508913C PUBLICATION DATE 25 AUG 2006.DOC PROGRAMMING MANUAL 3

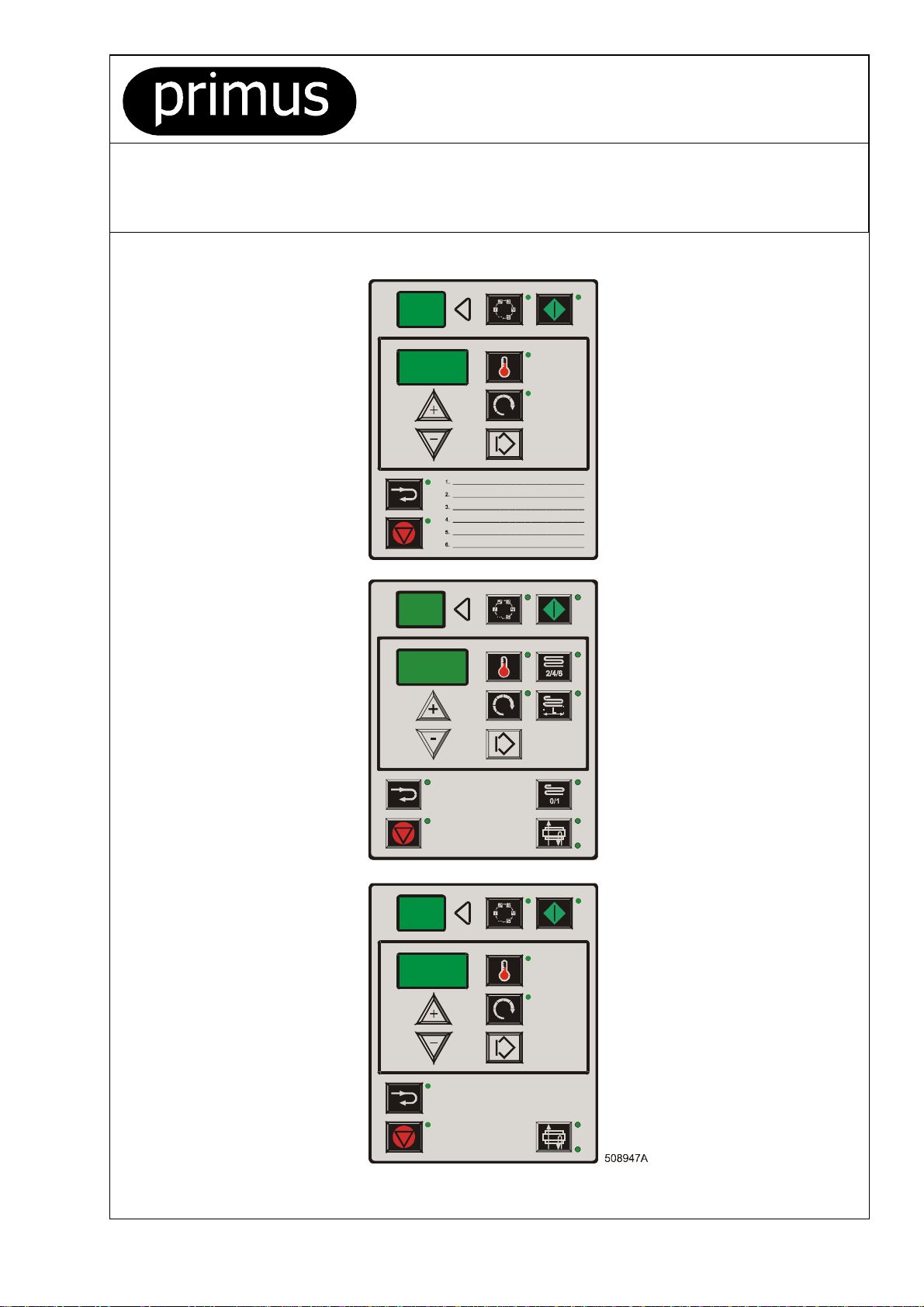

3. DESCRIPTION OF CONTROLS

THE CONTROL ENABLES:

–Version OPL: create 20 programs (number 1÷20), each of them is combination of temperature, speed,

direction of cloths delivery and for ironer with front/rear delivery with folder also parameters for folding;

additionally the program 0 is saved in memory, adjusted from manufacturer to 80°C, 4 m/min, which is not

possible to change.

–Version with coin meter: starting the machine by coin automat with adjustable value of coins and minimal

price necessary for start.

–Simple control by buttons

–Displaying of error messages

IT IS POSSIBLE TO DISPLAY THE FOLLOWING INFORMATION DURING IRONING

OR FOLDING:

Version OPL:

–Program, which has been selected

–Required temperature and actual temperature

–Ironing speed in m/min

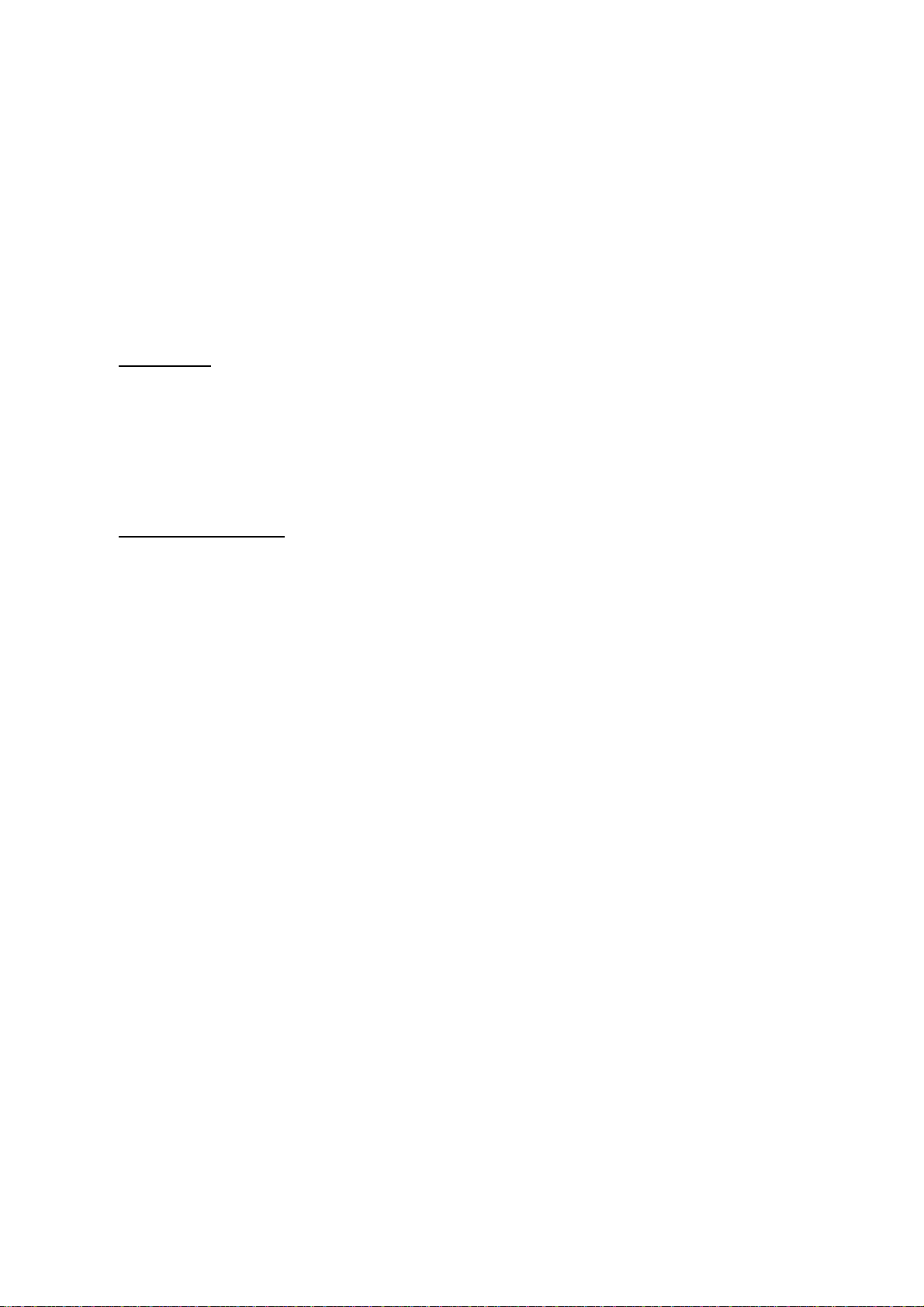

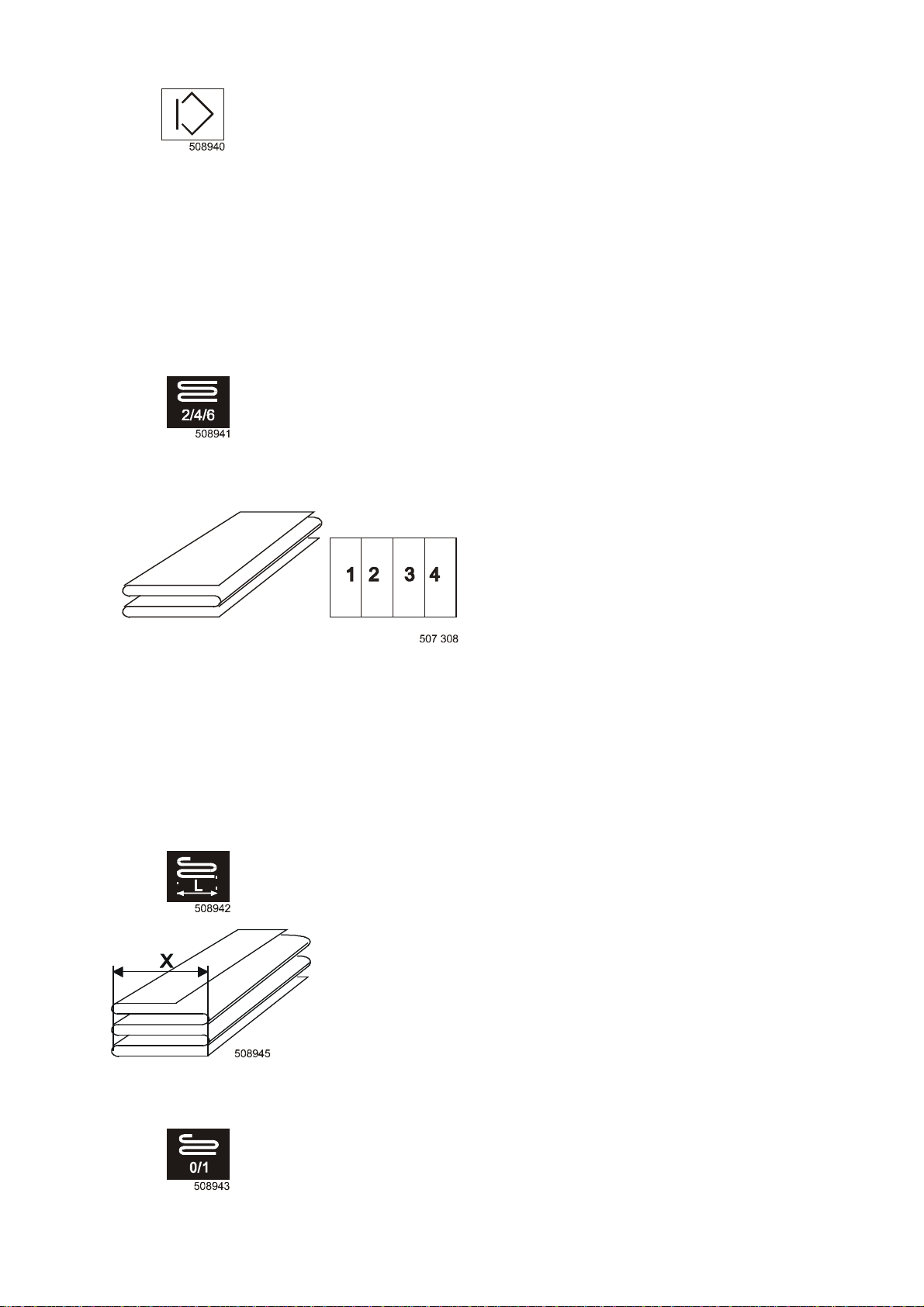

–For ironer with front/rear delivery with folder in addition number of folds or the fold width

–Light indicators LED next to individual buttons show: machine condition (in operation, cooling down), which

of parameters is just displayed on the lower display (temperature, speed, number of folds, width of fold),

on ironer with front/rear delivery with folder also the state of folding and direction of finished linen delivery

Version with coin meter:

–Remaining paid time in minutes

–If the counting down the time is active (machine is operating), the decimal point is blinking in the displayed time

3.1. DESCRIPTION OF BUTTONS FUNCTIONS – VERSION OPL

Pressing some of buttons for the program parameters (speed and temperature and on ironer with front/rear

delivery with folder also parameters of folding) or the button „Program selection“ causes:

–Button activation (LED next to the button lights up), which enables to change given program parameter by

buttons „+“ and „-“, see description of individual buttons

–Deactivation of previous button (corresponding LED will switch off)

–Displaying of given parameter on the lower display (not applicable for the button „Program selection“)

Then, if you want to display e.g. temperature on the lower display, press the button „Temperature“. Now, if

you want to change the speed, press the button „Speed“ first and then change the speed using the buttons

„+“ and „-“.

Change of parameters:

It is possible to change individual program parameters and save new values in memory. For the change of

parameter, which is just being displayed, it is necessary to keep the button of corresponding parameter pressed

for the time period 2s. After this time period, the display starts blinking and parameter can be changed using

the buttons „+“ and „-“. After required value has been set, it is necessary to confirm this new value by another

short press of the parameter button, otherwise the change will not be executed and after 2s the original value

will be displayed again.

An exception are parameters „Ironing speed“ and selection of the program number – these values can be

changed directly by pressing the buttons „+“ and „-“ and the new values need not be confirmed.

Such executed parameter changes remain valid just until the machine is switched off. When the machine is

switched on again, original values will be read from the memory again. If you want to save the changes

even after switch off, it is necessary to save the program (see button for program saving).

Example – temperature set-up:

–If the button „Temperature“ is not active, activate it by a short press – actual temperatureis shown on the display

–Required temperature value is displayed after another short press, the dot on the display indicates required

value (actual and required value exist only for temperature, other parameters have only one value)

–Activate mode of value editing by long press (2s) of the „Temperature“ button – display will start blinking

–Set new required value using the buttons „+“ and „-“

–Confirm the value by a short press of the „Temperature“ button