Prio Expert MO Series User manual

Prio®Expert

User’s Guide

MO530

MO520

MO510

MO___

Reverse Osmosis

Filtration System

(Storage Tank,

Main Filtration Unit Set)

2

Before operating this appliance, please read the instructions carefully. You

may want to save this guide for your future reference. Failure to follow the

instructions or meet the operating requirements may lead to the product’s

failure, malfunction, property damage or personal injury.

Safety Warning

■Do not place the storage tank near the sources of heat, radiators, etc.

■Keep the appliance out of reach of pets or other animals.

■Do not use the appliance if operating requirements such as water tempera-

ture/water pressure/electrical supply, etc. are not met. There may be other

local regulations to comply with.

■Do not use the appliance with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or aer the system.

■Do not use the waste water produced by the appliance for drinking or cooking.

■Never store or operate the appliance in direct sunlight.

■This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction con-

cerning use of the appliance by a person responsible for their safety.

■Children should be supervised to ensure that they do not play with the ap-

pliance.

■At the end of its life, the appliance should be disposed o in an appropriate

manner.

Disposal

Old appliances still contain many recyclable materials. Therefore, please take

used unit to your retailer or recycling center so that it can be recycled.

3

Description

Congratulations on your purchase of the Prio® Expert R.O. ltration system! With proper

installation and maintenance, it will provide you with high quality drinking water for many

years.

This R.O. system removes odor and most harmful substances such as heavy metal ions and

total dissolved solids from tap water making it tasty, fresh and vital.

Please familiarize yourself with the general concept behind the product and main modes of

operation.

Key Features:

■Clean and safe drinking water right in your home. No need to transport and dispose of

bottled water any more.

■Factory-preinstalled lters and membrane for faster and easier setup.

■Filters and membrane quick-change housings for easy regular maintenance.

■Compact and beautiful design.

■Quick ttings for easy tube connections and change of lters.

4

How It Works:

This Prio® Expert reverse osmosis system is a multi-stage automatic ltration machine.

Reverse Оsmosis (R.O.) is a water purication technology that uses a semipermeable mem-

brane to remove ions, molecules and larger particles from drinking water. R.O. can remove

many types of dissolved and suspended species from water, including bacteria, and is used in

both industrial processes and the production of potable water.

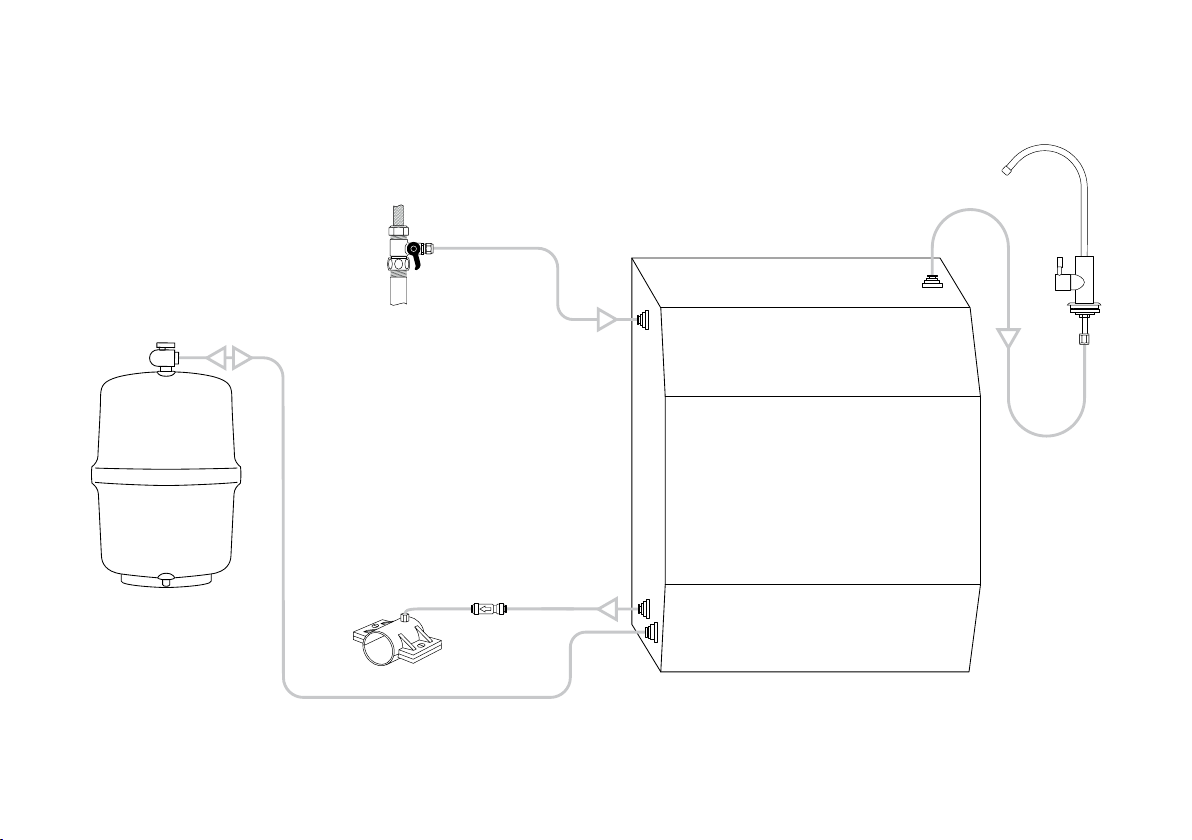

Water supply is done through the inlet valve, ltered water is rst stored in the water tank and

then delivered through the faucet, and waste water is drained through the drain saddle. Detailed

connection scheme is shown on the following charts.

Inlet valve:

An adapter ball valve is included to be installed into the cold water supply line to feed water

to the ltration unit inlet.

5

Faucet:

Designer faucet for ltered water is included and usually mounted on the sink deck or counter-

top for dispensing the clean, ltered water from the ltered water storage tank.

Water Storage Tank:

Air pressurized storage tank is used for ltered water storage.

Drain saddle:

Fits a standard 1.5” diameter drain pipe to drain the waste water from the drain outlet of the

ltration unit.

Pre-Filters:

The main R.O. unit has two pre-lters: sediment pre-lter on the rst stage and activated

carbon pre-lter on the second stage. They provide initial ltration of the water and protect

the following thin lm composite R.O. membrane from dirt and aggressive chemicals such as

chlorine oen found in tap water.

R.O. Membrane:

The third and main stage of the ltration is R.O. membrane. It is “semi-permeable”, which

means that it allows water to pass through but prevents dissolved particles from passing

through. It splits the feed water into two streams: clean water goes to the post-lter and then

onto the tank and faucet. Waste water with rejected particles goes down the drain.

Post-Filter:

Last stage of ltration is an activated carbon post-lter and/or remineralization for ne con-

ditioning and keeping the extra freshness of your water.

Specication

Operating Requirements:

■Minimum supply water pressure1: 30 psi (0.2 MPa)

■Maximum supply water pressure: 80 psi (0.55 MPa)

■Minimum water temperature: 41 oF (5 oC)

■Optimal water temperature: 59–77 oF (15–25 oC)

■Maximum water temperature: 95 oF (35 oC) / up to 105 oF (40.5 oC) short-term

■Ambient air temperature: 41–105 oF (5–40.5 oC)

■Water source: tap water supply, chlorinated or non-chlorinated, bacteriologically safe

■Supply water pH range: 4.0-11.0

■Supply water turbidity: < 1 NTU

■Supply water components: Hardness (CaCO3) <180 mg/L (<10.5 gpg), Iron <0.1 mg/L,

Manganese <0.05 mg/L, Hydrogen Sulde 0.00 mg/L

■Maximum supply water TDS: 1000 ppm

■Indoor use only.

■Tubing: ¼”

1If below 40 psi, a booster pump may be required. X845 Pump Bot is then recommended.

6

Performance:

Performance of the appliance such as ltered water delivery rate, rejection rate, etc. is highly

dependent on local conditions (inlet water pressure, temperature, TDS and degree of contam-

ination, tank air pressure, etc.) and R.O. system use pattern. Actual performance may vary.

■Filtered water production rating: 75 gpd (270 lpd) maximum

■Filtered water delivery rate (from the tank), typical: 0.27–0.74 gpm (1–2.8 l/min)

■Membrane rejection rate1, typical: 90%

■Recovery rate (system eciency2), typical: 15%

■Drain water ow restrictor: 300 cc (ml/min) nominal, up to 360 cc in working mode.

■Tank Storage Capacity (Total Volume): up to 2.5G (4.0G)3

■Tank full rell time4, typical: 70-120 min

Weight and Size:

R.O. ltration unit:

Size (WDH), body only, excluding protrusions: 13.46 x 3.35 x 14.80” (342 x 85 x 376 mm)

Weight, without water and tubing: 8.8 lbs (4.0 kg)

Storage tank:

Tank model No. X842G X852G

Storage Capacity (Total Volume) up to 2.0G (3.2G) up to 2.5G (4.0G)

Size (WxDxH), body only,

excluding protrusions

9.8 x 9.8 x 13.6”

(250 x 250 x 347 mm)

10.55 x 10.55 x 14.90”

(268 x 268 x 378 mm)

Weight, without water and tubing 4.7 lbs (2.1 kg) 6.0 lbs (2.7 kg)

Warranty:

1 year worldwide limited warranty (+ local regulations if applicable)

Package Contents:

(1) The R.O. ltration unit with installed l-

ters (K871, K870, K866, K875 for MO510;

K871, K870, K866, K880 for MO520,

MO530)

(1) Storage tank (X842G model for MO510,

MO520; X852G model for MO530)

(1) Universal worldwide adapter ball valve

(G1/2” - G3/8” - UNEF 9/16”-24 - JG 1/4”)

(1) Teon tape roll

(1) Faucet

(1) Drain saddle

(1) Wrench

(1) ¼” tank valve

(26 / 8 m) Water tubing ¼”

(1) ¼” x ¼” union check valve

(2) ¼” x ¼” x ¼” union tee tting

User’s guide

1 For all dissolved solids combined as measured by TDS or conductivity meter.

2 Eciency rating means the percentage of the inuent water to the system that is available to the user as

reverse osmosis treated water under operating conditions that approximate typical daily usage.

3 Depending on current SKU scope of supply.

4 Depending on supply water pressure.

7

Installation

Notes:

1. Shut o the cold water supply under the sink or the location where the system will be

installed. If the existing valve is inoperable, the water supply to the house must be shut

o. Then, relieve the water pressure by opening the cold water tap. Do not connect the

system to hot water source.

2. Depending on your plumbing system and sink/countertop type you may need to use tools

like variable speed drill, drill bits, screw driver, wrench, etc. You may want to ask a profes-

sional service provider such as certied plumber to install the inlet valve adapter, faucet,

and drain saddle to assure a trouble-free setup.

3. During installation you will need to cut the supplied ¼” tubing into segments as needed.

Use your utility knife for that or similar tool. See the following charts to determine the

connection scheme and length of hoses necessary. You may need to purchase extra tubing

for far-reaching or other corner case installations.

4. With initial operation, check for leaks. If a leak is observed, verify that the tubing is

pushed into the quick tting far enough to seal the tubing against the O-ring and that the

tubing was cut at 90°.

8

drain

saddle

check valve

tank

waste water outlet

permeate outlet to the tank

to drain or waste water

collection container

filtered

water

faucet

filtration unit inlet

inlet valve

(optional)

General connection scheme:

9

IMPORTANT: Cut Tubing At 90° to Ensure a

Watertight Seal:

Units Placement Guide:

R.O. ltration unit

Remember this unit must be serviced at regular intervals. Therefore it should be reasonably

accessible (for changing lters or membrane, etc.).

To Connect the Tubing to a Fitting:

1. Remove the lock if present (not present in self-locking ttings).

2. Push. Insert the tube rmly until full stop.

3. Pull the collet back slightly.

4. Replace the lock (if present).

To Disconnect the Tubing:

1. Remove the lock if present (not present in self-locking ttings).

2. Push the collet and hold.

3. Pull the tubing out.

4. Replace the lock (if present).

1

4

3

2

1

3

ut

1

4

2

3

No skewed cut!

4

3

2

1

10

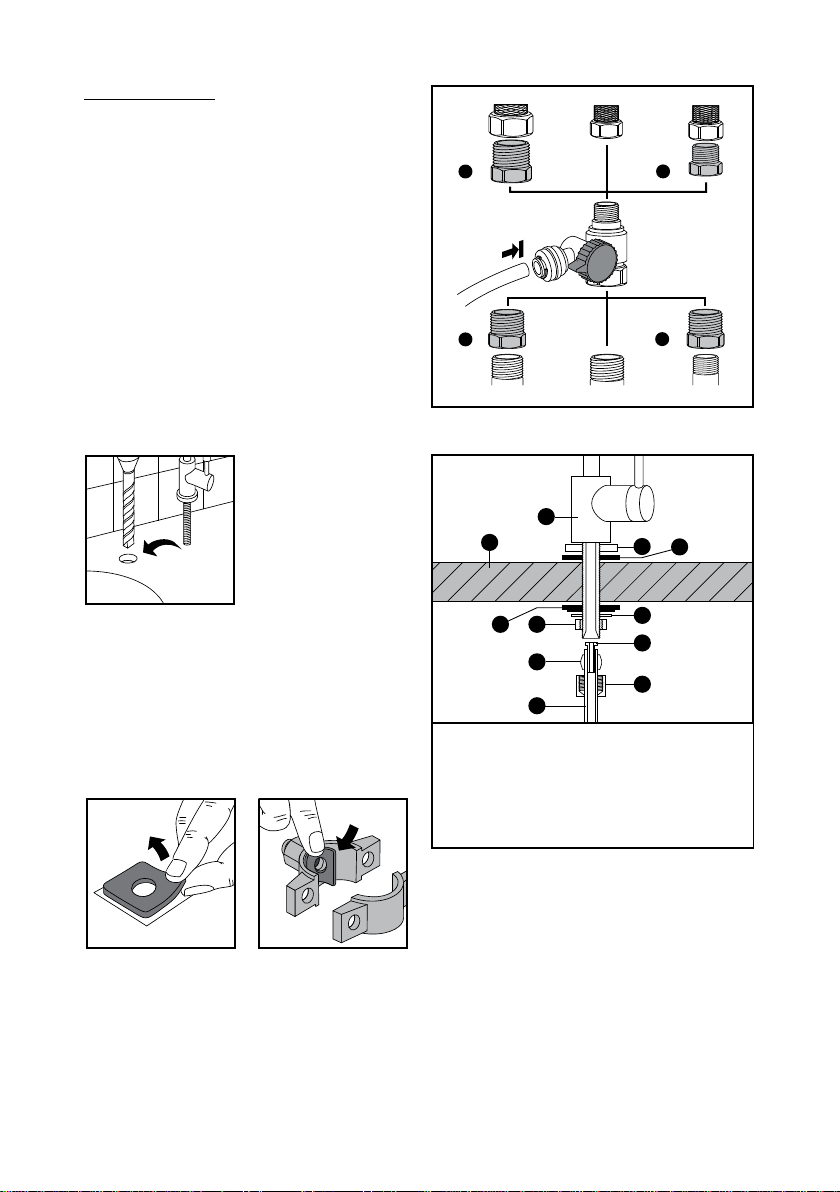

Installation Steps:

1. Install adapter ball valve (included) to the

cold water supply.

Use some Teon or plumbers sealing tape to

prevent leaks. Use three included threaded

adapters to make dierent connection con-

gurations (see chart for details).

2. Create ½” hole for the ltered water faucet and install it.

Tip: If you have a soap dispenser or a water

sprayer in an existing hole you may remove it

and use its hole for the ltered water

faucet.

3. Install drain saddle.

t

The square foam gasket with a circle cut out must be applied to the inside of the drain sad-

dle. Remove sticky tape backing and stick to the drain saddle as shown.

1

23

4

56

7

8

9

10

11

1. Faucet

2. Chrome washer

3. Black rubber washer

4. Countertop or

sink deck

5. Black washer

6. Lock washer

7. Lock nut

8. Insert

9. Sleeve

10. Compression nut

11. Tubing

UNEF 9/16”-24

G3/8” G1/2”

G1/2”

Adapter Adapter

UNEF 9/16”-24

UNEF 9/16”-24

G3/8”

G1/2”

1

Adapter

1

Adapter

2

3

11

mount drain

saddle here

never

mount

here

never mount

here

Drill a ¼” hole in the drain pipe

above the trap and on the ver-

tical or horizontal tail piece. Lo-

cate the drain connection away

from the garbage disposal to

prevent potential contamination

and system fouling.

4. Install water storage tank and mount tank valve.

Tank is a clean water storage container.

Never place the tank in direct sunlight or

near the sources of heat. It’s recommended

to have the tank been installed near the R.O.

ltration unit and the faucet.

Mount tank valve on the inlet-outlet port of

the tank. Use some Teon or plumbers seal-

ing tape to prevent leak.

5. Remove gags and connect tubes as follows. See the connection chart for details.

■Insert water supply tubing from inlet valve adapter into the “inlet”

tting of the R.O. ltration unit.

■Connect with the tubing the “tank” outlet tting of the R.O. ltration

unit with the tank valve tting.

■Insert the waste tubing from the “waste water” outlet tting of the

R.O. ltration unit into the drain saddle (through the optional union

check valve on the way) or to a waste water collection container. Install

the check valve with the arrow in the direction of ow.

■Insert ltered water tubing from the “faucet” outlet tting of the R.O. ltration unit into the fau-

cet using insert, sleeve and compression nut. See faucet installation chart for deta ls.

3/

m un dra n

n t

12

Initial Washing:

Aer installation it is recommended to perform the initial washing of the system. For this:

■shut o the tank

valve

■open cold water

supply valve

■open the inlet

valve

■open the ltered

water faucet

15-30 min

■wait for water to arrive at the faucet (it may take a while, especially rst time, water foam

and air may be going out of the system); wait for 15-30 minutes for more or less steady

weak ow from the faucet.

■shut o the faucet, and open the tank valve.

■wait for tank full rell then drain the tank by opening the faucet.

■repeat tank rell and drain once again by shutting o and opening the faucet, then shut o

the faucet and wait for tank rell with clean water.

■your system is ready for use.

13

Regular Use

To get clean water just open the ltered water faucet. The ltered water stored in the tank

will be delivered. R.O. water ltration system will rell the tank gradually even aer you shut

o the faucet. The system will shut o automatically when the tank will become full again.

Please note that R.O. membrane needs up to 50 hours of active operation before reaching

peak performance in terms of water ow, recovery and rejection rates. The delivery rate and

available amount of ltered water depend on how full the tank is. You may need to shut o the

faucet and wait for the tank rell to get more water.

Tips:

■You may install the optional union tee tting to the tubing line prior to the ltered water

faucet to get another line of clean water going to the other point-of-use (such as a sink in

a bathroom or ice maker in your fridge).

■Operating the system using soened feed water greatly reduces the chances of membrane

failure and prolongs lters and membrane service life.

Changing Filters and Membrane

This R.O. system contains the replaceable components critical to the eciency of the system.

Replacement of a component should be with one of identical specications, as dened by the

manufacturer, to assure the same eciency and contaminant reduction performance.

To reduce the risk of water leakage or ooding, and to ensure optimal R.O. system performance:

■Change the disposable pre-lters every 6 months or sooner if you observe a noticeable

reduction in water production rate.

■Change the disposable post-lter every 12 months or sooner if you observe a noticeable

reduction in water ow or production rate.

■Change the disposable R.O. membrane every 24 months or sooner if you observe a notice-

able reduction in water production rate.

Failure to replace the disposable lters & membrane at recommended intervals may lead to re-

duced system performance and cracks in the lter housings, causing water leakage or ooding.

Please note the capacity of the lters and membrane is limited. Their service life depends on

the degree of contamination of the water supply and system usage. All terms apply to normal

household use. Actual performance may vary. You may need to change lters or the mem-

brane sooner than indicated if you notice chlorine or other tastes or smells, etc. Manufacturer

recommends a TDS test every six months.

Replacement Filters:

■K871 (sediment pre-lter)

■K870 (activated carbon pre-lter)

■K866 (R.O. membrane)

■K880 (activated carbon post-lter and

conditioner)

■K875 (granular activated carbon post-lter)

Optional post-lters which can also be used

instead of K875/K880:

■K873 (granular activated carbon with

schungite natural mineral post-lter)

■K870 carbon block pre-lter may also be

used as a post-lter.

14

To prevent leakage or cracks and ensure the safety of operation and top performance do not

disassemble the lters or try to regenerate them.

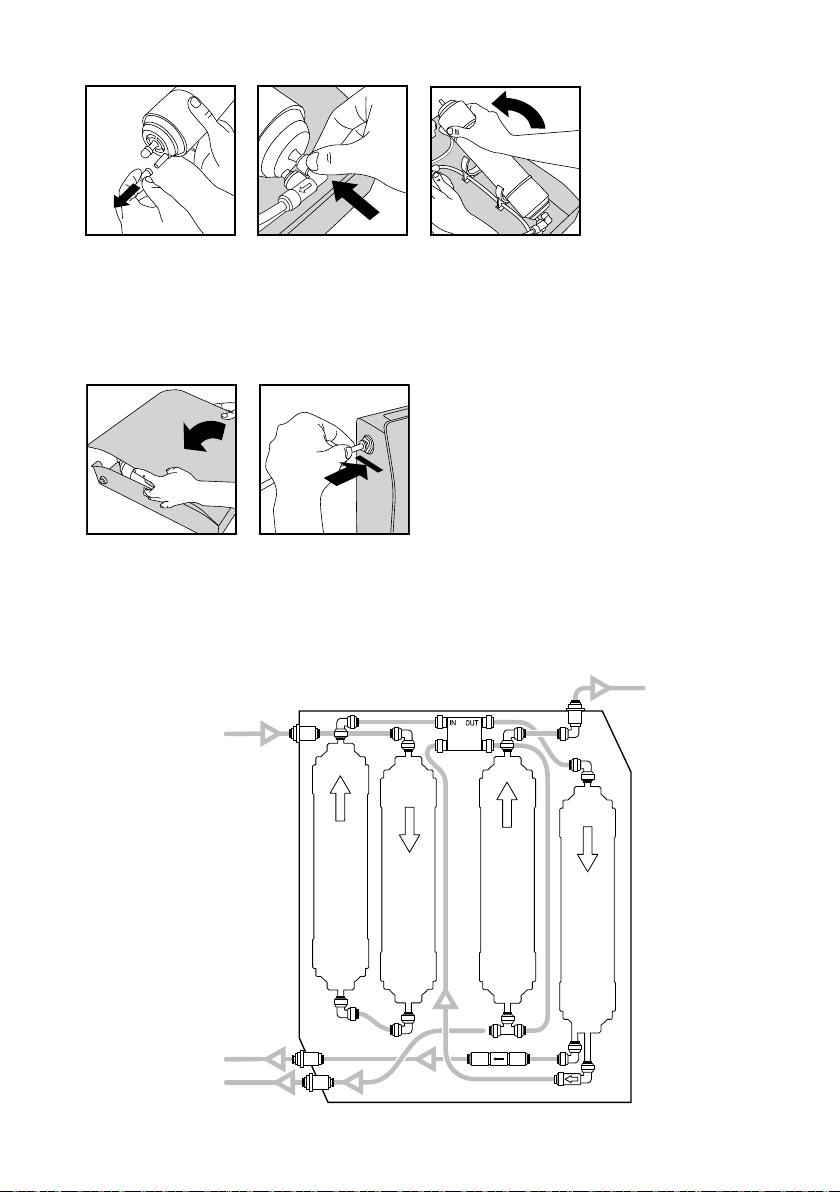

To change lter(s) or membrane:

time

times

■shut-o the inlet

valve

■shut o the tank

valve

■relieve the water

pressure by open-

ing the ltered

water faucet

■remove the R.O. ltration unit from its place

for easier access (disconnect external tubes

if necessary) and open the unit’s cover

■locate the lter (membrane) to be

changed, disconnect its inlet and outlet

ttings and remove it

■take new lter (membrane) and install it in the place of the removed one observing the

water ow direction arrow on its label and restoring the connections (see the internal con-

nections chart for details)

15-30 min

or

Note: Remove and change back one lter at

a time, one aer another. Do not remove all

lters at once to avoid mixing up the tubes.

15

Note: For a pre- or post-lter you only need to connect its inlet and outlet. For the membrane

you have to connect the third outlet – to the waste water line. This outlet is located o the

center of the membrane housing. Elbow check valve tting (with the arrow) has to be con-

nected to the central (permeate) outlet of the membrane housing.

■close the cover, reconnect the external tubes and place the unit back in its place

Aer you nished changing lters or the membrane follow the “initial washing” procedure as

described above. With initial operation, check for leaks. If a leak is observed, verify that the

tube or branch pipe of the lter/membrane housing is pushed into the quick tting far enough

to seal the tube against the O-ring and that the tubing was cut at 90o.

membrane K866

pre-filter K871

pre-filter K870

post-filter K875/K880

waste water outlet

permeate (to tank)

R.O. unit inlet

to the faucet

R.O Filtration Unit Internal Connections Chart

16

Water Storage Tank Service

Water storage tank may require air repres-

surizing if you notice low water delivery rate

even with full tank.

The storage tank has the bladder inside

which separates air from water. On the lower

side of the tank there is the air valve con-

nected to the compressed air chamber. The

top water inlet-outlet port (where the tank

valve is mounted) is connected to the pure

water chamber. When you open the faucet,

the compressed air would compress the

bladder to force the water out of the tank.

In an empty tank, air pressure in the air

chamber should be 5-8 psi (0.35-0.55 bar). If

pressure drops below this threshold you may

notice low delivery rate of pure water from

the tank.

To recharge the tank:

■Shut o the water supply valve.

■Drain the tank by opening the faucet to al-

low water to run until it stops.

■Check to see if there is still water in the

storage tank. If the tank feels heavy,

that means you need to recharge the

air chamber and continue the following

steps. If the tank feels light, that means

it is not time yet to recharge the tank at

this moment.

■Locate the air valve. Use bicycle tire air

pump to pump air into the tank through

this valve. Keep the faucet open while

pumping air so that all water inside the

tank can be purged.

■Aer all water has been drained from the

tank, use an air pressure gauge to check

the tank pressure. The tank should have

5-8 psi (0.35-0.55 bar) of pressure when

it’s empty. Add or purge air if necessary.

■Open the water supply valve and close the

faucet to allow relling of the tank.

Please note that storage tank service life is

limited. Take into consideration that it stores

water of room temperature and is not ster-

ile, thus it may become the source of a sec-

ondary contamination over time. Unpleas-

ant smell or taste may appear in the water.

If changing the post-lter doesn’t solve the

problem your tank may require retirement

and your system needs a new tank.

Prio, Prio logo are the trademarks of DWT Deutsche Wassertechnologien GmbH, Germany.

As used herein, ® denotes registered trademark status in Germany only.

Copyright © DWT Deutsche Wassertechnologien GmbH, Germany, 2014, 2019

This manual suits for next models

3

Table of contents

Other Prio Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Pure-Pro

Pure-Pro EC106R user manual

Pure-Pro

Pure-Pro M100-P user manual

Fillmaster Systems

Fillmaster Systems Fillmaster Filtration Installation instructions and service guide

Bluebird

Bluebird Pure Diamond user manual

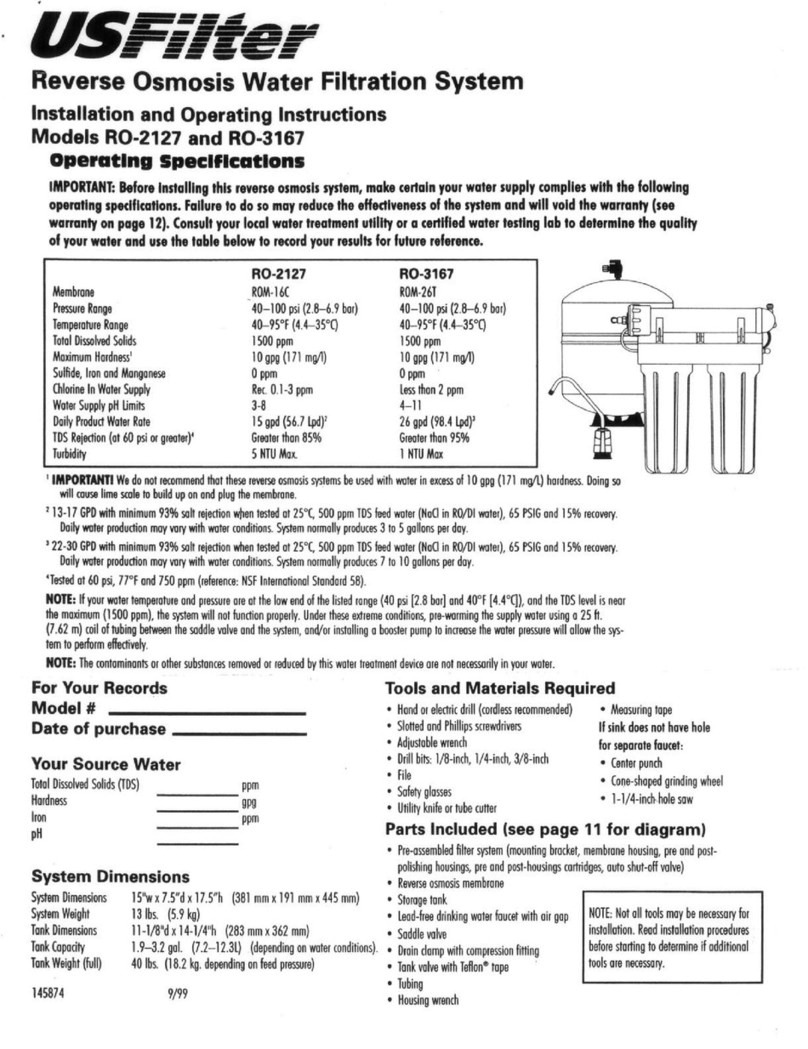

USFilter

USFilter RO-2127 Installation and operating insctructions

WaterTech

WaterTech Reionator Pro RX10 owner's manual