HIAB HIAB T-HiDuo 013 CE User manual

This operator’s manual is an Original Instruction

and applies for cranes from serial number:

BL013000001, BL018000001, BL023000001, BL029000001, BL038000001

2016-04

Operator's Manual GB

HIAB T-HiDuo

013/018/023/029/038 CE

2Operator's Manual GB

Congratulations with your new crane!

You are now the owner of a quality product from

Cargotec, built to the highest standards of safety and

quality.

The aim of this manual is to help you handle your crane

safely and with full satisfaction.

Please read the complete manual. It provides detailed

information about the crane, control system and the

practical management and maintenance of the crane.

We advise you to read it carefully and familiarize yourself

with your crane before you start to use it.

Help us to improve this manual. Please send your

3

Table of Contents

Operator's Manual GB

1. Knowledge required............................................................................... 6

1.1 This Operator's Manual is intended for operators of this HIAB crane. .... 6

1.2 Indications in the Operator’s Manual ................................................ 7

1.3 The Machinery Directive 2006/42/EC ............................................. 10

1.3.1 Identification of the loader crane ............................................ 11

2. Structure and parts of the HIAB crane..................................................... 12

2.1 Main groups ............................................................................... 12

2.2 Crane base with column and slewing system .................................... 12

2.3 Boom system .............................................................................. 12

2.4 Boom system with hoist................................................................ 13

2.7 Stabiliser leg system..................................................................... 14

2.8 Operating system - hydraulic components ........................................ 15

2.9 LHV Load holding valves ............................................................. 15

2.10 Description of HIAB T-HiDuo 013/018/023/029/038 ......................... 16

3. Safety precautions and warnings............................................................. 17

3.1 Operating conditions .................................................................... 17

3.2 Definition of a HIAB loader crane.................................................. 18

3.2.1 Noise declaration................................................................. 19

3.2.2 Warning signs..................................................................... 20

3.2.3 Maximum load.................................................................... 20

3.2.4 Maximum load moment........................................................ 23

3.2.6 Determination - Hoist........................................................... 25

3.3 Signals when using a crane............................................................ 25

3.4 Wind speeds ............................................................................... 28

3.5 Use of the crane .......................................................................... 29

3.5.1 Preparations for use ............................................................. 31

3.5.4 Ending crane operation ......................................................... 35

3.6 Use of the Hoist .......................................................................... 36

3.7 Use of lifting equipment ............................................................... 38

3.8 Use of demountable cranes............................................................ 38

4. The Safety system................................................................................ 40

4.1 Safety System SPACE 4000 and Remote Control.............................. 40

4

Table of Contents

Operator's Manual GB

4.2 How the safety system works......................................................... 40

4.3 Components of the SPACE 4000 Safety System ............................... 41

4.4 Operating components .................................................................. 42

4.5 Main control valve....................................................................... 43

4.6 User panel SPACE 4000............................................................... 44

4.7 Indicator LEDs on user panel, SPACE 4000..................................... 45

4.8 XSDrive Lite controller ................................................................ 46

4.9 Indicator LED's on XSDrive Lite controller...................................... 48

4.10 Remote control XSDrive Lite with radio.......................................... 49

4.11 Battery charger XSDrive Lite ........................................................ 50

4.12 Menu selection XSDrive Lite......................................................... 50

4.13 Locking and unlocking the controller .............................................. 51

4.14 Functions in XSDrive Lite............................................................. 52

5. Starting crane operation ........................................................................ 54

5.1 Starting operations ....................................................................... 54

5.2 Extend stabiliser extensions and set stabiliser legs ............................. 56

5.3 Operate the crane out of parked position.......................................... 59

6. During operation ................................................................................. 60

6.1 OLP (Overload protection) ............................................................ 60

6.2 Manual extensions [option] ........................................................... 61

7. Change from hoist to hook operation ...................................................... 64

7.1 Change from hoist to hook operation .............................................. 64

8. Ending crane operation ......................................................................... 66

8.1 Operate the crane to parking position .............................................. 66

8.2 Placing the stabiliser legs in the transport position............................. 66

8.3 Switching off the safety system...................................................... 68

8.4 Emergency operation main control valve ......................................... 69

8.5 TWI Transport warning interface.................................................... 69

9. Maintenance and Service ...................................................................... 71

9.1 Service ...................................................................................... 71

9.2 Warranty.................................................................................... 72

5

Table of Contents

Operator's Manual GB

9.3 Follow the maintenance instructions! .............................................. 73

9.3.1 Daily inspection .................................................................. 75

9.3.2 Monthly inspection and maintenance....................................... 77

9.3.3 Annual maintenance............................................................. 79

9.3.4 Check rope ......................................................................... 80

9.3.5 Cleaning the rope ................................................................ 80

9.3.6 Requirements of the rope ...................................................... 81

9.3.7 Change of rope.................................................................... 82

9.4 Lubrication................................................................................. 84

9.4.1 Lubrication schedule ............................................................ 85

9.4.2 Lubrication of the column bearings......................................... 86

9.5 Hydraulics.................................................................................. 86

9.5.1 Replacing the cartridge in return oil filter ................................ 86

9.5.2 Checking the oil tank level.................................................... 87

9.5.3 Changing the hydraulic oil .................................................... 87

9.5.4 Hoist gear, top up or exchange oil .......................................... 90

9.5.5 Bleeding air from the hydraulic system.................................... 91

9.6 Troubleshooting .......................................................................... 93

9.6.1 Main fuses.......................................................................... 93

9.6.2 Faults on the crane............................................................... 94

9.6.3 Faults in the hoist ................................................................ 96

10. Decommissioning ................................................................................ 98

10.1 Decommissioning a crane.............................................................. 98

11. Technical Data .................................................................................. 100

11.1 Load plate table ......................................................................... 100

6

Knowledge required

Operator's Manual GB

1

1.1 This Operator's Manual is in-

tended for operators of this

HIAB crane.

This manual describes:

• Operation

• Safety precautions and warnings

• The crane control system

• Maintenance and troubleshooting

Enclosed to this manual the Installer will

provide:

• Technical Data for your crane

• Technical Data and manuals for add on

equipment if fitted

Study these instructions carefully

DANGER

If you do not study the complete Operator’s

Manual for your crane carefully, it could lead

to fatal accidents or serious damage.

Therefore you should:

• Study the entire Operator’s Manual carefully.

• Study the operating manuals for other add-on

equipment, if fitted.

• Use the crane only after having done so.

• Follow the directions for use, operation and

maintenance of the crane and add on equip-

ment exactly.

• Store the Technical Data and manuals from

the Installer, together with this Operator's

manual.

! NOTE

The manufacturer reserves the right to change

specifications, equipment, operating instructions

and maintenance instructions without prior notice.

7

Knowledge required

Operator's Manual GB

1.2

NOTE

HIAB shall at all times have the right to:

• install, maintain and dismantle automated re-

mote diagnostics system or similar sensor-

based system (the “System”) in and from the

Equipment; and

• access, send, receive, collect, store and use

any and all information and data gathered or

created by such System including but not

limited to information concerning operation,

operating environment, movement, condition,

logon, location and similar information relat-

ing to the Equipment (the “Information”).

The Customer shall not in any way remove or

alter the System, nor interfere with the use of the

System or the Information. The System and the

Information and all their further developments

shall at all times be and remain the exclusive

property of HIAB without granting any right or

license to the customer.

1.2 Indications in the Operator’s

Manual

What must you do and not do?

The following indications are used in the Opera-

tor’s Manual:

DANGER

Danger to life for yourself or to bystanders.

Follow the instructions carefully!

WARNING

Danger of injury to yourself or to bystanders,

or danger of serious damage to the crane or

other objects.

Follow the instructions carefully.

8

Knowledge required

Operator's Manual GB

1.2

CAUTION

Hazard for the crane or crane components.

Follow the instructions carefully.

Important:

If actions are numbered

1. Do this

2. Do that

3. ......

4. .....

5. .....

you should carry them out in numerical order!

! NOTE

Extra information that can prevent problems.

TIP

Tip to make the work easier to carry out.

Symbol for reference to a component in an

illustration

①Refers to a component in an illustration.

[option]: Indication for parts that are not-standard

for the crane, but are an option.

DANGER

Only persons with the requisite knowledge and

experience with cranes may use the crane.

Never operate the crane when you are sick,

tired, under the influence of medicines, alcohol

or other drugs.

• Take the delivery instructions from your

HIAB Service workshop, or receive instruc-

tion from an experienced person from your

own company. Only then should you operate

your crane.

9

Knowledge required

Operator's Manual GB

1.2

• Ensure that you comply with the statutory

requirements of the country in which you use

the crane (for example, certificate, obligatory

safety-helmet).

DANGER

• Carry out yourself only the service and

maintenance work you have the requisite

knowledge and experience of.

• All other maintenance work may only be

carried out by a HIAB service workshop.

• Ensure that every defect is rectified imme-

diately, according to the instructions.

• Follow the instructions exactly!

• All other work to rectify faults must be

performed by personnel in a HIAB service

workshop!

WARNING

• Never clean the electronic system, plastic

components, signs or bearings with a high-

pressure jet cleaner. It could cause damage.

• Never expose the electronic system to high

electrical voltages. This could damage the

safety system.

• Never immerse the controller in water or

other liquid. This will make the controller

unusable.

If your crane is equipped with add-on lifting

equipment:

• The operation of the crane with add-on

lifting equipment can differ from the oper-

ation as described in this manual.

• You should therefore study the Operating

Manual for the add-on equipment careful-

ly, before you use the crane.

• Take particular note whe placing the crane

in to or out of transport position.

Declaration of conformity with the

Machinery Directive 2006/42/EC

We ………………….

…………………

…………….

hereby declares that the loader crane:

Mark: …………..

Type:

Serial number:

……………..

.………………

Manufact. year: ………….

complies with the provisions of the machinery

directive 2006/42/EC;

also complies with the provisions of the

directive on electromagnetic compatibility

2004/108/EC as amended.

Technical file in accordance with Directive

2006/42/EC, Annex VII A is compiled by:

Name: …………………….

Address: ..............................

…………………….

This declaration is drawned up by:

Name …………………….

Position ……………………..

➀

➁

➂

➃

➄

xxxxxxxxxxx

xxxxxxxxxxx

10

Knowledge required

Operator's Manual GB

1.3

1.3 The Machinery Directive

2006/42/EC

• The Declaration of Conformity, delivered

with the crane contains ①:

• Business name and full address where the

crane is manufactured ②:

Factory addresses:

Hiab Cranes S.L.U. Pol. Ind. Malpica, calle

E, 86 50016 Zaragoza, Spain

Cargotec Poland Sp. z o. o. Ul. Metalowa 2,

73-102 Stargard, Poland

• Description and identification of the loader

crane ③:

Mark

Type: see chapter Identification of the crane.

Serial number

Manufact. year

Declaration of which provisions the loader

crane fulfils.

• Name and address of the person authorised to

compile the technical file ④:

Name

Address

• Identity and signature of the person who

drawn up the declaration ⑤:

Name

Position

Date and Signature

11

Knowledge required

Operator's Manual GB

1.3.1

1.3.1 Identification of the loader crane

The information below is to be filled in by the

installer. The same information will be found on

the serial number plate on the crane:

Mark: HIAB

Type: ..........................

Serial number: ............................

Manufact. year: ............................

12

Structure and parts of the HIAB crane

Operator's Manual GB

2

2.1 Main groups

The HIAB crane consists of the following main

groups:

• Crane base with column and slewing system

• Stabiliser system

• Boom system

• Operating system

2.2 Crane base with column and

slewing system

Crane base, column and the slewing:

• Crane base

worm wheel

hydraulic motor

• Column

bearings

• Cog wheel

2.3 Boom system

The boom system consists of the following

components:

• 1st boom ①

• Hydraulic extension ②

The length of the hydraulic extension depends

on the type of crane.

• Manual extension ③

Manual extension is slid by hand into the

hydraulic extension.

①

13

Structure and parts of the HIAB crane

Operator's Manual GB

2.4

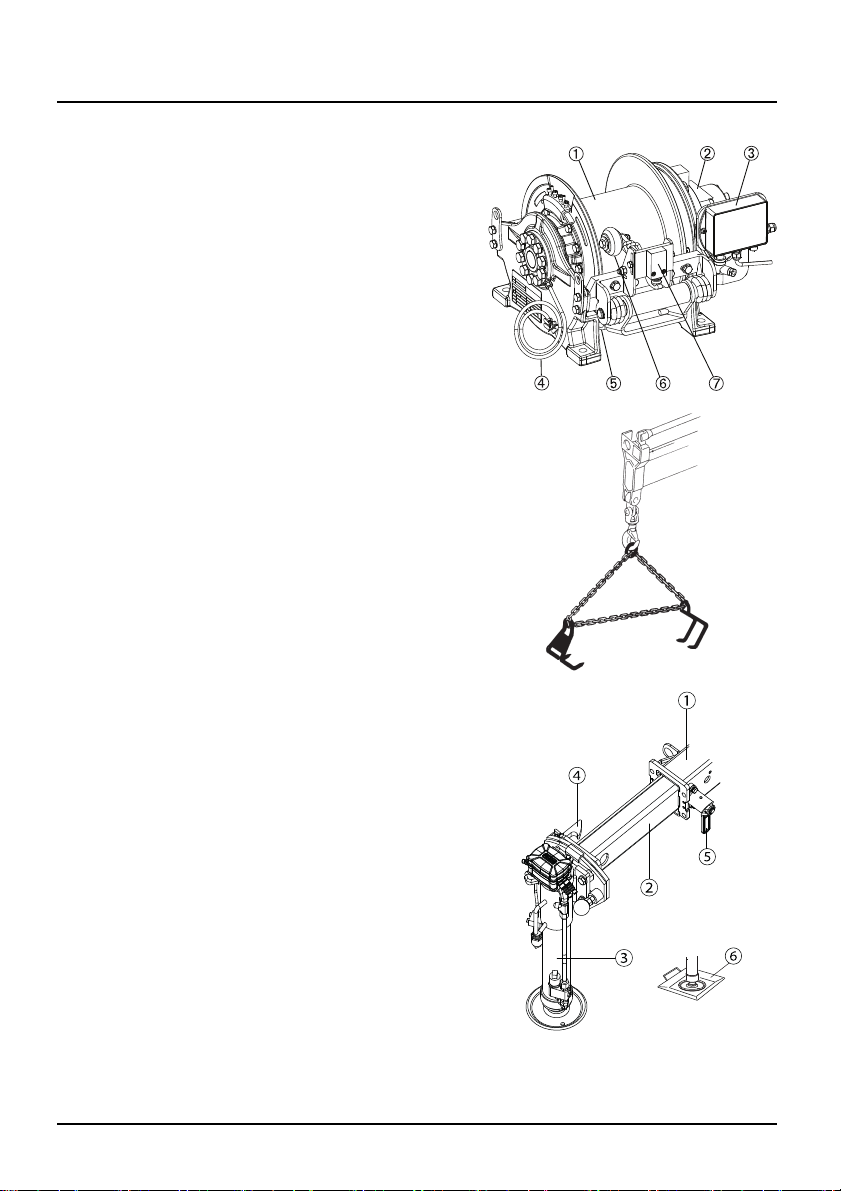

2.4 Boom system with hoist

The boom system consists of the following

components:

•①1st boom

•②Hydraulic extensions

The length of the hydraulic extension depends

on the type of crane.

•③Hoist [option]

•④Sheave block [option]

The sheave block must only be attached to a

hydraulic extension. Never to a manual exten-

sion.

•⑤Counterweight [option]

•⑥Hook [option]

14

Structure and parts of the HIAB crane

Operator's Manual GB

2.7

Hoist [option]

The hoist consists of the following components:

①Rope

②Motor

③Electronic box

④Electrical wire to load sensor

⑤Pressure roller

⑥Wear plate for rope end monitoring

⑦Switch for 3-rolls left to rope end monitoring

Separate lifting accessories [option]

Separate lifting accessories, help to make or use a

slinging device: eye-hooks, shackles, eye-bolts

etc.

2.7 Stabiliser leg system

Every truck mounted HIAB crane has a minimum

of one stabiliser leg. Auxiliary stabilisers may be

needed for heavy cranes.

• Stabiliser beam ①

• Stabiliser extension ②.

• Stabiliser leg ③

• Stabiliser leg locking device ④

• Stabiliser extension locking device ⑤

• Support plate ⑥. The support plates are used

under the stabiliser legs for additional sup-

port.

15

Structure and parts of the HIAB crane

Operator's Manual GB

2.8

2.8 Operating system - hydraulic

components

The operating system consists of the following

hydraulic components:

• oil tank

• hydraulic pump

PTO or a 12V/24V motor

• Main control valve

• hydraulic hoses and pipes

• actuators:

first boom cylinder

extension cylinder/s

• filter/s

2.9 LHV Load holding valves

The cylinder is equipped with a load-holding

valve. After a crane movement it holds the crane

in position.

If there is a leak or a component fractures, such

as a pipe, hose or a coupling, the load-holding

valve will stop the boom from collapsing down,

even when the hydraulic system is switched off,

and you operate a particular crane function.

To operate a hydraulic cylinder equipped with a

load holding valve, an opening pressure is re-

quired.

16

Structure and parts of the HIAB crane

Operator's Manual GB

2.10

2.10 Description of HIAB T-HiDuo

013/018/023/029/038

The HIAB T-HiDuo 013/018/023/029/038 are

compact, hydraulically operated goods cranes and

fulfil the European Machinery Directive require-

ments specified in the standard EN12999. The

cranes are stress class S0, according to EN13001.

Lifting capacity:

• HIAB T-HiDuo 013 = approx. 1,2 tonne

metres

• HIAB T-HiDuo 018 = approx. 1,8 tonne

metres

• HIAB T-HiDuo 023 = approx. 2,3 tonne

metres

• HIAB T-HiDuo 029 = approx. 2,8 tonne

metres

• HIAB T-HiDuo 038 = approx. 3,6 tonne

metres

The cranes are supplied in versions from:

HIAB T-HiDuo 013-1 (reach 2 metres) to HIAB

T-HiDuo 013-3 (reach 4,2 metres)

Note! VSL is not available on Hiab T-HiDuo 013

HIAB T-HiDuo 018-1 (reach 2 metres) to HIAB

T-HiDuo 018-3 (reach 4,2 metres)

HIAB T-HiDuo 023-2 (reach 3,4 metres) to

HIAB T-HiDuo 023-3 (reach 4,4 metres)

HIAB T-HiDuo 029-2 (reach 3,4 metres) to

HIAB T-HiDuo 029-4 (reach 5,5 metres)

HIAB T-HiDuo 038-2 (reach 3,6 metres) to

HIAB T-HiDuo 038-4 (reach 6 metres)

The crane type and the manufacturer are marked

on the serial number plate.

! NOTE

The exact technical information for your crane is

shown in the Technical Data.

17

Safety precautions and warnings

Operator's Manual GB

3

3.1 Operating conditions

You may only use the crane under the following

conditions:

• In the open air, or in spaces with sufficient

ventilation.

DANGER

• If you use the crane in a confined space

you could suffocate from the exhaust gases

from the vehicle.

• With a mean wind velocity less then 13.3

m/sec (approx. 29.7 mph). See the wind

speed table.

• Never use the crane in a high wind or

storm. When the mean wind velocity ex-

ceeds 13.3 m/sec (approx. 29.7 mph) the

crane will behave unpredictably. Never use

the crane during a thunderstorm.

•Never use the crane at temperatures below

-40° C (-40 °F), as the steel's properties

deteriorate below this temperature.

WARNING

• At temperatures below 0 °C (32 °F):

Do not touch the operating levers during

the first few minutes.

• When starting in cold weather, the wear on

the hydraulic system is greater than at

normal working temperatures.

To minimise wear, the crane should be started as

follows:

• Engage the power take-off at low rpm.

• Allow the system to idle for a few minutes.

• Operate the stabiliser leg up for one minute in

order to warm up the oil.

• Working with hoist in temperatures below -10

°C (14 °F) operate the hoist in both directions

without load for a few minutes to warm up

the oil.

18

Safety precautions and warnings

Operator's Manual GB

3.2

3.2 Definition of a HIAB loader

crane

Usage of the crane

The HIAB loader crane is used to lift and move

loads in the working area permitted by the load

plate and the load diagram. The cranes are

normally mounted on a vehicle but they can also

be mounted on a fixed base plate. The crane can

be equipped with a number of accessories.

Loader cranes are designed for loading and

unloading the vehicle, as well as for other duties

as specified:

Permitted duties:

• Loading and unloading cargo from/to a vehi-

cle

• Lifting of loads from the ground/vehicle to a

higher place

• Installation work (beams, concrete plates,

windows...) in building constructions

• Lifting construction material (wall boards,

bricks, blocks…) on a pallet fork to a build-

ing, taking the material from the vehicle on

which the crane is mounted, from another

vehicle or from the ground

• Hoisting, e.g. beams, concrete plates and any

other material and equipment used in building

construction

• Collection of waste and recycling material

(glass, paper, cardboard, plastic…)

• Installation of informative posts, road signs,

notice boards, traffic lights, street lights…

• Handling submerged pumps in wells, using a

hoist

Forbidden duties:

• Crane mounted onboard ships or floating

structures, only permitted in cases authorized

by HIAB

19

Safety precautions and warnings

Operator's Manual GB

3.2.1

• Continuous use as a production crane in

assembly lines, foundries…, except for cranes

prepared for that purpose

• Loading cargo that is partially loaded or

fastened by other means, without making sure

the capacity of the crane is enough for the

entire load

• Any duty which implies:

• Pressure against the ground, unless the

crane is specifically prepared for this

• Push/pull with the boom system against

any type of obstacle (wall, ground…)

3.2.1 Noise declaration

The following values for emitted noise may be

taken as general and conservative values for

ordinary installations of loader cranes on normal

diesel engine powered trucks. Declared dual-

number noise emission values in accordance with

ISO 4871:

• Emitted A-weighted sound power level for

basic loader cranes in accordance with ISO

3744: LwA = 103 dB (Uncertainty: KwA = 2

dB).

• Emitted A-weighted sound power level for

loader cranes with hoist in accordance with

ISO 3744: LwA = 107 dB (Uncertainty: KwA

= 2 dB).

• A-weighted sound pressure level at loader

crane control stations in accordance with ISO

11201: LpA = 95 dB (Uncertainty: KpA = 4

dB).

Particular installations can be quieter, in which

case a post installation noise measurement in

accordance with clause 6.3 of EN 12999:2011

may be used to prove this.

LOADER CRANE

METALOWA2, 73-102 STARGARDSZCZECINSKI

CARGOTECPOLAND SP. Z 0.0.

POLAND

187-5931/2

x.x x.x x.x x.x

x.x

xxxx xxxx xxx xxx

xxx

kg

xxxxxxx

kg

3874744

8 m

7

6

5

4

3

2

1

0

-1

-2

-3

-4

0 1 2 3 4 5 6 m

1820 1065 725 550 430

20

Safety precautions and warnings

Operator's Manual GB

3.2.2

3.2.2 Warning signs

3.2.3 Maximum load

Lifting capacity

Your crane has a certain lifting capacity, ex-

pressed in kNm or tm. This lifting capacity is

also known as the load moment. The lifting

capacity is: the payload at hook multiplied by the

outreach in metres that the crane can operate at

different positions. The lifting capacity of your

crane determines the maximum load your crane

may lift within its working zone. However take

careful note; the greater the operating radius of

the crane, the lower the lifting capacity will be

because of the weight of the boom system itself.

The load plate and the load diagram on your

crane show the maximum loads you may lift in

the operating reach of your crane.

This manual suits for next models

4

Table of contents

Other HIAB Construction Equipment manuals

HIAB

HIAB J14S User manual

HIAB

HIAB L-HiPro 145 User manual

HIAB

HIAB K-HiPro 285-425-4 Series User manual

HIAB

HIAB 422-477 HiPro CD User manual

HIAB

HIAB X-HiPro 358-408-418 X4 User manual

HIAB

HIAB 190TM Guide

HIAB

HIAB 335K HiPro CD CE User manual

HIAB

HIAB 435K HiPro CD User manual

HIAB

HIAB X-Duo 044 User manual

HIAB

HIAB 322 HiPro CD User manual

Popular Construction Equipment manuals by other brands

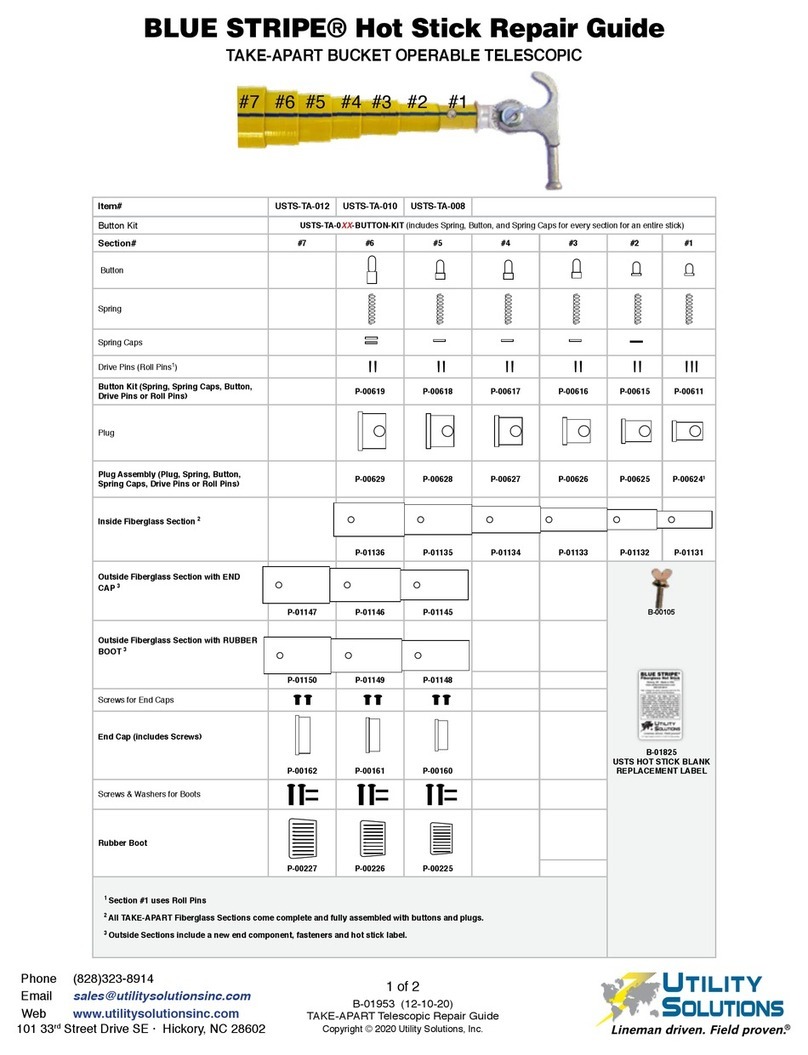

Utility Solutions

Utility Solutions BLUE STRIPE Hot Stick Repair guide

SANY

SANY STG210C-8 Safety, Operation & Maintenance Manual/Parts List

Jet

Jet JHC-200X Operating instructions and parts manual

Doka

Doka Ringlock User information

Tadano

Tadano Mantis 10010MX Operating and maintenance manual

Dynapac

Dynapac CS 141 maintenance