Page 6 Presto-ECOA Lifts AX, AXR, AXS & AT Series and AL Series

SAFETY ALERT SYMBOLS AND SIGNAL WORDS

The safety of all persons operating, maintaining, repairing, or in the vicinity of this equipment is of paramount concern. This is

a powerful machine with moving parts, and is capable of causing personal injury if proper precautions are not taken. Therefore,

throughout this manual, certain hazards have been identied which may occur in the use of the machine, and there are appropriate

instructions or precautions which should be taken to avoid these hazards. In some cases, there are consequences which

may occur if instructions or precautions are not followed. Below are the symbols and signal words along with their denitions

referenced from ANSI Z535.4 - Product Safety Signs and Labels.

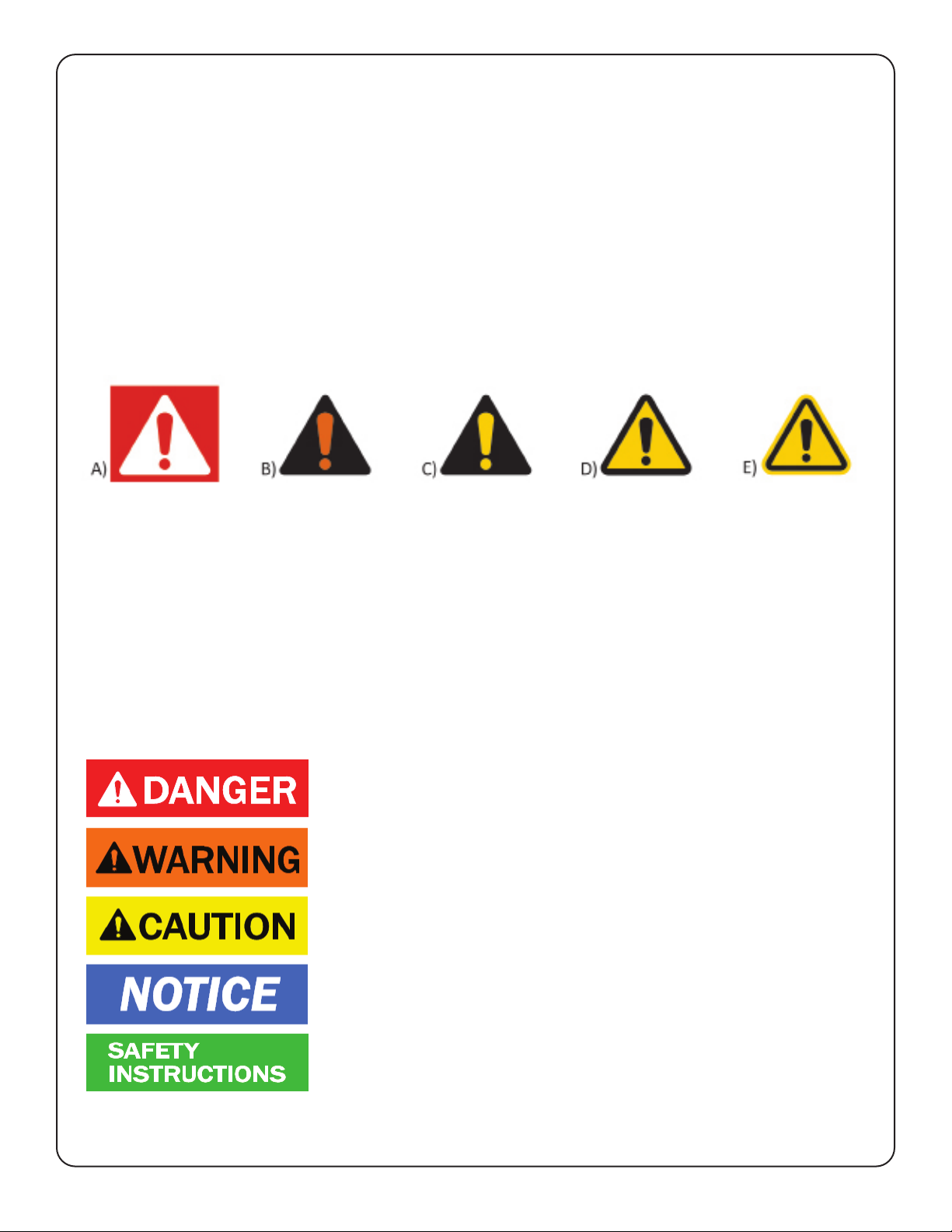

4.11 Safety Alert Symbols: A symbol that indicates a hazard. It is composed of an equilateral triangle surrounding

an exclamation mark. The safety alert symbol is only used on hazard alerting signs. It is not used on safety notice and safety

instructions signs.

4.14 Signal Words: The words used in the signal word panel. The signal words for hazard alerting signs are “DANGER,”

“WARNING,” and “CAUTION.” Safety notice signs use the signal word “NOTICE.” Safety instruction signs use signal words that

are specic to the situation.

DANGER indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

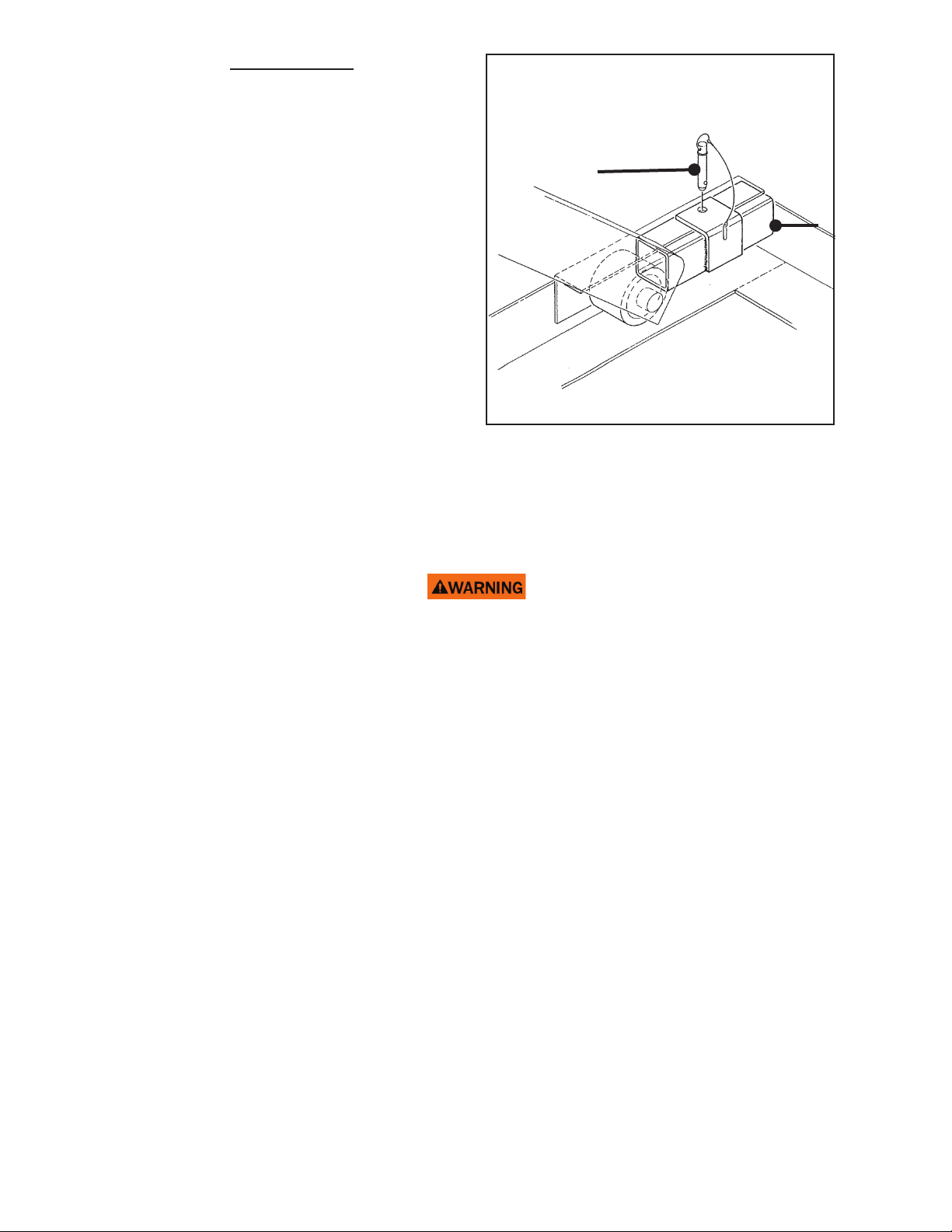

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE is used to address practices not related to physical injury.

SAFETY INSTRUCTIONS (or equivalent) signs indicate specic safety-

related instructions or procedures.

NOTE: DANGER, WARNING or CAUTION should not be considered for property damage accidents unless personal injury risk

appropriate to these levels is involved.

A): for use with DANGER signal word; (safety white triangle, safety red exclamation mark, safety red background)

B): for use with WARNING signal word; (safety black triangle, safety orange exclamation mark)

C): for use with CAUTION signal word; (safety black triangle, safety yellow exclamation mark)

D) and E): for use with DANGER, WARNING, or CAUTION signal word; (D: is a safety yellow triangle with a

black border and safety black exclamation mark; E: is a safety yellow triangle with a safety black exclamation mark and a

safety yellow border around a safety black band)

NOTE: D and E are provided to allow for consistency with certain ISO standards such as ISO 3864-1 and ISO 3864-2.