Makita HR001G User manual

Other Makita Power Tools manuals

Makita

Makita DTW284 User manual

Makita

Makita DTW450 User manual

Makita

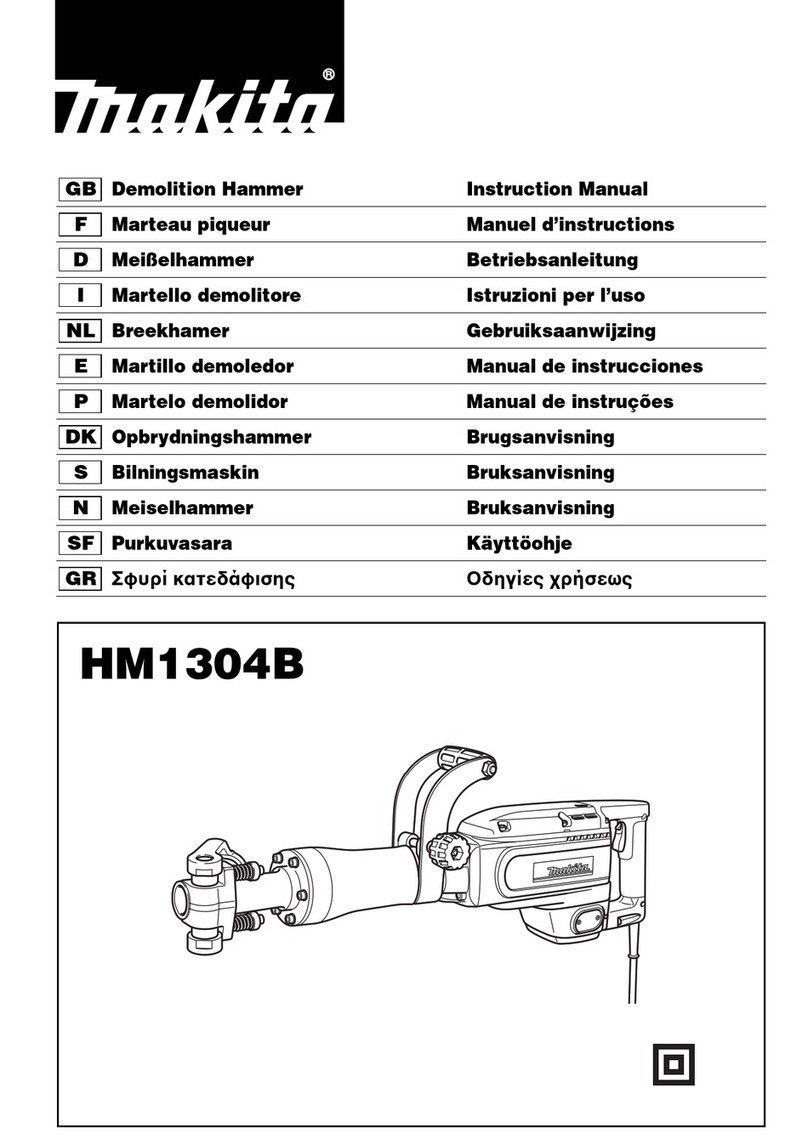

Makita HM1304B User manual

Makita

Makita RP1800 User manual

Makita

Makita DTM41 User manual

Makita

Makita SG1251 User manual

Makita

Makita LXJP02 User manual

Makita

Makita DTS131 User manual

Makita

Makita HM1800 User manual

Makita

Makita DHR182 User manual

Makita

Makita DHR263 Manual

Makita

Makita DTW250 User manual

Makita

Makita JS1600 User manual

Makita

Makita TB131 User manual

Makita

Makita DHR263Z User manual

Makita

Makita Makstar BVR450 User manual

Makita

Makita DTW450 User manual

Makita

Makita DTW253Z User manual

Makita

Makita JR100D User manual

Makita

Makita HM1801 User manual