Preco S Series Quick start guide

1

FLIGHT CONVEYOR

S, SL and SB series

ASSEMBLY AND OPERATIONAL

MANUAL

2

Content

INTRODUCTION.................................................................................................................................................................... 4

EU DECLARATION OF CONFORMITY............................................................................................................................ 5

SAFETY INSTRUCTION........................................................................................................................................................ 6

General safety.................................................................................................................................................................... 6

Electrical safety ................................................................................................................................................................. 7

Security stickers................................................................................................................................................................ 7

STANDARD EQUIPMENT ................................................................................................................................................... 8

Standard equipment for S type.................................................................................................................................. 8

Standard equipment for SL type................................................................................................................................ 9

Standard equipment for SB type .............................................................................................................................10

CONVEYOR SUPPORT.......................................................................................................................................................11

LIFTING CONDITIONS.......................................................................................................................................................12

ASSEMBLY OF FLIGHT CONVEYOR..............................................................................................................................13

Tension unit .....................................................................................................................................................................14

Drive unit...........................................................................................................................................................................14

Overflow membrane.....................................................................................................................................................15

Top cover dismantling .................................................................................................................................................15

Tension unit, extensions and drive unit.................................................................................................................16

Chain assembly...............................................................................................................................................................17

Chain tension...................................................................................................................................................................18

Top cover assembly ......................................................................................................................................................18

Double-sided inlet assembly.....................................................................................................................................19

Inlet assembling .............................................................................................................................................................20

Outlet assembling..........................................................................................................................................................20

ACCESSORIES.......................................................................................................................................................................21

Cover of inner-floor ......................................................................................................................................................22

Enclosed double-sided inlet ......................................................................................................................................23

Slide assembly.................................................................................................................................................................24

Motor cover assembly..................................................................................................................................................25

Slide cover assembly ....................................................................................................................................................25

Support truss...................................................................................................................................................................26

Shaft speed monitor.....................................................................................................................................................27

3

ELECTRICAL ASSEMBLY....................................................................................................................................................27

STARTING UP THE FLIGHT CONVEYOR .....................................................................................................................28

MAINTENANCE....................................................................................................................................................................28

TROUBLESHOOTING .........................................................................................................................................................29

MAINTENANCE PERIODIC TABLE.................................................................................................................................30

4

INTRODUCTION

The assembly and operating manual contains information about flight conveyor technical

specifications, main parts, accessories, assembly, general and electrical safety instructions.

Preco flight conveyors are ideal for product transportation horizontally or at an angle up to

45 degrees. Available in various models and sizes, depending on required capacity. Preco conveyors

are made in an industrial performance that guarantees safety in operation.

Conveyor is designed for indoor and outdoor use in temperatures from -25℃to + 40℃.

The conveyor must be connected to a three-phase AC power source with a current frequency

of 50Hz, 380V voltage, grounding and safety switch.

IMPORTANT!

•Read this assembly manual carefully before starting the installation and start-up

operations

•Electrical installation work may be carried out only by a qualified electrician / electro

engineer

•Always disconnect conveyor from the power source before installation, maintenance

and repair of the conveyor

•Keep the manual in an accessible place.

CE label:

The label is located on the tension section and is proof that the machine is manufactured in

accordance with EU directives and safety regulations.

A –Manufacturer

B –CE marking

C –Conveyor type / model

D –Conveyor serial nr.

E –Year of production

B

A

C

D

E

5

EU DECLARATION OF CONFORMITY

Manufacturer: Ltd. “PRECO”

Address: Dravnieku Street 16, Lielvārde, Lielvārdes reg.,

LV-5070, Latvia

Tel.: +371 650 71 850

We declare that

Equipment: Flight conveyors

Equipment models: S40, S80, S100, S150, S200, S300, S500 /

S40B, S80B, S100B, S150B, S200B, S300B, S500B /

S40L, S80L, S100L, S150L, S200L, S300L, S500L

Year of production:

Are designed and manufactured in accordance to following directives and standard regulations:

•MK Nr.195 - 2008.03.25. (2006/42/EU) Machinery Directive

TP TC 010/2011 Technical Regulation of the Customs Union

•MK Nr.209 - 2016.04.12. (2014/35/EU) The Low Voltage Directive

TP TC 004/2011 and TP TC 020/2011 Technical Regulation of the Customs Union

•ATEX 2014/34/EU Zone 21, category II 2D/0D Safety of machinery. Equipment and

protective systems intended for use in potentially explosive atmospheres.

•LVS EN ISO 12100:2010 Safety of machinery. General principles for design - Risk

assessment and risk reduction

•LVS EN ISO 13857:2008 Safety of machinery. Safety distances to prevent hazard zones

being reached by upper and lower limbs.

6

SAFETY INSTRUCTION

General safety

The manual must be freely available to assembly personnel, electricians, service engineers and

equipment operators at any time. Incorrect assembly and/or operation may lead to personal injury

or damage to the equipment. It can also cause malfunctions or a reduction in capacity. Carefully read

the assembly and operational manual before assembly, electrical equipment connection,

maintenance or operation start. If any part of these instructions is not understandable, please contact

with manufacturer for assistance.

WARNING!

•Disregarding warnings given in this instruction may cause serious personal injury or death.

•Ignoring the instructions given may cause damage to the equipment.

•Ensure that everyone responsible for assembly, electrical connection, maintenance and

operation of the conveyor has read and understood the instructions and safety information.

•Wear protective gloves, head protection, steel-toed boots, ear protection, protective goggles

and high visibility vest when carrying out assembly, electrical connection, maintenance and

operation of conveyor.

IMPORTANT!

•For drive and tension section maintenance whose supports are located at the height of

more than 2 m from the floor it is required to assemble service platforms with handrails.

The service platforms must comply with local government laws and regulations.

•Conveyor supports are not included in standard delivery. It is customer responsibility

to arrange supports for the conveyor. Maximum distance between them must not

exceed 6 m.

•All rotating parts must be safely secured and protected. Do not operate with safety

guards removed.

7

Electrical safety

WARNING!

•Stop the conveyor and turn off electric power before attempting any type of assembly,

electrical or maintenance work

•Do not start the conveyor with removed or damaged safety covers.

•All electrical connections must be mounted properly and fully enclosed. Electrical installation

must be performed by Qualified electrician.

•Conveyor usage is forbidden without electrical grounding.

INFORMATION!

•If the conveyor is assembled outdoors, it must be fitted with a motor cover.

•If a short circuit occurs, ensure that the electrical equipment is in working order before

continuing an operation.

•Ensure that the electrical equipment is kept free from dirt, dust, moisture and electrostatic

charge.

Safety stickers

1.

Read instruction carefully before

use!

2.

High voltage! Electric shock risk

3.

Warning for rotating drum

4.

Warning for rotating drive shaft

5.

Electrical grounding (on the side

of the conveyor)

8

STANDARD EQUIPMENT

Flight conveyor is manufactured from galvanized sheet metal (275 g/m2) in accordance with

the EU Machinery Directive 2006/42/EC, EU Low Voltage Directive 2006/95/EC and designed in

accordance with EN ISO 12100 part 1-2 which guarantees machinery safety. Intended for horizontal

or elevated transportation up to 45° angle. Model capacity for grain with 750 kg/m3density and 15%

moisture content. Transporting beans or peas conveyor capacity needs to be reduced by half using

a slide or a flow regulator. Please take note that every 1% increase in moisture content above 15 %

decreases capacity by 3-4 %.

Standard equipment for S type

Model

S40

S80

S100

S150

S200

S300

S500

Capacity, t/h

25

60

80

120

150

250

500

30

80

100

150

200

300

50

60

Capacity, m³/h

33-91

58-124

110-159

174-226

238-303

343-440

584-723

Chain speed, m/s

0.31-

0.92

0.47-

0.93

0.64-

0.79

0.62-

0.94

0.66-

0.88

0.71-

0.86

0.57-

0.76

Chain type, FV

63-63

90-100

90-100

112-125

140-160

180-160

250-160

180-160

250-160

315-160

315-160

400-160

400-160

Thickness, mm

side/floor

2/2

2/2

2/2

3/3

3/3

4/5

4/5

*On-demand performance of other models ** Capacity for wheat 0.75 t/m3, 15% moisture

1. Drive unit

2. Tension unit

3. Extensions in various standard lengths

4. Inlet in respective angle

5. Outlet in respective angle

9

Standard equipment for SL type

Model

S40L

S80L

S100L

S150L

S200L

S300L

S500L

Capacity, t/h

25

60

80

120

150

250

500

30

80

100

150

200

300

50

60

Capacity, m³/h

27-84

54-112

110-139

158-202

202-267

294-440

528-667

Chain speed, m/s

0.28-

0.83

0.44-

0.86

0.60-

0.75

0.70-

0.87

0.61-

0.81

0.62-

0.81

0.57-

0.70

Chain type, FV

63-63

90-100

90-100

112-125

140-160

180-160

250-160

180-160

250-160

315-160

315-160

400-160

400-160

Thickness, mm

side/floor

2/2

2/2

2/2

3/3

3/3

4/5

4/5

*On-demand performance of other models ** Capacity for wheat 0.75 t/m3, 15% moisture

1. Drive unit

2. Tension unit

3. Extensions in various standard lengths

4. Outlet in respective angle

5. Bend section in respective angle

10

Standard equipment for SB type

Model

S40B

S80B

S100B

S150B

S200B

S300B

S500B

Capacity, t/h

25

60

80

120

150

250

500

30

80

100

150

200

300

50

60

Capacity, m³/h

28-84

54-112

110-139

158-202

202-267

294-440

528-667

Chain speed, m/s

0.28-

0.83

0.44-

0.86

0.60-

0.75

0.70-

0.87

0.61-

0.81

0.62-

0.81

0.57-

0.70

Chain type, FV

63-63

90-100

90-100

112-125

140-160

180-160

250-160

180-160

250-160

315-160

315-160

400-160

400-160

Thickness, mm

side/floor

2/2

2/2

2/2

3/3

3/3

4/5

4/5

*On-demand performance of other models ** Capacity for wheat 0.75 t/m3, 15% moisture

1. Drive unit

2. Tension unit

3. Double-sided inlet

4. Outlet in respective angle

5. Bend section in respective angle

6. Extensions in various standard lengths

11

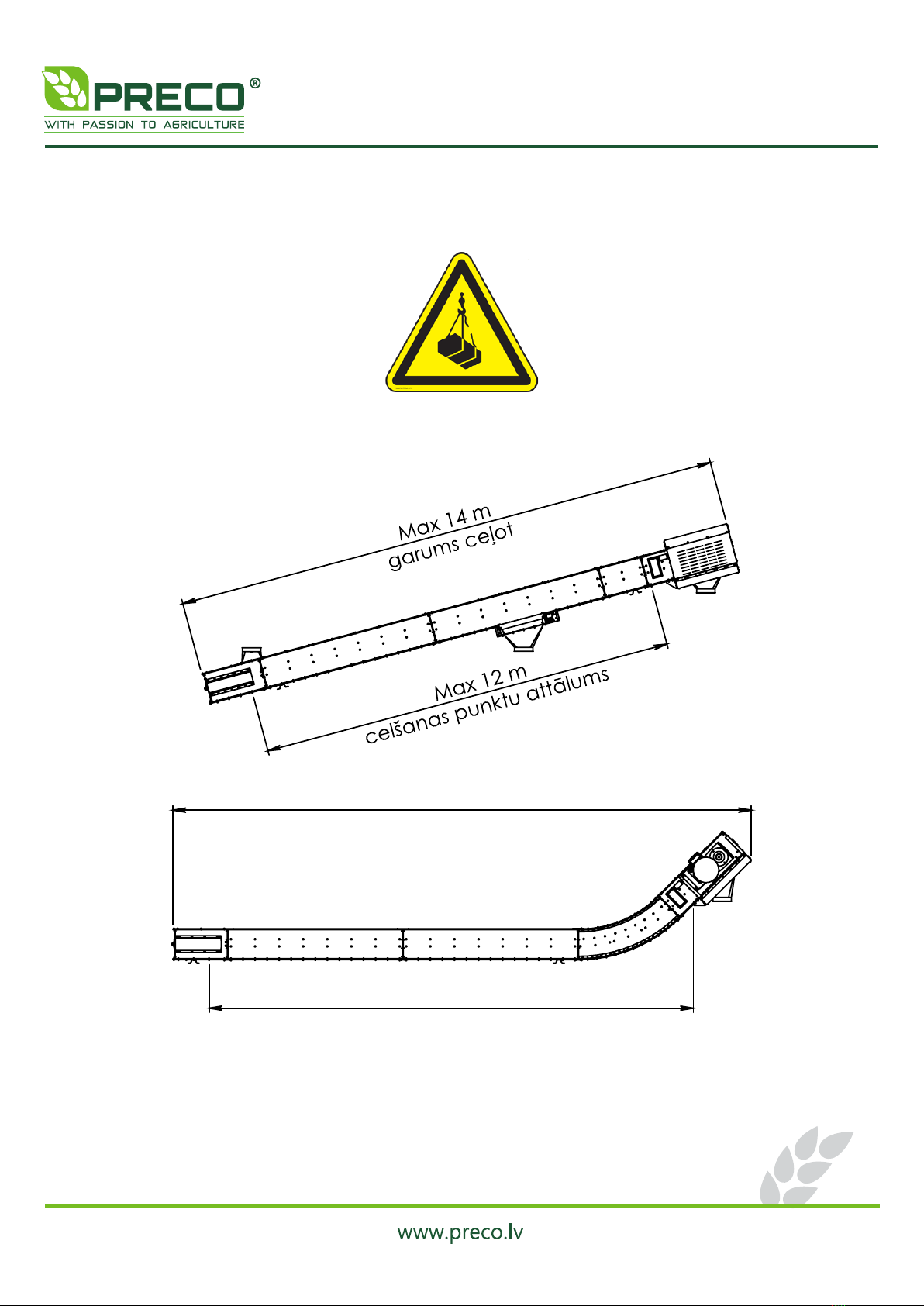

CONVEYOR SUPPORT

Flight conveyor must be placed on a stable and even surface. We recommend to use support

feet. The maximum free span distance in the picture below. Conveyor support feet are not included

in standard delivery.

WARNING!

The conveyor must be level widthwise and centered lengthwise.

12

LIFTING CONDITIONS

Lifting equipment must meet technical requirements and it shall be able to lift conveyor and

its parts.

Attention! Lifted load! Always make sure that no one is standing under lifted load.

13

ASSEMBLY OF FLIGHT CONVEYOR

Please check that there is enough space for conveyor assembly. The conveyor can be

assembled directly in the place or assembled separately and then lifted in the place. Find out location

of inlet and outlet before starting the assembly. Conveyor consists of tension section, intermediate

sections, bend section, drive section, chain, overloading membrane, inlet and outlet. Manufacturer

provides various type of inlets and outlets, weather cover for motor, reversible drive unit, shaft speed

monitor with cover, inline and lateral outlet slides

INFROMATION!

Bolt tightening must be done according to maintenance instructions.

Bolt torque table (Nm)

Bolt size

Bolt strength grade

8.8

10.9

12.9

M4

3.2

5

6

M5

6.4

9

11

M6

11

16

19

M8

27

39

46

M10

53

78

91

M12

92

135

155

M16

230

335

390

M20

460

660

770

M24

790

1150

1300

M30

1600

2250

2650

M36

2780

3910

4710

M42

4470

6290

7540

14

Tension unit

Delivered assembled and fitted with threaded rods (1) for chain tensioning.

Drive unit

Drive unit is complete with gearbox motor (1) and fitted with overloading membrane (2).

For motor maintenance and overloading membrane manual, please see the attached supplier

information.

15

Overflow membrane

MOLLET MFE-EE is assembled by manufacturer. For overflow membrane regulation, please

see the attached supplier manual.

Top cover dismantling

Before you start to assemble tension unit, extensions and drive unit, you have to dismantle

top covers (1) and connection plates (2), please see picture below. Dismantled bolts and nuts you

will need when top covers will be assembled back to conveyor.

16

Tension unit, extensions and drive unit

Standard drive unit is equipped with a pair of inspection windows. Standard extension lengths

are 0.3 m, 0.6 m, 1.2 m and 2.4 m. Bend section is available in 15, 30 or 45 degrees. By combining

multiple extensions it’s possible to acquire the desired conveyor length.

Connect sections using connecting plates. Bolt them together with included bolts and nuts.

INFROMATION!

If you have a conveyor with more than one extension, connect it first and assemble drive

section in the end.

17

Chain assembly

Pull the chain into the conveyor. Shorten if necessary. Connect the chain with chain

connections, as it is shown in the picture below. Arrow shows chain direction. Assemble chain and

tighten it with tighten bolts on the tension section.

18

Chain tension

Check the chain tension by pressing it down between the two chain return pulleys. It is

tensioned correctly if it can be pressed down to 3-5 mm and max 30 mm on the tension pulley, as

it is shown in the picture. Adjust the chain tension on regular basis.

Top cover assembly

When assembling top covers use hermetic sealant between mating surfaces.

19

Double-sided inlet assembly

Dismantle connection plates from extensions. Assemble extensions with double-sided inlet.

Bolt them together with included bolts and nuts. Mount covers and connection plates.

Remove all screws from the end of the double-sided inlet. Connect two inlets using the

removed screws as shown in the image below.

20

Inlet assembling

Attach inlet flange to the extension’s cover,

cut the hole for inlet and drill the holes for bolt

assembling (inlet flange should be used as stencils),

as it is shown in the picture below. Minimum

distance is 1000 mm from the end of tension unit.

Then mount the inlet flange using included bolts

and nuts. Use hermetic sealant supplied for sealing.

Outlet assembling

Mount outlet flange to drive

unit using bolts and nuts, as shown

in the picture.

Other manuals for S Series

1

This manual suits for next models

23

Table of contents

Other Preco Accessories manuals

Popular Accessories manuals by other brands

Leviton

Leviton Provolt ODC05-UDW installation instructions

Panasonic

Panasonic AG-BS300E operating instructions

Huawei

Huawei Airbridge cBTS3612 Maintenance manual

Ashcroft

Ashcroft GC35 Installation and Maintenance

HoMedics

HoMedics Aroma ARMH-590 instruction manual

FARMDROID

FARMDROID FD Base Station V2.0 Original user manual