Presto GEOSYSTEMS GEOWEB Instruction sheet

PRESTO

PRESTO GEOSYSTEMS®

670 NPERKINS STREET,APPLETON,WISCONSIN,USA 54914

Ph: 920-738-1328 or 800-548-3424 ■Fax: 920-738-1222

e-mail: INFO@PRESTOGEO.COM WWW.PRESTOGEO.COM/

GWLS000 18-APR-2011

GEOWEB®

LOAD SUPPORT SYSTEM

INSTALLATION GUIDELINE

Distributed by: Bowman Construction Supply, 10801 E. 54th Avenue, Denver, CO 80239; Phone: (303) 696-8960

PRESTO

GEOWEB®

LOAD SUPPORT SYSTEM

INSTALLATION GUIDELINE

GW/LS000 18-APR-2011 COPYRIGHT 2011 –PRESTO PRODUCTS CO.

Table of Contents

Subgrade Preparation ...................................................................................................................................1

Figure 1 Unpaved Access .....................................................................................................................1

Figure 2 Flexible Pavement ..................................................................................................................1

Figure 3 Trackbed Stabilization ............................................................................................................1

Figure 4 Pipeline Support......................................................................................................................1

Figure 5 Spread Footing .......................................................................................................................1

Geotextile Underlayer....................................................................................................................................1

Figure 6 Geotextile Placement..............................................................................................................1

Installation of Geoweb® Sections .................................................................................................................2

Figure 7 Stake Anchorage ....................................................................................................................2

Figure 8 ATRA®Anchor Placement Options.........................................................................................2

Figure 9 Infilling Perimeter Cells ...........................................................................................................2

Figure 10 Use of Stretcher Frame ........................................................................................................2

Installation of Geoweb® Sections on Curves................................................................................................3

Figure 11 Curved Expansion of Section ...............................................................................................3

Figure 12 Tapered Expansion of Section..............................................................................................3

Connecting Geoweb® Sections ....................................................................................................................3

Figure 13 ATRA® Key Connection Device ...........................................................................................3

Placement and Compaction of Geoweb® Infill .............................................................................................4

Figure 14 Fill Placement with Loader....................................................................................................4

Figure 15 Fill Placement with Excavator...............................................................................................4

Figure 16 Infill Compaction ...................................................................................................................4

Dimensions and Weights of Palletized Geoweb® Sections..........................................................................4

Table 1 V-Series Geoweb®Shipping Dimensions and Weights ...........................................................4

Infill Volumes .................................................................................................................................................5

Table 2 Infill Volumes for Geoweb®Sections .......................................................................................5

Tools and Equipment ....................................................................................................................................5

Table 3 Standard Construction Tools for Installation of the Geoweb®System ....................................5

Excavation and Materials Handling Equipment.........................................................................................5

Compaction Equipment .............................................................................................................................5

Limited Warranty ...........................................................................................................................................6

PRESTO

GEOWEB®

LOAD SUPPORT SYSTEM

INSTALLATION GUIDELINE

GW/LS000 18-APR-2011 COPYRIGHT 2011 –PRESTO PRODUCTS CO. PAGE 1OF 6

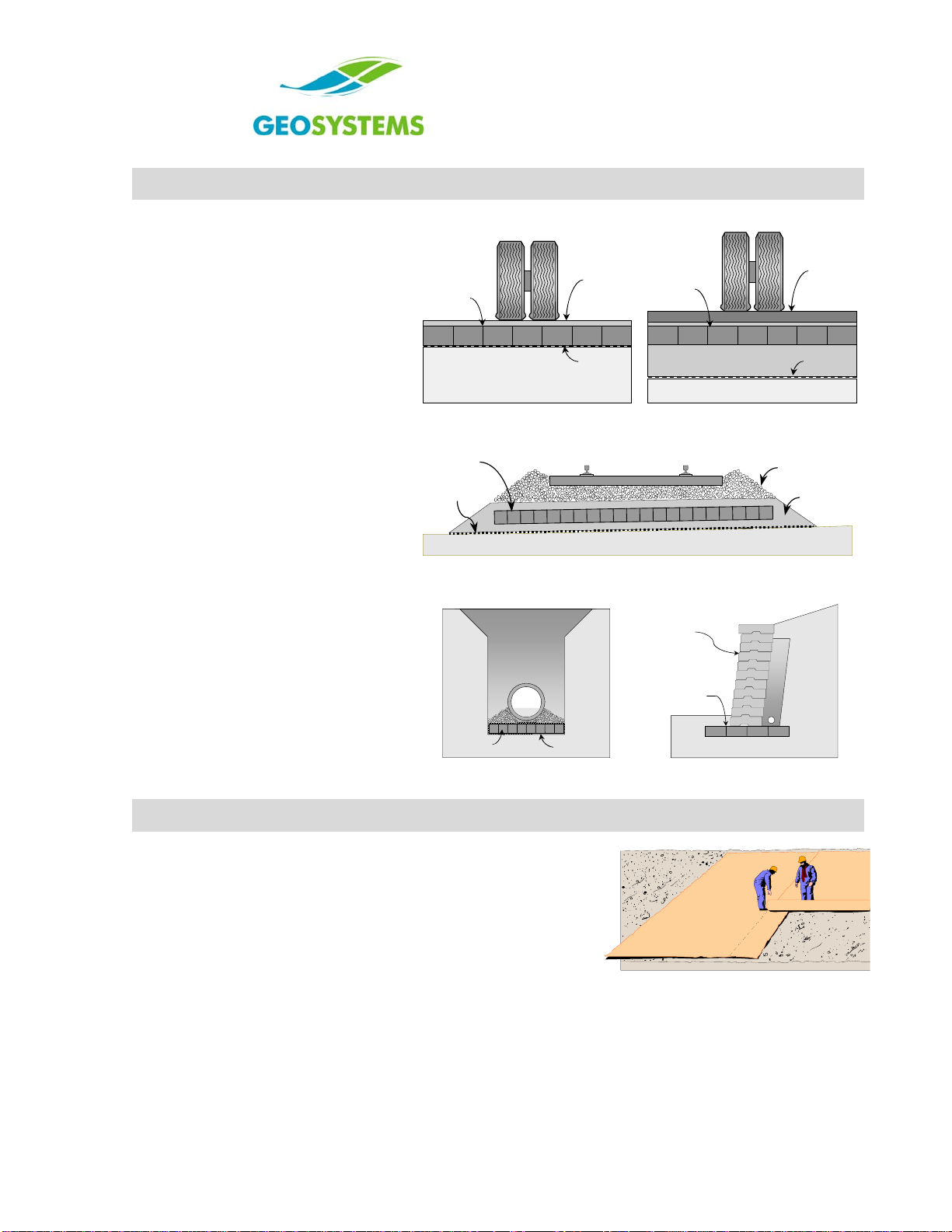

Subgrade Preparation

Geoweb®load support applications are

generally classified as follows and

illustrated in Figure 1 - Figure 5:

1. Unpaved access roads and hard-

standing areas.

2. Base and subbase stabilization of

flexible pavement structures.

3. Stabilized trackbed structures.

4. Raft construction on soft soils.

5. Structural spread footings.

The extent and nature of subgrade

preparations depend on the type of

structure and the subsoil conditions.

•Paved roads, railroad trackbeds

and structural footings require

accurate grading, shaping and

proof-rolling of the subgrade soils.

•Provision of adequate cross-fall or

crowning at formation level is

particularly important.

•Raft construction, involving

extremely weak compressible

subsoils, generally limits subgrade

preparation work to the clearing of

large vegetation. Any existing root

mass is normally left intact.

Geoweb

Section

Subgrade

Geotextile

Gravel

Surcharge

Figure 1 Unpaved Access

Geoweb

Section

Granular Base

Subgrade

Geotextile

Flexible

Pavement

Figure 2 Flexible Pavement

Geoweb

Section Primary

Ballast

Geotextile Sub-ballast

Figure 3 Trackbed Stabilization

Geoweb

Section Geotextile

Figure 4 Pipeline Support

Geoweb

Section

Spread

Footing

Modular Concrete

Retaining

Wall

Figure 5 Spread Footing

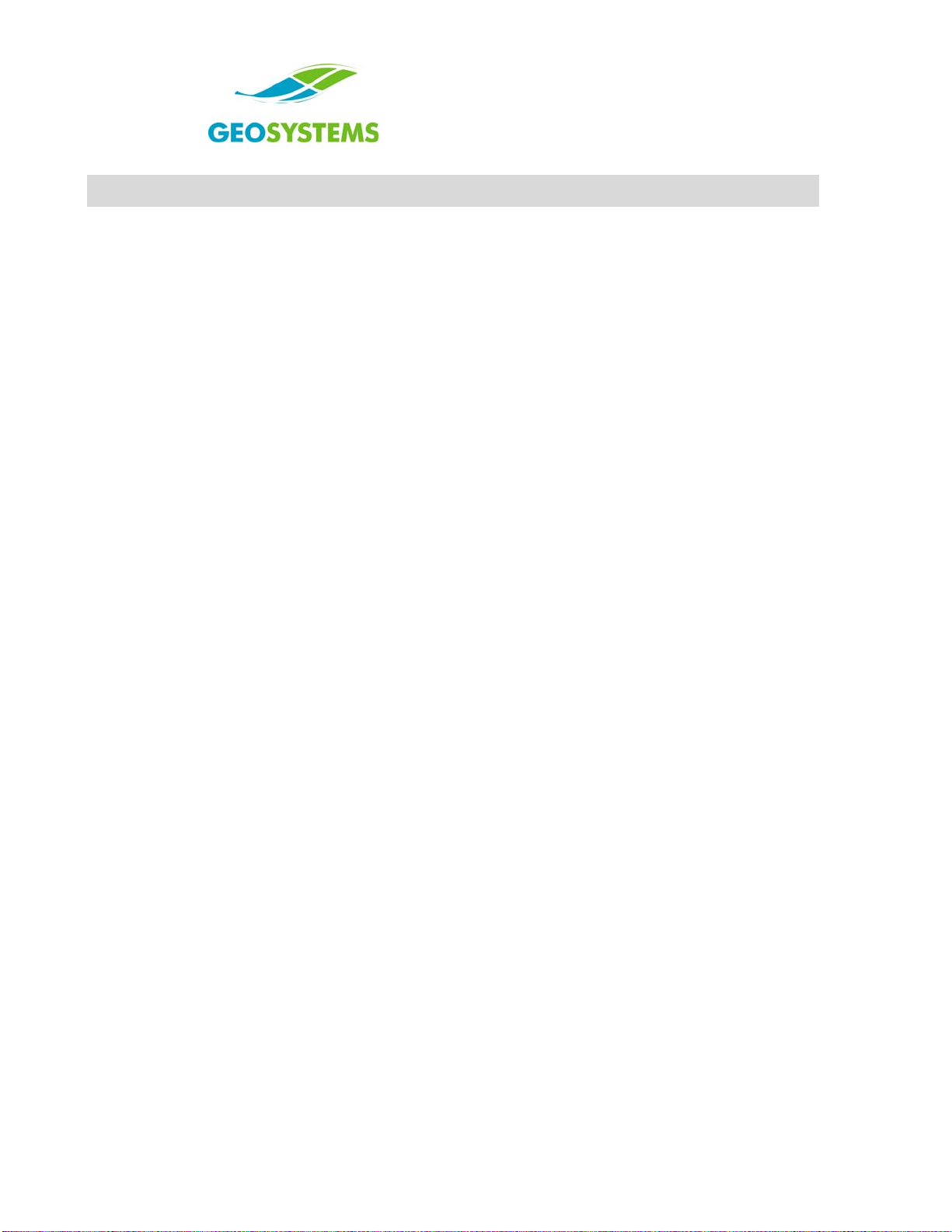

Geotextile Underlayer

•Most load support applications involve a geotextile separator

layer at the subgrade surface. When required, this

separation layer is critical to the performance of the load

support system.

•Ensure that minimum overlap between rolls is maintained.

See Figure 6.

•The geotextile may also function as a lateral drainage

medium. A thick, non-woven geotextile or geo-composite

materials are then required. Figure 6 Geotextile Placement

•High-strength geotextiles are used when building Geoweb®

structures over soft compressible soils. Pre-sewn seams,

rather than overlapped joints, may be required in some

situations.

PRESTO

GEOWEB®

LOAD SUPPORT SYSTEM

INSTALLATION GUIDELINE

PAGE 2OF 6 COPYRIGHT 2011 –PRESTO PRODUCTS CO. GW/LS000 18-APR-2011

Installation of Geoweb® Sections

•Option 1: Expand the specified Geoweb®section

into position and anchor with stakes.

See Figure 7. When ATRA®Anchors are used,

ensure the ATRA®Clip arm is hooked over the cell

wall or placed through the cell-wall slot hole. See

Figure 8.

•Specialized driving tools are available through

Presto Geosystems’ authorized distributors and

representatives to speed driving of ATRA anchors.

•Option 2: Expand and manually fill selected

perimeter cells prior to machine infilling.

See Figure 9.

•Option 3: The use of stretcher frames is

generally recommended only for underwater or

extremely cold applications.

Expand and fit the Geoweb®section over the

dowels of a suitably dimensioned stretcher frame.

Invert the frame and position the section to receive

infill material. When the Geoweb®section is filled,

remove the frame and repeat the process.

See Figure 10.

Figure 7 Stake Anchorage

Figure 8 ATRA®Anchor Placement Options

Figure 9 Infilling Perimeter Cells

Figure 10 Use of Stretcher Frame

PRESTO

GEOWEB®

LOAD SUPPORT SYSTEM

INSTALLATION GUIDELINE

GW/LS000 18-APR-2011 COPYRIGHT 2011 –PRESTO PRODUCTS CO. PAGE 3OF 6

Installation of Geoweb® Sections on Curves

Over-expand

the outer cells

Under-expand

the inner cells

Direction

of Geoweb

section expansion

Direction

of Geoweb

section expansion

Figure 11 Curved Expansion of Section

Under-expand

the outer cells

Over-expand

the inner cells

Direction of

Geoweb section

expansion

Direction of

Geoweb section

expansion

Figure 12 Tapered Expansion of Section

Method 1: Geoweb® sections can be readily adapted to

cover curved areas by varying the degree of cell

expansion across the width of individual sections.

See Figure 11.

Method 2: Progressively vary the degree of

cell expansion along the length of a section.

See Figure 12.

Connecting Geoweb® Sections

Figure 13 ATRA® Key Connection

Device

•Verify that the expanded dimensions of each Geoweb®

section are correct.

•Interleaf sides and abut ends of adjoining sections, ensuring

that the upper surfaces of adjoining sections are flush.

•Connect each of the interleaved and abutted cells with the

ATRA® key connection device. Position the ATRA key

through the slots of overlapping sections (side-to-side), or

where cells connect (end-to-end), and turn key to “lock” in

position. See Figure 13.

•When Geoweb sections are connected end-to-end, under-

expand a few rows of the adjoining section to allow easy

placement of the ATRA keys before fully expanding the

connecting section. For easiest placement, insert the key

completely through one cell before inserting through the

adjoining cell. Adjoining sections should also be fully

connected prior to infilling.

•The use of the ATRA key device will reduce construction

time significantly and offers cost-savings compared to

stapling operations.

•Geoweb sections may also be connected with pneumatic

staplers either side-to-side or end-to-end.

•The ATRA key connection device and pneumatic staplers

are available through Presto Geosystems and their

authorized distributors/representatives.

PRESTO

GEOWEB®

LOAD SUPPORT SYSTEM

INSTALLATION GUIDELINE

PAGE 4OF 6 COPYRIGHT 2011 –PRESTO PRODUCTS CO. GW/LS000 18-APR-2011

Placement and Compaction of Geoweb® Infill

•Place fill into expanded cells with suitable material

handling equipment such as a front-end loader or

excavator. See Figure 14 and Figure 15.

•Limit drop-height of infill material to a maximum of

1 m (3 ft).

•Overfill Geoweb®sections at least 50 mm (2 in) above

the cell walls before trafficking or compacting.

•Compact infill material to the specified density with

conventional compaction equipment. See Figure 16.

See Compaction Equipment on page 5 for limitations.

Figure 14 Fill Placement with Loader

Figure 15 Fill Placement with Excavator

Figure 16 Infill Compaction

Upon completion of the installation, ensure that an aggregate surcharge of at least 10 mm (0.4 in) is

maintained above the Geoweb®cell walls at all times.

Unbound aggregate surfacing must be graded and maintained on a regular basis.

NOTE: When pea gravel or other highly rounded stone is used for the infill and will have direct traffic over

the surface, blend it with 40%-45% sand to prevent excessive movement of the material.

Dimensions and Weights of Palletized Geoweb® Sections

Geoweb®sections are normally tri-folded and palletized for shipment to the site. Table 1 provides typical

pallet dimensions and weights for a range of section and cell sizes.

Table 1 V-Series Geoweb®Shipping Dimensions and Weights

Cell Depth Pallet Dimensions Minimum Weight Maximum Weight

100 mm (4 in) 1070 mm x 1070 mm (42 in x 42 in) 400 kg (880 lb) 730 kg (1,600 lb)

150 mm (6 in) 1070 mm x 1070 mm (42 in x 42 in) 360 kg (800 lb) 660 kg (1,450 lb)

200 mm (8 in) 1070 mm x 1070 mm (42 in x 42 in) 400 kg (880 lb) 730 kg (1,600 lb)

PRESTO

GEOWEB®

LOAD SUPPORT SYSTEM

INSTALLATION GUIDELINE

GW/LS000 18-APR-2011 COPYRIGHT 2011 –PRESTO PRODUCTS CO. PAGE 5OF 6

Infill Volumes

Table 2 Infill Volumes for Geoweb®Sections

Cell Depth 100 mm (4 in) 150 mm (6 in) 200 mm (8 in)

Volume (m³/ 100 m² of area) 10.0 m315 m320.0 m3

Volume (yd³/ 100 yd² of area) 11.1 yd³ 16.7 yd³ 22.2 yd³

Tools and Equipment

Installation efficiency is greatly improved by the appropriate choice of construction equipment and tools.

The following guidelines apply to most Geoweb®system applications. Non-standard tools and equipment

may provide additional benefits in some situations.

Table 3 Standard Construction Tools for Installation of the Geoweb®System

Geoweb® Components Power Tools Concrete Finishing Surveying Equipment

ATRA® Clips/Anchors Heavy-duty drill Bull floats Surveyor’s auto-level

ATRA® Connection Device Circular saw Hand floats Tripod and rod

Hand Tools Percussion hammer Steel trowels Laser beacons

Shovels and spades Stanley-Bostitch stapler Poker vibrators Audio target receiver

Rakes and screed bars SB103020 wire staples Tamping rods Survey stakes

Sledge hammers Gas generator Markers + spray cans

Crowbars Air compressor String-lines + spirit level

Utility knives

Spikes, nails + lumber

Templates

Excavation and Materials Handling Equipment

Conventional excavators, front-end loaders, mini-excavators and skid-steer loaders, equipped with

smooth-edged buckets, are normally employed for the installation of Geoweb®systems. Infilling of

Geoweb®sections can also be carried out with conveyors, chutes and skips. As a rule, the overall rate of

installation relates directly to the speed and efficiency of infill placement and compaction.

Compaction Equipment

Fully compacted infill is critical to the performance of the load support systems. When building a load

support system over a very soft subbase, a wave may occur in the system during the compaction

process. If the wave continues while compacting, full compaction will not be obtained. To remedy this

situation, the use of lighter compaction equipment is mandatory.

PRESTO

GEOWEB®

LOAD SUPPORT SYSTEM

INSTALLATION GUIDELINE

PAGE 6OF 6 COPYRIGHT 2011 –PRESTO PRODUCTS CO. GW/LS000 18-APR-2011

Limited Warranty

Presto Geosystems warrants each Geoweb®section which it ships to be free from defects in materials

and workmanship at the time of manufacture. Presto’s exclusive liability under this warranty or otherwise

will be to furnish without charge to Presto's customer at the original f.o.b. point a replacement for any

section which proves to be defective under normal use and service during the 10-year period which

begins on the date of shipment by Presto. Presto reserves the right to inspect any allegedly defective

section in order to verify the defect and ascertain its cause.

This warranty does not cover defects attributable to causes or occurrences beyond Presto's control and

unrelated to the manufacturing process, including, but not limited to, abuse, misuse, mishandling,

neglect, improper storage, improper installation, improper alteration or improper application.

PRESTO MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED, WRITTEN OR ORAL,

INCLUDING, BUT NOT LIMITED TO, ANY WARRANTIES OR MERCHANTABILITY OR FITNESS FOR

ANY PARTICULAR PURPOSE, IN CONNECTION WITH THE GEOWEB®SYSTEM. IN NO EVENT

SHALL PRESTO BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES FOR THE BREACH OF ANY EXPRESS OR IMPLIED WARRANTY OR FOR ANY OTHER

REASON, INCLUDING NEGLIGENCE, IN CONNECTION WITH THE GEOWEB®SYSTEM.

Geosystems®, Geoweb®, and ATRA® are registered trademarks of Presto Products Company.

Distributed by: Bowman Construction Supply, 10801 E. 54th Avenue, Denver, CO 80239; Phone: (303) 696-8960

Table of contents

Other Presto GEOSYSTEMS Construction Equipment manuals