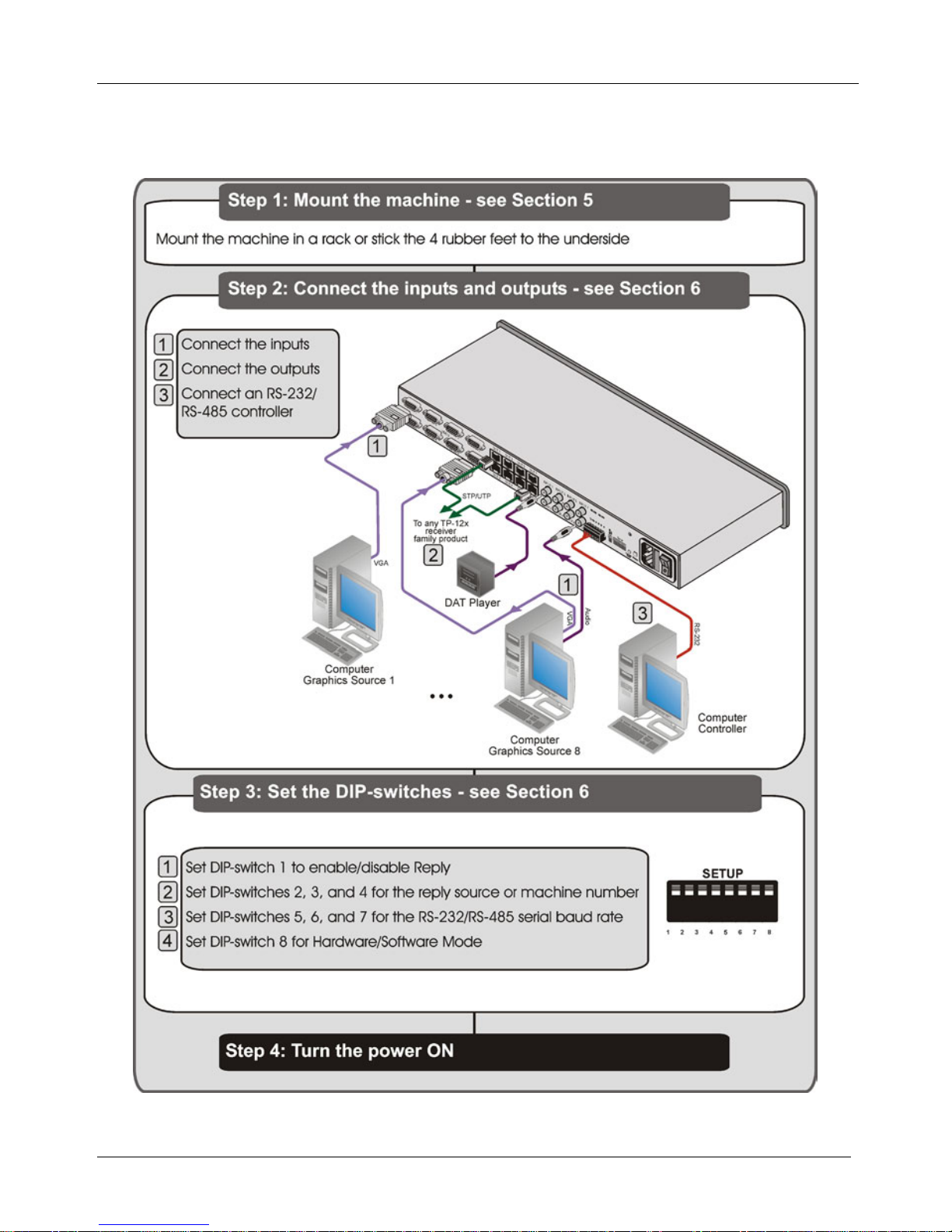

3 Overview

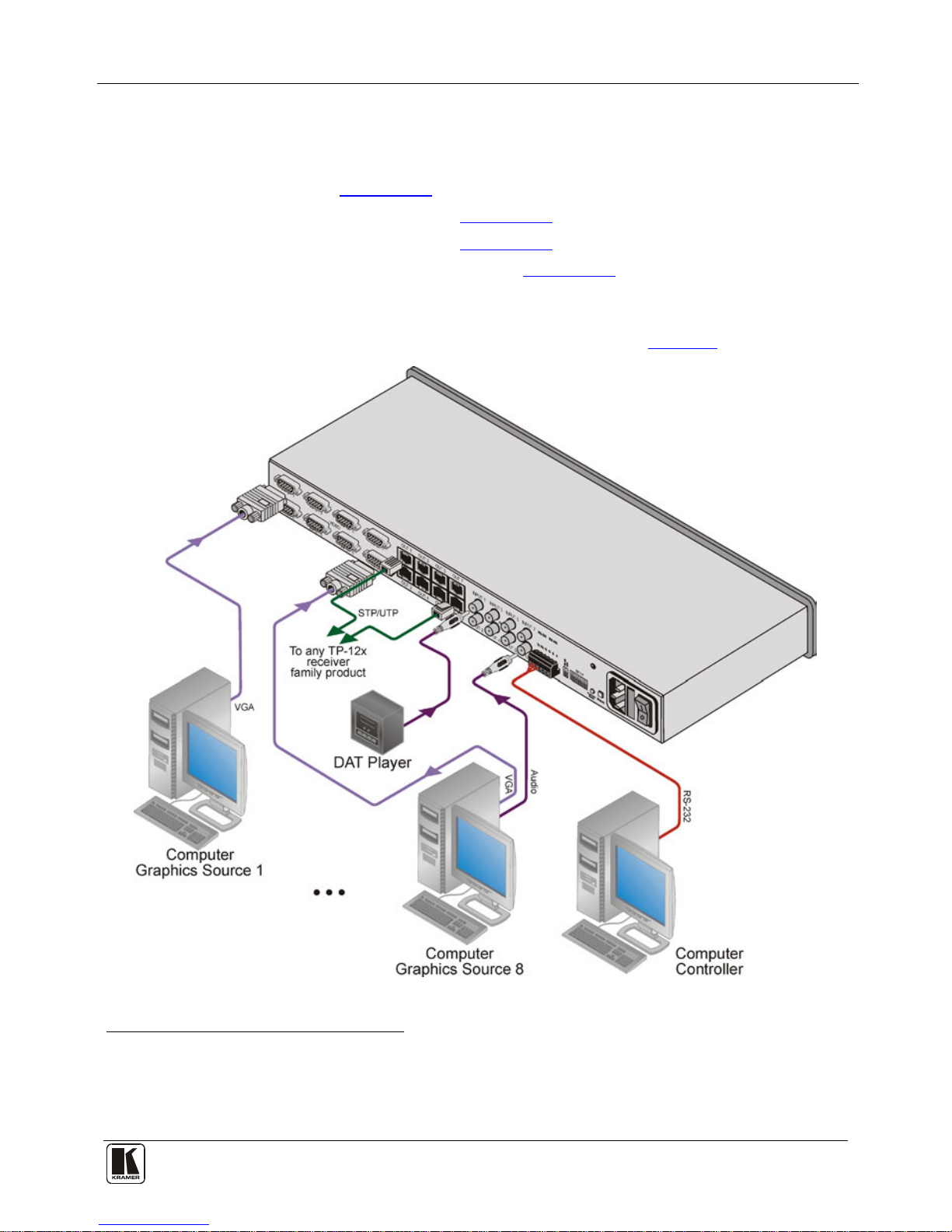

The TP-185 is a high performance, 8 channel VGA/UXGA1

In particular, the TP-185, 8 Channel UXGA/Audio/RS-232 to CAT 5 Transmitter

features:

, audio and RS-232 to CAT 5

transmitter for high resolution video, stereo unbalanced audio and RS-232 signals. The

CAT 5 outputs can be connected to any Kramer compatible TP receiver, for example, the

TP-126. The TP-185 can also route data from the RS-232 or RS-485 port to any of the

CAT 5 outputs.

•Eight UXGA video inputs

•Eight stereo unbalanced audio inputs on 3.5mm mini jacks

•Eight RJ-45 STP/UTP outputs

•Transmission of RS232/RS-485 data from one input to any or all of the eight

CAT 5 outputs, and one reply from the selected output

The TP-185 can differentiate between RS-232/RS-485 commands that control the unit

itself and commands that are destined for end-user equipment (see Section 7.1.5.2

The TP-185 is dependable, rugged, and fits into one vertical space (1U) of a standard

19” professional rack.

).

To achieve the best performance:

•Use only good quality connection cables2

•Do not secure the cables in tight bundles or roll the slack into tight coils

to avoid interference, deterioration

in signal quality due to poor matching, and elevated noise levels (often

associated with low quality cables)

•Avoid interference from neighboring electrical appliances that may adversely

influence signal quality, and position your Kramer TP-185 away from

moisture, excessive sunlight and dust

3.1 Shielded Twisted Pair/Unshielded Twisted Pair

We recommend that you use Shielded Twisted Pair (STP) cable. There are different levels

of STP cable available, and we advise you to use the best quality STP cable that you can

afford. Our non-skew-free cable, Kramer BC-STP is intended for analog signals where

skewing is not an issue. For cases where there is skewing, our UTP skew-free cable Kramer

BC-XTP, may be used. Bear in mind though, that we advise using STP cables where

possible, since the compliance to electromagnetic interference was tested using those

cables. Although Unshielded Twisted Pair (UTP) cable might be preferred for long range

applications, the UTP cable should be installed far away from electric cables, motors and so

on, which are prone to create electrical interference.

However, since the use of UTP cable might cause inconformity to electromagnetic

standards, Kramer does not commit to meeting the standard with UTP cable.

1 Up to and including WUXGA 1920 x 1200 resolution

2 Available from Kramer Electronics on our Web site at http://www.kramerelectronics.com