Manual Serie TT-2000 Klay Instruments B.V.

H/EN/2000-TT/09-2021/09 Page 4

4. Position the weld-on nipple in the vessel hole and tack six places.

5. The weld sequence is shown in the figure above. Weld the weld-on nipple in place using

0,03 to 0,045 in. (0,762 to 1,143 mm) stainless rod as filler material in the beveled area.

Adjust amperage for penetration pliers (1/8").

6. Remove mandrel after the welding operation.

3.2 MOUNTING POSITION

When the transmitter is mounted horizontally, the cable gland must be pointed downwards.

3.3 CALIBRATION

All transmitters are fully calibrated at the factory, to the conditions stipulated in users order. When the

customer has not requested calibration, the transmitter will be calibrated 0-100 °C.

3.4 WIRING

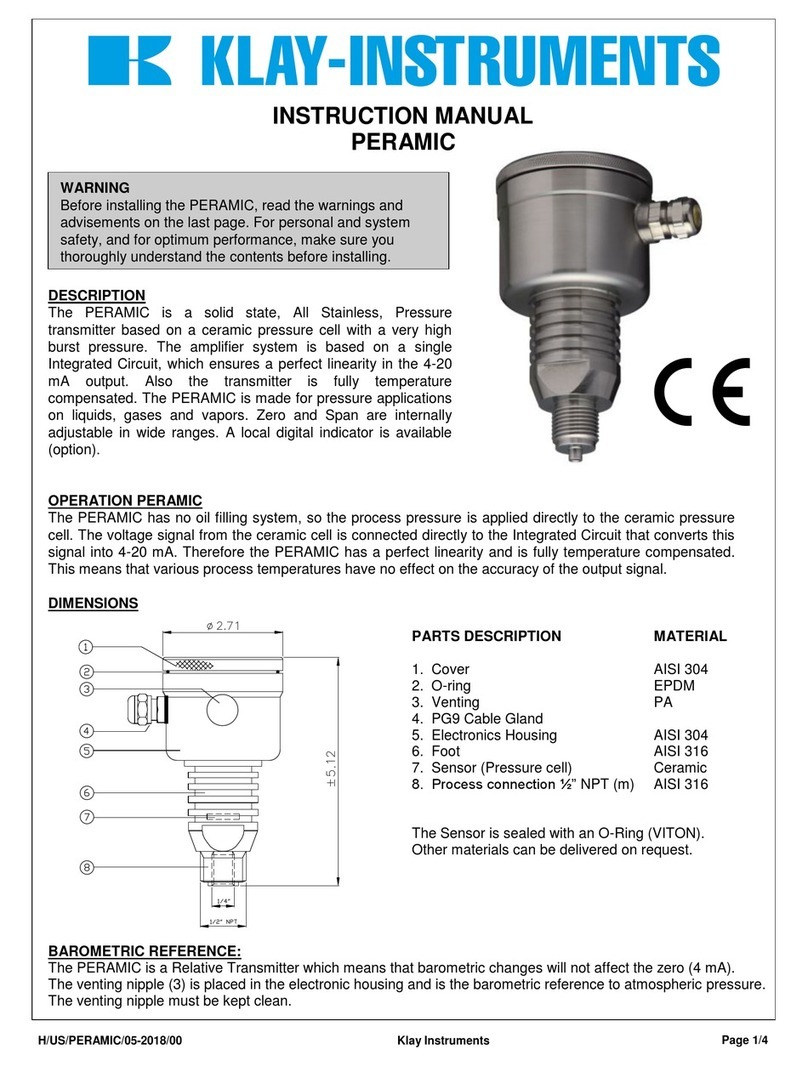

Under the cover (3) you will find the terminal board. Under the other cover (1) are the buttons for the

zero and span adjustment.

External loads must be placed in the negative leg of

the 2-wire loop.

The figure left shows the wiring connection of the

transmitter. The 2-wires must be connected to 3 (-) and

4 (+) of the terminal board.

The signal wiring must be shielded and twisted pairs

yield best results. Do NOT run signal wiring in open

trays with power wiring, or near heavy electrical

equipment (Frequency controller or heavy pumps).

Shielding must always be connected at the side of the

power supply.

In case the mounting position is already connected to

earth (by tank or pipe line) do NOT connect the

instrument to earth. Please ensure that the instrument

is not connected to earth twice to prevent the

occurrence of an 'earth loop'. In applications with

synthetic mounting positions the case grounding

terminal (internal or external) must be connected to

earth.

Care must be taken to assure that the polarity of the power supply is correct, a reversal of wiring

polarity will not damage the transmitter, but it will not function until the wiring is connected correctly.

4. REMAINING

4.1 DIGITAL LOCAL INDICATOR

All temperature transmitters from the series TT-2000 are standard equipped with a digital display. In the

standard version closed covers are used. The push buttons and the display are behind the cover (3).

As an option an transparent cover can be delivered for the application as a local display in the process

(Option: "I" extra price). The full-scale point may be set to any value between 0000 and 9999 (4 digit)