PRIMEX®4 Pump Watch™Express User Manual

ACTIVATION AND SERVICE

The data management for Pump Watch™remote cellular devices is hosted by: Aqua Management

Incorporated, 6280 S. Valley View Blvd. Suite 212, Las Vegas, NV 89118

All Pump Watch™Express RTUs are provided with a year of pre-paid cellular service. Activation of

your device is required for operation. An account needs to be setup if this is your first Pump Watch™

device.

Activate a new

Pump Watch™or

Pump Watch™Express device.

User must send Activation request

to a PRIMEX®contact person

including the device ID + existing

account name.

PRIMEX®will forward request to AMI via:

Support @aquamanagement.com

Device typically activated within 2

hours

(During office hours 9am-5pm Pacific

time.)

User must fill in the Account Setup

form and send it to a PRIMEX®

contact person.

Data needed:

- Device ID number

- Name and email of End User

(will get the bill for service after the

first year)

- New Account name

(Example: City of Fargo)

- User login name request.

PRIMEX®will forward request to AMI via:

Support @aquamanagement.com

New Account will be created within 24

hours + device activated.

End User

Will receive login instructions via email.

Will verify contact and billing information.

Existing account?

(User already has an

account and

Pump Watch™devices)

YES NO

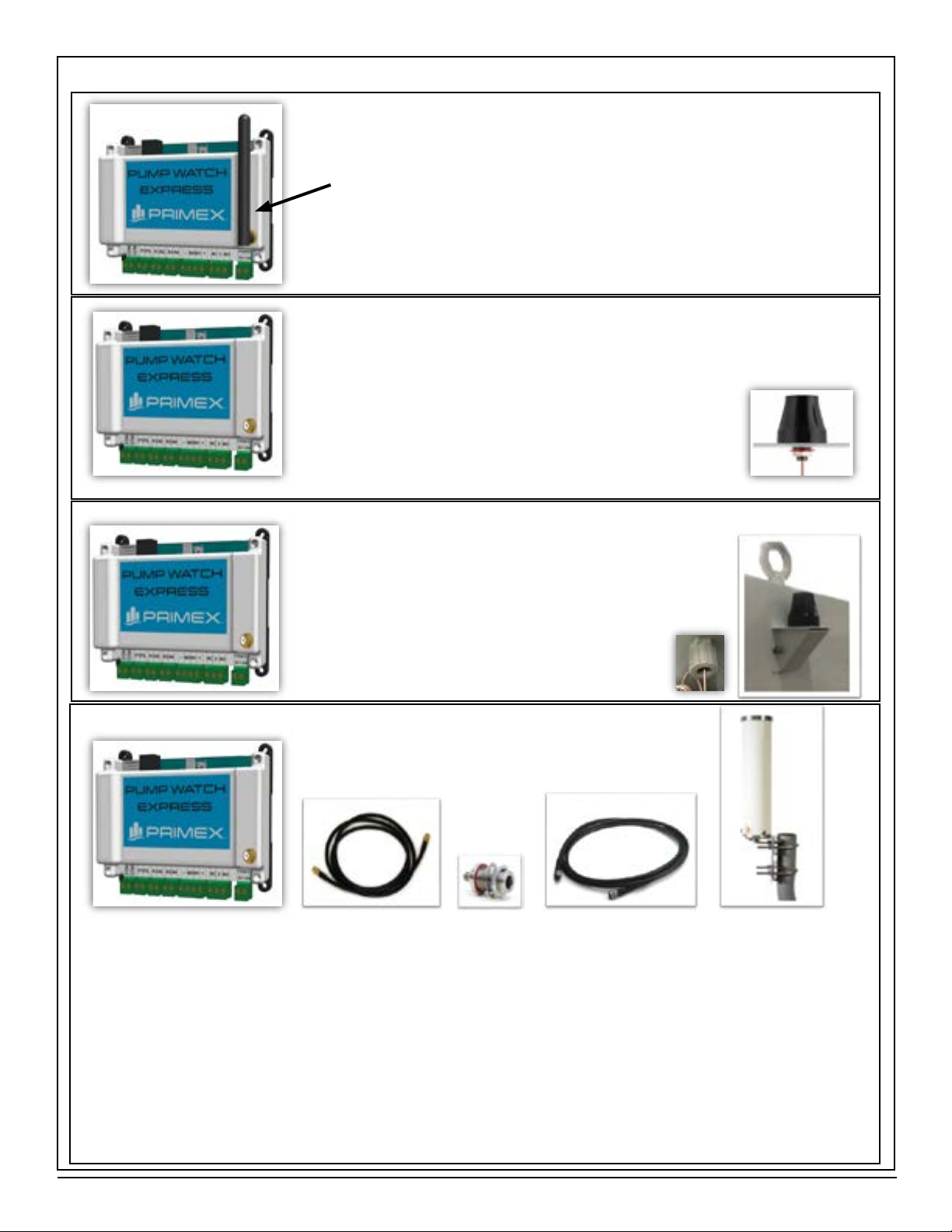

Pump Watch™Express ID number (Located on the device)

LIGHT:

ID: 60XXXLIGHT - 3G GSM

ID: 65XXXLIGHT - CDMA

ID: 64XXXLIGHT - LTE

PREMIUM:

ID: 63XXXPREMIUM - 3G GSM

ID: 68XXXPREMIUM - CDMA

ID: 69XXXPREMIUM - LTE

GATEWAY:

ID: 66XXXGATEWAY - 3G GSM

ID: 62XXXGATEWAY - CDMA

ID: 67XXXGATEWAY - LTE

The Account Setup Form can be downloaded from:

www.primexcontrols.com/pumpwatchremotemonitoring.html

Updated: 7/24/2018

Please fill in foror accounts. If existing account, provide device ID and account name.

Example:

Example: Plymouth

Example:

Example:

Example: 555

Example: plymouth

Example:

Example: Plymouth MN 55441

Example:

Example: 555

Example: mplymouth

End Users who wish to create an account for monitoring Pump Watch devices and those who will be responsible for

the service fee after the initial period is complete.

Example of End Users: A City, Municipality, Water district, Utility Service Company, etc…

This form provides contact and billing information to AMI (Service Company). This will allow them to contact the End

User directly with service renewal options after the initial period is complete.

Information from this new account will be used to setup a login username and password to grant access to the web

portal.

Complete this form and send to your PRIMEX contact person:

Clearwater, FL Julian Atchia (800-746-6287 x3462) julian.atchia@sjeinc.com

Ashland, OHJason Mailloux (800-746-6287x4110) jason.mailloux@sjeinc.com

Plymouth, MN Troy LaDoux (763-559-0568 x6915) troy.ladoux@sjeinc.com

Detroit Lakes, M

N Marty Grabarkewitz (800-746-6287 x3357) marty.grabarkewi[email protected]

It is recommended this form be submittedat least 24 hourspriorto thedeviceactivation.

Once the form is submitted, the User will receive an e-mail from AMI with a link and instructions for login and account

verification. The link will expire after 7 days. Click on the link or cut and paste it intoyour browser URL. Once the

account is verified, power up thedevice forfinal activation and setup. The device is then ready for use.

Once the account is setup, the End Usercan activate additionalPump Watch RTUs in the futurebyfilling in the

and the of the Pump Watchthatneeds to be activated.

1056819C

8/2018