Priva NUTRIJET User manual

Manual

>NUTRIJET - USER

Contact

Priva (head office)

Zijlweg 3

2678 LC De Lier

The Netherlands

See www.priva.com for contact information of a Priva office or partner for your region.

Article number:

00.002Version:

April 2022Date:

© Copyright Priva B.V. All rights reserved.

No part of this publication may be reproduced, published or stored in a retrieval system without

written prior permission of Priva.

This publication has been developed with care. However, the products shown may differ in dimensions

and design from the actual products. Priva will not accept any responsibility for damages caused by

any errors or deficiencies in this publication. Priva may modify its products and the associated

manuals without prior notice. Priva advises to check product, installation, hardware and if present

software on irregularities.

Priva owns the patents, patent applications, trademarks or other intellectual property rights regarding

the products described in this publication. With this publication Priva does not grant the use of the

aforementioned intellectual property rights. Product and company names this publication may not

be used without the permission of Priva.

All Priva products and services are subject to the relevant Priva general terms and conditions. These

general terms and conditions can be read and downloaded at www.priva.com/general-conditions.

Contents

Aim and scope .................................................................................................. 3

Target groups and required competencies ....................................................................................... 3

Availability of the manual .................................................................................................................... 3

Explanation of symbols in this document ..................................................... 3

Warranty ............................................................................................................ 3

Safety ................................................................................................................. 4

Safety - general ..................................................................................................................................... 4

Meanings of safety icons ..................................................................................................................... 5

Safety icons on the unit ....................................................................................................................... 6

Personal protective equipment .......................................................................................................... 6

Safe handling of chemical substances ............................................................................................... 6

Electrical safety ..................................................................................................................................... 7

Safety with mechanical parts .............................................................................................................. 8

Safety with hot parts ............................................................................................................................ 8

Noise safety ........................................................................................................................................... 8

Safeguards ............................................................................................................................................ 8

Residual risks ........................................................................................................................................ 9

Product description ........................................................................................ 10

Functions and intended use ............................................................................................................. 10

Structure .............................................................................................................................................. 11

Structure - hydronic part ............................................................................................................... 11

Structure - electrical part ............................................................................................................... 14

Operating principle ............................................................................................................................ 16

NutriJet Inline .................................................................................................................................. 16

NutriJet Bypass ................................................................................................................................ 18

Transport and storage ................................................................................... 19

Operation ........................................................................................................ 20

Basic facility requirement .................................................................................................................. 20

Workplace ........................................................................................................................................ 20

Location and environmental conditions ...................................................................................... 20

Operating software ........................................................................................................................... 21

Process phases ................................................................................................................................... 22

Turning the unit on and off ............................................................................................................... 22

Power supply failure .......................................................................................................................... 23

Topping-up fertilisers and acid or lye .............................................................................................. 23

1NutriJet - user - 00.002

Adjusting the user settings ............................................................................................................... 23

Maintenance and repair ................................................................................ 25

Preventative maintenance schedule ................................................................................................ 25

Setting the unit to maintenance mode ............................................................................................ 26

Maintenance work ............................................................................................................................. 26

Cleaning the exterior of the unit ................................................................................................... 26

Cleaning the inline dirt filter .......................................................................................................... 27

Cleaning the dirt filter of the dosing channel .............................................................................. 27

Cleaning the pH sensors ................................................................................................................ 28

Cleaning the flow sensor ............................................................................................................... 30

Troubleshooting ............................................................................................. 31

Troubleshooting - general ................................................................................................................. 31

Troubleshooting - process computer ............................................................................................... 36

Taking out of operation ................................................................................. 37

Disposal of waste equipment ........................................................................................................... 37

Appendices ...................................................................................................... 38

EC Declaration of Conformity .......................................................................................................... 39

Supply water quality .......................................................................................................................... 40

Preparing an acid supply ................................................................................................................... 42

Technical specifications - Product options ...................................................................................... 44

Technical specifications – general ................................................................................................. 44

Technical specifications - process computer ............................................................................... 45

Technical specifications - Mechanical .............................................................................................. 47

Technical specifications - mechanical ........................................................................................... 47

Technical specifications - pumps .................................................................................................. 51

Technical specifications - inline dirt filter ..................................................................................... 51

Spare parts .......................................................................................................................................... 52

NutriJet ............................................................................................................................................ 52

Nutri-Line ........................................................................................................................................ 54

Dosing channels .............................................................................................................................. 55

Terms and abbreviations ................................................................................................................... 62

NutriJet - user - 00.0022

Priva

Aim and scope

This manual contains all of the information required to safely and correctly operate, maintain and

decommission the fertiliser dosing unit. This manual will also allow you to effectively observe and

resolve any faults.

The data and the illustrations in this manual relate to the various models of the fertiliser dosing unit.

In addition, each fertiliser dosing unit has customer-specific features, which may differ slightly from

the description in this manual. You can find details about this in the project drawings and documents

that have been created specifically for your delivery.

For the sake of simplicity this manual uses the term 'unit' to refer to 'fertiliser dosing unit'.

Target groups and required competencies

Training, knowledge and experience requiredTasks and responsibilitiesTarget group

ability to do the following with the unit:

User management • general technical insight

• operate • knowledge of the crop's water requirement

and fertiliser requirement• check in the event of a malfunction and

resolve simple malfunctions • some knowledge of the characteristics and

hazards of the chemical substances used in

the water installations

• maintain it in accordance with the

maintenance schedule (simple

maintenance only)

Availability of the manual

This manual must be available in the workplace at all times for the personnel who operate and

monitor the unit.

In addition to this manual, other relevant user manuals, such as the process computer software

manual, must also be available.

Explanation of symbols in this document

DANGER

Instruction to prevent physical injury or damage to the product, the installation or the

environment.

CAUTION

Instruction to prevent problems with the product or the service.

INFORMATION

Additional information.

TIP

A tip or other useful information.

Warranty

The warranty expires if the product is not installed, used and maintained in accordance with the

instructions in the Priva manual. For more details refer to the general terms of delivery (Priva will

supply these on request and refer to www.priva.com) and the specifically agreed terms of delivery.

3NutriJet - user - 00.002

Aim and scope

Safety

• Before starting to work with the product, read the entire manual so that you are familiar

will all safety instructions and safety precautions.

• In addition, read any other manuals supplied with specific components.

Safety - general

• Only Priva approved installers/service engineers who have received product-specific training

from Priva are allowed to install, configure, repair and, if necessary, alter the product.

• Making alterations to the safeguards and safety icons on the equipment is prohibited.

• The internal connections are made in the factory and are to a large extent customer-specific

(refer to the supplied project drawings). Do not, therefore, alter the internal connections.

• External equipment or components that are connected to the unit, such as computers and

networks, must comply with the relevant safety instructions for electrical isolation.

•Both the installer/service engineer and the user must regularly check and maintain the equipment

(the safeguards in particular) in accordance with the instructions in the manual. Keep the

equipment clean and the surroundings tidy.

• Report malfunctions or damage to your installer immediately. Take the equipment out of

operation and do not use it if a defect is found.

• Only use original spare parts for repairs.

• After making repairs check the correct status and functioning of the equipment.

• If the user allows personnel to operate the equipment, he/she must adequately instruct this

personnel. In particular this should cover the safety risks and safety instructions stated in this

manual. He/she must also supervise correct compliance with the instructions.

• Ensure that the personal protective equipment prescribed in this manual is available and that

it is used.

• Display the safety icons that are applicable in the room where the equipment is set up.

• Ensure that the safety icons on and around the unit are clearly legible at all times. Replace any

stickers with the safety icons which have become illegible.

NutriJet - user - 00.0024

Priva

Meanings of safety icons

Below are the meanings of the general safety icons that may be found in, on or around the unit.

Warning symbols for specific hazards

Hazard: general warning

Hazard: corrosive substances

Hazard: hot surface

Hazard: high voltage (danger of electrocution)

Hazard: UV radiation

Hazard: oxidising substances

Hazard!

High leakage current.

Earthing required for the connection of the power supply.

Prescriptive symbols

Wear ear protection

Wear safety glasses

Wear ear protection and safety glasses

Wear non-permeable gloves that are resistant to chemical substances

Wear clean work clothes that cover as much of the skin as possible

Wear (safety) boots

Read the device manual

5NutriJet - user - 00.002

Safety

Safety icons on the unit

Personal protective equipment

When working on the unit, tanks and lines always wear the following protective equipment to prevent

injury or damage to your health:

Safe handling of chemical substances

When working near or on equipment for chemical substances, there is a danger of contact with

concentrated fertilisers, acid, lye or hydrogen peroxide. These chemical substances may be caustic

and corrosive. Hydrogen peroxide is also caustic, is a strong oxidising agent and can react violently

with certain other substances. This presents a risk of injury to the eyes and skin and of damage to

the equipment.

Ask the supplier of the chemical substances for detailed safety information. Ensure that everyone

working with or near the chemical substances is aware of the following:

• the names of the substances and the concentrations;

• the risks;

• the protective measures required;

• action to be taken in the event of contact with the skin or eyes or after inhalation or ingestion;

• action to be taken in the event of leaks.

NutriJet - user - 00.0026

Priva

The following safety precautions apply for working with chemical substances:

• Position the unit and tanks above a spill containment facility: a liquid-resistant floor or a

liquid-tight drip tray. The floor, together with walls, barriers or raised edges, forms a spill

containment facility. ¹

• The spill containment facility must be of sufficient strength to withstand the liquid pressure

arising from a leakage and must be resistant to the effects of the substances stored in the

tanks. ¹

• The spill containment facility must be able to contain the total volume of the tank. If several

tanks are located above the spill containment facility, the collection capacity must be equal

to the volume of the largest tank plus 10% of the combined volume of the other tanks. ¹

• A tank for storing acid must be placed in a different spill containment facility from a tank

for storing a basic substance. ¹

¹Source: https://www.infomil.nl/

• Make sure that hydrogen peroxide does not come into contact with other substances.

• Set the components up in such a way that they cannot easily be damaged.

• Ensure the dilutions are correct and use materials that are resistant to chemical substances.

• Clearly mark tanks and lines with the substances they contain.

• Ensure that the room is well-ventilated.

•Wear safety glasses, safety gloves and (safety) boots that are impervious to chemical substances.

Wear clean work clothes that cover as much of the skin as possible.

• Ensure that there are facilities for showering and bathing the eyes near at hand. Ensure that

everyone understands where these facilities are and how to use them. Ensure that the facilities

are working at all times and are clean. Regularly rinse eyewash fountains in particular to prevent

bacterial pollution.

• Remove clothing immediately if it has been contaminated with chemical substances. Wash the

skin and the clothing with copious amounts of water.

• Ensure that the telephone number of professional emergency services is known in case that

service is required. Notify the emergency services of which substance is involved in the event

of a disaster.

• Ensure that facilities for collecting leaking chemical substances, cleaning them up, diluting them

with water and rinsing them away are always close to hand.

• Never add water to concentrated substances – add the concentrated substance to the water!

This keeps the consequences of the reactions (gas formation, heat generation, effervescence,

splashing) to a minimum.

• Isolate the system from the main line and empty the equipment and lines and/or rinse them

thoroughly with water before opening them for maintenance.

• Drain discharge water - if not reused - in accordance with the locally applicable environmental

regulations.

Take the following preventative measures when working with acids:

• Never add water to acid but always acid to water. This is on account of the strong heat

development and the risk of acid splash when you add water to acid.

• Always check first where the safety facilities (such as an eyewash fountain) are located in the

operating area.

• When working with acid, always keep an eyewash fountain and a bucket of tap water within

reach.

• Make sure that the stock of acid has been installed in accordance with the regional and relevant

regulations.

• During maintenance work, remember that the water in the unit may be acidic. Before starting

maintenance work, flush the system, e.g. with non-acidic rinse water.

• Concentrated acid is found in all the components of the acid dosing system. Always clean these

components thoroughly before starting maintenance work on the acid dosing system.

Electrical safety

The unit is powered from the mains voltage. There is a potential hazard of electrocution or fire

resulting from a short circuit. You must therefore adhere to the following safety instructions:

• Keep the housings of electrical components closed.

• Keep the electrical parts dry.

7NutriJet - user - 00.002

Safety

• Make sure that the earthing is connected correctly.

• Ensure that the unit is connected to its own fuse group with the correct fuses.

• The electrical connection must comply with the locally applicable regulations.

During installation, maintenance or while resolving faults it may be necessary to open the housing

for the electrical components. In this case, adhere to the following safety instructions:

• Preferably, make the unit totally free of electricity by removing the plug from the socket outlet

or by removing fuses from the fuse group.

• If the unit cannot be made free of electricity then take extreme care. Use well-insulated tools

and do not touch the ends of wires, connections and electrical components with your bare

hands. Keep the surroundings dry and ensure that there is someone close by to keep an eye on

you.

• Wear an earthed wrist strap when working in the cabinet. Otherwise the electronic components

may be damaged due to static electricity.

• Once the work has been completed, close the cabinet in the correct manner.

Safety with mechanical parts

Adhere to the following safety instructions to prevent injury from mechanical causes:

• Transport and position the unit in accordance with the instructions in the (installer) manual. The

unit is heavy!

• Install lines/hoses in such a way that no one can trip over them. Keep the surroundings tidy and

dry to prevent trips and slips.

• Keep the frequency controller, pumps and electrically operated valves closed in order to prevent

water damage.

Take measures to prevent water hammer to avoid damage to equipment. Fill lines gradually and

bleed them before switching the pumps to full operation or fully opening main valves.

Safety with hot parts

Parts of the unit that may become hot are equipped with this sticker and protected as much as

possible.

Do not touch these parts during or shortly after operation.

Noise safety

The emission sound pressure depends on the configuration selected. Wear ear protection when

noise-producing equipment is present in the room.

Safeguards

The unit has the following safeguards:

• The cabinet containing electrical components is closed with a locked door.

• The fan of the electric motor on the system pump is protected by a cover.

• The motor protection switches the system pump off if it is consuming too much current due to

overloading. The process computer detects this situation and then shuts down the entire unit.

NutriJet - user - 00.0028

Priva

• The power supply of the modules in the cabinet is connected to a circuit breaker that removes

the power if overloading occurs.

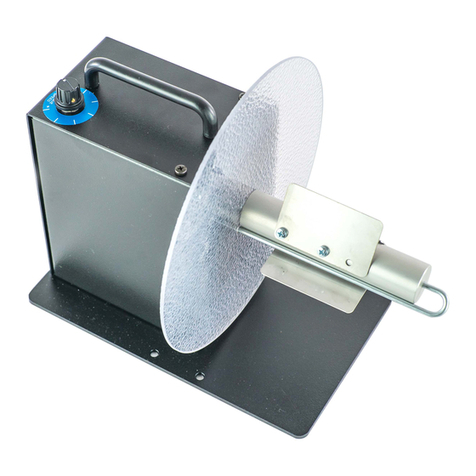

• The hot parts of the dosage valves are protected by a transparent, L-shaped plastic sheet.

Shielding on a dosage valve

• Install and use the equipment in accordance with the instructions in the manual to ensure that

the safeguards function correctly.

• Never bridge or remove the safeguards: this may lead to a serious accident.

Residual risks

The following risks could not be excluded in the design:

• If the unit is altered or is used in such a way that it becomes contrary to the instructions in this

manual, unforeseen risks may occur.

• If the pump switch is set to automatic, the process computer can start the pump. Therefore, set

the switch to off during maintenance when the process computer must remain on.

• Because the unit is usually connected to other external electrical equipment the unit has not

been fitted with an emergency stop. The installer must install a separate emergency button near

the unit which can be used to switch off the entire installation.

9NutriJet - user - 00.002

Safety

Product description

Functions and intended use

The unit belongs to the type of industrial equipment for controlling processes. The unit controls the

fertigation process in the horticulture industry by measuring various output values and adjusting

them to set values.

The function of the unit is to supply the desired irrigation water by suctioning in and mixing supply

water and fertilisers, while at the same time measuring and adjusting:

• the electrical conductivity of the irrigation water;

• the pH value of the irrigation water;

• the pressure and capacity of the irrigation water (optional).

The unit adjusts these output values to values that have been set by programming from a local or

remote process computer. For operation, a local process computer can be equipped with a local

wireless network.

Suctioning and mixing of supply water and fertilisers

The unit draws in the diluted fertilisers that have been dissolved in water from several fertiliser tanks

and mixes them with supply water to form homogeneous irrigation water.

Optionally, it is possible to select the pre-mixing of various water supply sources and/or filtration of

the irrigation water.

Measuring and controlling the electrical conductivity of the irrigation water

The electrical conductivity of the irrigation water is a measure of the fertiliser concentration and is

measured by the unit using EC sensors. Depending on the measured values and the programmed

recipe, the process computer adjusts the quantity of suctioned-in fertilisers by controlling the fertiliser

dosing channels.

Measuring and controlling the pH value of irrigation water

The unit brings the pH value of the irrigation water to the desired level. The pH value is measured

by the unit using pH sensors. Depending on the measured values and the programmed recipe, the

process computer controls the necessary pH correction. For the pH correction, one of the fertiliser

dosing channels is used to dose acid or lye.

Measuring and controlling the pressure and capacity of the irrigation water (optional)

The pressure and capacity of the irrigation water supplied by the unit are dependent on the pump

on the unit. Optionally, you can choose to regulate the pressure of the irrigation water with a

frequency controller.

NutriJet - user - 00.00210

Priva

Structure

The structure of the unit, both the hydronic and the electrical part, is partly customer-specific and

is determined during the purchasing process. These customer-specific features may differ in detail

from the images shown in this chapter.

Structure - hydronic part

In essence, the structure of the unit can be divided into the groups that are explained in this chapter.

The table gives an overview of the variants with references to the associated images and dimension

tables.

Explanation of the table

Use the table to find the correct image, technical drawing and dimension table for a variant

of the NutriJet.

The basic variants (without post-filtration, without pre-mixing) of the NutriJet Inline are in

row 1, the other variants of the NutriJet Inline are in rows 2 and 3.

The NutriJet Bypass is in row 4.

NutriJet variants in main groups

Technical drawing

and dimension

table

DiagramPre-mixingPost-filtrationNumber of

mixing

chambers

Inline /

Bypass

Max. dosage

capacity (l/h)

Technical

specifications -

mechanical (page 47)

NutriJet 100/300/600

Inline (page 12)

--1 or 2Inline100, 300, 600

Technical

specifications -

mechanical (page 47)

NutriJet 100/300

Inline, with

post-filtration and/or

pre-mixing (page 12)

√√1 or 2Inline100, 300

-√

√-

Technical

specifications -

mechanical (page 47)

NutriJet 600 Inline, 1

mixing chamber,

with post-filtration

and/or pre-mixing

(page 12)

√√1Inline600

-√

√-

Technical

specifications -

mechanical (page 47)

NutriJet 600 Inline, 2

mixing chambers,

with post-filtration

and/or pre-mixing

(page 12)

√√2

-√

√-

Technical

specifications -

mechanical (page 47)

NutriJet 300/600

Bypass (page 13)

--1 or 2Bypass300, 600

Legend for the following 5 images

EC sensorsHcabinetA

holder for pH sensorsIdosing channelsB

extra frame with adjustable legs (optional)Jmixing chamberC

EC sensor for EC pre-control (optional)Kframe with adjustable legsD

pre-mix valve (optional)Lsystem pumpE

connection for drain line filter (optional)Mconnection for supply lineF

filter for post-filtration (optional)Nconnection for main irrigation line (line to crop)G

11NutriJet - user - 00.002

Product description

NutriJet 100/300/600 Inline

NutriJet 100/300 Inline, with post-filtration and/or pre-mixing

NutriJet 600 Inline, 1 mixing chamber, with post-filtration and/or pre-mixing

NutriJet 600 Inline, 2 mixing chambers, with post-filtration and/or pre-mixing

NutriJet - user - 00.00212

Priva

NutriJet 300/600 Bypass

13NutriJet - user - 00.002

Product description

Structure - electrical part

Controls

The cabinet can be operated from the outside with the switch of the system pump and the main

switch.

A. system pump switch ('pump switch')

B. main switch

System pump switch:

For convenience, the switch of the system pump is called the "pump switch" in this manual.

The pump switch has the following positions:

•Off: the pump is off and cannot be switched on by the process computer

•Manual: the pump is on and cannot be switched off by the process computer

•Automatic: the pump is controlled by the process computer

Main switch:

The main disconnect switch has the following positions:

•Off: no electrical power is being supplied to the unit

•On: electrical power is being supplied to the unit

NutriJet - user - 00.00214

Priva

Type plate

Location of the type plate

(the type plate shown here is for recognition purposes and its details may differ from the type plate on your product)

The type plate on the product contains the following information (form top to bottom and from left

to right):

• Product name and type designation

•Serial No: serial number

•Year: year of construction

•Connection: specification of the connections to the mains voltage

•Mains: required mains voltage in VAC

•Frequency: required mains frequency in Hz

•Power: nominal power consumption in kW of system pump

• Name and address of the manufacturer (Priva B.V.)

• Manual icon

• CE mark

15NutriJet - user - 00.002

Product description

Operating principle

In terms of working principles, the NutriJet has two variants:

• NutriJet Inline: the unit is installed between the supply line and the main irrigation line, so that

all the irrigation water flows through the unit

• NutriJet Bypass: the unit is installed next to the main line. Part of the water is guided out of the

main line, via the unit, back to the main line. The unit delivers such a high dosage that the correct

dosage is achieved after mixing in the main line.

NutriJet Inline

Graphic of NutriJet Inline fertiliser dosing unit

Not all components are supplied as standard. The components that are shown as transparent depend on the

configuration.

The electrical cables are drawn with a dotted line.

Mixing chamber

The system pump (12) suctions the water out of the supply line (4) through the mixing chamber (8)

and pumps it via a non-return valve (13) to the crop (3). Some of the pumped water goes to the

branch (15). The water in the branch flows back into the mixing chamber via the dosing channels.

A mixing chamber has five connections for dosing channels. With an optional second mixing chamber

in series, a maximum of ten connections in total is therefore possible. Not all of the connections

have to be used.

To degas the mixing chamber, a degas line (10) has been made in the mixing chamber. Through the

drain point (9) the mixing chamber can be emptied. A visual check of the suction pressure can be

done by means of the pressure gauge (12) after the mixing chamber.

Dosing channels

The inline dirt filters (17) in the branch prevent clogging of the venturi nozzles in the dosing channels.

The optional pressure reducing valve (18) reduces the pressure of the water to the dosing channels.

A visual check of the pressure of the supply water upstream of the venturi is carried out using the

manometer (32). The nozzles in the venturi (25) create a vacuum that draws in the fertilisers (30)

and acid or lye (31).

NutriJet - user - 00.00216

Priva

A dirt filter (26) for filtering the fertiliser solution is located in the fertiliser line of a dosing channel.

Using a rotameter (27), the fertiliser suction can be checked and the dosage valve adjusted. The

adjusting of dosage valves is primarily of importance for fertiliser solutions, and not so much for

acid or lye solutions. Partly for this reason, a dosing channel for acid or lye does not have a rotameter.

A dosage valve (29) and a non-return valve (29) are installed in the fertiliser, acid or lye lines just

before the venturi. The control software pulses the dosage valves to control the open time, based

on a recipe and EC and pH measurements. The time that the dosage valves are open and closed

determines the flow rate of fertiliser, acid or lye that is dosed on average.

Various types of dosing channels are available. The type and number of dosing channels on the unit

is customer-specific and is determined during the purchasing process.

EC and pH sensors

The electrical conductivity of the irrigation water is a measure of the fertiliser concentration and is

measured using EC sensors (19) on the branch. The optional line (20) serves to minimise the drop

in pressure across the EC sensors. The pH sensors (21) measure the pH value of the irrigation water.

The pH sensors are located in a sensor holder that is connected to the branch line with a thin line

to eliminate the disruptive influence of the pump pressure.

By using two EC sensors and two pH sensors, the control software can compare the measured values

of the two sensors. If the measured values differ excessively from one another, the control software

signals that one of the two sensors is not working (correctly) and automatically stops the unit in

order to prevent crop damage.

In order to remove the sensors safely, e.g. for maintenance purposes, the line between the manually

operated valves (16 and 24) can be isolated with these valves and made pressureless via the drain

taps (22 and 23) near the pH and EC sensors. These drain taps can also be used to empty the line,

e.g. if the unit is taken out of operation for a longer period of time due to a period of freezing

temperatures.

Cabinet

On a standalone system, the cabinet (33) on the unit contains the whole process computer. If the

cabinet on the unit is a substation of a process computer, the process computer communicates with

the electrical components in the cabinet via the network (Connext) or via direct I/O connections

(Compass). Depending on the model, various other connections (34) are available in the cabinet, e.g.

for the mains supply, irrigation valves, a flush valve or sensors.

Frequency controller

In order to guarantee constant pressure to the crop, a frequency controller (35) may be used. The

frequency controller controls the speed of the pump based on the pressure at the outlet of the unit

which is measured by a pressure transmitter (36). If a frequency controller is not used, the pump is

only switched on or off by the process computer.

EC pre-control

If drain water is reused, an EC pre-control can be used. The pre-control consists of two valves (38)

that are contra-controlled by a common motor. The further one valve closes, the further the other

opens and vice versa. In this respect, one valve allows drain water (with a high EC value) to pass and

the other fresh water (with a low EC value). The EC value of the mixed water is measured by a separate

EC sensor (39). The control software controls the motor on the valves so that the supply water has

a constant, desired EC value. For effective control, the EC values of the drain water and clean water

must differ by at least 0.5 mS/cm.

In order to disassemble the EC sensor safely, e.g. for maintenance, it can be isolated with the manually

operated valves (40). To prevent the mixed water from flowing back into one of the supply lines,

there is a non-return valve (37) in each supply line.

Post-filtration

To prevent blockages in the distribution system, an automatic self-cleaning filter (41) can be used

after the unit. The self-cleaning filter suctions the deposited dirt out of the filter mesh, without the

filtering process being interrupted. The rinse water is discharged via the drain line (42). If not already

present on the unit, a non-return valve (43) must be installed behind the filter. If non-return valve

(43) is present on the unit, non-return valve (13) is not required.

17NutriJet - user - 00.002

Product description

NutriJet Bypass

Graphic of NutriJet Bypass fertiliser dosing unit

Not all components are supplied as standard. The components that are shown as transparent depend on the configuration.

The electrical cables are drawn with a dotted line.

An external pump (1) pumps the water through the main line (2) to the crop (3). Some of the water

flows to the unit via the supply line (4). The system pump (12) suctions some of the water out of the

supply line via the bypass line (6) and the mixing chamber (8) and pumps it back into the main line

via a non-return valve (13) and the outlet line (14).

In the bypass line there are one or more pressure reducing valves (7) that control the suction pressure

of the mixing chamber. These pressure reducing valves are necessary in order to guarantee the

required minimum pressure difference across the venturis. The manometers (44 and 45) make it

possible to visually check the inlet and outlet pressure of the unit.

In order to be able to stop the supply and discharge of water in an emergency or during maintenance,

both the supply line (4) and the outlet line (14) must be equipped with a manually operated valve

(5).

The operation of other components of the NutriJet Bypass and those of the NutriJet Inline are the

same.

A frequency controller, EC pre-control or post-filtration cannot be used with the NutriJet Bypass.

NutriJet - user - 00.00218

Priva

Table of contents