Primo Water RAVEN XR15 User manual

TABLE OF CONTENTS

TABLE OF CONTENTS 2.........................................................................

RAVEN-XR15 TECHNICAL DATA 3...........................................................

RAVEN-XR15 ROASTER DRAWINGS 4......................................................

FRONT VIEW 5...................................................................................

LEFT SIDE VIEW 6...............................................................................

REAR VIEW 7.....................................................................................

RIGHT SIDE VIEW 8.............................................................................

TOP VIEW 9.......................................................................................

FRONT VIEW WITH CYCLONE 10.............................................................

SAFETY INFORMATION 11.....................................................................

THINGS TO CONSIDER 12......................................................................

PRE-INSTALLATION 13.........................................................................

INSTALLATION 14................................................................................

EXHAUST DUCTING & GENERAL INFORMATION 16.....................................

EXHAUST DUCTING, HOT AIR - ROASTERS & AFTERBURNERS 17...................

EXHAUST DUCTING, AMBIENT AIR -LOADERS & DESTONERS 18....................

OPERATING MACHINE 19.....................................................................

MAINTENANCE & CLEANING 21.............................................................

ADDITIONAL DOCUMENTS & INFORMATION 23.........................................

raven-xr15 TECHNICAL DATA

1. Raven-Xr15 Roaster Technical Data

This section contains a table, on the next pages, with technical data information applicable to

both the Standard Raven-Xr15 and a Custom Raven-Xr15 roaster. Information in this table is subject

to change.

RAVEN-Xr15 Information

Technical Data

Green coffee capacity, min-max

15 - 33 lb.; 6.80 - 15 kg

Dimensions, maximum L x W x H

90” x 80” x 78”

Shipping Weight (Approximate)

1,650 lb; 748.42 kg

Roaster

1200 lb; 544.3 kg

Cyclone

300 lb; 136.1 kg

Full Batch Roast Time

Approximately 15 minutes

Hourly Output

95.46 lb/hr.; 43.3 kg/hr.

Roast Air, Maximum

360 scfm

Cooling Bin Air, Maximum

1125 scfm

Cyclone Exhaust Diameter

6 in; 152.4 mm

Roaster Exhaust Diameter

6 in; 152.4 mm

Temperature High Limit

500F/ 260C

Gas Information

Gas Types

Liquid Propane (LP) or Natural Gas (NG)

Maximum Consumption

300,000 BTU/hr.; 88 kW

Typical Consumption per roast

53,000 BTU; 15.5 kWh

Inlet Pressure LP

11 in WC; 27.4 mbar

Inlet Pressure NG

7 in WC; 17.4 mbar

Inlet Gas Supply Connection

3/4” in male NPT on the roaster

Electrical Information

Volts AC

220V 14.5 amps

Frequencies

60Hz

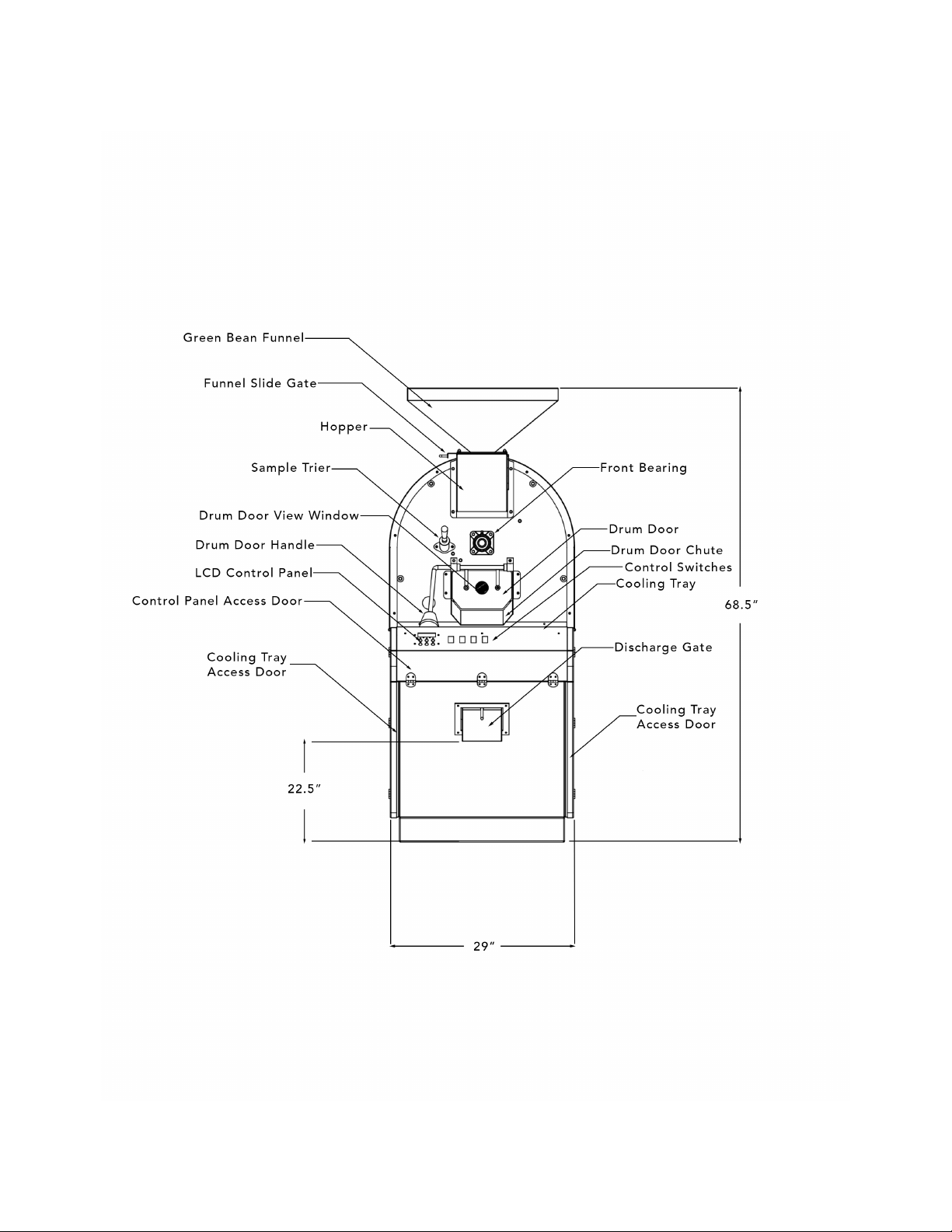

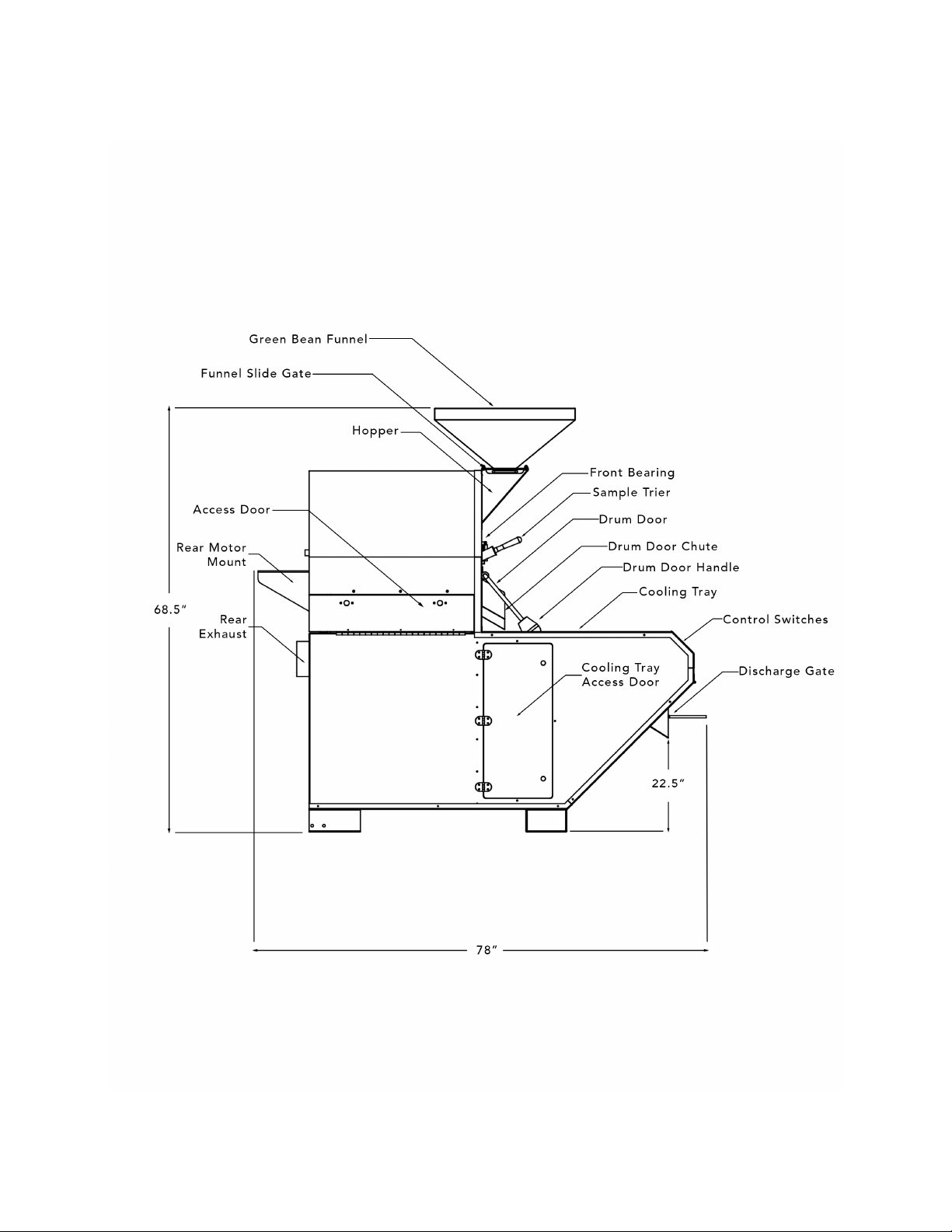

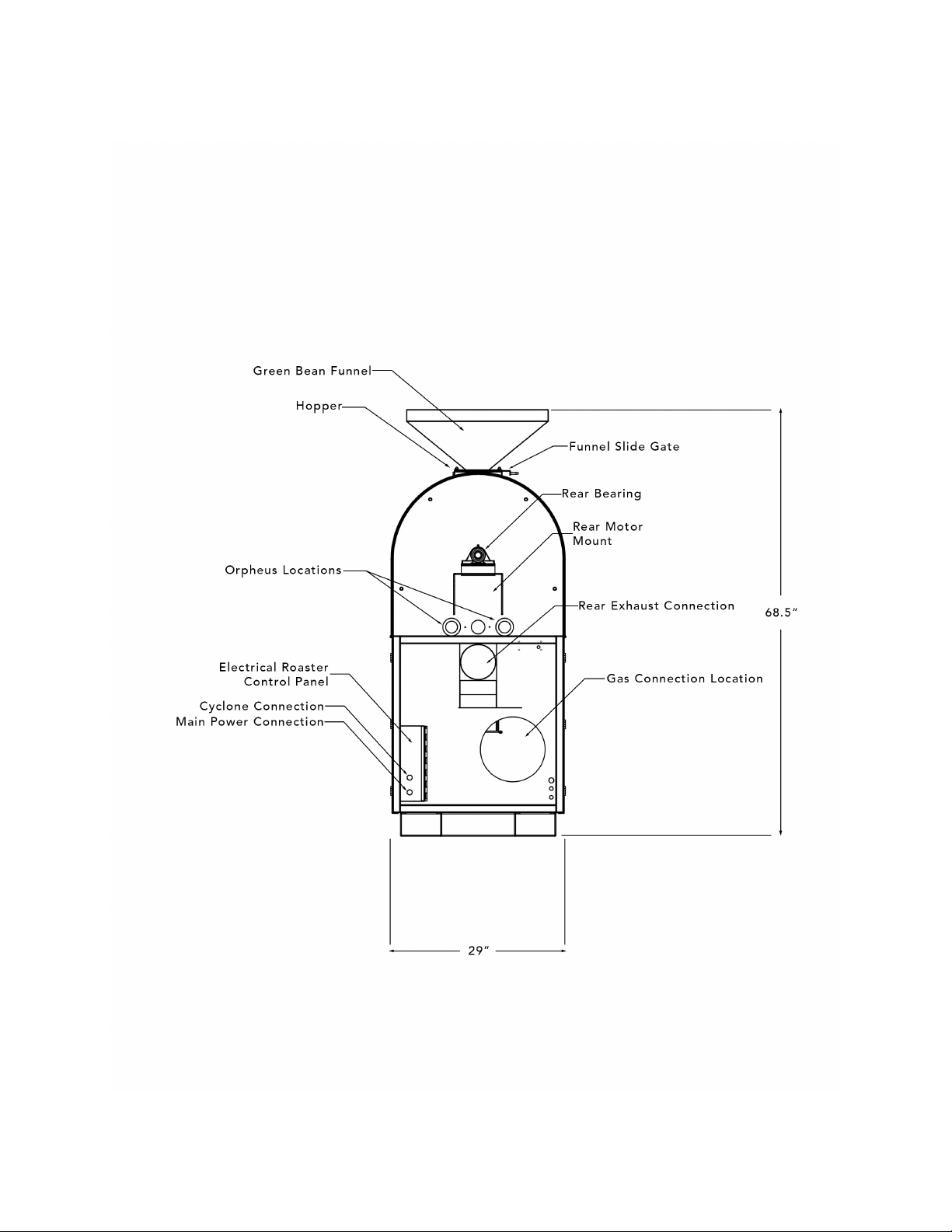

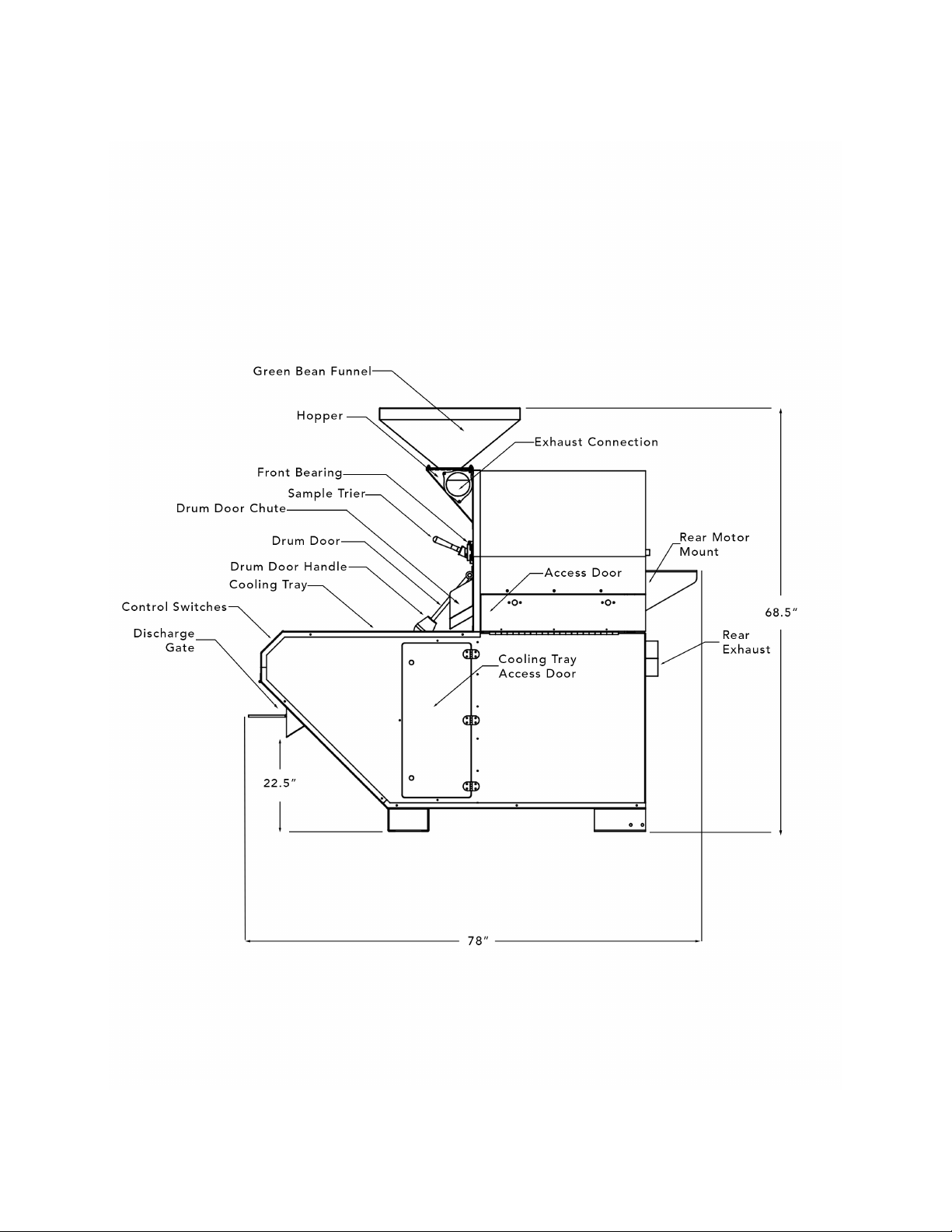

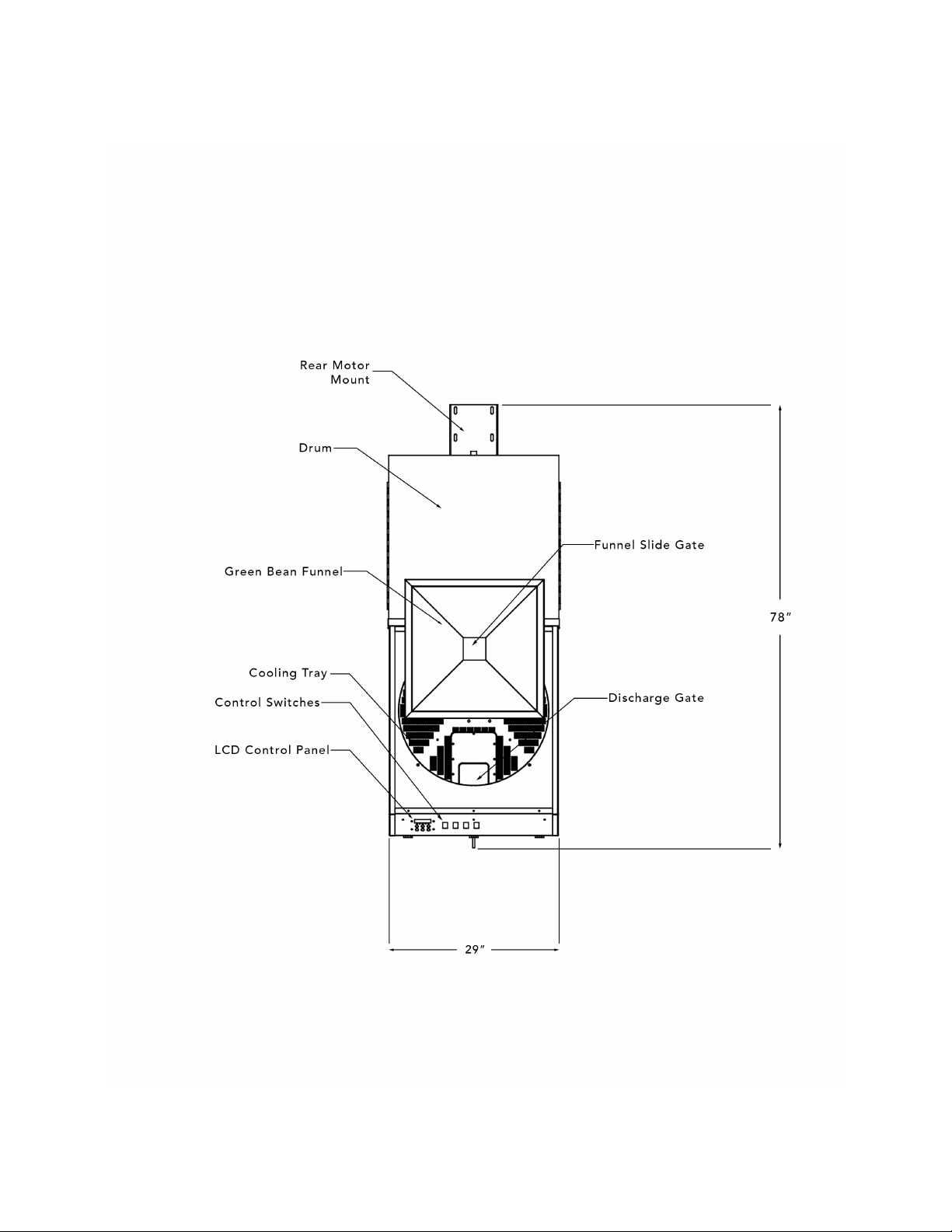

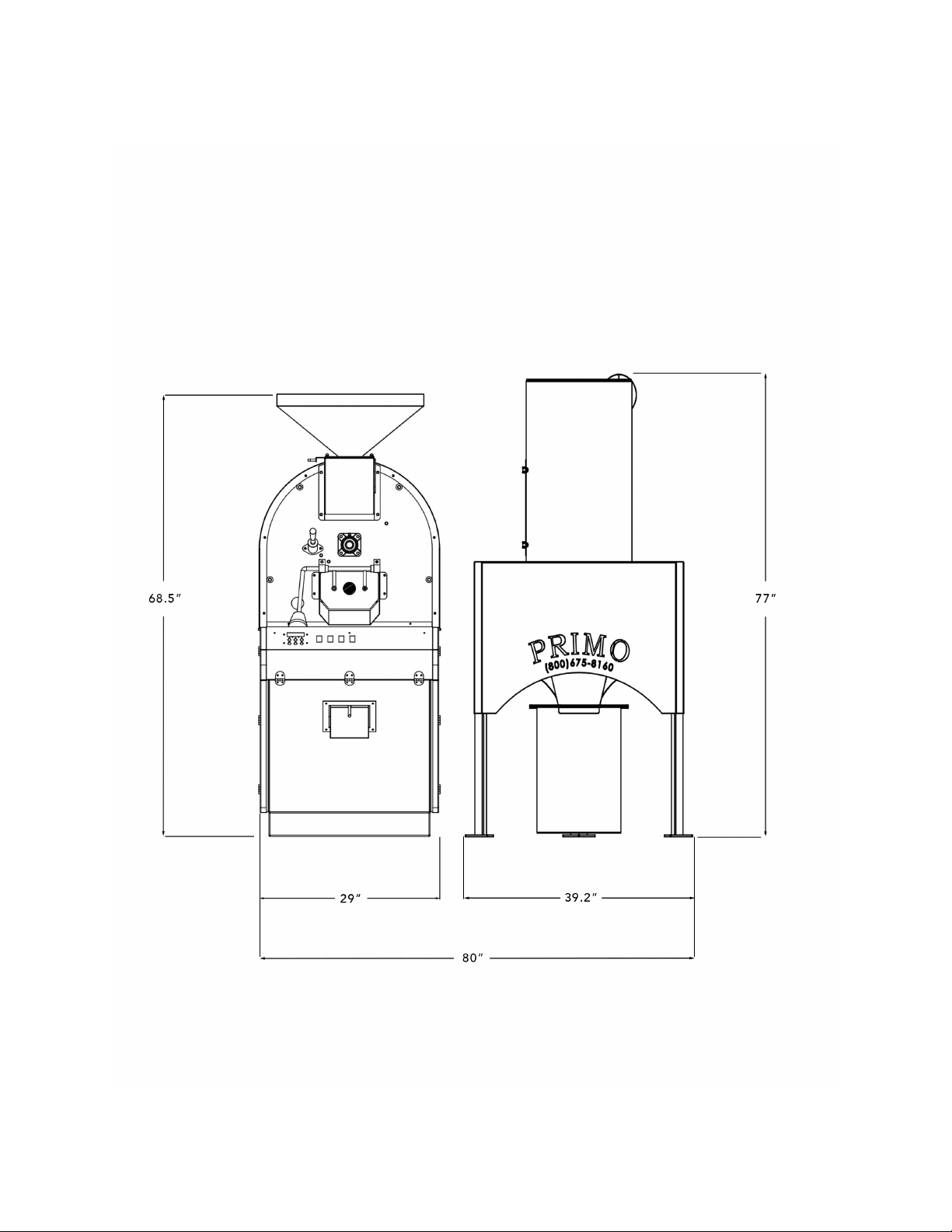

raven-xr15 Roaster Drawings

2. Raven-Xr15 Roaster Drawings

This section contains drawing views with dimensions and component descriptions. These

drawings are valuable for familiarization with the Raven-Xr15 roaster and for space and utility

connection planning.

Dimensions and some details are subject to change.

These drawings each take a full page so the remainder of this page is intentionally blank.

Front view

Scale 1:32

Left side view

Scale 1:32

Rear view

Scale 1:32

Right side view

Scale 1:32

Top view

Scale 1:32

Front view with cyclone

Scale 1:32

Roaster to Cyclone Connection Not Pictured Above*

Safety information

Prior to installing & operating your roaster please read the entire manual. If you see

this symbol in the manual, make sure to read what follows because it is a caution for

actions that can cause harm or damage to your machine and/or the operator.

Death, injury, or property damage can be caused because of improper installation,

adjustment, alteration, service, or maintenance. The entire installation guide must be

read prior to installing, cleaning, operating, or servicing this roaster.

It is the owner’s responsibility to ensure the installation, cleaning, and operation of the

roaster are done safely/properly. Only a qualified professional should operate this

roaster.

Keep any flammable items including but not limited to, gases, vapors, liquids, & solids,

far away from the roaster at all times. The roaster needs to have a fire extinguisher

nearby easily accessible incase of fire. Your local fire department will have information

on which fire extinguishers should be used. Fires may be caused from not cleaning the

roaster or exhaust system correctly and/or often enough.

The roaster needs 18 inches of space around it at all times. Do not touch hot

surfaces.

Once the installation of the roaster is completed, you will need to have it inspected to

ensure it is compliant to local building codes. A local fire inspector must also inspect

the machine. These things must be done prior to operating. The Primo Roasting

Equipment warranty may be null/void if the inspections are not done. This would

relieve Primo Roasting Equipment from any liability that has to do with the use of the

machine & how the installation was done.

Instructions for what to do when the roaster operator finds a gas leak and/or smells

gas need to be posted in a location easily accessible/readable. Your local gas company

or company that supplies gas will have the instructions for you to get from them.

Things to consider

i. Ease of movement

ATTENTION: Prior to moving machine and/or cyclone make sure the

roaster is turned off, unplugged, and the gas is disconnected/off.

To move the roaster and/or cyclone the machine must be taken apart.

1. Remove exhaust arm by pulling it off via compression fittings and set aside.

2. Unbolt cyclone from ground if applicable.

(1) Use forklift to pickup machine from the back *make sure to tilt forklift

back once the roaster is lifted up to avoid it sliding off or tipping the

forklift*

3. Place roaster in desired location using the installation guide/spacing

requirements.

Make sure to leave ample room behind the machine in order to let forklift have

access for movement purposes.

*Every time the machine is moved, disassembled, & put back together the

operator must inspect machine prior to resuming operations*

Pre-installation

i. Receiving/Un-Crating

ATTENTION: Hire a professional to install your roaster.

Roaster:

The roaster comes in a crate.

Cut plastic walls off to expose roaster.

*Be careful not to drop/slide the tool you are using to cut into the

crate, on the roaster*

Once all walls are taken off, cut the steel cord strapped over the cooling tray to the

pallet.

After the roaster is free standing on the pallet use forklift to move off of the pallet.

Pick up roaster from the back of the machine to get off of the pallet

*Make sure to tilt the forklift arms up once roaster is in the air*

*We recommend keeping the roaster as close to the ground as possible

when moving*

Set roaster in desired area *Spacing requirements further down*

Cyclone:

The cyclone comes bolted down on a pallet, wrapped in plastic.

Remove plastic wrap from cyclone & pallet Move pallet as close to desired position

for the cyclone to make moving it easier.

*Use spacing requirements further down*

Remove bolts from cyclone legs.

Pick up cyclone using forklift in-between the cyclone legs.

*Wrap and protect the forklift arms/cyclone arms to prevent abrasion on

the cyclone when moving*

Place cyclone on correct side of roaster using spacing requirements below.

Spacing Requirements:

Be sure you have ample access to the green bean funnel, control panel, access

doors, chaff bin, hopper, etc.

Space your roaster about 18” from back wall to ensure you have ample access for

venting the machine.

The footprint of the roaster and cyclone is 90” x 80” x 78”. The cyclone needs to be

placed 12” to the right of the roaster. The cyclone vent should be flush with the

roaster vent to make adding the exhaust arm simple & easy. There must be easy

access to the following areas: cyclone chaff bin, left and right side access doors,

control panel, hopper, and gas line connection located on the back of the machine.

Having easy access to these places will make cleaning and maintenance much easier.

Installation

ATTENTION: Hire a professional to install your roaster. This manual must

be read completely through prior to any installation. Check with local

building authorities for their local codes & installation requirements prior to

installation.

i. Electrical

ATTENTION: Use a licensed electrical company when installing the

electrical on your Primo roaster.

Consult your licensed electrician to ensure proper installation of either the 110 V or

220 V, based off requested voltage. If using 220v a 3 prong 220v will not be included

and must be wired to the 3 wires from the machine.

ii. Gas

ATTENTION: Use a licensed gas company when installing the gas line on

your Primo roaster.

Local codes, regulations, and/or laws must be followed when doing the gas

installation for the machine.

*Propane roasters must use propane only and are required to use a gas

regulator.

*Have a certified gas worker inspect and double check any gas connection

work you do.*

iii. Roaster Funnel & Cyclone Exhaust Fitting

1. Remove a total of four nut caps (7/16”) from the hopper.

2. Place funnel slide gate in designated position on top of the hopper.

3. Place green bean funnel on top of the funnel slide gate.

4. Before tightening the green bean funnel to the hopper ensure that your funnel

slide gate is operating smoothly. (Slide gate should move with ease.)

5. After the slide gate and green bean funnel are in position you may begin

tightening the four nut caps using a (7/16”) wrench.

6. Finally, slide the exhaust on, connecting the roaster and cyclone via compression

fit.

iv. Cyclone

ATTENTION: When installing the cyclone to your roaster use a licensed

contractor.

The cyclone uses 6" ducting too vent.

Consult your licensed contractor to ensure proper installation of duct work.

Exhaust ducting & general information

1. Throughout the remainder of this document, the term exhaust ducting refers to

the ducting that the customer, or their contractor/representative, select, acquire, and

install. The exhaust ducting will connect to the applicable Primo Roasting provided

equipment.

2. One of the most important aspects of the equipment installation is the use of an

approved exhaust ducting system. Its design can greatly affect the equipment

performance and the product quality. The cost and time to order and install the

exhaust ducting are also important customer considerations.

3. Designing the exhaust ducting system requires a qualified professional to calculate

the efficiency of the system and the proper size of ducting. The ducting must be of

sufficient diameter to accommodate the air flow (SCFM - standard cubic feet per

minute or SCMH - standard cubic meters per hour), and meet applicable regulations. A

licensed engineer or Heating, Ventilation, Air Conditioning (HVAC) professional can

assist. Information the qualified professional will need, such as the diameter of the

exhaust ducting and the maximum exhaust air flow, is located on page 3 Technical

Data table. Customers should contact their sales or project manager representative

with any questions.

4. A properly designed and installed chimney and rain cap is essential to the

equipment performance and longevity. Water leaking in may cause an electrical short

or damage the equipment. Your contractor will be able to coordinate with local

jurisdictions for the correct cap. The cap should not have a screen since it will clog

with residue of chaff over time.

5. The Primo Roasting Equipment (roaster, cyclone, Afterburner, loader, or destoner,

as applicable) MUST NOT support the weight of the exhaust system.

6. The exhaust air from Primo products fits into one of the two general categories.

Either hot exhaust air, such as from the roaster or an afterburner; or ambient/room

temperature exhaust air, from products such as loaders and destoners. The sections

that follow will discuss ducting considerations specific to these general categories.

Exhaust ducting, hot air - roasters & afterburners

1. The exhaust air from the roasting process is hot and contains oils and residues

which are flammable. In the event of a ducting/flue fire, the internal duct temperatures

can exceed 1000° F (538°C), which could cause nearby combustible materials to

ignite. Thus, Diedrich recommends, at a minimum, stainless steel, double wall, positive

pressure grease ducting that meets the applicable region/local standards, such as UL

for USA, ULC for Canada, and CE for the European Union.

2. An important consideration when designing an exhaust ducting system is the

static pressure. The static pressure is the back-pressure or suction within the system.

The exhaust ducting that connects to the roaster, cyclone, or afterburner, must be

designed to operate with a static flue pressure between negative 0.15”WC (suction)

and positive 0.25”WC (back-pressure) at the exhaust of the roaster (cyclone or

Afterburner, as applicable) while in operation.

3. For Roasters (with or without cooling bin cyclone, and without an Afterburner).

Ducting must be suitable for 500°F (260°C) continuous, 2,000°F (1,093°C) for

30, minutes, and comply with UL-1978/ULC-SC662 Standard for Grease Ducts in the

USA/Canada, and/or equivalent standards for other countries (such as CE standards for

the European Union).

Installation must be done in accordance with appropriate NFPA standards in the

USA or equivalent standards in other countries. The installation must also comply with

the manufacturer’s installation specifications and allowable distance to combustible/

noncombustible materials.

4. For Roasters with an Afterburner.

Ducting from the Afterburner must be suitable for 1,000°F (538°C) continuous,

1,400°F (927°C) intermittent, and comply with UL103/ULC_ORD-C959 in the USA/

Canada, and/or equivalent standards for other countries (such as CE standards for the

European Union).

Installation must be done in accordance with appropriate NFPA standards in the

USA or equivalent standards in other countries. The installation must also comply with

the manufacturer’s installation specifications and allowable distance to combustible/

noncombustible materials.

Exhaust ducting, ambient air -loaders & destoners

DANGER

DO NOT USE CLASS B OR SPIRAL-WRAP DUCTING FOR ROASTER OR

AFTERBURNER DUCTING UNDER ANY CIRCUMSTANCES.

DANGER

Fires are caused by failure to maintain a clean roaster and its exhaust

ducting system. Regular cleaning of the roaster and exhaust ducting will

prevent the buildup of residues that could cause fire.

1. The exhaust air from loaders and destoners is about the same temperature as the

ambient air in the room or operating area. The regulatory requirements for the

exhaust ducting for these components are much less stringent than the

requirements for the hot air roaster, cyclone and afterburner exhaust.

2. The exhaust air from the green bean loader and the destoner will likely contain

some dust and/or other particulate matter. A dust collection system should be

considered.

Operating machine

Primo Roasters have 3 or 4 switches depending on model. The switches in order

from left to right: Ignition (IGN), Drum (DRUM), Cooler (COOLER), & Agitator (AGT).

Every Primo Roaster is outfitted with a LCD screen. This LCD screen shows your

current drum temperature, Temp 1 & Temp 2 set points, and your Burners switch (ON/

OFF).

i. Starting Roaster

1. Make sure roaster is properly connected to correct gas source.

2. Make sure roaster is properly plugged in to correct outlet.

3. Make sure the chaff bin is empty and that the under cooler & side panels are

clean of debris.

How to turn roaster on:

ii. Roasting

1. Preheat roaster before first roast for 15-20 minutes or at 400 F.

2. Turn Drum on by pushing in the drum switch on the control panel of the roaster.

3. Next push in the ignition switch next to the drum switch to activate the LCD

screen.

4. Press the ON button located on the LCD screen to ignite the burners.

5. Push temp 1 button on the LCD, use keypad to set desired temperature.

6. Push temp 2 button on the LCD, use keypad to set desired temperature.

7. Let roaster preheat to desired temperature and stay constant for 3 minutes.

8. Fill hopper with raw material.

9. Once filling stops pull funnel slide gate open to allow material to fall into the

drum.

10.Close funnel slide gate.

11.Once the material reaches desired temperature turn on the agitator switch and

the cooler switch.

12.When material is finished open drum door to allow all material to fall into the

cooling tray.

13.Allow machine to reheat prior to next material.

14.Open discharge gate to allow first roast to be transported before the new roast

reaches desired degrees.

15.Close discharge gate when all roasted material is out of cooling tray to prepare it

for the batch currently roasting.

16.Repeat steps for multiple batches.

iii. Cooling

Cooler/Agitator

Primo Roasters are equipped with an agitator/cooler to cool down the roasted

material.

Before dropping roasted material into the cooler tray turn on the agitator and cooler

switches (The Genesis-Xr3 & Ranger-Xr5 models do NOT have both switches).

Once your material has cooled to the desired temp you can open the discharge gate

to drop material into storage bin. Be sure to close the discharge gate correctly before

dropping the next batch of material into the cooler tray.

iv. Misc

Shut-off

1. Open funnel slide gate and the drum door when shutting off to speed up cooling

process.

2. Push stop button on the LCD screen until the burners turn off.

3. Leave the drum switch on until temp drops to 200 degrees F.

4. Turn all switches to the off position once the roaster has cooled down.

5. Close funnel slide gate and drum door.

6. Turn gas valves off and unplug the roaster.

Table of contents

Other Primo Water Kitchen Appliance manuals

Primo Water

Primo Water FlavorStation 100 User manual

Primo Water

Primo Water EL-16C User manual

Primo Water

Primo Water PR303IKP User manual

Primo Water

Primo Water MAXI User manual

Primo Water

Primo Water PDR-16 User manual

Primo Water

Primo Water PS-12 User manual

Primo Water

Primo Water WARDEN-XR30 User manual

Popular Kitchen Appliance manuals by other brands

Westinghouse

Westinghouse QL302 owner's manual

Steba

Steba Litho KS 1 Instructions for use

EuropAce

EuropAce EWC 6340S instruction manual

Rasonic

Rasonic Floral Tea Cook Master Operation manual

Brentwood Appliances

Brentwood Appliances AR-136 Operating and safety instructions

Black & Decker

Black & Decker JE2001 Use and care book