© Copyright 2006 PREO SRL

All rights reserved

EAW530E2MV

Edition

03/2006

CONTENTS

SECTION 1 ............................................................................................................................................. 1

SAFETY ................................................................................................................................. 1

1.1

KEY TO SYMBOLS .......................................................................................................... 1

1.2

USER RESPONSIBILITIES .............................................................................................. 1

1.3

GENERAL WARNINGS AND SAFETY PRECAUTIONS......................................................... 1

1.4

COMPLIANCE WITH STANDARDS.................................................................................... 1

SECTION 2 ............................................................................................................................................. 3

INTRODUCTION ...................................................................................................................... 3

2.1

USE OF THE MANUAL .................................................................................................... 3

2.2

PRODUCT DESCRIPTION ................................................................................................ 4

2.3

METHODS OF USE ......................................................................................................... 4

2.4

PRODUCT IDENTIFICATION ............................................................................................ 5

2.5

PRODUCT CODE CONFIGURATION .................................................................................. 5

2.6

SAFETY LABELS ............................................................................................................. 6

2.7

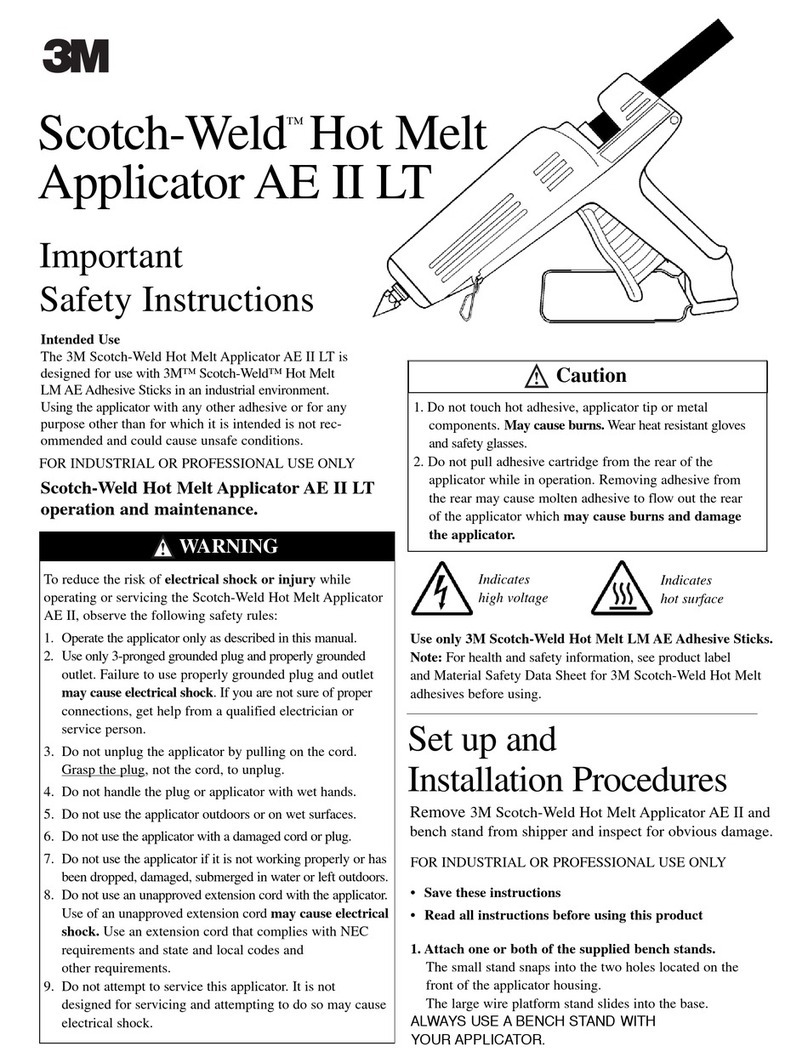

MAIN APPLICATOR COMPONENTS.................................................................................. 6

SECTION 3 ............................................................................................................................................. 7

INSTALLATION ....................................................................................................................... 7

3.1

INTRODUCTION ............................................................................................................. 7

3.2

INSTALLATION REQUIREMENTS .................................................................................... 8

3.3

CHECKING YOUR PURCHASE ......................................................................................... 8

3.4

REMOVING THE PACKAGING .......................................................................................... 8

3.5

APPLICATOR ASSEMBLY ................................................................................................ 9

3.6

POWER SUPPLY CONNECTION ....................................................................................... 9

3.7

PNEUMATIC SUPPLY CONNECTION .............................................................................. 11

3.8

HEATED HOSE CONNECTION ....................................................................................... 11

3.9

GUN CONNECTION....................................................................................................... 12

3.10

GUN SOLENOID VALVE SIGNAL CONNECTION .............................................................. 13

3.11

MACHINE READY SIGNAL CONNECTION ....................................................................... 13

3.12

RS232 CONNECTOR CONNECTION ............................................................................... 14

SECTION 4 ........................................................................................................................................... 17

OPERATION.......................................................................................................................... 17

4.1

FILLING THE MELTING TANK ....................................................................................... 17

4.2

STARTING UP THE SYSTEM ......................................................................................... 17

4.3

GENERAL OPERATING INFORMATION .......................................................................... 18

4.4

DESCRIPTION OF COMPONENTS .................................................................................. 19

4.5

INTEGRATED FUNCTIONS ............................................................................................ 20