4

TABLE OF CONTENTS

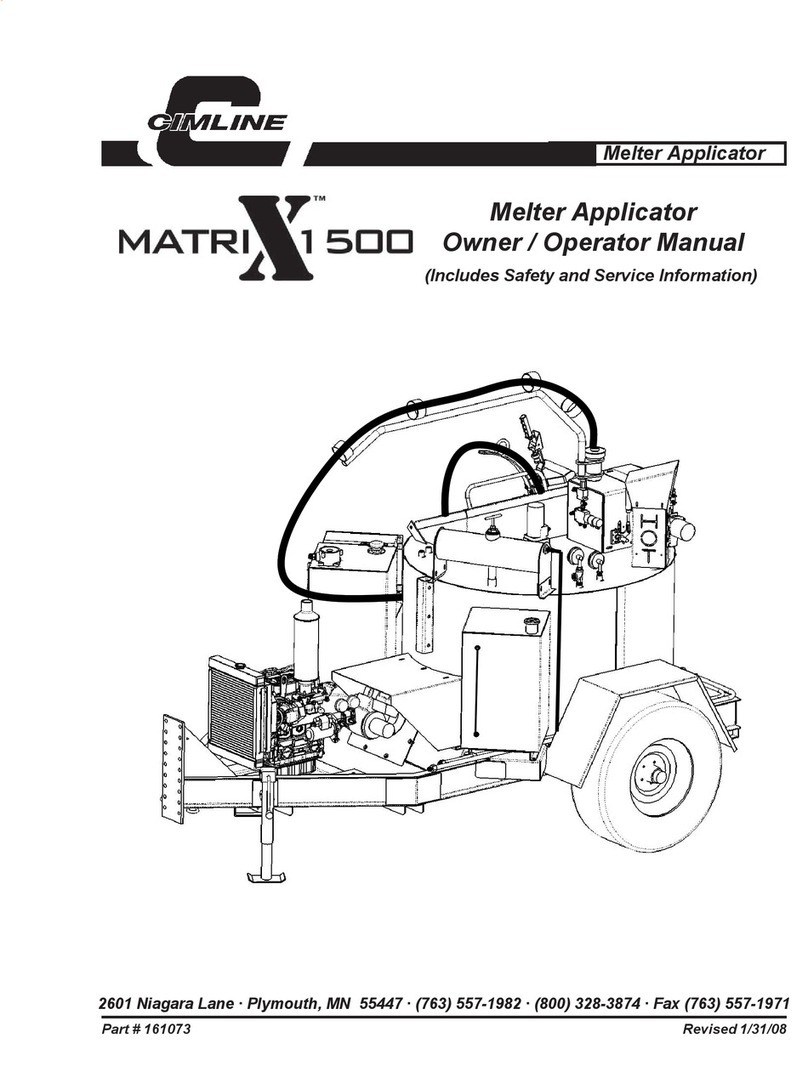

SuperShot125DieselMelter...................................................................................................... 5

SafetyPrecautions....................................................................................................................... 6-7

LimitedWarranty.......................................................................................................................... 7

WarrantyClaimInstructions......................................................................................................... 8

Specifications............................................................................................................................... 9

Introduction...................................................................................................................................10

Operating Instructions

MachineStartUp...................................................................................................... 11-12

DispensingtheMaterial/ActivePump Protection..................................................... 13

Loading The Machine/Shutdown and Clean-out Procedures/Storing Machine.......14

Instructions For Ordering Parts/Electric Hose Care and Cautions.......................... 15

HoseTransportInstructions..................................................................................... 16

Maintenance

MaintenanceInstructions......................................................................................... 17

MaintenanceChart/ServiceInstructions.................................................................. 18

RecommendedFluidsansLubricants/TypicalSpecifications................................. 19

SuperShotPumpReplacement.............................................................................. 20

SuperShotPump Replacement Diagram............................................................... 21

Trouble Shooting

Trouble Shooting Guide - Hose Does Not Heat...................................................... 22

HoseCircuitDiagram............................................................................................... 23

Trouble Shooting Guide - Hose Does Not Heat (continued)................................... 24

Trouble Shooting Guide - Material Does Not Dispense ......................................... 24

HoseCircuitDiagram............................................................................................... 25

Trouble Shooting Guide - Material Does Not Dispense.......................................... 26

Trouble Shooting Guide - Pump Rotates but No Material Is Discharged................ 26

Trouble Shooting Guide - Material Dispening Rate Too Slow................................. 26

HoseCircuitDiagram............................................................................................... 27

RTDSensor - Ohms vs.Temperature...................................................................... 28

DieselBurnerAdjustments/Diesel Burner Settings.................................................. 29

BurnerSchematic..................................................................................................... 30

BurnerTrouble Shooting.......................................................................................... 31

HydraulicSchematic................................................................................................. 32

Trouble ShootingHydraulics.................................................................................... 33

Parts SS125Diesel MelterDiagramsandParts............................................................... 34-39

TankDetail Diagram and Parts................................................................................ 40-41

ControlBoxDiagramandParts............................................................................... 42-43

EngineAssemblyDiagram and Parts...................................................................... 44-45

HydraulicControlValve DiagramandParts............................................................ 46

Pump/AgitatorMotorAssemblyDiagramandParts................................................ 47

DieselBurnerDiagramandParts............................................................................ 48-49

HydraulicDiagramandParts................................................................................... 50-51

ElectricalCablesandParts...................................................................................... 52-53