Princess auto 8111544 User manual

3–POINT HITCH

LOGSPLITTER

OPERATOR’S MANUAL

AND

PARTS LIST

1

TABLE OF CONTENTS

SECTION PAGE

1. GENERAL INFORMATION 1

2. SAFETY GUIDELINES 2

2.1 DEFINITIONS 2

2.2 SAFE OPERATING PROCEDURE 3

3. LOG SPLITTER ASSEMBLY 4

4. LOG SPLITTER STARTUP 4

5. 3–POINT HITCH LOG SPLITTER ASSEMBLY 16 TON 6

1. G

ENERAL

I

NFORMATION

Congratulations on your choice of Princess Auto Log Splitter. This equipment has been designed and

manufactured to meet the needs for commercial and private log splitting use.

All structural parts are designed from high quality steel, and all power pack items are selected specifically to

meet your industrial and consumer needs.

Safe, efficient and trouble free operation of your Log Splitter requires that you and anyone else using the Log

Splitter read and understand all of the safety, operation maintenance and troubleshooting information

contained within this Operator’s Manual.

WARRANTY- PARTS - SERVICE

If you experience any problems and need assistance or parts and repair service please contact Princess Auto

Ltd. at: Telephone # 1-800-665-8685 Fax # 1-800-265-4212

To obtain prompt, efficient service, always provide the serial number and item number of your unit. See the

parts list for location of the serial number decal. Please mark the numbers in the space provided for easy

reference.

SERIAL # ________________________

ITEM # ________________________

Printed in Canada 10003200

Issue Date: AUGUST 2006 Revision 0

2

2. SAFETY GUIDELINES

2.1 DEFINITIONS

Safety symbols identify important safety messages that alert to the possibility of personal injury or death.

Review them carefully before operating the unit and before performing maintenance or repairs. Check the

rules and regulations at your location and identify possible hazards. The appropriate signal word for each

message has been selected using the following guide - lines:

- Danger indicates an immediate and specific hazard, which will result in severe personal

injury or death if the proper precautions are not taken.

-

Warning indicates a specific hazard or unsafe practice, which could result in severe

personal injury or death if proper precautions are not taken.

-

Caution indicates potentially hazardous situation, which may result in minor or moderate

injury if proper practices are not taken.

____________________________________________________________________________

IMPORTANT SAFETY INSTRUCTIONS

Read and understand operator’s manual and all safety alerts before operating or maintaining your Log

Splitter. Be certain that everyone operating this equipment is familiar with the recommended operating and

maintenance procedures and follows all the safety precautions. Never let children or untrained adults operate

the machine.

________________________________________________________________________________

RISK OF CARBON MONOXIDE POISONING

Do not operate equipment in enclosed area. Engine exhaust contains carbon monoxide, an odorless,

colorless, deadly poison.

RISK OF HOT SURFACES

Contact with hot surfaces, such as engines exhaust components could result in serious burn.

RISK OF FLUID INJECTION

Make sure all hydraulic components are maintained in good condition. Replace kinked, cracked or otherwise

damaged hydraulic components or hoses. Do not check for leaks with your hands, use wood or cardboard as

a backstop instead. Escaping fluid under pressure can have sufficient force to penetrate the skin causing

serious personal injury or even death. If hydraulic fluid penetrates the skin, seek medical attention

immediately. A serious infection or reaction will develop.

Wear proper eye protection when searching for a high-pressure hydraulic leak. Do not remove the cap

from the hydraulic reservoir while log splitter is running. Hot oil under pressure could result in serious injury.

3

2.2 SAFE OPERATING PROCEDURE

• Read and understand the Operator’s Manual completely before using

your log splitter.

• Do not allow anyone to operate your log splitter who has not read the

Operator’s Manual or who has not been instructed on the safe operation

of your log splitter.

• Never allow children or un-trained adults to operate your log splitter.

• If a helper is assisting in loading or un-loading logs ensure they are clear

of the working area when actuating the controls.

• Always keeps hands, clothing or other body parts clear of moving parts.

• Never place hands, clothing or other body parts between the splitting

knife and the log, or the log and base end of the splitter beam during

operation.

• Never allow anyone to ride on your log splitter.

• Never transport cargo on your log splitter.

• Never attempt to load the log splitter when the knife is in motion.

• Always use your hand to operate the control lever. Never use another

body part, rope or any extension device to operate the control lever.

• Always wear safety glasses/goggles, shoes or boots, gloves and hearing

protection.

• Always keep fingers away from cracks that may occur in logs.

• Your log splitter is only intended for splitting wood. Do not use it for other

purposes.

• Never alter the log splitter or any part of its manufactured design.

4

3. LOG SPLITTER ASSEMBLY

The log splitter is shipped in a crate and requires assembly before it can be

used. Parts are heavy; ensure you have someone to assist you with the

assembly. Proper safety measures must be applied to avoid injury.

1. Select an area that is firm and dry with sufficient space to work around all

sides of the unit.

2. Carefully remove the lid from the crate and inspect the contents of the

shipping crate to ensure all of the. Components for your Log Splitter

model are within. If there are any missing or damaged components

contact your local Princess Auto store or Customer Service at either:

Telephone # 1-800-665-8685 Fax # 1-800-265-4212

When mounting to tractor, tractor should be turned off and in park. Install lift

arms first to 3 pt. hitch ensuring that lift arm pins are secure with retaining pins.

Install top link pin to tractor, adjust the tractor’s top link arm to connect the top

link on the log splitter, do not try to lift up splitter, insert top link pin and

retaining pin.

Adjust lift arms to ensure that the log splitter beam is horizontal, not leaning to

one side; the logs must be able to sit firmly on the beam.

*For tractors under 25 hp front wheel weights are recommended.

4. LOG SPLITTER STARTUP

1. Place the Log Splitter on a level surface. Clear the area of people,

especially small children. Keep the tractor at least 6 ft. away from

buildings, obstructions and flammable objects. Do not aim engine exhaust

at materials that could catch fire.

2. Check all fasteners and fittings for tightness. Inspect hydraulic hoses for

wear, cracking or fatigue. Replace if damaged.

3. Add hydraulic oil to tractor reservoir. (Available at Princess Auto stores).

Use a quality mineral based hydraulic fluid, a viscosity in the 70-250 SUS

range and operating temperature is recommended. ISO grade 32 would

work well for the majority of applications.

4. Start the engine. Run at slow idle for 3-5 min. Allowing the engine to warm

up.

5

5. Cycle the cylinder at least three times with no load to fill the system with

oil and bleed the system of air.

6. Stop the engine and add more hydraulic oil if necessary.

7. Your Log Splitter should now be ready for operation.

6

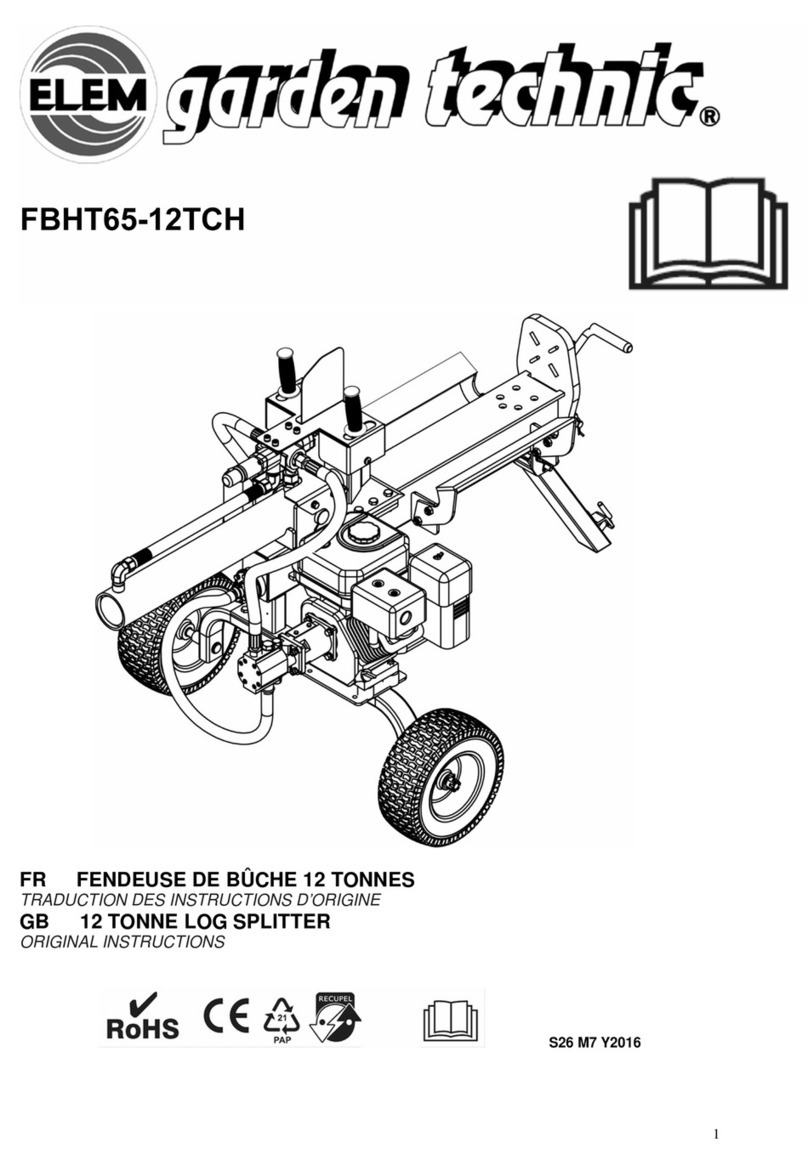

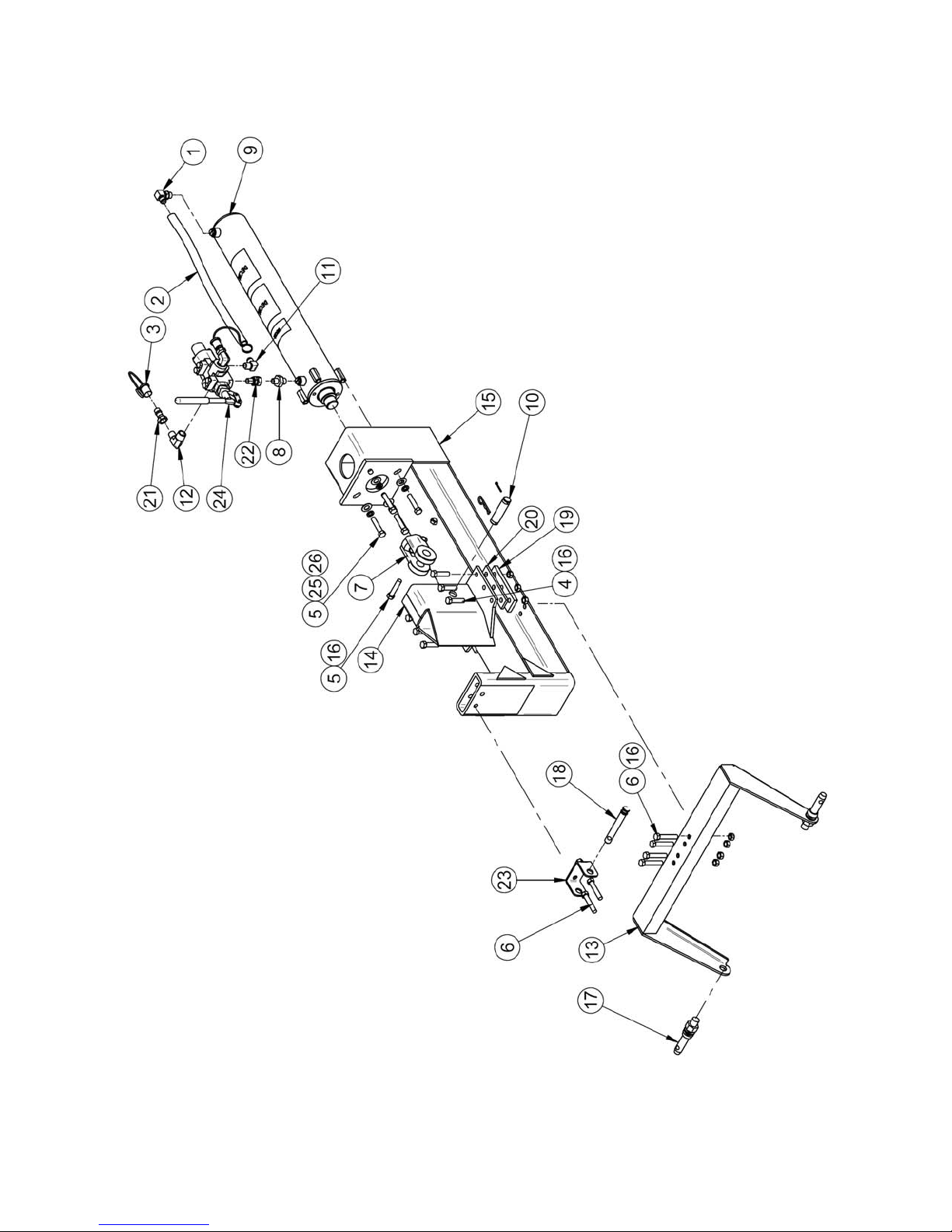

5. LOG SPLITTER 3 POINT HITCH ASSEMBLY 16 TON

7

LOG SPLITTER 3 POINT HITCH 16 TON

ITEM 8111544

No. Part Number Description QTY

1 1195-08-08 #8 ORB MALE X 1/2 JIC MALE ELBOW 1

2 10003043 1/2 HOSE, 2 WIRE X 22 LG /3000psi / FITTINGS: FJIC-08 /

FJIC-08 1

3 8029634 1/2 INCH DUST CAP FOR MALE QUICK ATTACH FITTING 2

4 9804410 BOLT HEX .500-13 UNC X 2.00LG GR 5 PTD 6

5 9804436 BOLT HEX .500-13 UNC X 2.50 LG 4

6 9804444 BOLT HEX .500-13 UNC X 2.75 LG 6

7 10001847 CLEVIS ROD 1.50 UNF 1.00 DIA 1

8 1293323 CONNECTOR 08 MALE ORB X 08 MALE NPT 1

9 10001088 CYL 4024 LOGSPLITTER 1

10 10003040 CYLINDER PIN KIT 1 X 3.25 1

11 1295021 ELBOW .50 JIC X .50 NPTM BRASS 1

12 1291814 ELBOW 90 12 MALE NPT X 12 MALE NPT 2

13 10002928 HORIZONTAL WELDMENT -3PT. HITCH: PAINTED 1

14 10002912 KNIFE ASM - 3PT HITCH 1

15 10002910 MAIN FRAME ASM 1

16 9857574 NUT LOCK UNITORQ .500-13 UNC 12

17 3806791 PIN LIFT ARM .875 DIA X 1.75 LG TYPE A 2

18 3806700 PIN TOP LINK 1

19 10002914 PLATE KNIFE BACKING 2

20 10003038 PLATE KNIFE SPACER-3PT HITCH 2

21 1290079 QUICK ATTACH NIPPLE MALE, 08 FEMALE NPT ON FRONT 2

22 1291947 SWIVEL CONNECTOR 08 FEMALE NPT X 08 MALE NPT 1

23 10003056 TOP LINK BRACKET: PAINTED 1

24 9224650 VALVE LOGSPLITTER 2500 PSI 1

25 9853375 WASHER LOCK SPLIT REG .50 PTD 4

26 9850058 WASHER PTD .656 ID X 1.312 OD 4

Table of contents

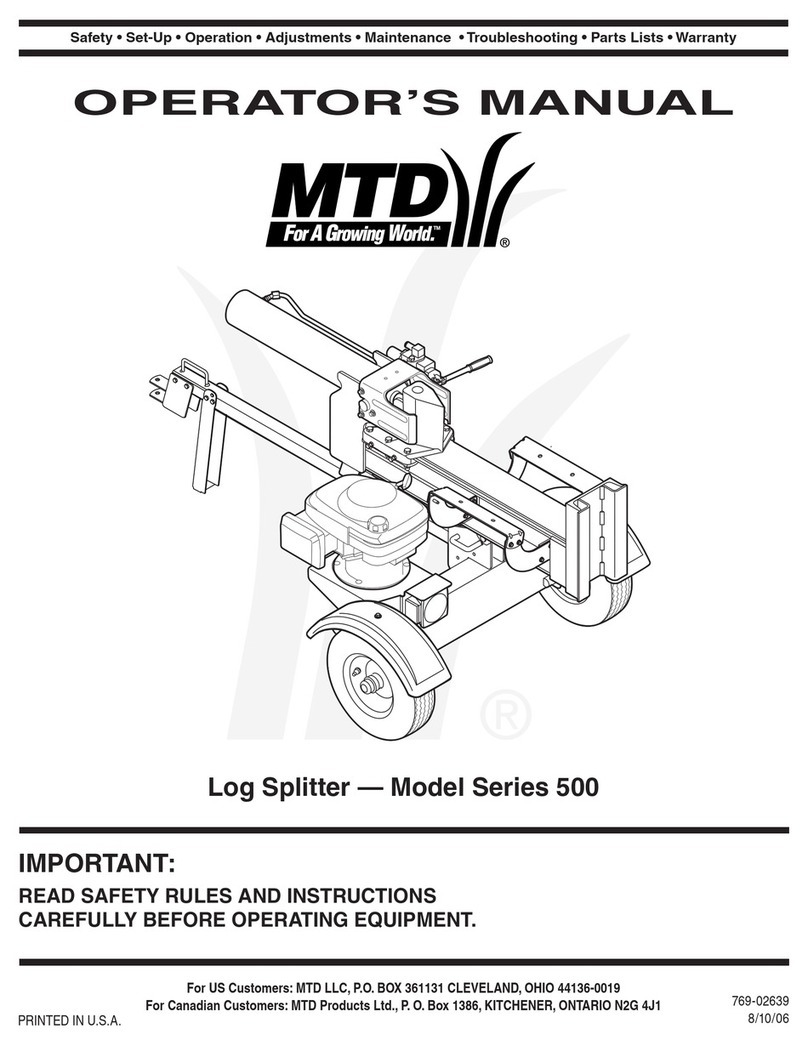

Popular Log Splitter manuals by other brands

Scheppach

Scheppach HL455 Translation of original instruction manual

Oxdale

Oxdale RT400 Operating and maintenance instructions

SpeeCo

SpeeCo S401622PH owner's manual

power King

power King PK0322 Owner's Manual and Operating Instructions

Greyhound

Greyhound 39981 Assembly & operating instructions

Wallenstein

Wallenstein WX980L Setup instructions