Printronix P5000 Series User manual

User’s Manual

General Purpose Input/Output (GPIO)

Manager and Module

Product Warranty

Printronix warrants that the Products furnished under this Agreement shall be

free from defects in material and workmanship for a period of one year from

the date of shipment from the Printronix facility. This warranty is applicable

only if the products have had normal utilization within the published

specifications as modified from time to time, have been maintained in

accordance with recommended procedures with Printronix approved parts,

and have not been modified or altered in a manner not approved by

Printronix.

For printers sold within the area in which Purchaser normally provides field

service:

For all printers the Purchaser will provide the end-user with a 90-day

on-site warranty. Any printer or part therein found defective within one

year of original shipping date from a Printronix facility shall be returned to

Printronix and be repaired or replaced at the option and expense of

Printronix. Purchaser shall pay shipping cost to the Printronix facility and

Printronix will return the item(s) at its expense.

For printers sold outside the area, within the Continental United States, in

which Purchaser normally provides field service:

Any printer found defective within 90 days from the date of shipment to

the end user will be repaired at the end user’s location. If the end user is

located within 100 miles of an Authorized Service Provider’s location,

warranty service will be performed at no charge. If the end user is located

more than 100 miles from an Authorized Service Provider’s location,

travel time and expenses in excess of 100 miles will be billed to the end

user at current rates or the printer may be shipped to the nearest

Authorized Service Center for repair. If the end user elects to ship the

printer for warranty repair, the end user shall pay the shipping cost to the

Authorized Service Center and the printer will be returned at Printronix’

expense.

The Products may be equipped with a general purpose input/output circuit

board and corresponding pin connection (GPIO) which allow the Purchaser’s

or end user’s printer to function as a controller in a computer system.

Printronix publishes the specifications associated with GPIO and the pin

connection and warrants that the printer’s input and output parameters at the

pin connection conform to those specifications. Except as expressly

warranted, GPIO is sold on an “as is” basis. There are no other warranties

whatsoever, express or implied, concerning GPIO.

Purchaser’s remedies are expressly limited to Printronix’ obligations as stated

above, and in no event shall Printronix be held liable for any incidental or

consequential damages or loss of use, or other commercial loss, however

occasioned.

The warranties set forth in this article and the obligations and liabilities

thereunder are in lieu or, and the purchaser hereby waives, all implied

guarantees and warrantees, including without limitation, any warranty of

merchantibility or fitness for a particular purpose. In no event shall Printronix

be held liable for any incidental or consequential damages or loss of use, or

other commercial loss, however occasioned.

Notice of Copyright

This document contains proprietary information protected by copyright. No

part of this document may be reproduced, copied, translated, or incorporated

in any other material in any form or by any means, whether manual, graphic,

electronic, mechanical, or otherwise, without the written consent of Printronix,

Inc.

All non-Printronix registered and/or unregistered trademarks used throughout

this manual are the sole property of their respective owners.

COPYRIGHT 2003, 2005, PRINTRONIX, INC.

All rights reserved.

1 Introduction ........................................................... 7

Overview................................................................................................ 7

Events and Actions ................................................................................ 7

The Hardware ........................................................................................ 7

2 The GPIO Manager............................................... 9

Overview................................................................................................ 9

The Menus .................................................................................... 10

The Entry Fields ............................................................................ 11

Password ...................................................................................... 12

Events and Actions ....................................................................... 13

Entry Control Buttons........................................................................... 23

Multiple Actions ............................................................................. 24

The ON Flag.................................................................................. 25

The Initial State ............................................................................. 25

Data Fields........................................................................................... 26

Data Field Events And Actions...................................................... 27

Data Field Events .......................................................................... 29

Defining Reports .................................................................................. 31

Sections ........................................................................................ 33

Reports.......................................................................................... 35

Using Reports ............................................................................... 36

3 Mapping .............................................................. 37

Download Mapping Tables .................................................................. 37

Pre-Loaded Table ................................................................................ 37

Mapping Examples .............................................................................. 38

PPI-1 ............................................................................................. 39

PPI-2 ............................................................................................. 41

Printronix T3000 and Equivalent Printers...................................... 44

Other Competitors ......................................................................... 46

Indicator Lights Example ............................................................... 48

Simple Applicator Example ........................................................... 50

Protected Printer Example ............................................................ 51

Panel Selected Label Printing ....................................................... 52

Table of Contents

Table of Contents

A Technical Information.......................................... 55

Opto-couplers ...................................................................................... 55

Relays.................................................................................................. 56

Voltages............................................................................................... 56

I/O Connector ...................................................................................... 56

B Basic GPIO Schematic Diagram ......................... 59

C Electrical Inputs And Outputs.............................. 61

GPIO Opto-coupled Input Circuit......................................................... 61

GPIO Opto-coupled Output Circuit ...................................................... 61

7

1Introduction

Overview

This document describes the Printronix General Purpose Input/Output (GPIO)

function available for the Printronix T5000 series Thermal printers and the

P5000 series Line Matrix printers.

GPIO is both hardware and software. The hardware is the I/O board to be

mounted in the printer,and the software is the GPIO Manager which is part of

the Printronix Remote Management Software Advanced Tool Kit. The GPIO

hardware is a printed circuit board containing optically isolated inputs and

outputs as well as relays. The GPIO software is both a printer resident GPIO

event parser and a PC-based GPIO manager that allows the user to define

how the general purpose I/O hardware should behave for the given

application.

Events and Actions

The operation of GPIO is based on Events and Actions. Events can be either

printer internal such as “paper out” or “print complete,” or they can be printer

external such as “opto-coupler 1 active.” Actions are the result of (or the

reaction to) an event and can be printer internal such as “paper feed” or

printer external such as “relay 1 active” or “reply to host” where data is

transmitted over the serial, parallel, or network interface. You can also define

a number of events to be acted upon without the GPIO card installed in the

printer, which allows the printer to be adapted for the application in use.

The Hardware

The GPIO hardware (see Figure 1 on page 8) consists of 16 opto-couplers,

4 SPDT relays, a real time clock, and the logic required to connect this

hardware into the printing system.

NOTE: Although the GPIO hardware includes a real time clock, it will not be

described in this manual. Its programming and use are strongly

related to PGL and equivalent languages, and those manuals

document the real time clock.

8

Chapter 1 The Hardware

Eight of the 16 opto-couplers are used as isolated inputs; these are the

connections on which the external events happen. The remaining eight

opto-couplers and the four SPDT relays are used as isolated outputs. Each of

these outputs can be activated as an action in response to some event. The

board is connected into the printing system through the printer’s expansion

port.

None of the inputs or outputs is connected to any voltage source; it is the

user’s responsibility to make those connections. A separately fused

5-volt and a separately fused 24-volt are available on the 50 pin connector in

which all inputs and outputs are terminated.

Figure 1. GPIO Hardware

GPIO

Logic

Outputs 1 . . 8

R

T

C

System Interface

Relay 1 . . 4

Inputs 1 . . 8

9

2The GPIO Manager

Overview

The GPIO Manager is part of the Advanced Tool Kit (ATK) version of the

Printronix Remote Management Software (RMS).

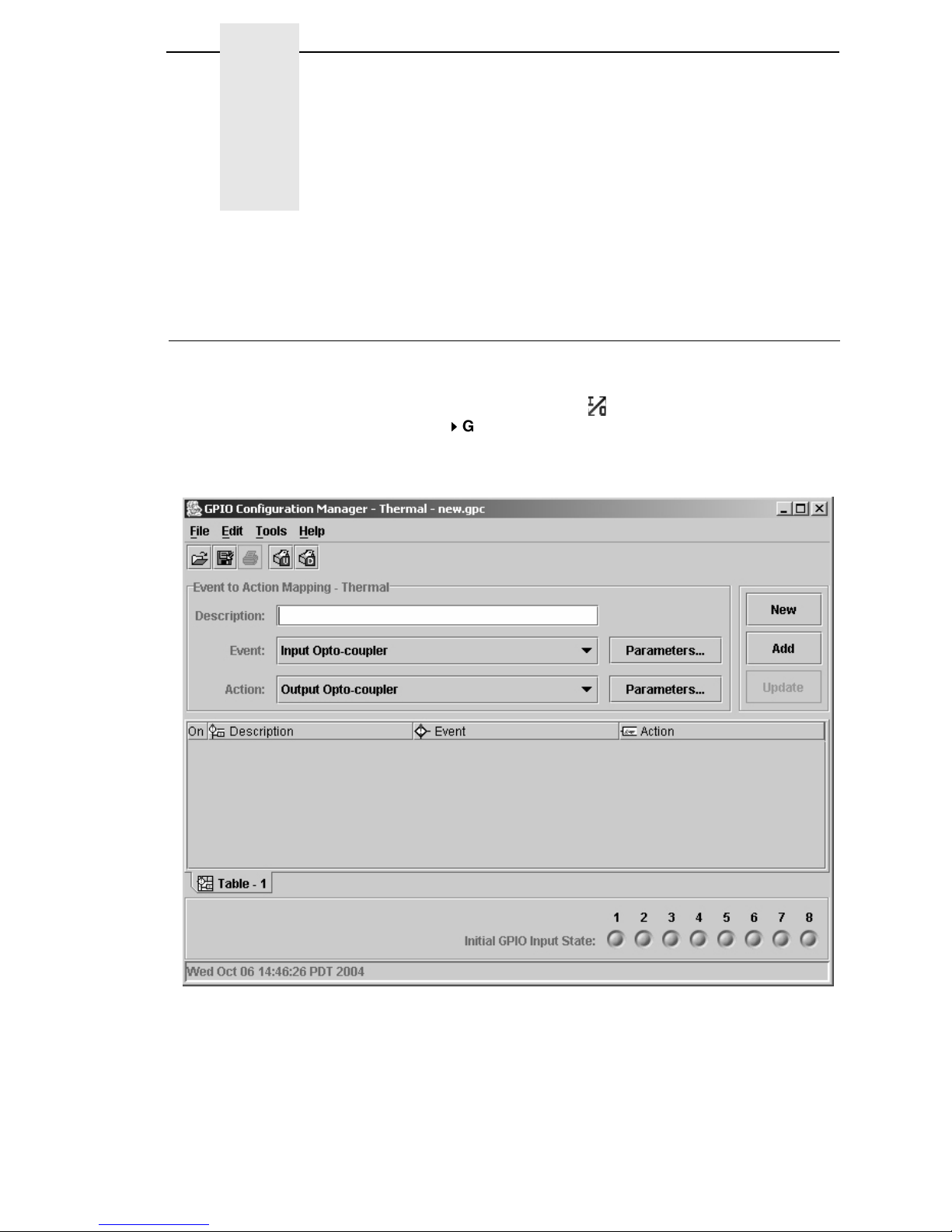

To access the GPIO Manager, click the icon in the RMS/ATK toolbar or

select Applications

GPIO Manager. The screen in Figure 2 displays. The

fields on this screen is described in detail in the following pages.

Figure 2. The GPIO Configuration Manager

10

Chapter 2 Overview

The Menus

The toolbars are like any other toolbar; they allow the usual handling of files

and text.

Figure 3. The GPIO Configuration Manager Toolbar

File

The File menu allows you to create, open, or save a new or existing I/O

configuration. The Print option is currently disabled. The Properties option

allows you to select the type of printer, Thermal or Impact, that the I/O

configuration is to be created for. Password allows you to attach a password

to a mapping table.

Edit

The Edit menu allows you to define, delete, and rename mapping tables. You

can also define data fields and reports to customize mapping table.

Tools

The Tools menu allows you to upload or download an I/O configuration. You

also have the option to select the last selected upload printer or the last

selected download printer. This option allows you to quickly select a

previously uploaded or downloaded printer without having to go to the RMS

printer database for your selection.

Help

The Help menu allows you to open the User Guide of this program if the guide

is stored in the correct directory on the user’s system. If it cannot be found, an

error message displays. The About option provides basic information about

the GPIO Configuration Manager as seen in the startup splash screen.

The Entry Fields

11

The Entry Fields

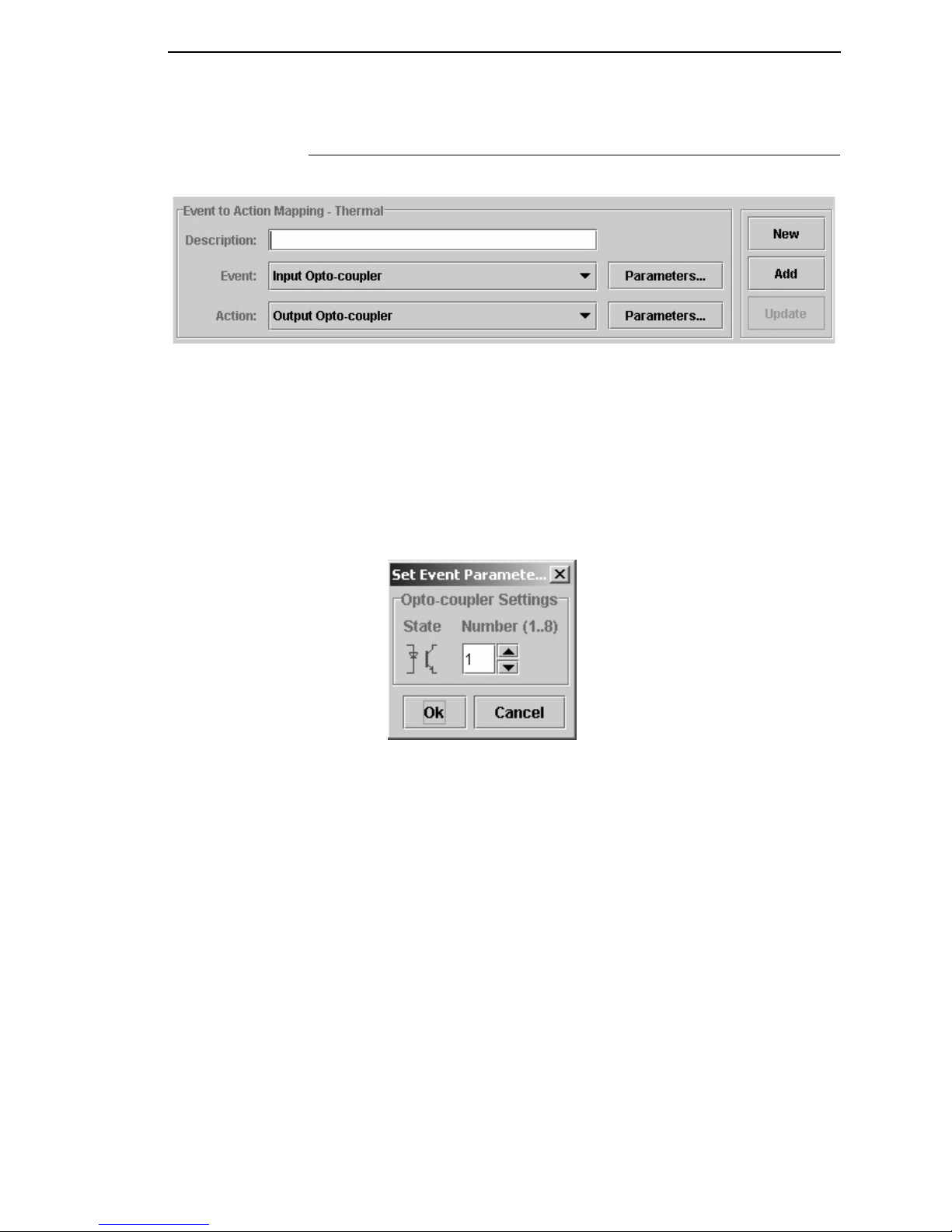

Figure 4. The Event To Action Mapping Fields

Setting the criteria for mapping tables takes place here (Figure 4). The

Description

field allows you can enter a descriptive name to indicate the use

of the event and its related action.

NOTE: The window header indicates which printer the mapping table is

created.

The Event field allows you to select the event on which some action is to be

taken. Table 1 on page 13 lists the events currently available in the software.

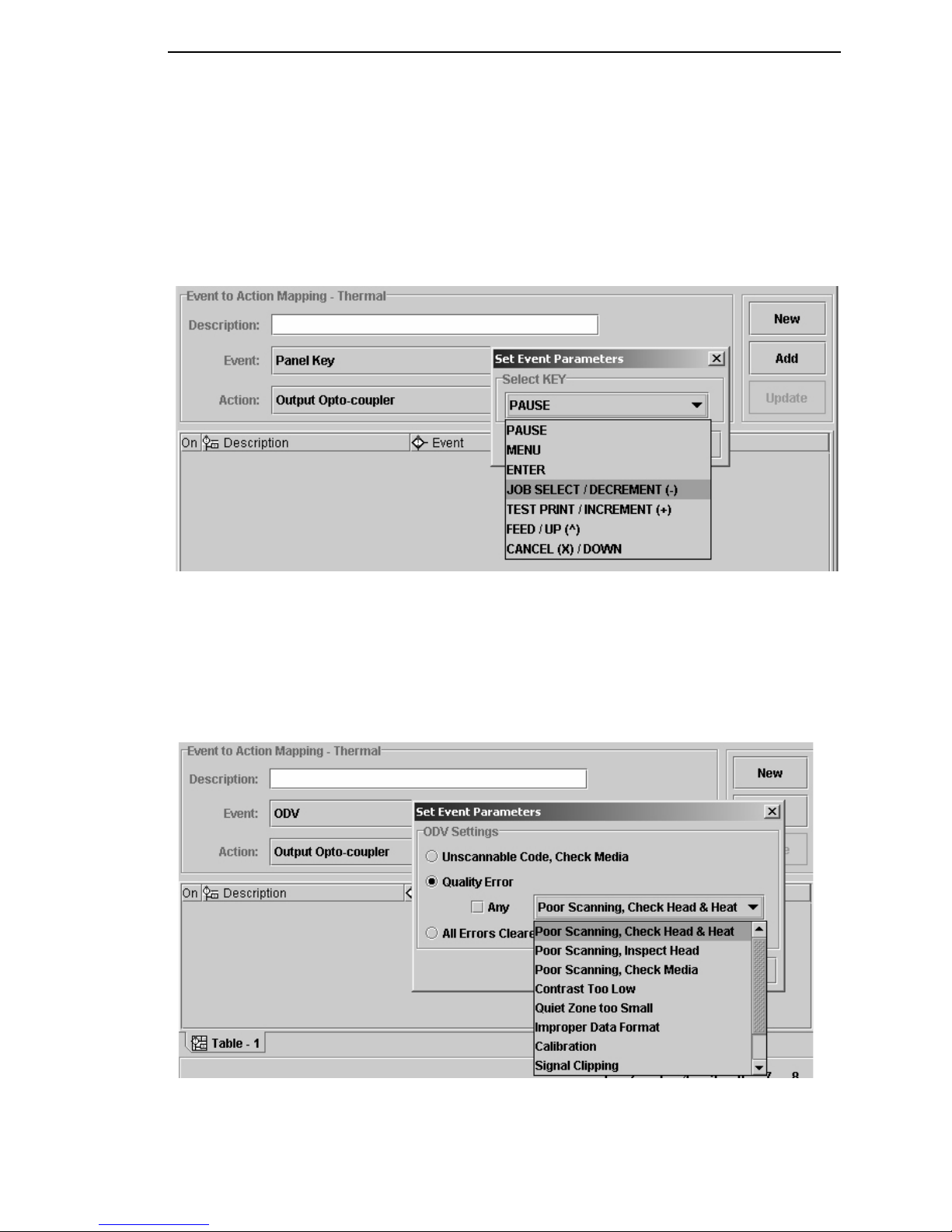

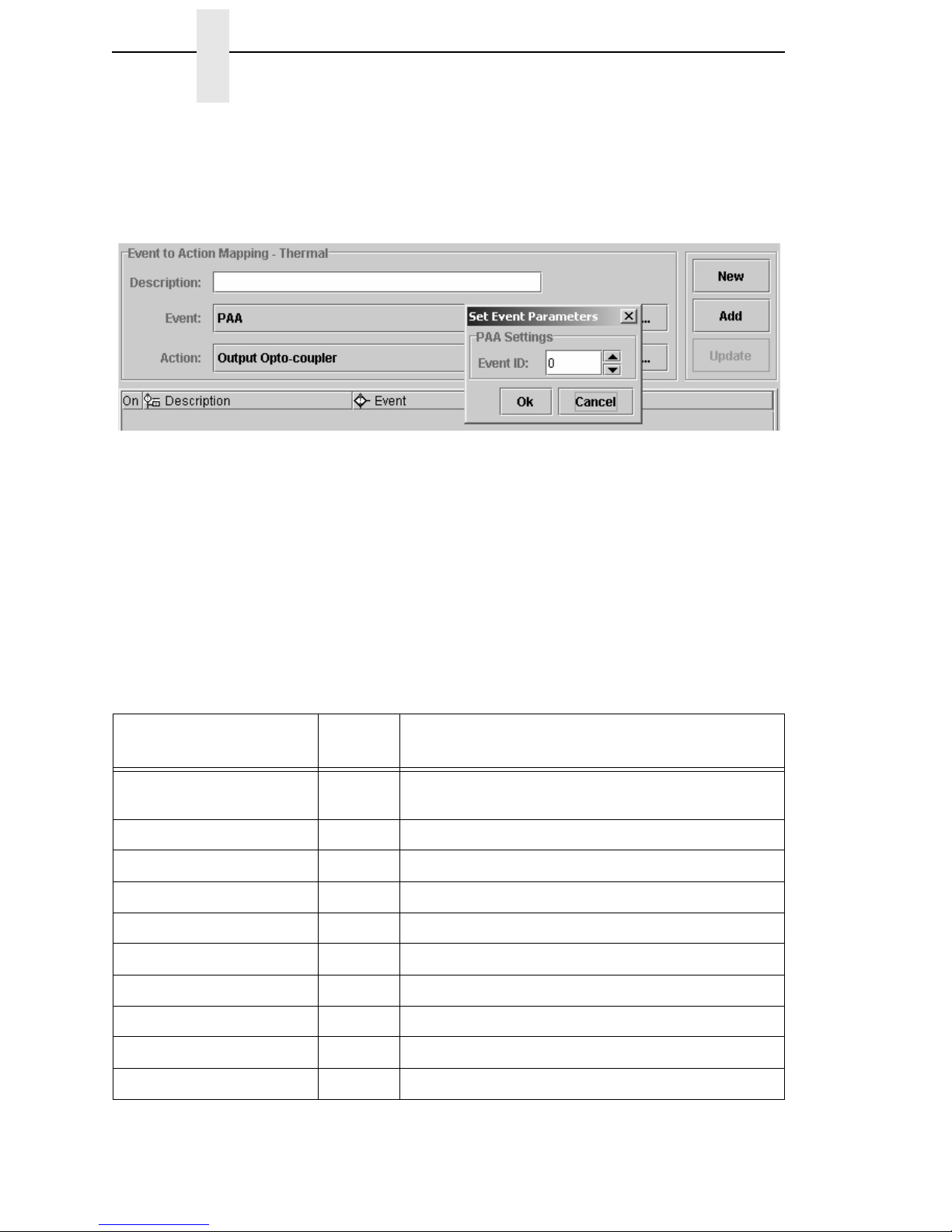

Figure 5. Setting Event Parameters

The Event Parameters button allows you to select additional conditions

related to the event (Figure 5).

12

Chapter 2 Overview

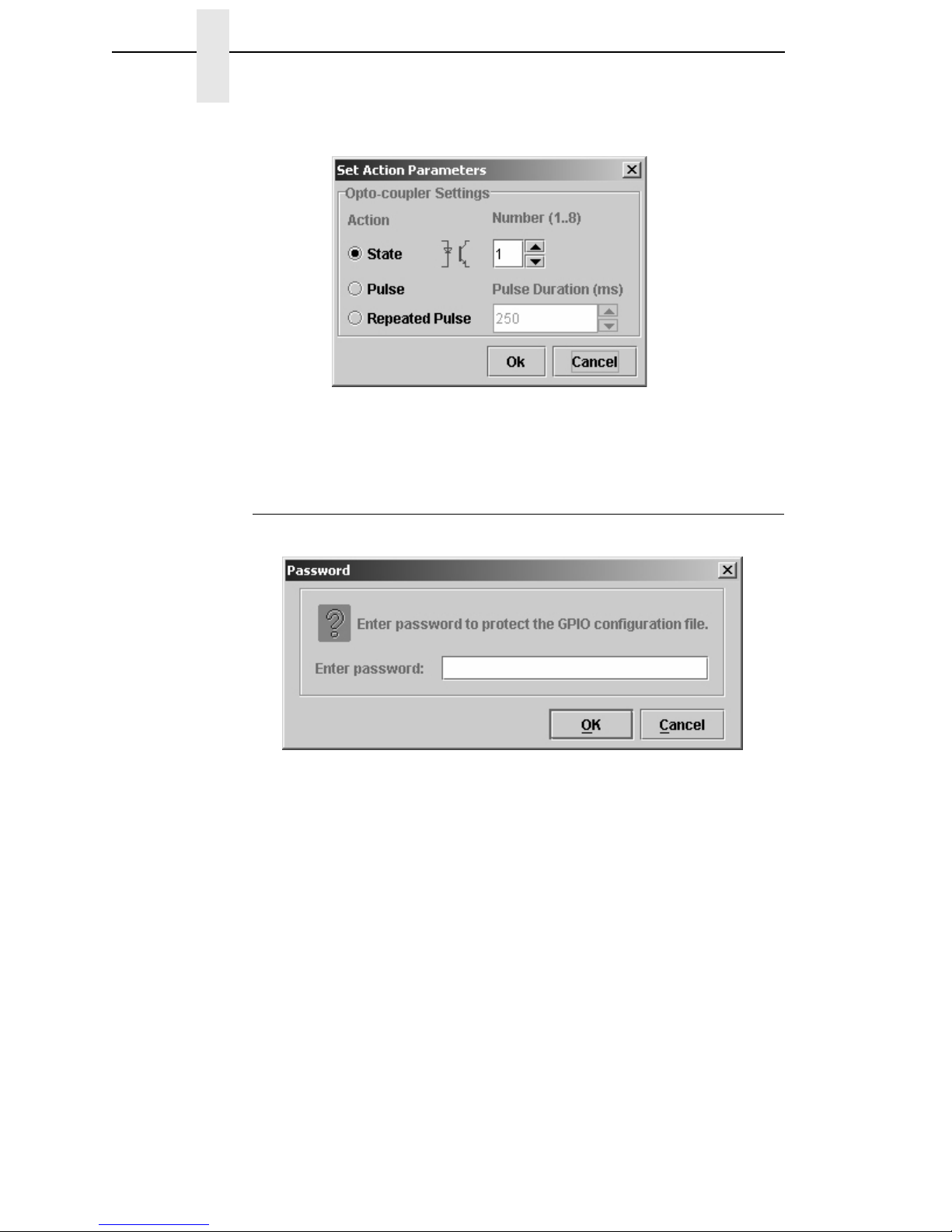

Figure 6. Setting Action Parameters

The Action Parameters button allows you to select all possible actions that

are programmed to take place as a result of some event (Figure 6).

Password

Figure 7. Setting Passwords

A password can be attached to the mapping table (also called the GPIO

Configuration file). This password will be stored, in the GPIO configuration

file, in the printer’s flash memory. Uploading of a password-protected file is

possible, but before any operation can be performed on or with this file, you

must enter the password.

Events and Actions

13

Events and Actions

The Events

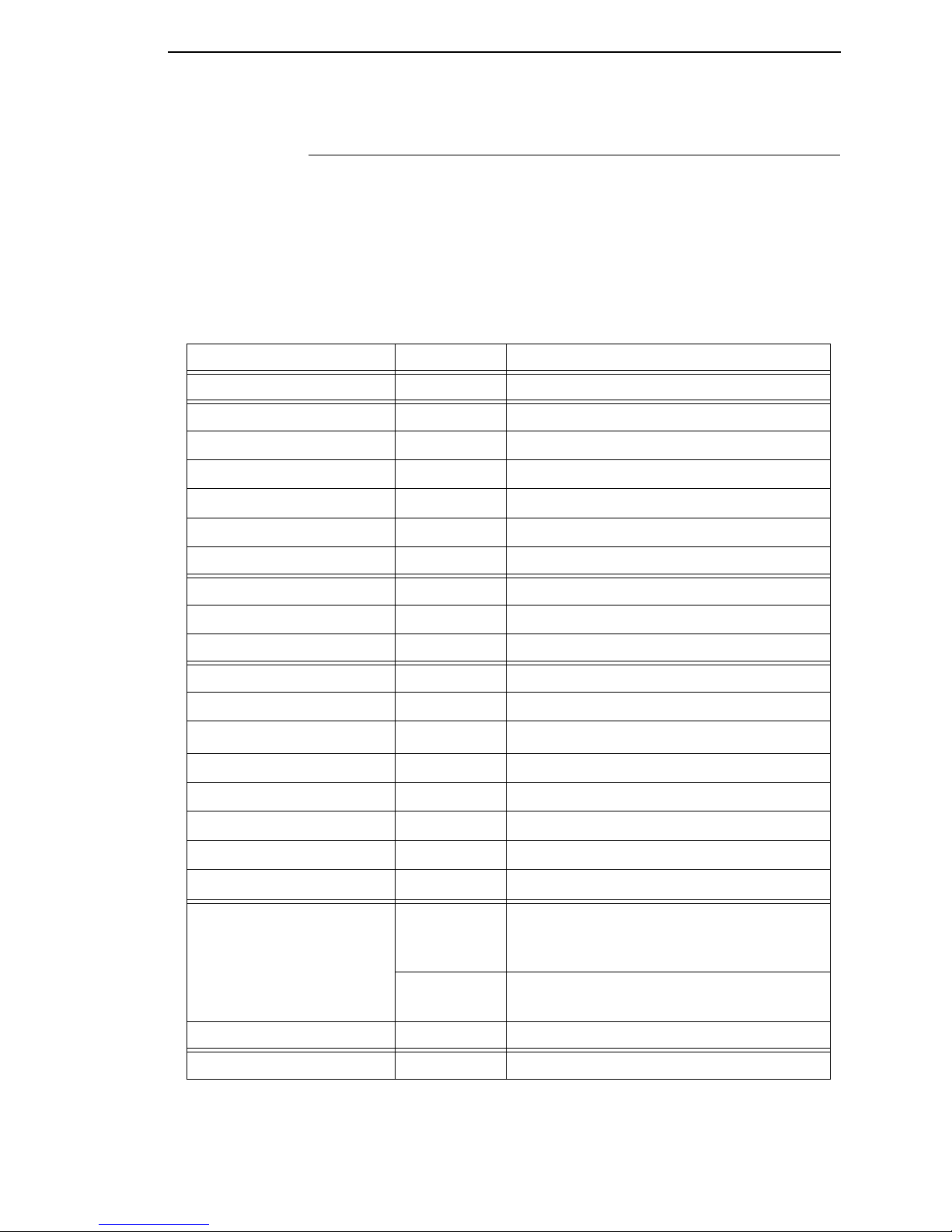

Table 1 lists the available events and the related parameters. Each of the

events will be described separately. Parameters on events are valid for the

Input Opto-Couplers, Panel Key Pressed events, ODV events, Printer Error

and Warning events, and PAA events.

Table 1: Events And Parameters

Events Printer Type Parameters

Input Opto-Coupler Opto-Coupler Number (1..8), Active, Inactive

Printer Powered Up n.a

Printer Online n.a

Printer Offline n.a

Printer Local n.a

Power Save Mode Active n.a

Power Save Mode Cleared n.a

Start Data Processing n.a

End Data Processing n.a

Printer Buffers Empty n.a

Label Pending Thermal n.a

Start Printing n.a

Start Paper Move Impact n.a

Label Printed Thermal n.a

Label Present Thermal n.a

Label Taken Thermal n.a

Job Printed n.a

End Paper Move Impact n.a

Printer Error Thermal Any, Paper Out, Paper Jam, Ribbon Out,

TOF Detect Fault, Head Open, RFID Tag

Failed, RFID Max Retry

Impact Any, Platen Open Paper Jam, Paper Empty,

Ribbon Stall, Stacker Fault, Stacker Full

Printer Warning Thermal Any, Ribbon Low

Panel Key Event Thermal Printer Type related Key Description

14

Chapter 2 Overview

Event Descriptions

•Input Opto-Couplers

For external input signals. You can specify the number of the

opto-coupler to view and the level on which the event is seen as active.

Clicking the opto-coupler symbol selects the active state.

Figure 8. Setting the Opto-coupler Number and State

•Printer Powered Up

This event is delayed until the moment the printer reaches the Powered-

up-online or Powered-up-offline state. The delay is required so the printer

can finish its power-on reset cycle before any reaction to an event is

generated.

•Printer Online

When the printer goes online by pressing the Pause key, the action

related to this event is taken.

•Printer Offline

When the printer goes offline by pressing the Pause key or the menu key,

or if there is any other reason that causes the printer to switch offline, the

action related to this event is taken.

•Printer Local

This event happens when the printer is paused by pressing the Pause

key. The printer accepts data from the host and parses this data until its

buffers are full. No printing occurs. The print engine is offline, but the

printer’s data processing unit is still online.

ODV Events Thermal Missing barcode, Quality error – Any or a

specific one, All ODV errors cleared

PAA Event Event identifier

Data Field Changed Data Field, Condition, Type, Value

Table 1: Events And Parameters

Events and Actions

15

•Power Save Mode Active

This event signals the moment when the printer enters Power Save

Mode.

•Power Save Mode Cleared

Opposite of the Power Save Mode Active, this mode signals the moment

the printer becomes active.

•Start Data Processing

This event signals the start of the processing of received data. This is not

the same as the Start Printing event.

•End Data Processing

This event signals the end of the data processing cycle. This is not the

same as the end printing event.

•Buffers Empty

This event takes place as soon as the print buffers are emptied.

•Label Pending

This event generates when the printer is in Local mode (i.e., the print

engine is temporarily stopped) and all incoming data has been processed.

•Start Printing

This event happens when the printer starts printing. The printer starts

printing when all data processing is done, there is actual data to print, and

the printer is no longer in local mode. The event will not happen on “paper

moves without print.”

•Start Paper Move

This event is only available in the Impact Printer mode of the GPIO

Manager. It indicates the beginning of the paper motion.

•Label Printed

This event occurs when a number of labels stored in the printer have

finished printing. If the labels print as a single job without any wait time,

the event will be a short pulse. If the printer is placed in local mode and

the labels are printed using the

print next label

action, the event will

happen once for each label.

•Label Present

In label peel off applications, this event happens when the label present

sensor detects a label in position (ready for application). It may be used to

signal the availability of a label to an applicator system.

•Label Taken

This event is generated when the label is taken from its ready to apply

position. It can be used to tell the host that a new label can be printed.

•Job Printed

This even is generated if everything in the buffer has been printed.

16

Chapter 2 Overview

•End Paper Move

This event is only available in the Impact Printer mode of the GPIO

Manager. It indicates the end of the paper motion.

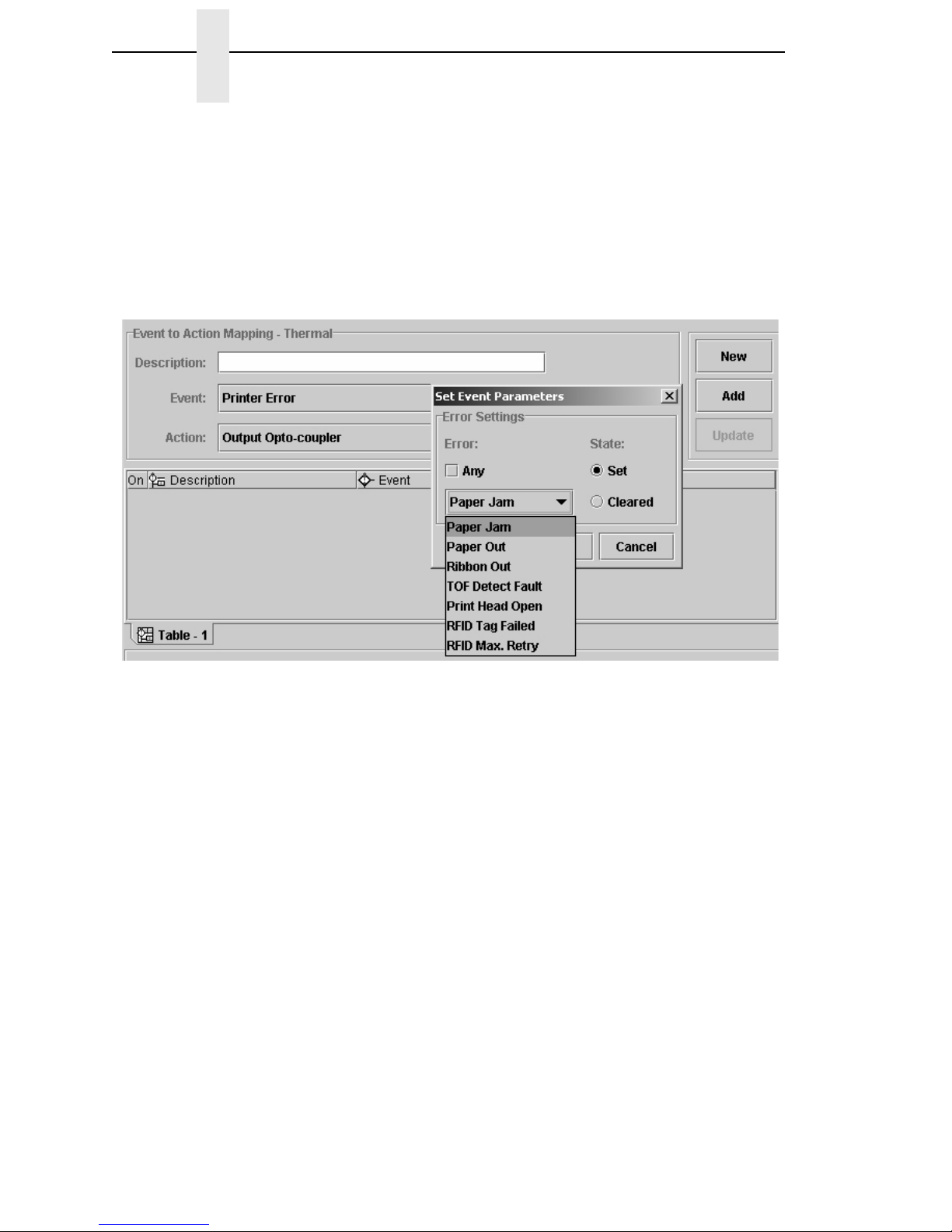

•Printer Error/Printer Warning

These events signal printer errors and warnings. They allow selection of

the error or warning that is seen as the event. Impact printers do not

support warnings.

Figure 9. Setting Errors for an Event Parameter

To select the Printer Error event, click the Event drop-down menu and

select Printer Error as the event parameter. Click the Parameters button

to the right of the event then click the Any box to uncheck the setting. A

list of errors (or warnings) is now available for selection. From the Error

drop-down menu, select the required parameter (Figure 9).

The Set state identifies the event when the problem happens. The

Cleared state specifies the event when the problem is solved.

Events and Actions

17

•Panel Key Event

This is an event in which the operator panel keys are parameters. The

event allows you to change the function of some of the keys or to disable

selective keys. For example, if the panel key event with JOB SELECT/

DECREMENT(-) results in the action “Do Nothing,” the menu key is

disabled.

Figure 10. Setting Panel Key Event Parameters

•ODV Events

This selection allows you to react to output from the Online Data

Validator. The parameters allow you to program GPIO to act when there

is no barcode, when there are barcode errors, or when all ODV errors are

cleared. This event is not available for Impact printers.

Figure 11. ODV Event Parameters

18

Chapter 2 Overview

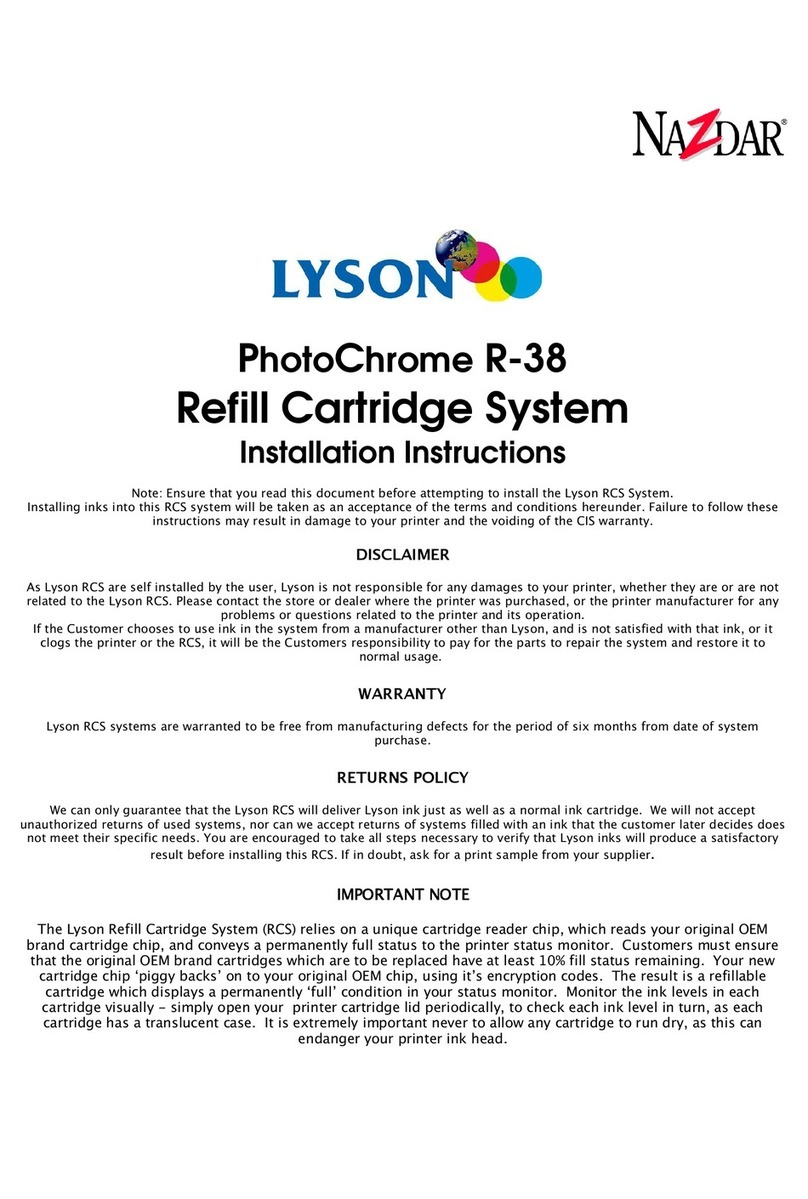

•PAA Event

PAA generates an event on a user-specified input string. A large number

(32000+) of PAA events can be generated through the use of an

identifier.

Figure 12. PAA Event Parameters

•Data Field Changed

This event happens if the value in a given data field changes. Certain

conditions are applicable. See “Data Fields” on page 26.

The Actions

The Action field allows you to specify which action should be linked (or

mapped) to the selected event. Table 2 lists all possible actions and related

parameters.

Table 2. Event Actions and Parameters

Actions Printer

Type Parameters

Output Opto-Coupler Opto-Coupler Number (1..8), Activate, Deactivate,

Pulse

Output Relay Relay Number (1..4), Activate, Deactivate, Pulse

Printer Online n.a

Printer Offline n.a

On/Offline Switch n.a

Clear Buffer n.a

Pulse Printing n.a

Start Printing n.a

Print Next Label Thermal n.a

Reprint Last Printed Label Thermal n.a

Events and Actions

19

Form Feed n.a

Move Paper TOF, Specified Distance Forward/Backward

Cut Once Thermal n.a

Delete Page n.a

Lock Operator Panel n.a

Unlock Operator Panel n.a

Keyhandling Consume

Disable GPIO Events n.a

Enable GPIO Events n.a

Reply to Host Data to be Transmitted, Interface to be used

Wait Time to Wait in mSeconds

PAA Control: Reset CST

Select Mapping Table Name of Table to switch to

Data Field Destination, Operator, Source, Type

Send Report Name, Destination, Duration

Table 2. Event Actions and Parameters

Actions Printer

Type Parameters

20

Chapter 2 Overview

Action Descriptions

•Output Opto-Couplers

The opto-coupler number to activate can be specified as well as the level

(or state) required for this output. You can select the state by clicking the

opto-coupler symbol. If the Pulse parameter is selected, the pulse

duration can be set in increments of 50 msec between 50 and

2,147,483,647 msec. This allows pulses up to 24.8 days in duration. If

Repeated Pulse is selected, the pulse will repeat with a 50% duty cycle

until deactivated.

Figure 13. Setting Ouput Opto-coupler Action Parameters

•Output Relay

The relay number to activate can be specified as well as the level (or

state) required for this output. You can select the state by clicking the

relay symbol. Pulsed behavior for the relays is equivalent to the pulsed

behavior of the opto-coupled outputs.

Figure 14. Output Relay Settings

Other manuals for P5000 Series

7

This manual suits for next models

1

Table of contents

Other Printronix Printer Accessories manuals

Popular Printer Accessories manuals by other brands

LYSON

LYSON PHOTOCHROME R-38 installation instructions

Fujitsu

Fujitsu PA03753-0002 Consumable replacement and cleaning instructions

Epson

Epson OT-BZ20 instruction manual

Sharp

Sharp MX-LCX2 Service manual

Xerox

Xerox C123 Copycentre Office Finisher Installation Guide

Canon

Canon Finisher-U1 INSTALLATION PROCEDURE