Hydrogen transmitter E2618-H2 is a member of new PluraSens® family of

multifunctional measurement instruments. Applications include battery charging

rooms, laboratories, gas storage areas, H2filling stations, and other confined

spaces, where potentially explosive concentration of hydrogen can accumulate.

The instrument utilises novel fully calibrated and temperature compensated

semiconductor metal oxide gas sensor with excellent repeatability, stability and

long lifetime.

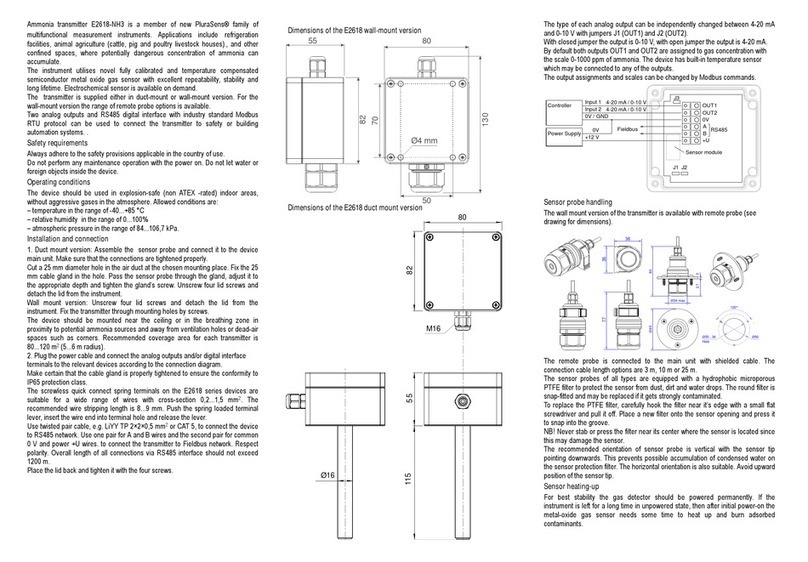

The transmitter is supplied either in duct-mount or wall-mount version. For the wall-

mount version the range of remote probe options is available.

Two analog outputs and RS485 digital interface with industry standard Modbus

RTU protocol can be used to connect the transmitter to safety or building

automation systems.

Safety requirements

Always adhere to the safety provisions applicable in the country of use.

Do not perform any maintenance operation with the power on. Do not let water or

foreign objects inside the device.

Operating conditions

The device should be used in explosion-safe (non ATEX -rated) indoor areas,

without aggressive gases in the atmosphere. Allowed conditions are:

– temperature in the range of -40...+85 °C

– relative humidity in the range of 0...100%

– atmospheric pressure in the range of 84...106,7 kPa.

Installation and connection

1. Duct mount version: Assemble the sensor probe and connect it to the device

main unit. Make sure that the connections are tightened properly.

Cut a 25 mm diameter hole in the air duct at the chosen mounting place. Fix the 25

mm cable gland in the hole. Pass the sensor probe through the gland, adjust it to

the appropriate depth and tighten the gland’s screw. Unscrew four lid screws and

detach the lid from the instrument.

Wall mount version: Unscrew four lid screws and detach the lid from the

instrument. Fix the transmitter through mounting holes by screws.

The device should be mounted near the ceiling in proximity to potential hydrogen

sources and away from ventilation holes or dead air spaces such as corners.

Recommended coverage area for each transmitter is 80...120 m2(5...6 m radius).

2. Plug the power cable and connect the analog outputs and/or digital interface

terminals to the relevant devices according to the connection diagram.

Make certain that the cable gland is properly tightened to ensure the conformity to

IP65 protection class.

The screwless quick connect spring terminals on the E2618 series devices are

suitable for a wide range of wires with cross-section 0,2...1,5 mm2. The

recommended wire stripping length is 8...9 mm. Push the spring loaded terminal

lever, insert the wire end into terminal hole and release the lever.

Use twisted pair cable, e.g. LiYY TP 2×2×0,5 mm2or CAT 5, to connect the device

to RS485 network. Use one pair for A and B wires and the second pair for common

0 V and power +U wires. to connect the transmitter to Fieldbus network. Respect

polarity. Overall length of all connections via RS485 interface should not exceed

1200 m.

3. Place the lid back and tighten it with the four screws.

The type of each analog output can be independently changed between 4-20 mA

and 0-10 V with jumpers J1 (OUT1) and J2 (OUT2).

With closed jumper the output is 0-10 V, with open jumper the output is 4-20 mA.

By default both outputs OUT1 and OUT2 are assigned to gas concentration with

the scale 0-100 % LEL (0 -40 000 ppm / 0-4 % vol) of hydrogen H2 . The device

has built-in temperature sensor which may be connected to any of the outputs.

The output assignments and scales can be changed by Modbus commands.

Sensor probe handling

The wall mount version of the transmitter is available with remote probe (see

drawing for dimensions).

The remote probe is connected to the main unit with shielded cable. The

connection cable length options are 3 m, 10 m or 25 m.

The sensor probes of all types are equipped with a hydrophobic microporous

PTFE filter to protect the sensor from dust, dirt and water drops. The round filter is

snap-fitted and may be replaced if it gets strongly contaminated.

To replace the PTFE filter, carefully hook the filter near it’s edge with a small flat

screwdriver and pull it off. Place a new filter onto the sensor opening and press it

to snap into the groove.

NB! Never stab or press the filter near its center where the sensor is located since

this may damage the sensor.

The recommended orientation of sensor probe is vertical with the sensor tip

pointing downwards. This prevents possible accumulation of condensed water on

the sensor protection filter. The horizontal orientation is also suitable. Avoid upward

position of the sensor tip.

Sensor heating-up

For best stability the gas detector shall be powered permanently. If the instrument

is left for a long time in unpowered state, then after initial power-on the metal-oxide

gas sensor needs some time to heat up and burn adsorbed contaminants.

4-20 mA/ 0-10 V

4-20 mA/ 0-10 V

0V / GND

0V

Controller

Power Supply

Input 1

Input 2 OUT1

OUT2

0V

A

BRS485

+U

J1 J2

Fieldbus

Sensor module

+12 V

J3

Dimensions of the E2618 wall-mount version

Dimensions of the E2618 duct mount version

Ø4 mm

55 80

130

82

50

70

36

77

Ø35...36 Ø50

120°

Ø65 80

327

Ø34 max

Hole

35

55

115

M16

82

80

Ø16