OPERATION

To regulate the Cold Air Gun temperature, turn the

adjustment knob at the back of the Gun. Turning the knob

counterclockwise will reduce the temperature and volume

of the cold air stream. When operating the Cold Air Gun at

compressed air pressures below 100 psig (6.9 Bar), it is

possible to open this valve too far so that there is no cold air

ow. Turn the knob clockwise to increase the cold air ow

and temperature.

Maximum cooling capacity (not the coldest temperature)

occurs when there is a balance between cold air volume

and cold air temperature drop. In other words, there must

be an adequate volume of cold air at a reasonable cold

temperature to achieve the maximum cooling effect. In

normal operation, this will occur when the adjustment knob

is turned 1/4 to 3/8 open (counterclockwise) from the full

closed (clockwise) position.

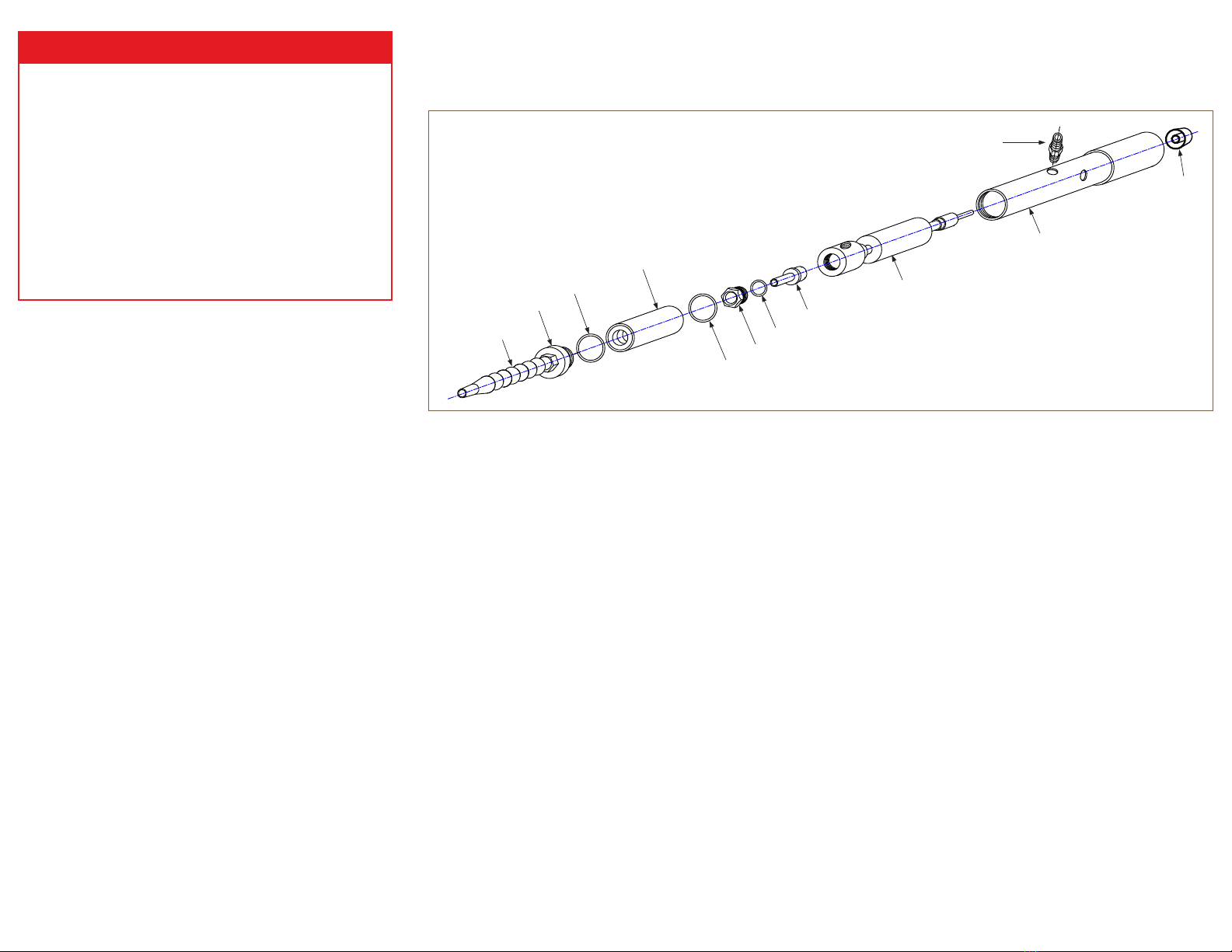

MAINTENANCE

The Cold Air Gun has no moving parts (other than the

adjustment knob), and requires only ltered compressed air

for proper operation.The Cold Air Gun can be disassembled

for cleaning, if necessary, as shown above. If the Gun has

been disassembled for cleaning, the Cold Cap must be

reassembled tightly to ensure that the Generator seats

tightly against the body assembly. A loose Cold Cap will

reduce cooling capacity.

1. Do not operate the Cold Air Gun at air pressures

above 150 psig (10.3 Bar).

2. Do not operate the Cold Air Gun at line temperatures

above 110

o

F (43

o

C).

3. Avoid direct contact with compressed air.

4. Do not direct compressed air at any person.

5. When using compressed air, wear safety glasses

with side shields.

ADJUSTABLE COLD AIR GUN ASSEMBLY

LIMITED WARRANTY

Vortec compressed air products manufactured by ITW Air

Management will be replaced or repaired if found to be

defective due to manufacture defect within ten years from

the date of invoice.

Refer to our website www.vortec.com for full warranty

details and limitations. ITW Air Management makes no

specic warranty merchantability or warrant of tness to a

particular purpose.

Insufficient airow may be caused by the following:

1. Undersized compressed air line size.

2. Compressed air pressure too low.

3. Partial or complete blockage of internal compressed air

path, due to dirt. See Maintenance section for cleaning

instructions; and Compressed Air Supply section for lter

recommendations.

4. Insufficient compressed air volume.

5. Loose cold cap. This may occur if not tightened properly

after disassembled for cleaning.

If trouble persists, please contact Vortec at 1-800-441-7475.

TROUBLESHOOTING

The compressed air supply must be ltered to remove water

and dirt using a 5 micron or smaller lter. Failure to use a

lter may cause clogging (and freezing) of the compressed

air paths inside the Vortec product. Filter recommendations

are given in Table 1.

Filter elements must be changed on a regular basis.

Frequency of change is determined by the condition of

the compressed air supply. Filters should be installed in

the compressed air supply line as close as possible to the

Vortec product.

The appropriate size of compressed air supply line should

be selected to ensure optimal performance of the Vortec

product. Please refer to Table 2 to determine what supply

line size is recommended for your application. Contact

Vortec at 1-800-441-7475 for further assistance.

When the desired cold air stream temperature is less than

32oF (0oC), a compressed air dryer may be necessary to

prevent ice formation on the inside of the Vortec product.

COMPRESSED AIR SUPPLY

INSTALLATION

A Cold Air Gun can be installed by directly plumbing to the

appropriately-sized hard piped compressed air source that

does not exceed 150 psig (10.3 Bar).

INTRODUCTION

A Cold Air Gun is a device that converts ltered, 100 psig

(6.9 Bar) compressed air into a cold airstream.

The Adjustable Cold Air Gun consumes 15-35 SCFM (425-

990 SLPM) of compressed air and is perfect for a wide range

of industrial spot cooling and dry machining applications.

(Drawings shown below are not to scale)

Model 610, 620 and 630

GENERAL SAFETY CONSIDERATIONS

WARNING: COMPRESSED AIR COULD CAUSE

DEATH, BLINDNESS OR INJURY

Flexible Nozzle

Assembly

Threaded Cap

-219 size O-ring

Cold Air Mufer Assembly

-029 size O-ring

Cold End Cap

-116 size O-ring

Generator (see Table 1)

Main Body Assembly

Blue Encapsulation Sleeve

Adjustment

Knob

Inlet Fitting