Precision Sharpening Devices Bevel Buddy User manual

Bevel Buddy™

Instruction

Manual

We at Precision Sharpening Devices Inc. believe there are two very important

steps in maximizing the savings this equipment can provide your company. First,

use this manual to educate your operators in the proper set-up and operation

of this equipment. Second, plan to keep the knives sharp at all times. Do not let

the knives go beyond the resharpening point. A chipper is no better than the

knife edge itself. We always invite your questions and comments concerning

our products. We feel that these innovative resharpening devices will help

you remain competitive in the wood processing industry.

Table of Contents

1. Safety Instructions

2. Type of machine the sharpener is being used on and which abrasive to use

3. Proper Operating Procedures

4. Abrasive indexing procedure

5. Assembly view and parts list

6. Bevel Buddy™ Accessories

7. Limited Warranty

Precision Sharpening Devices Inc.

5051 Iroquois Ave.

Erie, PA 16511

Phone :814-899-0796 Fax :814-899-8777

www.bevelbuddy.com

www.precisionsharpeningdevices.com

1. Safety Instructions

READ BEFORE USING

Do not expose this sharpener to rain or wet conditions

ALWAYS remove the battery from the tool or disconnect from

the power source before making any adjustments or changing /

indexing the abrasive, and storing the sharpener in the supplied

storage case.

When the battery pack is not in use, do not store it around any

loose metal objects, keep it in the storage box.

If the battery ever has leakage, remove it from use and replace

it with a new one.

DO NOT store the sharpener or the battery in temperatures

below 32º or above 113º Fahrenheit, battery or motor damage

may occur. Charge the battery pack in temperatures between

32º and 113º Fahrenheit only as well. Please recycle your dam-

aged or worn out batteries at a certified recycling center.

ALWAYS wear safety glasses when the sharpener is in use and

avoid breathing the grinding dust associated with the resharp-

ening .

ALWAYS lock out the chipper drive motor to ZERO ENERGY

STATE before resharpening the knives.

NEVER force the resharpener into a work area, always ease into

the knife sharpening.

2. Type of machine the sharpener is being used on and which abrasive to

use for that set-up.

When using our resharpeners you must ALWAYS counter grind / back bevel on the side of the knife that the material

discharges from only!! NEVER attemptto resharpen the feed side of the knife!

Pocket mounted knife for disc style chipper,

use drum style abrasive #A-MDA0195-D80.

Note: Roller position and abrasive contact to

knife.

FOR KNIVES BETWEEN 29º TO 36º

FOR KNIVES BETWEEN 29º TO 36º

FOR KNIVES BETWEEN 29º TO 36º

Face mounted style knife, use drum style

abrasive #A-MDA0195-D80.

Note: Roller position and abrasive contact to

knife.

Drum style chipper knife, use drum style abra-

sive #A-MDA0195-D80.

Note: Roller position and abrasive contact to

knife.

Plywood lathe knife set-up,

use cone style abrasive

#A-MDA0197-C80 with large

diameter of abrasive away

from the drive motor.

Pole Peeler or some small chippers knife set

-up. Use cone style abrasive

#A-MDA0197-C80 with large diameter of

abrasive toward the drive motor. There

may be times on this more blunt angle style

knife when you need to make a minor ad-

justment on the top roller bracket opening

(#2 spring loaded bracket.) Using a pair of

pliers slightly bend each side outward,

1/16” at a time until proper abrasive knife

contact is achieved.

Disc chipper modified set-up, there may be

times on a disc chipper set-up when a knife

is shortened to make a smaller chip like

those used in pellet manufacturing. The uni-

versal grinding head may come in contact

with the disc wear plate. In this set-up you

must do two things: Use the cone style

abrasive #A-MDA0197-C80 with the large

end away from the drive motor. Then you

may have to tune the lower set of rollers by

bending them away from or back towards

the drive motor approximately 3/16” to 1/4”

making sure they are both bent at the same

angle. This will allow the motor mount to

move away from the disc wear plate.

FOR KNIVES BETWEEN 22º TO 25º

FOR KNIVES BETWEEN 42º TO 45º

3. Proper Operating Procedures

Before using the Bevel Buddy Resharpener make sure the proper abrasive for the task is

applied to the resharping tool, refer to section 2 for the set-up.

When performing the resharpening process on the knife, as you are facing the disc and it

turns counter clockwise start the sharpening process from your right and move to the left.

On a clockwise rotating disc, start the sharpening process an your left and move to the

right.

Apply very little pressure on the sharpener to knife edge. The diamond abrasive is very

aggressive, so to avoid over grinding always keep sharpener in motion while sharpening the

knife. One pass per knife is usually sufficient per sharpening. *REMEMBER let the abrasive

do the work!

The counter ground path on the back of the knife should be approximately 1/16” to 1/8”

wide.

We suggest resharpening the knives in the chipper no more than 3 times before removing

them to be sharpened in your stationary grinder or reversed on a turn knife system.

Drive motor operating speed for the Bevel Buddy™ Max:

4. Abrasive Indexing Procedure

When the abrasive becomes worn on the drum or cone area, the drive motor can be adjusted

back to a fresh area for proper sharpening.

A.) Loosen the thumb screw on the sharpener head

B.) Hold universal grinding head and turn the drive motor counter clockwise 180º or ½ turn.

C.) Snug set screw slightly to lock the head and motor, this will give you a new abrasive area

to sharpen your knives.

D.) This indexing procedure can be performed 3 times before the abrasive must be replaced.

E.) Make sure your sharpener is in the zero energy state—unplugged from power source.

F.) To replace the abrasive: Remove the battery from the drive motor or disconnect the

drive motor from the power source. Loosen the locking set screw, turn the drive motor

counter clockwise to remove the universal grinding head. Hold the spindle lock button down

and twist the abrasive clockwise to remove it. Reverse the procedure to attach the new abra-

sive

G.) When threading the drive motor back into the universal grinding head, make sure you DO

NOT cross thread it. The motor threads are plastic.

Clean grinder head weekly. (Blow off with compressed air only)

12 volt battery sharpener must be started in low speed. You then increase

it to high speed, sharpen your knives, then decrease back to low speed to

turn it off.

12 volt charger green light will be blinking while the battery is charging and

on solid green when the battery is fully charged.

12 volt corded—ON / OFF switch

120 volt —ON / OFF switch

5. Bevel Buddy™ Max Assembly view & parts list.

7. Limited Warranty

Precision Sharpening Devices Inc. warrants this product to the original purchaser for one

year from the date of purchase. We will repair, free of charge, any defects caused by faulty

material or workmanship.

This warranty shall not apply to equipment or parts thereof which have been altered or re-

paired outside of the Precision Sharpening Devices Inc. factory, or subjected to mis-use,

abuse, neglect or accident, or damage by improper installation or application.

This warranty is non-transferable and does not cover damage resulting from other than de-

fect in material or workmanship, damage caused by unreasonable use, including the failure to

provide reasonable and necessary maintenance.

This limited warranty is in lieu of all other express warranties. Any implied warranty of fit-

ness for a particular purpose, merchantability or otherwise, applicable to this product shall

be limited in duration to the duration of this limited warranty. Precision Sharpening Devices

Inc. shall not be liable for any special, incidental or consequential damages.

Some states do not allow limitations on how long an implied warranty lasts, so the above limita-

tions on how long an implied warranty lasts may not apply to you.

This warranty gives you specific legal rights and you may also have other rights which vary

from state to state. QUALITY AND PERFORMANCE ASSURED

Our motto to our knived friends,

“Chip more not change more!”

Drum Abrasive #A-MDA0195-D80………….…..$79.95 USD

Price is subject to change without notice.

Rev 3-5-2013

Mount permanently to your machine this 12 volt

plug assembly for the Bevel Buddy™ Sharpener.

Chrome over brass with water resistant cap.

BBPLUG………….……………………………………$34.00

6. Bevel Buddy™ Accessories

Maxx

12 Volt Battery #B812-01…..…………………………………………...…..$64.95 USD

Reversible Cone Abrasive #A-MDA0197-C80..$79.95 USD

(for plywood, pole peelers and some small chippers)

Table of contents

Popular Power Tools manuals by other brands

Omer

Omer 32.18 M Use, maintenance and spare parts manual

Edge Craft

Edge Craft Chef'sChoice 490 instructions

Vortec

Vortec 610 Operation & Safety Instructions

Bosch

Bosch GOF 2000 CE Original instructions

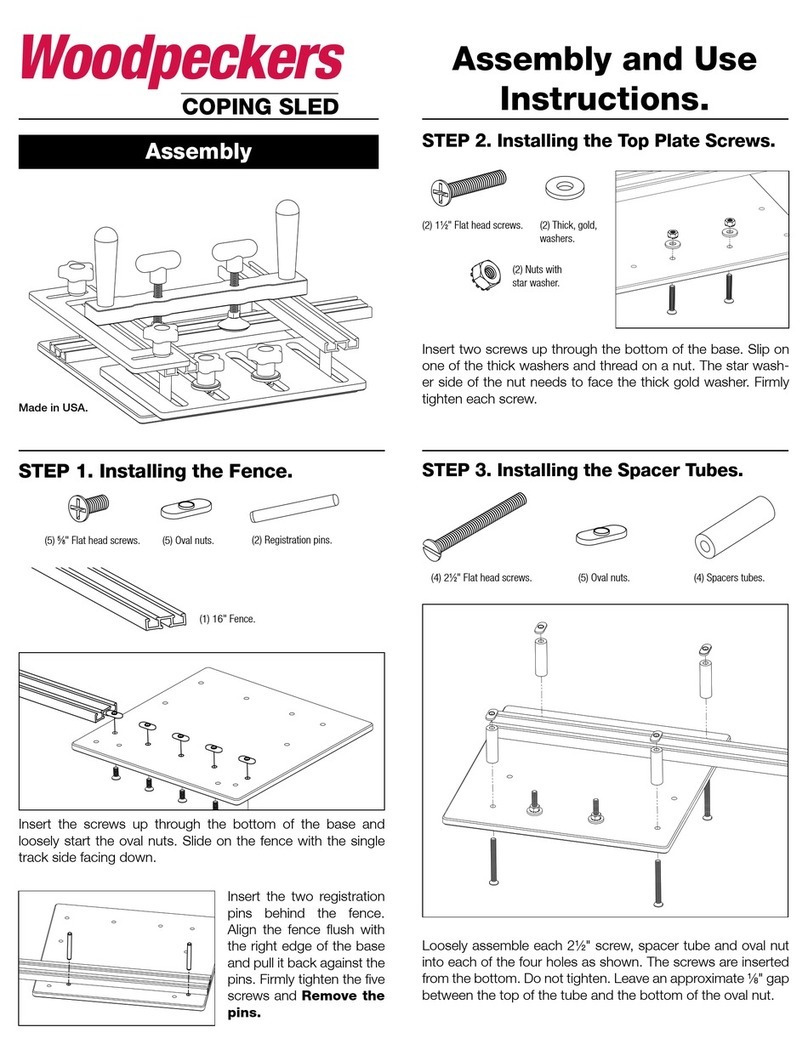

Woodpeckers

Woodpeckers Coping sled Assembly and use instructions

ALFRA

ALFRA TMC 300 operating instructions

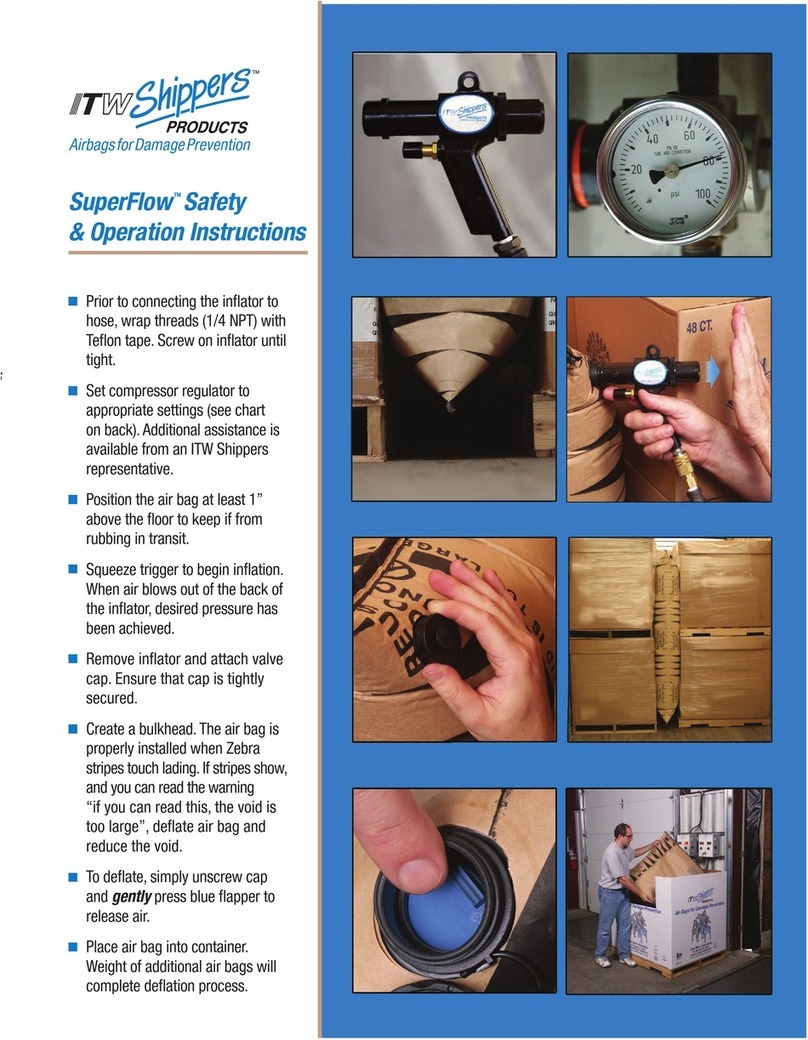

ITW

ITW SuperFlow Safety & Operation Instructions

Hitachi

Hitachi H 25PV Handling instructions

Black & Decker

Black & Decker RT5300 instruction manual

Black & Decker

Black & Decker Wizard RT550; Wizard RT555; Wizard RT560 instruction manual

molex

molex TM2000 Operation manual

Kompernass

Kompernass Sensitive Drill Assembly instructions