PRECITEC CHRocodile CLS0.2 User manual

1

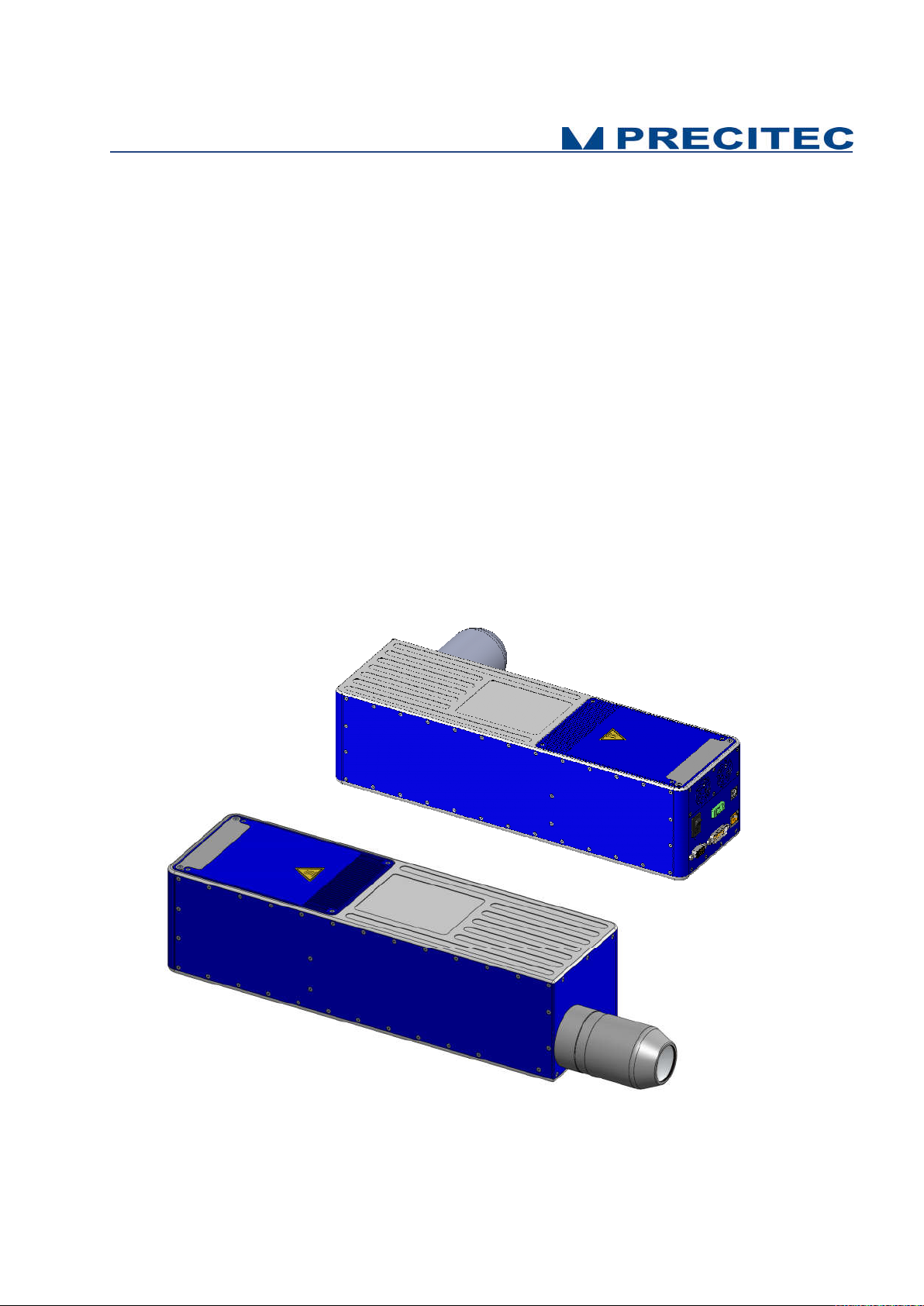

CHRocodile CLS

Optical line sensor for non-contact distance and thickness measurement

Operation Manual

2

Imprint

This documentation is under the copyright of Precitec Optronik GmbH.

It may not be reproduced or used in a manner contrary to the company’s legal interests without prior

written approval of Precitec Optronik GmbH. It is strictly intended for use in the context of service

operations. Any other use is impermissible. Any sharing of this documentation with third parties

requires the prior, expressed written approval of Precitec Optronik GmbH.

Changes in the technical details from the descriptions, data and figures in this documentation are

reserved.

Printed in the Federal Republic of Germany.

Responsible for Contents

Original Edition

Precitec Optronik GmbH

Schleussnerstrasse 54

63263 Neu-Isenburg / Germany

Telephone: 0049 (0)6102 / 36 76 – 100

Telefax: 0049 (0)6102 / 36 76 – 126

e-mail: info@precitec-optronik.de

Website: http://www.precitec.de/en/precitec-group-start-page/

Representatives

Please visit our website to know the current addresses of our representatives.

PRECITEC OPTRONIK's regional contacts for the Optical Measuring Technology can be found here:

http://www.precitec.de/en/contact/precitec-worldwide/

3

Version Control

Version –

Manual Date Type of Change

1.0.0.0 2014/01/29

Original edition

1.0.0.1 2014/03/13

Updated Mechanical plans and specifications

1.0.0.2 2014/05/12

Auto Reference procedure

1.0.0.3 2014/05/22

Specifications correction

1.0.0.4 2014/09/09

EMC compatibility + Jumbo packet + Medical or safety-relevant usage

1.0.0.5 2014/11/06

Ethernet connection + Status LED + Optical head specifications

1.0.0.6 2015/09/17

Optical head specifications + Sync In additional information + CLS

Explorer + 6KHz measuring mode + CLS Explorer Library coming soon +

DLL C++.

1.0.1.0 2016/03/10

New Optical Head CLS2.3

1.0.1.1 2016/07/18

Encoder interface modification + CLS Explorer Ultimate version + High

frequency mode used with CLS2.3 + Auto-reference procedure disabled

4

Table of Contents

Table of Contents ........................................................................................................... 4

Basic Safety Instructions ................................................................................................ 8

1.1 Warranty and Liability ...................................................................................... 8

1.2 Safety Symbols .................................................................................................. 8

1.3 Proper Use ......................................................................................................... 9

1.4 Duty of Operator and Personnel ..................................................................... 10

1.5 Safety Measurements in Normal Operation ................................................... 10

1.5.1 Protection from Electronic Shock .......................................................................................... 10

1.5.2 Protection from Optic Radiation / Eye Safety ..................................................................... 10

1.5.3 Grounding the device .............................................................................................................. 11

1.6 Medical or safety-relevant usage .................................................................... 11

1.7 Storage and Transport ..................................................................................... 11

1.8 Emergency Procedures .................................................................................... 11

Product Description ....................................................................................................... 12

2.1 General Description ......................................................................................... 12

2.2 Measuring principle .......................................................................................... 13

2.2.1 Optical principle ..................................................................................................................... 13

2.2.2 Principle applied to multiple points sensor .......................................................................... 14

2.3 Sensor Functionalities ...................................................................................... 15

2.4 Typical applications (Overview) ...................................................................... 17

2.5 List of Deliverables ......................................................................................... 18

2.6 Connections and Interfaces ............................................................................ 20

2.6.1 ON / OFF Switch button .........................................................................................................20

5

2.6.2 Power supply jack ...................................................................................................................20

2.6.3 USB port RS232 serial communication................................................................................... 21

2.6.4 Ethernet connector ................................................................................................................. 21

2.6.5 Encoder-input .......................................................................................................................... 21

2.6.6 Trigger Input/Output / RS422 serial communication .......................................................... 22

2.6.7 Status LED ................................................................................................................................ 24

2.7 Sensor Characteristics .................................................................................... 25

2.7.1 Sensor unit characteristics ..................................................................................................... 25

2.7.2 High Frequency Mode.............................................................................................................. 26

2.7.3 Optical Heads characteristics ................................................................................................ 27

2.8 Optical Head Specifications definitions ......................................................... 28

2.9 CHRocodile CLS performance specifications: ................................................ 29

Operational Start up ...................................................................................................... 31

3.1 Connections and Interfaces ............................................................................. 31

3.2 CHRocodile CLS Explorer and Drivers installations ....................................... 33

3.3 Communication with CHRocodile CLS ............................................................ 33

3.4 CLS Explorer Library ....................................................................................... 34

Measurements Start Up ................................................................................................ 36

4.1 Calibration Table ............................................................................................ 36

4.2 Dark Acquisition .............................................................................................. 36

4.3 Auto Reference procedure ............................................................................. 37

4.4 Mechanical interfacing ................................................................................... 37

4.5 Basic Settings Configuration ........................................................................... 38

4.6 Data measurement Training ........................................................................... 38

Advanced Configuration ................................................................................................ 41

5.1 Commands List ................................................................................................. 41

This manual suits for next models

3

Table of contents