- 2 -

Table of Contents

Shipping Papers and Information ..................................................................................... 3

Safety Notes........................................................................................................................ 4

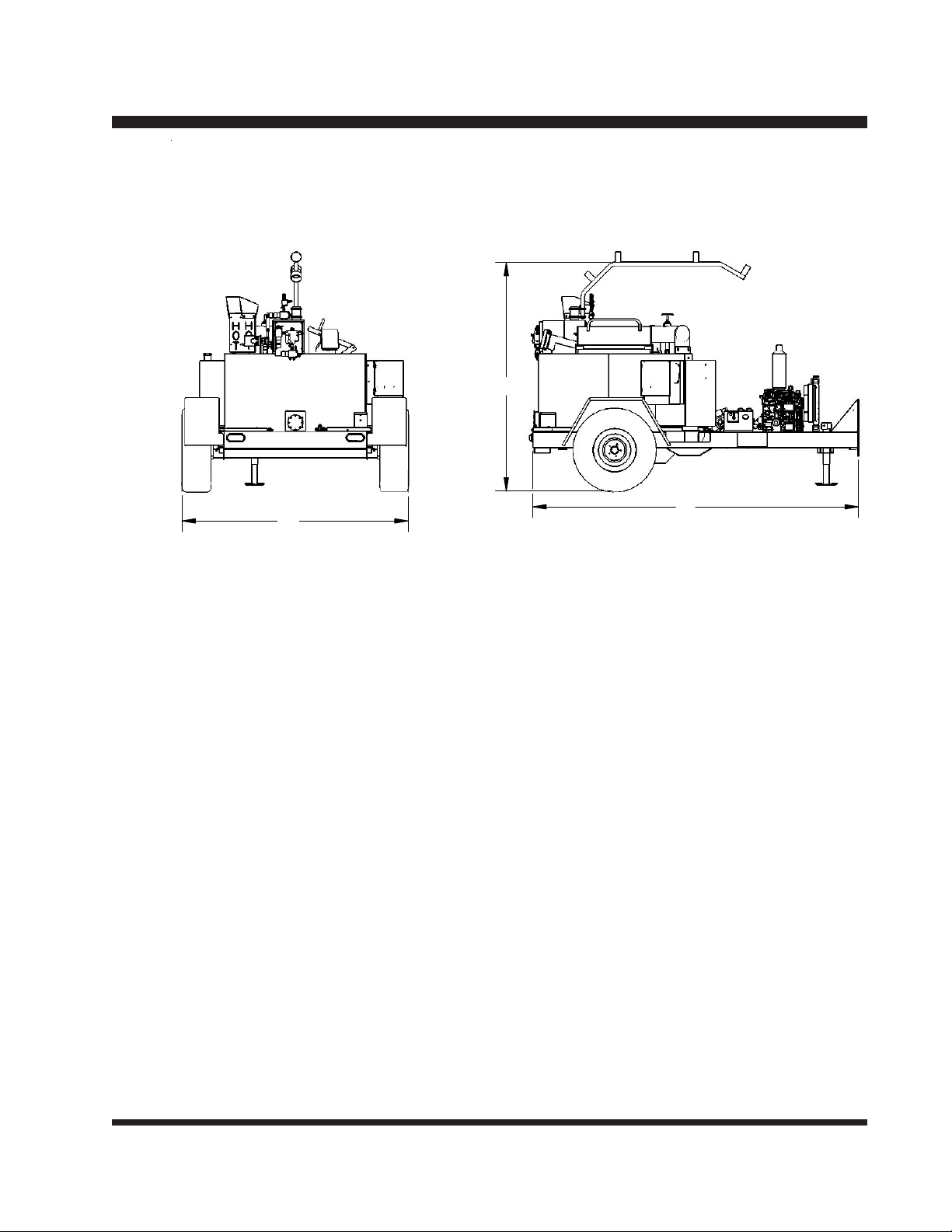

Dimensions and Weights ................................................................................................... 5

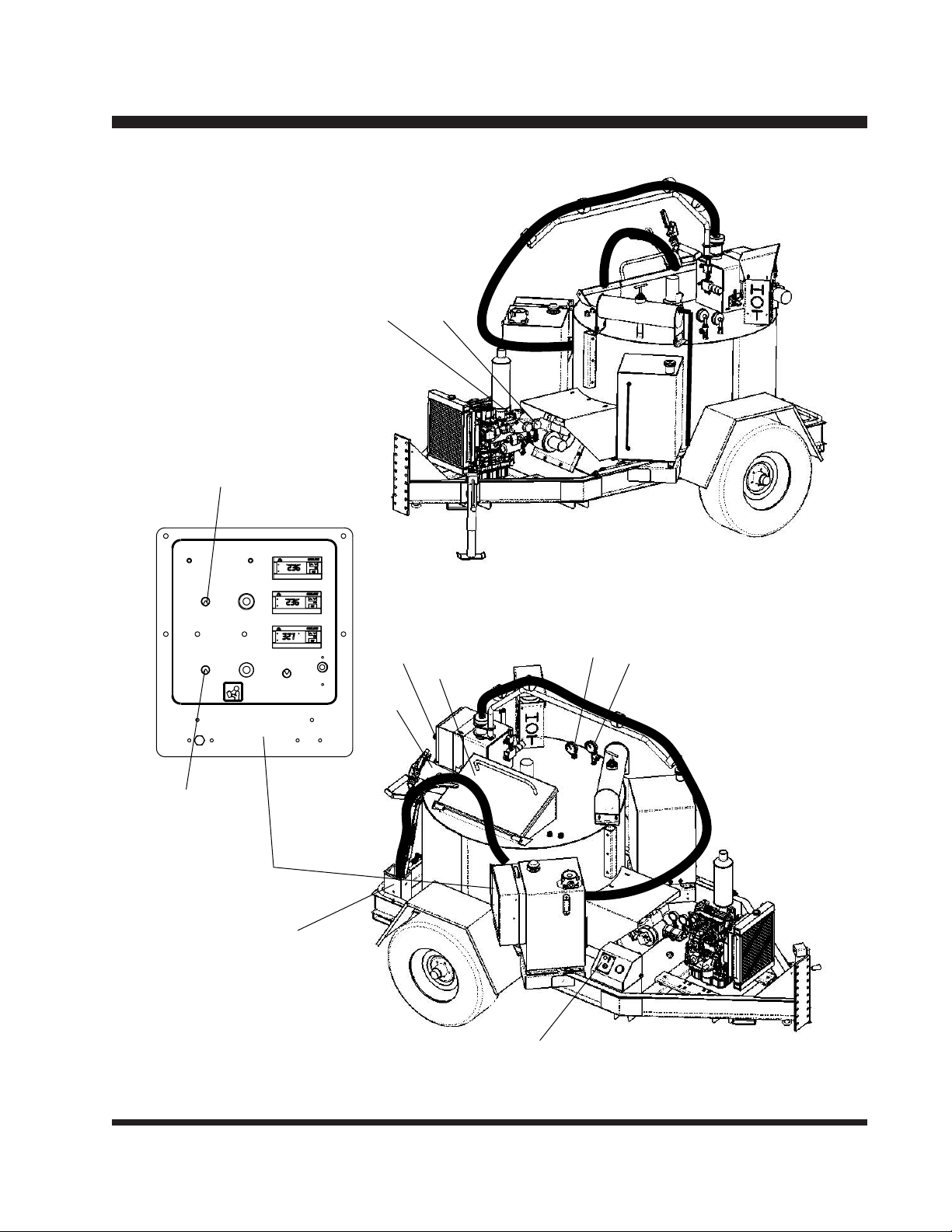

Controls and Their Functions ........................................................................................... 6

Operating Sequence .......................................................................................................... 8

Starting the Engine.............................................................................................................9

Starting the Engine.............................................................................................................9

Automatic Temperature Control Setting......................................................................... 10

Setting Temperature Controllers..................................................................................... 11

Material Loading Procedure ............................................................................................ 12

Sealing Procedure ............................................................................................................ 12

Material System Cleanout ................................................................................................ 13

Electric Eye and Fuse Inspection ................................................................................... 14

Burner Motor Brush Inspection ...................................................................................... 14

Burner Nozzle Replacement ............................................................................................ 15

Chamber Lining Inspection ............................................................................................. 15

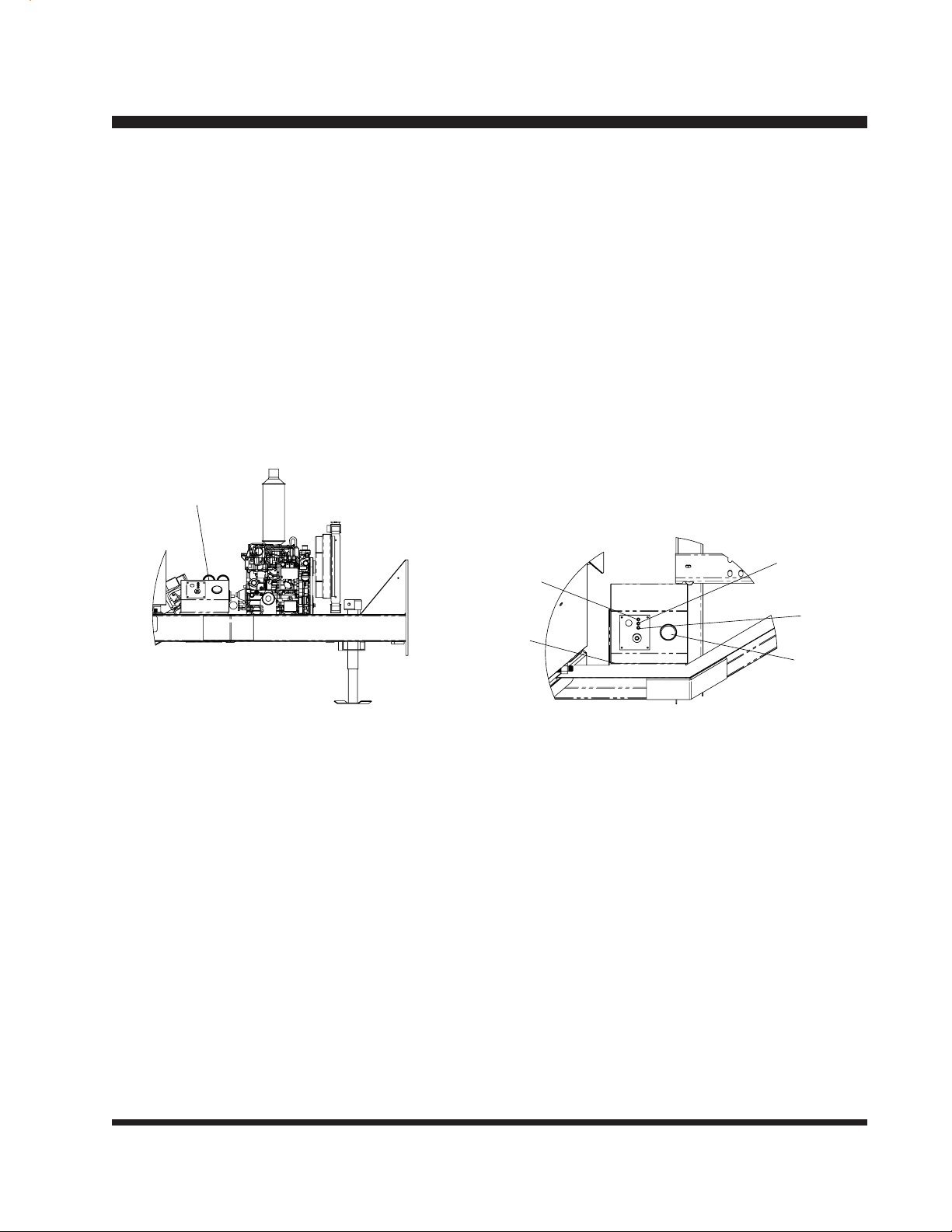

Adjusting Replacement Burner ....................................................................................... 16

Adjusting Fuel Pump Pressure ....................................................................................... 17

Adjusting Burner Nozzle, Electrode and Head Position ............................................... 18

Maintenance...................................................................................................................... 21

Fluid and Components Specifications ........................................................................... 22

Heat Transfer Oil Specifications ..................................................................................... 23

Material Tank Capacity ..................................................................................................... 24

Trouble Shooting Guide ................................................................................................... 25

Hydraulic Schematic ........................................................................................................ 26

Primary Control ................................................................................................................ 27

Wiring Diagrams ............................................................................................................... 28

Wiring Diagrams ............................................................................................................... 29

Electrical Components .................................................................................................... 30

Diesel Engine Components ............................................................................................. 31

Sealing Attachments ........................................................................................................ 32

Sealing Hose Accessories ............................................................................................... 33

Plumbing System Parts List ............................................................................................ 34

Plumbing System Parts List ............................................................................................ 35

Oil Burner Parts List ........................................................................................................ 36

Combustion Chamber Parts List..................................................................................... 37

Hydraulic and Fuel Tank Components ........................................................................... 38