PRI Entity User manual

DATALOGGER USER GUIDE

Page 1

Information contained within this document is subject to change without notice and does not

represent a commitment on the part of PRI Ltd or its agents. E&OE.

Copyright PRI Ltd, 2003. 9600-3008-2 Issue A

Care must be exercised during the installation of dataloggers and associated equipment due to the presence

of mains voltages.

Local best practice and regulatory stipulations must always be observed.

Installation should only be performed by suitably trained personnel. Various points under the terminal cover

operate at hazardous voltages.

Removing the cover with power applied exposes potentially hazardous voltages.

After installation access to the connectors and conductors must be prevented by fitting the cover supplied,

ensuring that it is secured in position with the screws provided.

PRI dataloggers are double-insulated. The electrical supply should be taken from a point fused at 3A using

cable rated for 3 A at 230 V.

An external two-pole switch or circuit-breaker must be mounted adjacent to the unit.

Replace fuses only with correctly rated items. The correct rating is shown adjacent to each fuse.

Use or installation other than in accordance with this document may result in safety hazards.

CE MARKING DECLARATION OF CONFORMITY

PRI dataloggers meet standard BS EN 610336:1997, and therefore conform to EU Directive

89/336/EEC ‘EMC Directive’ as amended by 92/31/EEC and 93/68/EEC.

IMPORTANT SAFETY INFORMATION

SECTION A: INSTALLATION

SECTION B: PHYSICAL ARRANGEMENTS

Fig. 1 Fixing Centres for Datalogger

How to fix the datalogger into position

PRI dataloggers are designed for vertical mounting, and can be fitted to meter panels, boards, enclosures or walls.

Suitable screws must be selected to ensure a

good fixture. Screws of up to M4 or 4BA size can

be used. PRI dataloggers use a three-point fixing

arrangement. The top screw is located on the

datalogger’s centre-line and fits into a ‘key-hole’

locator on the rear-plate of the unit. This screw

supports the unit in position on the surface to

which it is be attached. Two other screws are

fitted through the terminal block of the unit and are

used to secure it against the mounting surface.

The fixing centres are as shown on this view of a

datalogger rear panel.

1. Mark out the position of the unit on the

mounting surface, drill a hole and fit the top

fixing screw (A).

2. Fit the unit over the top fixing screw taking care

to align it correctly within the ‘key-hole’ locator.

3. With the terminal cover removed, mark out the

positions of the lower fixing screws (B).

4. Remove the unit, drill holes for the lower fixing

screws.

5. Fit the unit over the top fixing screw again.

6. Fit the lower fixing screws.

A

BB

Page 2

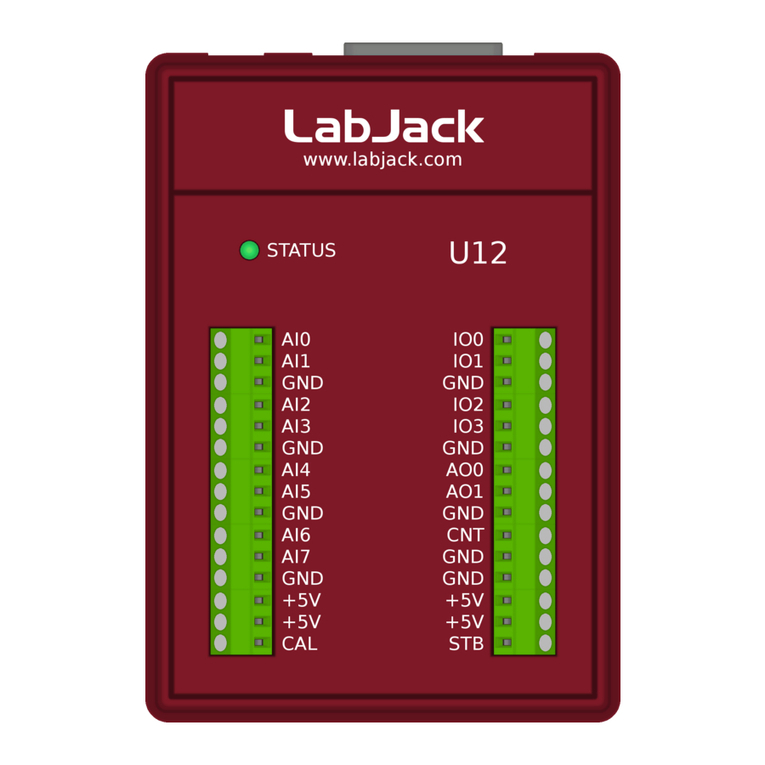

Fig. 2 Datalogger Principle Components

SECTION C: CONNECTIONS TO EXTERNAL EQUIPMENT

Page 3

Fig. 3 Connections to Mains and Pulse Inputs

The datalogger should be connected to a spur

fused at no more than 3 A, using suitable cable

rated at 230 V. The unit is designed to be

energized continuously and therefore is not fitted

with a power switch. The gland supplied with the

unit provides strain-relief so long as it is fitted

correctly and sufficiently tightened.

Pulsed input cables should also be fitted using

the supplied gland, which should be sufficiently

tight to provide strain-relief. Twisted-pair

unshielded cabling is recommended. The

Datalogger has wetted inputs that can drive up to

500 m of typical 7/0.2 mm cable.

Fig. 4 Pulse Input Connections to External Devices The datalogger input channels are

wetted with a dc voltage. Polarity

must therefore be observed when

connecting to devices with

solid-state outputs, such as

Sprint, Premier, Encore or Elite

meters.

Each input has a pair of terminals,

labelled ‘H’ and ‘L’. These must

be connected in the manner

shown in Figure 4. 16-channel

dataloggers have two rows of

connnectors; the lower one is for

inputs 9 to 16.

SECTION D: COMMUNICATING WITH DATALOGGERS

PRI dataloggers are fitted with three interfaces for commnunications with external devices.

The PACT port can be used for interrogation by local or remote PCs. A permanent connection can be made as part of a

PACTLAN network, using a PACT Netbox. The PACT port can also be used for connecting a notebook PC using a PACT

lead.

The Modem Input RJ-11 port can be used to connect the datalogger integral modem to a telephone line.

The PACTLAN Output can be used to connect the datalogger to a network of other PRI meters or dataloggers. The

PACTLAN network can only be accessed remotely via the internal modem. It is not possible to access the PACTLAN

network through the PACT port, so it is not possible to use a datalogger as a ‘PACTLAN repeater’.

Each datalogger channel is identified by number based on the hardware serial number which is used by PRI software,

such as EASEii and Principal, when reading out the half-hourly data.

Channel Number Format

8-channel: PD1Ynnnn 16-channel: PD2Ynnnn

Where Y is the channel number, and nnnn is the unique hardware serial number for the datalogger.

For example, a datalogger with serial number PD101234 would have 8 channels addressable by software as PD101234,

PD111234, PD121234, PD131234, PD141234, PD151234, PD161234 and PD171234. 16-channel dataloggers have

channels numbered 0 through F as the fourth character in the address number.

Each channel has an activity LED on the front panel that is illuminated to indicate when a pulse is detected. The LEDs

are labelled A1 to A8 for 8-channel devices, corresponding to inputs 1 to 8 on the input connector. The additional LEDs

on 16-channel units are labelled B1 to B8 for inputs 9 to 16 on the input connector.

The load survey is returned at 1200 bd, time-stamped against GMT, as ‘non-specific pulses’ (BF) data.

SECTION E: DATALOGGER PART NUMBERS AND SPECIFICATION

Dimensions: 264 wide x 228 high x 240 deep (mm)

Weight: 3.2 kg

Enclosure: IP65; ABS, UL 94 HB

Part Numbers: 8-channel:0300-0265; 16-channel: 0300-0264

Data Storage: 8-channel model: 70 days of half-hourly values

16-channel model: 35 days of half-hourly values

Data are maintained for at least 30 days in the event of a power interruption

Data Inputs: Self-wetted (up to 3 mA at approximately 12 V dc) for use with volt-free contacts. Inputs are

designed for use with unshielded twisted-pair 7/0.2 cable up to 500 m long. The inputs incorporate

debouncing and can detect pulses down to 50 mS duration at up to 4 Hz. Front-mounted indicator

LEDs show activity on each input channel.

Time Reference: Internal batttery-backed real-time clock

Communications: Front-mounted PACT (RS-232 compatible) serial communications port (1200 bd)

Integral V22 modem with RJ-11 socket mounted on the base of the unit

9-pin D-type connector on base of unit for built-in PACTLAN distribution unit for connecting up to 16

compatible PRI meters or dataloggers

Accessories: Glands for mains and pulse input cables. PACTLAN adapter cable; 9-pin D plug to free end, 5 m long.

Page 4

Fig. 5 Connecting Dataloggers to a PACTLAN Network