 Brown

Boom Angle

Drain Cap W/Washer

Grommet 5/8 H.D. X 3/8 Thick

3773

3611

3730

3729

3775

3723

3776

3725

3638

3719

3724B

3733

3639

1

1

1

1

1

1

2

2

2

2

1

1

1

PLUMBING ASSEMBLY

STEP 2 Attach Boom Mount to Cart Body using 5/16” x 3/4” Hex Head Bolts(2), 5/16” Flat Washers(4), 5/16” Lock Washers(5)

and 5/16” Hex Head Nuts (6),(Fig.5). Attach Boom Arm Assembly to Boom Mount using 5/16” x 3/4” Hex Head Bolts(2),

5/16” Flat Washers(4), 5/16” Lock Washers(5) and 5/16” Hex Head Nuts(6), (Fig. 6). Tighten all four Bolts with the 1/2”

wrenches.

Parts List for Pump Assembly

SEE BELOW FOR PLUMBING

ASSEMBLY

12

13

15

16

17

18

19

21

28

28

20

13

14

21

22

23

24

28

27

28

26

25

29

30

31

11

32

11

11 11

33

34

35

36

37

18

38

11

5/16” Hex Head Nut

5/16” Lock Washer

Fig. 6

14

Hose from Ball

Valve off of Pump

11

40

39

**Part quantities reflect pieces assembled at factory

and those in hardware sack.

Boom Arm

Assembly

Drain Cap

*The strainers for boom assembly are located inside

part number 39-Nylon Nozzle Fitting.

Introduction

Your sprayer has been manufactured to provide the maximum

in dependable efficient use. Proper operation and maintenance

will ensure long satisfactory service. Study this manual carefully

to become familiar with the operation and maintenance

instructions.

Keep your manual in a safe, convenient place for future

reference. Always mention the model and part number in any

correspondence. To insure correct parts service be sure to

use part number and description when ordering.

Operation

Operating power is obtained from a 12 volt direct source or

cigarette lighter plug. Be sure to connect the red to the

positive (+) source and attach the black to the negative ( - )

source.

Before spraying chemicals, fill the tank full

of plain water to allow familiarization with the sprayer and to

prevent waste of expensive chemicals.

IMPORTANT:

Sprayer Maintenance

.

A sprayer is a carefully designed and built machine that should

provide many years of reliable service if properly cared for.

The main rule in caring for any sprayer is:

Neglect costs dollars in repairs, wasted spray material and

premature replacement of the sprayer.

KEEP IT CLEAN

Cleaning & Storage

Most spray materials are highly corrosive. The most important

aspect of long dependable service from the sprayer is a thorough

cleaning immediately following each use. In addition, the residue

of one type of chemical could cause an undesirable effect when a

different chemical is used for a different purpose.

The most effective cleaning method is to pump several rinses of

clean water through the tank, pump, hoses, boom, spray gun, etc.

A neutralizing agent such as a solution of Nutra-Sol, a detergent or

household ammonia as recommended by the chemical manufacturer

can assist in removal of a persistent chemical. When the system is

thoroughly cleaned drain the tank, suction line, pump, hoses, etc.

The following steps should be followed for the maintenance and

storage of your sprayer.

1. Wash and flush out sprayer after completion of each phase

of your program. Flush out sprayer when changing chemicals if

there is a possibility of the chemicals being incompatible. Use of a

detergent is advisable if the chemical manufacturer does not make

specific cleaning recommendations. Flush system completely,

including nozzles. Never use metal objects to open clogged

nozzles.

2. Clean sprayer thoroughly before storing at the end of the

spraying season. Permanent type anti-freeze added to the final

rinse will leave a rust inhibiting film in parts of the sprayer.

37

41

Fig. 3

3/4” Flat Washer

Cotter Pin

Axle Slot

Fig. 1

Ref.

No.

Part

No.

1 1840 1/2”x 1-3/4” Clevis Pin

2 1248 5/16” x 3/4” Hex Head Bolt

3 1042 #14 Hitch Pin Clip

4 1044 5/16” Flat Washer

5 1276 5/16” Lock Washer

6 1275 5/16” Hex Head Nut

7 3739 3/4” In Diam. x 2” Flat Washer

8 1264 3/4” Flat Washer

9 1262 1/8” x 1-1/4” Cotter Pin

1

6

1

6

6

6

4

2

2

Part Description

Hardware

Sack Qty.

Trailer Sprayer

ASSEMBLY INSTRUCTIONS & PARTS LIST 03/05

PRECISION PRODUCTS, INC.

3736-6

Assembly Hardware

Assembly Instructions

Cart Body Assembly Parts

LIMITED WARRANTY

This unit is warranted against defects in materials and workmanship to the original

purchaser, under normal use and service, for a period of ninety (90) days from date

of sale. During the Warranty Period, we will repair or replace at our option free of

charge to the original purchaser, any part of the Unit that our examination shows to

be defective in workmanship or materials. This Warranty apply to damage

caused by misuse, abuse, neglect, accident, normal wear, or alterations by

unauthorized persons.

Does Not

The electric pump on this model has its own warranty. Precision Products, Inc. does not carry

a warranty on the pump. Please refer to the parts list and operation manual for the pump

included with this model.

PRECISION PRODUCTS, INC.

Fig.3

Tools needed for assembly:

Two 1/2” Wrenches

1 Pair Needle Nose Pliers

123

5

8

9

7

6

4

Fig. 2

3/4” Diameter x 2”

Flat Washers

Axle

1/2”x 1-3/4” Clevis Pin

5/16” x 3/4” Hex Head Bolt

#14 Hitch Pin Clip

5/16” Flat Washer

5/16” Lock Washer

5/16” Hex Head Nut

3/4” Diameter x 2” Flat Washer

3/4” Flat Washer

1/8” x 1-1/4” Cotter Pin

5/16” x 1/2” Hex Head Bolt

1

2

4

42

6

3

43

44

7

10

5

8

9

2

4

45

47

5

6

5

6

62

4

5/16” Lock

Washers

Fig. 4

5/16” x 1” Hex

Head Bolts

5/16” Flat

Washers

Clevis

5/16” Hex

Head Nuts

46

STEP 1 Insert Axle through Axle Slot on Cart Body. Once the Axle is through the hole, slide on one 3/4” x 2” Flat Washer(7) then the

Axle Tube Spacer(44), then slide the Axle through to the end of the Axle T

ube Spacer. Add another 3/4” x 2” Flat Washer (inside

of the Sprayer Cart body) and push the Axle through the other hole on the Cart Body. Once the Axle is through the second hole,

slide on a 3/4” ID x 2” Flat Washer(7), (Fig.2). Now slide on a wheel followed by a 3/4” Flat Washer(8) and then secure with

a Cotter Pin(9). Repeat this for both Wheels. Use Needle Nose Pliers to bend back ends of the Cotter Pin,(Fig.3). Repeat for

other side. Using 5/16” x 3/4” Hex Head Bolts(2), 5/16” Flat Washers(4), 5/16” Lock Washers(5), and 5/16” Hex Head Nuts(6)

attach Clevis, (42),(on topside of Cart Body) to the Cart Body (Fig. 4). Tighten Bolts with 1/2” wrenches. Insert Clevis Pin(1)

through Clevis and secure with #14 Hitch Pin Clip(3) underneath Cart Body.

1

2

3

4

5

6

7

8

9

10

Ref. Part Description Part Number

Qty.

1840

1248

1042

1044

1276

1275

3739

1264

1262

1249

1

6

1

6

10

6

4

2

2

4

42

43

44

45

46

47

Ref. Part Description Part Number

Qty.

Clevis

Axle

Axle Tube Spacer

10” Pneumatic Wheel for TCT

TCT Cart Body

Boom Mount

1243P

3769

3767

3768

3740R

3766R

1

1

1

2

1

1

**Part quantities includes pieces assembled at factory

and those in hardware sack.

TCT15

TCT15RT

Cart Body

3/4” Diameter x 2”

Flat Washers

Axle Spacer

5

When ordering parts, always give model number,

part description, & part number.

Precision Products, Inc.

Parts Division (217)735-1590

316 Limit Street (217)735-2435

Lincoln, IL 62656

or visit us on the world wide web :www.precisionprodinc.com

Send To:

Phone

Fax

Customer Service

CUSTOMER SUPPORT

At Precision Products, Inc. delivering quality, value and outstanding service is our goal.

However, sometimes parts do become damaged or lost during transport from our facilities to

the store. If you have any problems, please do not return this merchandise to the store.

Call us and we will take care of any problem you may have with this unit.

This manual suits for next models

1