Preliminary UNIFLEX CI 45 User manual

FEATURES

ØCompact design, only 22,5 mm

wide

ØClips onto top-hat DIN rail

ØPlug-in screw terminals or

spring-clamp connectors

ØDual-line LC display with addi-

tional display elements

ØProcess values always in view

ØConvenient 3-key operation

ØDirect communication between

rail-mounted transmitters

ØUniversal input with high signal

resolution (>15 bits) - also re-

duces stock keeping

ØUniversal output with high reso-

lution (14 bits) as combined volt-

age/current output

ØQuick response; only 100 ms cy-

cle time, i.e. also suitable for fast

signals

ØOne or two relay outputs

ØCustomer-specific linearization

ØMeasurement value correction

(offset or 2-point)

ØMin/max indicator (‘slave

pointer’)

ØLogical linking of digital outputs,

e.g. for common alarms

ØPreset for output value

APPLICATIONS

±Measurement, scaling, and sepa-

ration of electrical signals, e.g.

for:

±Heat treatment plants

±Drying equipment

±Furnace builders

±Metallurgy

±Kilns

±General machine building

±Research and development

±etc.

DESCRIPTION

UNIFLEX CI 45 transmitters are desig-

ned to give precise and cost-effective

signal detection and processing tasks.

Every CI 45 has at least one universal

input, one universal output and a relay.

Optionally, the transmitter can be fit-

ted with an additional relay.

Galvanic isolation is provided between

inputs and outputs as well as from the

supply voltage and the communication

interfaces.

Mounting

The compact CI 45 is clipped onto a

top-hat DIN rail, and can also be un-

mounted very simply.

All connections are of the plug-in type,

so that a transmitter can be replaced

very quickly without disturbing the wi-

ring.

Display and operation

The two-line LC display permits simul-

taneous indication of the measured va-

lue and all of the unit’s operating

functions.

Moreover, a LED and 4 other display

elements give a reliable indication of

operating status, operating mode, and

error messages.

The user-configurable engineering unit

of the measured value can be included

in the display. By means of the exten-

ded Operating Level, it is possible to

show any signal or parameter in the

2nd display line.

Interfaces and Engineering Tools

The transmitter settings are also confi-

gurable by means of an Engineering

Tool.

Via the BlueControl®software, inclu-

ding the transmitter simulation and

especially the convenient connection

via the BluePort®front interface, the

user can solve the task in hand wit-

hout having to work through operating

instructions.

Of course, practically all settings can

also be made from the device front.

UNIFLEX CI 45

Universal transmitter

Compact design

Display & operating functions

Communication features

High resolution

Fast cycle times

Universal input & universal output

Two relay outputs

Customer-specific linearization

Measurement value correction

Min/max indicator (‘slave pointer’)

rail line

Preliminary

Moreover, the CI 45 can exchange

data with superordinate systems and

PCs via an optional RS 485 interface

with MODBUS RTU protocol that is fit-

ted into the top-hat DIN rail.

Password protection

If required, unauthorized access to the

various Operating Levels can be pre-

vented with a password, or an entire

level can be blocked.

TECHNICAL DATA

INPUTS

Survey of inputs

Input Purpose

INP1 X1 (process value 1), universal

input

di1 Operation disabled; Reset of

stored alarms; Reset of min/max

indicator.

UNIVERSAL INPUT INP1

Resolution: > 15 bits

Decimal point: 0 to 3 decimals

Digital input filter: adjustable

0.0...999.9 s

Scanning cycle: 100 ms

Linearization: 31 segments,

adaptable with

BlueControl®

Measurement

value correction: 2-point or offset

Limiting frequency: 1,7 Hz

Thermocouples (Table 1)

Input resistance: ?1MW

Influence of source

resistance: 1 µV/W

Input circuit monitor: sensor break, polarity

Cold-junction compensation

Internal: for INP1

External: 0 ...100 °C

Additional error:

typ. ß_0,5 K

max. ß+ 2,4 K

Break monitoring

Sensor current: £1µA

Operating sense configurable

Resistance thermometer (Table 2)

Connection technique: 3 or 4-wire

Lead resistance: max. 30 W

(max. at range end)

Input circuit monitoring: break and short circuit

Measurement span

The BlueControl®software enables

the internal characteristic curve for the

KTY 11-6 temperature sensor to be

adapted.

Physical measurement range: 0...4500 W

Current and voltage

measurement (Table 3)

Span start and span: anywhere within the

measurement range

Scaling: freely selectable

–1999...9999

Input circuit monitoring

(current): 12,5% below span start

(2 mA)

2 UNIFLEX CI 45 - Preliminary-

Thermocouple type Measurement range Error Typical resol.

L Fe-CuNi (DIN) -100...900°C -148...1652°F £2K 0,05 K

J Fe-CuNi -100...1200°C -148...2192°F £2K 0,05 K

K NiCr-Ni -100...1350°C -148...2462°F £2K 0,1 K

N Nicrosil/Nisil -100...1300°C -148...2372°F £2K 0,1 K

S PtRh-Pt 10% 0...1760°C 32...3200°F £2K 0,1 K

R PtRh-Pt 13% 0...1760°C 32...3200°F £2K 0,1 K

T Cu-CuNi -200...400°C -328...752°F £2K 0,03 K

C W5%Re-W26%Re 0...2315°C 32...4199°F £3K 0,2 K

D W3%Re-W25%Re 0...2315°C 32...4199°F £3K 0,2 K

E NiCr-CuNi -100...1000°C -148...1832°F £2K 0,05 K

B * PtRh-Pt6% 0(400)...1820°C 32(752)...3308°F £3K 0,2 K

Special -25 … 75 mV £0,1% 0,005%

* Values apply from 400°C upwards.

Table 1: Thermocouple input

Type Sensor current Measurement range Error Typical resol.

Pt100 ***

ß0,25mA

-200...100 (150)°C -328...212 (302)°F £1 K 0,05 K

Pt100 -200...850°C -328...1562°F £1 K 0,05 K

Pt1000 -200...850°C -328...1562°F £2 K 0,05 K

KTY 11-6* -50...150°C -58...302°F £2 K 0,05 K

Special* 0...4500 W** £0,1% 0,005%

Special 0...450 W** £0,1% 0,005%

Potentiom. 0...160 W** £0,1% 0,005%

Potentiom. 0...450 W** £0,1% 0,005%

Potentiom. 0...1600 W** £0,1% 0,005%

Potentiom. 0...4500 W** £0,1% 0,005%

* Default setting is the characteristic for KTY 11-6 (-50...150°C)

** Including lead resistance

*** up to 150 °C at reduced lead resistance (max. 160 W)

Table 2: Resistive inputs

Measurement range Input resistance Error Typical resol.( )

0...10 V 110 kWß0,1 % 0,3 mV

-10...10 V 110 kWß0,1 % 0,6 mV

-5...5 V 110 kWß0,1 % 0,3 mV

-2,5...115 mV* >1MWß0,1 % 4 úV

-25...1150 mV* >1MWß0,1 % 40 úV

-25...90 mV* >1MWß0,1 % 4 úV

-500...500 mV* >1MWß0,1 % 40 úV

-200...200 mV* >1MWß0,1 % 20 úV

0...20 mA 20 Wß0,1 % 0,8 úA

* For INP1: high-impedance, without break monitoring

Table 3: Current and voltage input

CONTROL INPUT DI1

Configurable as direct or inverse switch

or contact!

Connection of potential-free contact that

is suitable for switching ‘dry’ circuits.

Switched voltage: 5 V

Switched current: 1 mA

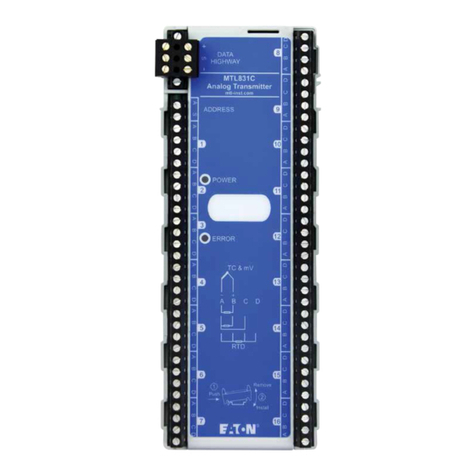

OUTPUTS

SURVEY OF OUTPUTS

Output Purpose

OUT1 OUT2

(relay)

Limit contact, alarms *

OUT3

(logic)

Same as OUT1 and

OUT2

OUT3

(continuous)

Analog output

(display value, INP1)

Transmitter supply

13V/22mA

*All logic signals can be ”OR-linked”.

RELAY OUTPUTS OUT1, OUT2

Type: 2 NO contacts with a

common terminal

Max. contact rating: 500 VA,

max. 250 V, max. 2 A

at 48...62 Hz,

resistive load

Min. contact rating: 6V, 1 mA DC

Service life (electrical): 800.000 switching cycles

at max. rating

Note:

If the relays OUT1 and OUT2 operate

external contactors, these must be fit-

ted with RC snubber circuits to manu-

facturer specifications to prevent

excessive voltage peaks at switch-off.

OUT3 AS UNIVERSAL OUTPUT

Galvanically isolated from the inputs.

Parallel current/voltage output with

common ‘minus’ terminal (combined

use only in galvanically isolated circuits).

Freely scalable

Resolution: 14 bits

Dynamic response Output follows the input:

(step change of input

signal) T90: ß540 ms

Tracking error I/U: £2%

Residual ripple: ß_1%

(rel. to range end) 0...130 kHz

Current output

0/4...20 mA, configurable.

short circuit proof

Dynamic range: -0,5...23 mA

Load: £700 W

Load effect: ß0,02%

Resolution: £1,5 µA

Error: £0,1%

Voltage output

0/2...10V, configurable

not continuous short-circuit proof

Dynamic range: -0,15...11,5 V

Load: ³2kW

Load effect: ß0,06%

Resolution: £0,75 mV

Error: £0,1%

Additional error when ß+ 0,09%

using simultaneously

the current output

OUT3 as transmitter supply

Output: 22 mA / ³13VDC

OUT3 as logic signal

Load £700 W0/£23 mA

Load > 500 W0/> 13 V

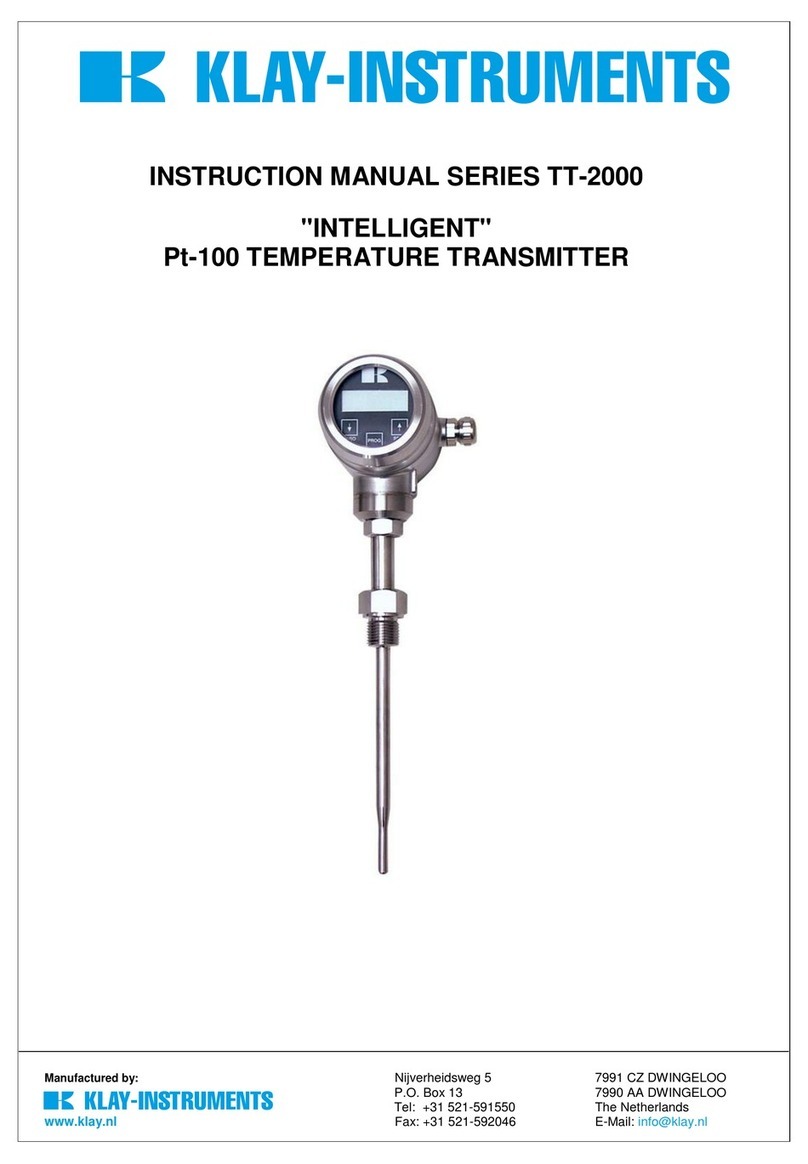

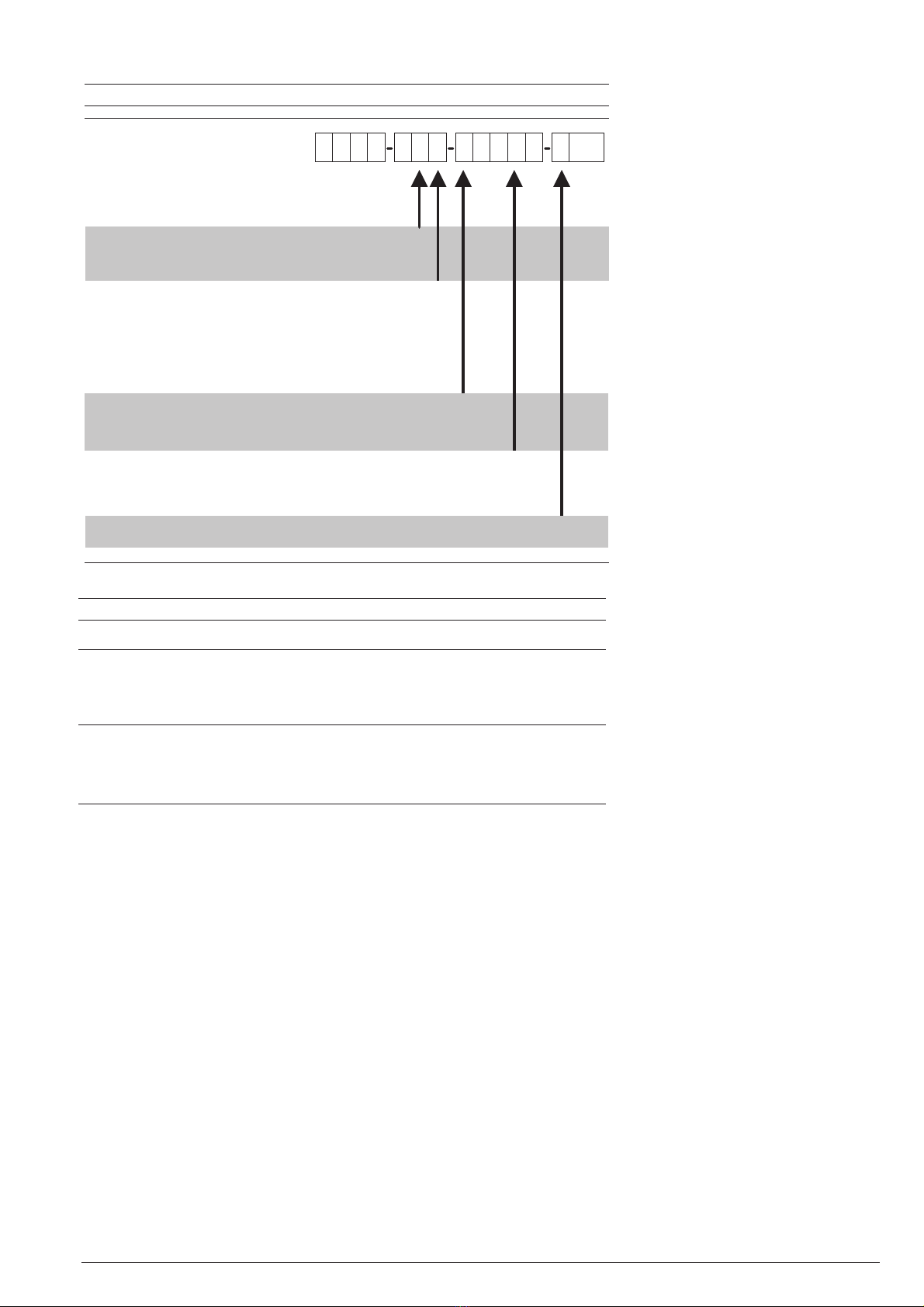

Galvanic isolation (see fig.1)

permissible voltages:

safety isolation ß300 Vrms AC against

earth

functional

isolation

ß30 Vrms AC against earth

FUNCTIONS

Signal processing

The selected input signal is conver-

ted into an analog output signal or is

accessible at the interface. Depen-

ding on the selected sensor type, the

following options are provided for

manipulating the input signal:

•Measurement value correction

(offset and 2-point)

•Scaling

•1st-order filter with adjustable

parameters (bandwidth, see below)

•Linearization with 31 segments

•Öx , with Ö-x=0

•x2

Behaviour on sensor break/short

circuit

•Response of the analog output is

selectable (upscale / downscale)

•Preset substitute input value, can

be disabled

Min/max indicator (slave pointer)

The minimum and maximum input va-

lues are stored in the CI 45, and can

be displayed by means of the keys D

(minimum) and I(maximum). The va-

lues are resettable.

Display of engineering units

The engineering unit for the measured

value can either be selected from a

predefined list of standard units, or it

can be defined by the user (BlueCon-

trol®). The unit appears in the second

line of the display.

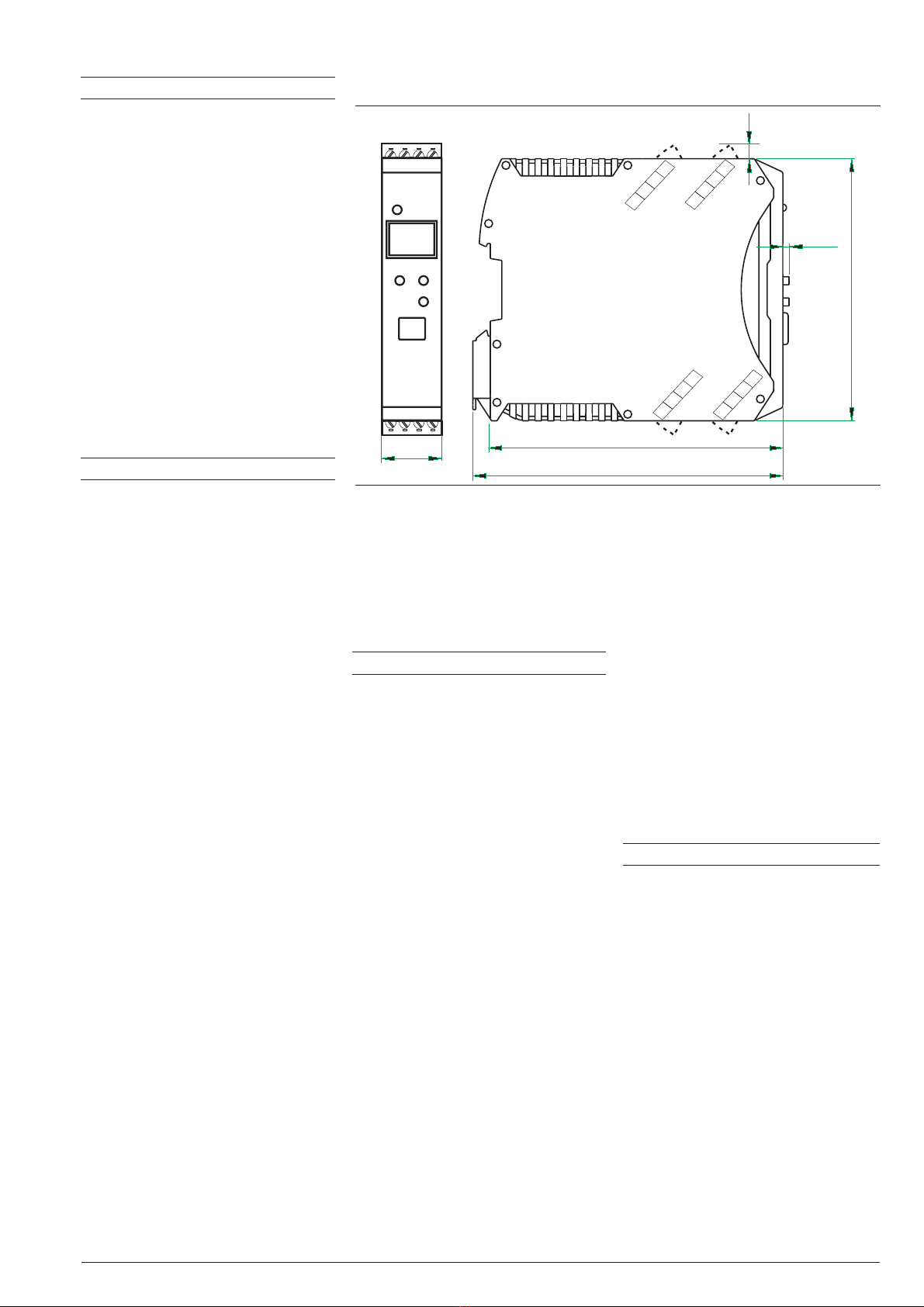

FILTER

The transmitter contains a 1st-order

mathematical filter with adjustable

time constant and bandwidth.

The bandwidth is the adjustable tole-

rance range within which the filter is

active above and below the process

value. Measurement value changes in

excess of the adjusted bandwidth are

not filtered.

- Preliminary- UNIFLEX CI 45 3

RS 485

power

relay 1

relay 2

input 1

di1 (contact)

output 3

safety isolation

functional isolation

front interface

Fig. 1: Galvanic isolation

Filterbandwidth b_F

x

t

input

output

Fig. 2: Filter function

LIMIT VALUE FUNCTIONS

Max, Min or Max/Min monitoring with

adjustable hysteresis.

Monitored signals

•Process value

•Input 1

Functions

•Input value monitoring

•Input value monitoring with storage

•Signal changes / with storage

•Reset via front panel or digital input

•Alarm discriminator adjustable from

0...9999 seconds

Several limit values and alarm messa-

ges can be logically ”OR-linked”.

ALARMS

Sensor break / short circuit

Depending on the selected input type,

the input circuit is monitored for break,

short circuit, and reversed polarity.

MAINTENANCE MANAGER

Display of error messages, warnings,

and stored limit value messages in the

error list. Messages are stored, and

can be reset manually.

Possible elements in the error list:

•Sensor break, short circuit, incorrect

polarity

•Stored limit values

•e.g. re-calibration warning (message

is generated when a predefined

operating time is reached)

•e.g. maintenance interval for a

switching device (message is

generated when a predefined

number of switching cycles is

reached)

•Internal fault (RAM, EEPROM, ...)

DISPLAY AND OPERATION

Display

LCD:

dual-line plus additional display ele-

ments

Upper line:

4 digits, 7-segment LCD

•for process value

Lower line:

5 digits, 14-segment LCD; configura-

ble contents (via BlueControl®)

•Engineering unit

•Parameters

•Extended Operating Level

Additional display elements

4 display elements (bars in the lower

line of the LCD, identified as 1, 2, F, E)

•Bars 1 and 2: OUT1/OUT2 active or

INP1/INP2 active

•Bar F: Function active (planned)

•Bar E: Entry has been made in the

error list

Dual-color indicator LEDs:

•Green = OK

•Red = limit value Lim1 triggered

•Red blinking = internal fault

Operating functions

Only three keys at the front of the

CI 45 are used to operate process va-

lues, parameters, and configuration

data. Different Operating Levels and

selected parameters can be disabled

by means of BlueControl®.

POWER SUPPLY

Depending on ordered version:

AC supply

Voltage: 90...260 V AC

Frequency: 48...62 Hz

Consumption: approx. 7 VA max.

Universal supply 24 V UC

AC supply: 18...30 V AC

Frequency: 48...62 Hz

DC supply: 1 8...31 V DC

Consumption: approx. 3 VA / W max.

Supply only from safety electrical low voltage

(SELV).

Behaviour with power failure

Configuration and parameter settings:

Permanent storage in EEPROM

BLUEPORT®FRONT INTERFACE

Connection to the transmitter front via

a PC adapter (see ‘Accessories’). The

BlueControl®software enables the

CI 45 to be configured, parameters

set, and operated.

4 UNIFLEX CI 45 - Preliminary-

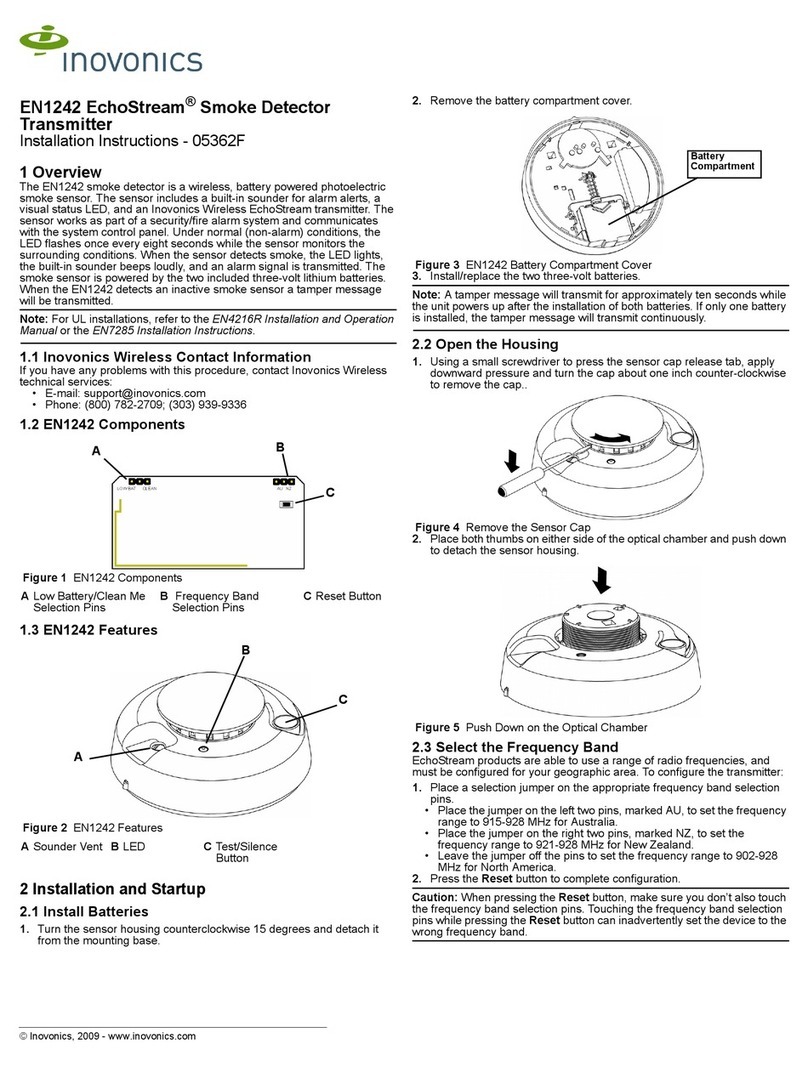

Data A

Data A

Data B

Data B

V

14

13

12

16

15

11

mV

mA V

17 18

INP1

OUT3

PWR

LNOUT1

OUT2

90...260V AC

24V AC/DC

di1

8

76

3

2

1

5

34

RGND

RGND

RS 485

top

Fig. 3: Connecting diagram CI 45

BUS INTERFACE (OPTIONAL)

RS 485

Connection via bus connector fitted in

the top-hat rail. Screened cables

should be used.

Galvanically isolated

Type: RS 485

Transmission speed: 2400, 4800, 9600,

19.200, 38.400 bits/sec

Parity: even, uneven, none

Address range: 1...247

Number of transmitters

per bus segment: 32

Protocol

•MODBUS RTU

ENVIRONMENTAL CONDITIONS

Protection mode

Front panel: IP 20

Housing: IP 20

Terminals: IP 20

Permissible temperatures

For specified accuracy: -10...55°C

Warm-up time: < 20 minutes

Temperature effect: ß0,05% / 10 K

add. influence to

cold junction compensation: ß0,75K/10K

Operating limits: -20...60°C

Storage: -30...70°C

Humidity

Max. 95%, 75% yearly average, no

condensation

Shock and vibration

Vibration test Fc (DIN EN 60068-2-6)

Frequency: 10...150 Hz

Unit in operation: 1g or 0,075 mm

Unit not in operation: 2g or 0,15 mm

Shock test Ea (DIN EN 60068-2-27)

Shock: 15 g

Duration: 11 ms

Electromagnetic compatibility

Complies with EN 61 326-1

•Meets the interference immunity

regulations for continuous,

unattended operation.

•Meets the interference radiation

regulations of Class B for residential

areas.

For 24 VAC devices high surge inferences

on mains cables can lead to a device

initialization.

GENERAL

Housing front

Material: Polyamide PA 6.6

Flammability class: VO (UL 94)

Connecting terminals

Material: Polyamide PA

Flammability class: V2 (UL 94)

for screw terminals

V0 (UL 94) for

spring-clamp terminals

bus connector

Electrical safety

Complies with EN 61010-1:

Over-voltage category II

Contamination degree 2

Protection class II

Electrical connections

Plug-in connector strips with terminals

for lead cross-sections from 0,2 to 2,5

mm2. Choice of screw terminals or

spring-clamp terminals.

Mounting method

Clip-on rail mounting (35 mm top-hat

rail to EN 50 022). Locked by means of

metal catch in housing base.

Close-packed mounting possible.

Mounting position: vertical

Weight:

0,18 kg

Standard accessories

–Operating instructions

–With ‘Interface’ option: bus

connector for fitting into top-hat rail

ACCESSORIES

BlueControl®(Engineering Tool)

PC program for configuring, parameter

setting, and operating (commissioning)

the CI 45 transmitter. Moreover, all

settings are saved and can be printed,

if required.

Depending in version, a powerful data

acquisition module with trend graphics

is available.

Show/hide function

The BlueControl®software enables

any number of parameters and confi-

guration setting to be shown/hidden.

This ensures that only permitted para-

meters & settings can be changed in

the transmitter. Safety-relevant para-

meters are not displayed.

- Preliminary- UNIFLEX CI 45 5

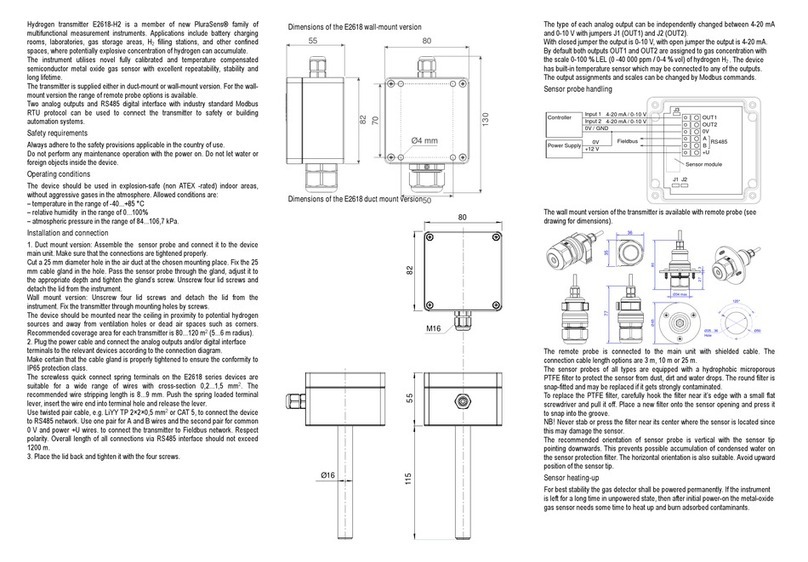

117.5 (4,63”)

99 (3,90”)

2.3

22.5

111 (4,37”)

5.5

(0,87”)

(0,08”)

(0,20”)

Klemme /

terminal

1516 17 18

5678

1234

11 12 13 14

Klemme /

terminal

Fig. 4: Dimensions CI 45

Simulation function

The built-in simulation serves to test

the settings.

Import function

Engineerings of UNIFLEX CI/CB crea-

ted by engineering tool ET/Uniflex can

be read and transformed if possible.

Software requirements:

Windows 95/98/NT/2000/XP

Configuration settings made only via

the BlueControl®software (not via the

transmitter’s front keys)

•Customer-specific linearization

•Enable forcing for inputs and

outputs

•Setting the limits for operating

hours and switching cycles

•Switch-over to 60 Hz mains

frequency

•Blocking operator functions,

Operating Levels, and password

definition

Hardware requirements:

A special PC adapter (see ‘Accesso-

ries’) is required for connecting to the

transmitter.

Updates and demo software from:

www.pma-online.de

6 UNIFLEX CI 45 - Preliminary-

Description Quantity Order no.

1Connector set with screw terminals 4 pieces 9407-998-07101

2Connector set with spring-clamp terminals 4 pieces 9407-998-07111

3Bus connector for fitting in top-hat rail 1 piece 9407-998-07121

4Plug for bus connection, connections at left,

horizontal cable entry

1 piece 9407-998-07131

5Plug for bus connection, connections at right,

vertical cable entry

1 piece 9407-998--07141

ACCESSORIES

Functionality Mini Basic Expert

parameter and configuration setting yes

download: writes an engineering to the transmitter

online-mode / visualisation SIM only

creation of user defined linearizations

configuration of extended operation level

upload: reads an engineering from the transmitter SIM only

basic diagnosis function no

saves files and engineering data

printer function

online documentation / help system

measurement correction (calibration procedure)

data acquisition and trend function SIM only

net- / multi licence

yes yes

yes yes yes

yes yes

yes yes yes

yes yes yes

yes yes

no yes

no yes yes

no yes yes

yes yes yes

yes yes yes

yes yes

no no yes

personal assistant function

BlueControl®, versions und functions:

Fig. 5: Interface parameters hidden, only

address visible

1

2

3

45

ACCESSORY PARTS

- Preliminary- UNIFLEX CI 45 7

Description Language Order no.

PC adapter for the BluePort® front

interface

9407-998-00001

USB serial adaptor (USB to RS 232) 9407-998-00081

Converter RS 232 to RS 422/485 galv. isolated ADAM-4520-D

Operating instructions for CI 45 German 9499-040-71718

Operating instructions for CI 45 English 9499-040-71711

Interface description for Modbus rail line German 9499-040-72018

Interface description for Modbus rail line English 9499-040-72011

BlueControl® Mini German/English www.pma-online.de

BlueControl® with Basic license rail line German/English 9407-999-12001

BlueControl® with Expert license rail line German/English 9407-999-12011

ADDITIONAL ACCESSORIES

CI45 1 0Universal transmitter CI 45

0

1

no plug-in connectors

2

18...30VAC/18..31VDC, mA/V/logic +1 relay 3

90..260V AC, mA/V/logic +2 relay

4

18...30VAC/18..31VDC, mA/V/logic +2 relay 5

0

1

Standard configuration 0

Configuration to order 9

Standard (CE-certified) 0

0

RS 485 / MODBUS - protocol

with screw-terminal plug-in connectors

90..260V AC, mA/V/logic +1 relay

1 universal-input, control-input

with display and BluePort®-interface

no option

0

ORDERING INFORMATION

PMA

Prozeß- und Maschinen- Automation GmbH

P.O. Box 31 02 29

D-34058 Kassel

Tel.: +49 - 561- 505 1307

Fax: +49 - 561- 505 1710

E-mail: [email protected]

Internet: http://www.pma-online.de

Your local representative

Printed in Germany - Edition 11/2004- Subject to change without notice - 9498 737 48313

- Preliminary-

Table of contents

Popular Transmitter manuals by other brands

Kramer

Kramer TA-110HD user manual

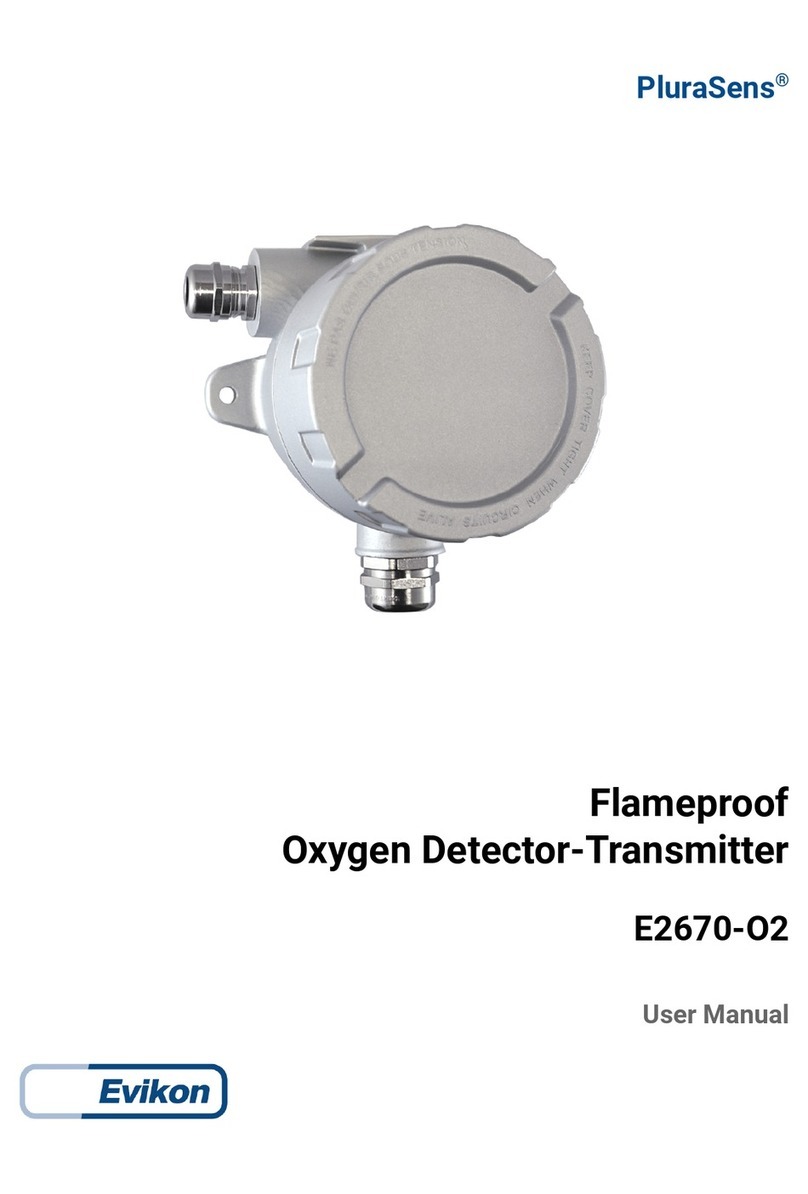

Evikon

Evikon PluraSens E2670-O2 user manual

Ramsey Electronics

Ramsey Electronics FM25A Assembly and instruction manual

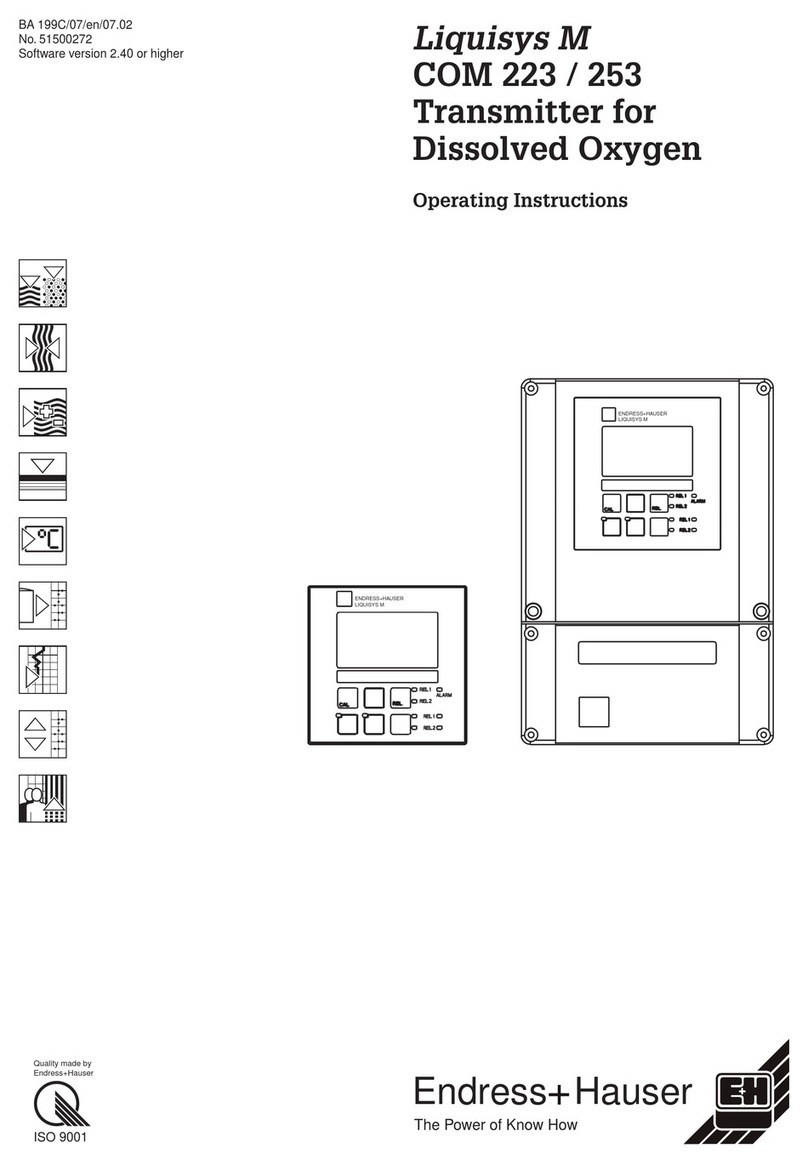

Endress+Hauser

Endress+Hauser Liquisys M COM 223 operating instructions

Primex

Primex XR TIME SYNCHRONIZATION Installation & user guide

AMX

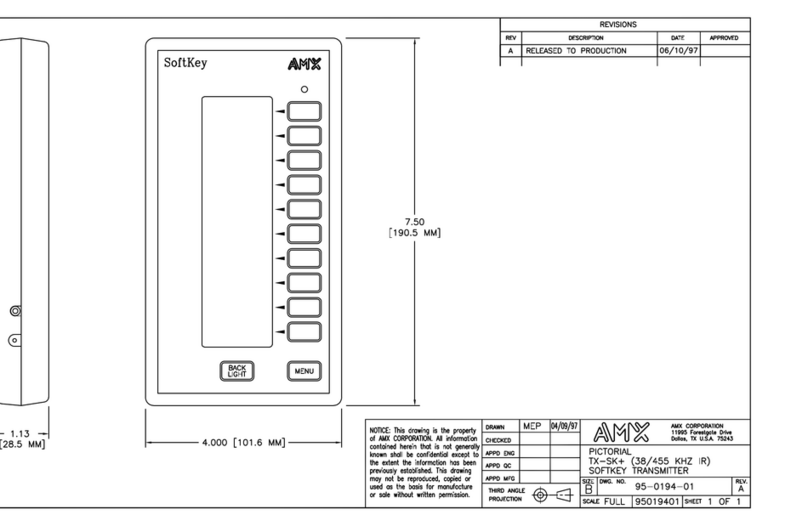

AMX TX-SK Plus Dimensional drawing