Pro Refrigeration CHILSTAR Series User manual

Operations Manual

ii | Pro Refrigeration, Inc

Contents

1 Preface iii

CUSTOMER SERVICE iii

MANUFACTURE’S INFORMATION iii

RECEIVING & UNLOADING iii

WARNINGS & CAUTIONS iii

PRO CHILLER MODEL NUMBER 2

SYSTEM OVERVIEW 3

ELECTRICAL CONTROL PANEL 3

GLYCOLCIRCULATION&PROCESSPUMPS 3

GLYCOL STORAGE TANK 3

REFRIGERATION EQUIPMENT 3

SPIRAL DRUM EVAPORATOR 3

PUMPCURVESSUPPLIEDBYPUMPSERIES 4

INSTALLATION,OPERATION,&MAINTENANCE 6

WIRING 7

MAINTENANCE iv

PIPING 6

RECEIVING AND INSPECTION 6

SETTING EQUIPMENT 6

SYSTEM CHARGING 7

SYSTEM EVACUATION 7

PRE START-UP CHECK LIST 8

MASERIESCHILLERQUICKSTARTGUIDE 9

SYSTEM WARRANTY 14

FAULTY COMPONENT 15

WARRANTY REPAIR PROCEDURE 14

WORKMANSHIP FLAW 15

RESOURCES 16

TROUBLESHOOTING 21

Table of Contents | III

1 Preface

is manual is intended to be used in conjunction with

Pro Refrigeration, Inc Chiller Systems

is manual will guide you through the process of install-

ing, commissioning, and maintaining your Pro Chiller

System.

Receiving & Unloading

Before signing the Bill of Lading please complete the

following:

•Check Service Panels for Damage

•Conrm positive pressure on refrigerant pressure gauges.

•Remove from service panels and visually inspect all pip-

ing for broken and or cracked lines.

Please note any obvious, or potential damage on bill of

lading prior to signing. Contact Pro Refrigeration, Inc

immediately 800-845-7781 to report any damage.

Manufactured By:

Pro Refrigeration, Inc.

Pro Refrigeration is located in Auburn WA. Auburn is

located 30 miles from Seattle, WA in the shadow of Mt.

Rainier.

Physical Address:

326 8th ST SW

Auburn, WA 98001

www.prochiller.com

Mailing Address:

PO BOX 1528

Auburn, WA 98071-1528

Telephone: 253-735-9466

Fax: 253-735-2631

Customer Service

Please feel free to contact customer service with any

questions pertaining to this or any other Pro Refrigera-

tion, Inc product.

Customer Support Hours:

Monday-Friday

7am-5pm (Pacic Standard Time)

Telephone: 253-735-9466

Fax: 253-735-2631

Email: ser[email protected]

Warnings & Cautions:

roughout this manual warnings & cautions will be

issued containing pertenant information regarding the

safety of you and/or your equipment. ese messages

will be accompanied by the following symbols:

Warning

Caution

2| Pro Refrigeration, Inc

Pro Chiller Model Number Identication

PB230F14R4400-A

TYPEOFREFRIGERANT

R5= R507

R4 = R404A

R2 =R22

TANKCAPACITY

20 100 200 250 400 550 1000 1500

SS = STAINLESS STEEL (HEATED TANK)

CL = CLASSIC (NOTANK)

X = NONE

COMPRESSORMAKE

B = BITZER

C = CARLYLE

M = MANEUROP

E = EMERSON (COPELAND)

X = NONE

P= PROREFRIGERATION

NUMBEROFREFRIGERATIONCIRCUITS

1 2 3 4 5

CIRCUITHORSEPOWER

HERMETIC SEMI-HERMETIC

02 10

03 20

05 30

08 (7.5) 40

10 50

12

EVAPORATOR COUNT 1 - 70

CONDENSINGTYPE:

A = PACKAGED AIR-COOLED

HA = PACKAGED AIR-COOLED HIGH AMBIENT

R = REMOTE AIR-COOLED

RHA = REMOTE AIR-COOLED HIGH AMBIENT

W = WATER

X = NONE

Packaged Glycol Chiller Systems | 3

SYSTEM OVERVIEW

e following list of components are standard on all of our chiller systems. We oer a wide selection of compres-

sors and condensing units that are incorporated with these components to produce one of the most ecient chiller

systems available. A brief summary of the common Packaged Chiller Components:

ELECTRICAL CONTROL PANEL

All of our chillers are equipped with a control panel with an ETL listing approval. All of the components are

wired to the National Electrical Code guidelines. ere is no internal wiring required on our standard systems. An

electrician must simply supply the chiller with main power service. If chiller is purchased without a main electrical

disconnect switch, most local electrical codes will require one to be installed adjacent to the chiller control panel.

GLYCOL STORAGE TANK

All standard models of chillers are supplied with an insulated glycol storage tank. Our glycol tanks are constructed

of berglass, stainless steel, or polyethylene.

SPIRAL DRUM EVAPORATOR

Our high ecient U.L. Listed evaporator counter ows liquid refrigerant with the chilled glycol water. e inter-

nal nned copper tubing oers 3.7 times the surface area of standard smooth copper tubing. By manifolding the

evaporators together, we can maximize the eciency of the heat exchanger surface area. We oer a 5 year replace-

ment warranty for the evaporator.e warranty does not cover failures due to internal freezing of evaporators.

REFRIGERATION EQUIPMENT

We use only the highest quality refrigeration components available. All of our components meet industry stan-

dards and are easily sourced for maintenance and repair. On our packaged systems, all of the refrigerant piping is

factory installed. e system is charged with refrigerant and functionally tested prior to shipment.

GLYCOL CIRCULATION & PROCESS PUMPS

CIRCULATION PUMP

PROCESS PUMP

• is stainless steel centrifugal pump is designed to circulate whenever a cooling demand exists. e circu-

lation pump transfers glycol from the storage tank through the evaporator chiller drum and back into the

glycol tank. e chiller system is controlled so the system will not operate unless the circulation pump is

running .

• is stainless steel pump is specied to supply your process load with chilled glycol. e process pump

takes the chilled glycol from the tank, to the process cooling application, and returns it to the glycol stor-

age tank. is pump does not need to be running in order for the chiller to operate. Our smaller ChilStar

chiller systems do not have a glycol process pump, we utilize a single pump for supplying the glycol to the

plant as well as circulate to the evaporator.

4| Pro Refrigeration, Inc

PUMP CURVES SUPPLIED BY PUMP SERIES

1ST Series Pump Curve

2ST Series Pump Curve

Packaged Glycol Chiller Systems | 5

3ST Series Pump Curve

5SH Series Pump Curve

6| Pro Refrigeration, Inc

INSTALLATION, OPERATION, & MAINTENANCE INSTRUC-

TIONS

RECEIVING AND INSPECTION

Immediately upon receiving shipment, equipment should be inspected for evidence of any damage received in

transit. If shipping damage has occurred, a claim should be made with the transportation company, and your

equipment representative should be advised of the nature of the damage.

Equipment should be inspected for compliance with original order acknowledgment (equipment model numbers,

voltage, refrigerant, etc.).

SETTING EQUIPMENT

When choosing a location for chiller, the following items should be considered:

a.) Front and sides of chiller have available service area.

b.) Electrical enclosure is visible for viewing alarm/indicator lights.

c.) Chiller should be located as close to process cooling application as possible.

d.) Availability of electrical power.

e.) Availability of city (well) water for water cooled condensing. (As applicable)

f.) Adequate air ow for air cooled condensing.e condenser must be at least 48” away from any

obstruction

g.) Level surface to mount unit.

PIPING

1. All piping must be in accordance with applicable local and state codes.

2. Refrigerant piping should be designed and installed in accordance with recommended practices outlined in ARI

or ASHRAE piping guide.

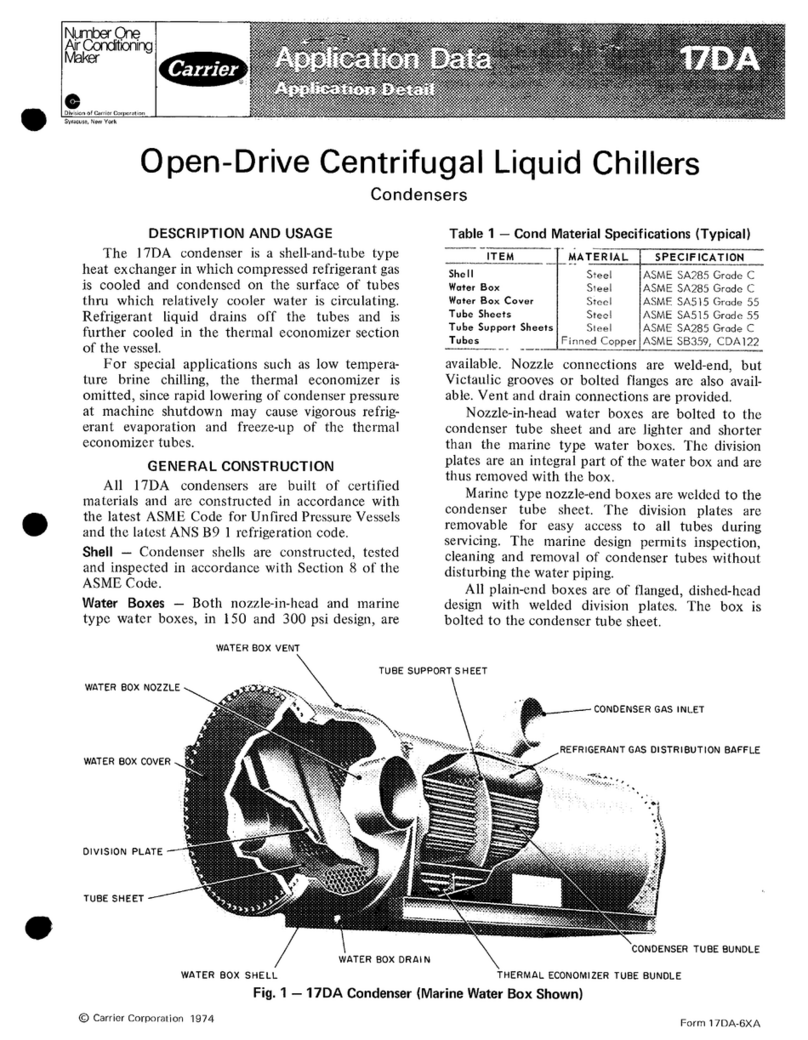

3. Water piping (for water cooled condensers) should be installed to meet application requirements. Keep in mind

that condenser barrels may need to be cleaned, all piping should have unions to enable end cap to be removed

from condenser. Any piping exposed to freezing ambient conditions should be insulated.

4. Water piping (chilled water) should be installed to meet application requirements. Properly size chilled water

process piping to insure that ow is not restricted due to extreme line pressure. It is recommended that chilled

water piping be ran in either of the following materials: industrial ABS, copper, or stainless steel. It is not advised

to run chilled water piping in galvanized or black-ironpipe (unless you are using a glycol with rust inhibitors), the

propylene glycol will erode the pipe and could also cause bacteria problems. Glycol piping should be insulated to

prevent condensation.

5. Check all chilled cooling application process piping for leaks prior to adding glycol solution.

6. Circulate water (without glycol) through process piping system and check for leaks.

Packaged Glycol Chiller Systems | 7

7. Remove any piping debris, ushed from tank and process piping. Do not turn the chiller switch on until all

debris has been removed from the system.

WIRING

1. Select or install an adequate electrical service to handle chiller load. Service must comply with all applicable

electrical codes. Refer to the MCA (Minimum Circuit Ampacity) rating recorded on the blue chiller identication

label in your chiller’s electrical control panel.

2. If not factory installed, an electrical disconnect switch should be installed adjacent to chiller control panel.

3. After electrical service has been properly connected to the chiller, chiller should be energized for at least 24 hr. to

allow crankcase heaters to boil out any liquid refrigerant which may have migrated to compressor during shipment.

4. Check all motors for proper rotation. Pump motors must rotate clockwise when inspected from motor end

(the end where wire connections are made).To change pump motor rotation, reverse the L1 with L3 power wires.

Compressors can operate in either rotation, unless noted on compressor housing.

SYSTEM EVACUATION (for remote air cooled condensers or remote condensing

units)

1. With refrigeration piping completed and pressure checked, the system is ready for evacuation. Do not use com-

pressor to evacuate system. A quality vacuum pump capable of a 350 micron evacuation is necessary for adequate

and dependable system vacuum. Moisture and contaminants in the system not removed by proper evacuation can

cause corrosion on compressor windings, expansion valve freeze-up, oil sludge, and high discharge pressures.

2. Attach vacuum pump to low and high side of system through compressor service valves. If check valves are pres-

ent, insure that vacuum lines are attached to both sides of check valves. Evacuate to 350 microns. A micron reading

device is necessary to ensure that no moisture or contaminants are present before system is charged with refriger-

ant.NOTE: All of the remote air cooled and remote condensing unit chillers leave the factory with a dry nitrogen

holding charge. If system is not pressurized on arrival, re-pressurize with dry nitrogen and leak check system before

beginning the refrigeration piping installation.

SYSTEM CHARGING

1. With system evacuated to 350 microns or less, chiller is ready to be charged with refrigerant. All charging lines,

hoses and manifolds must be purged with refrigerant to prevent non condensable from being introduced to system.

2. Connect charging line to liquid line access ttings and admit liquid refrigerant into system until ow stops due

to pressure equalization between cylinder and system.

3. Connect charging line to suction tting up stream of accumulator and admit vapor into low side of system.

4. Energize equipment to the refrigeration circuit and continue to admit vapor into low side of system until refrig-

erant liquid line sightglass clears. (It may be necessary to defeat low pressure freeze control on initial start-up to

prevent nuisance cycling of compressor until pressure is above low pressure cut out set point).

8| Pro Refrigeration, Inc

MAINTENANCE

1. e system should be checked periodically to make sure that the refrigeration system(s) is operating properly. Use only the

services of certied refrigeration mechanics for inspection and maintenance checks or service operations.

2. WATER COOLED CONDENSERS - Water cooled condensers should be checked for scale build-up and blockage. is

should be checked annually; if high head pressure problems occur a check of the condenser should be performed.

3. AIR COOLED CONDENSERS - Air cooled condenser coils must be kept clean through a regular preventive mainte-

nance program.

4. Compressor oil level should be checked regularly. Oil should be visible in the oil sight glass (located on the side of the

compressor) . Compressor oil sight glass should be 1/4 to 1/2 full.

5. Periodically check all electrical connections for possible loose or corroded wiring.

6. Monitor system pressures daily and amperages monthly.

7. Check system glycol tank level and percentage for proper freeze point. e freeze point should be at least 20 degrees F

lower than the operating setpoint temperature.

PRE START-UP CHECK LIST

All Electrical Connections are tight, these may loosen during shipment

Main Disconnect Energized for 24Hr. to allow Crankcase Heater to boil any liquid refrigerant out of

crankcase.

Field Process Piping has been leak checked

VOLTAGE of Chiller System matches customer supplied VOLTAGE

Glycol / Water Solution freeze point is at least 20 F. (11 C.) below T-Stat Setpoint

Glycol Pump Motors Rotation is CLOCKWISE when viewed from motor end

Glycol Storage Tank is at least 80% Full

Pressure Bypass Valve tested. To test, Close a valve on the Glycol Supply and visually check for return

ow into storage tank.

Chiller location allows adequate air ow to and from Air Cooled Condenser. (Air Cooled Only)

Adequate water supply provided to Water Cooled Condenser (Water Cooled Only)

Packaged Glycol Chiller Systems | 9

CHILSTAR & MA SERIES CHILLER QUICK START GUIDE

e quick start guide is designed to be used in conjunction with a Pro Chiller System. As such, this guide as-

sumes that all that all electrical and mechanical devices are in the condition provided by the factory.

STEP 1

Adequate clearance is required around the unit to provide air ow. Ideally you want at least 48” clearance around

all four sides of the system. Chiller systems located indoors require adequate ventilation to insure ecient opera-

tion. Contact the Factory with any questions about chiller location and placement.

Power must be supplied to chiller electrical panel. Check your local electrical codes, it is likely an

electrical disconnect/safety switch will need to be located near the chiller system. Check name plate or

manual for electrical power supply requirements.

STEP 2

Open Electrical Panel and make sure all electrical connections are tight. ese connections may loosen during

shipment. Loose connections can cause motor failures.

CAUTION Refrigeration ball valves are

shipped from the factory in the closed posi-

tion. Prior to operation adjust valves to the

open position.

WARNING Verify that all external power

sources have been removed before servicing

WARNING Do not turn on main power to

the chiller system until all of the electrical

connections are conrmed to be tight.

Please use the services of a licensed and skilled

refrigeration technician for chillerstart-up.

Contact Pro Technical Services with any

questions or concerns at

800-845-7781

10 | Pro Refrigeration, Inc

STEP 3

Remove Front and Side Service Panels as applicable. Open both of the glycol Valves by turning the handles counter

clockwise.

STEP 4

If a tank is installed on your Pro Chiller System ll it with water (no glycol at this time). Otherwise locate the

remote tank or water source and prepare the system to ush the piping with water.

Visually check for any leaks on the system before proceeding.

STEP 5

Turn each circuit’s STAGE switch to the ON position. If your chiller is a single circuit system turn the CHILL-

ER switch to the ON position

Your pump will energize and begin circulating water throughout the piping loop. Open all of the solenoids or

heat exchangers on the loop to get a complete system ush. Visually inspect all of your piping for leaks and repair

prior to proceeding.

Single Circuit Chiller System Dual Circuit Chiller System

Packaged Glycol Chiller Systems | 11

STEP 6

Conrm your pump rotation and that you have ad adequate ow. Motor Rotation is clockwise when viewed from

Motor end. If rotation is backwards, you will need to switch any two leads (3 phase systems only) on the incom-

ing power supply. Indication of ow does not insure proper pump rotation! In reverse rotation the glycol pump

ow is signicantly reduced and will eect chiller operation.

To conrm ow ,check the Flow Meter. If no ow is indicated, it is likely there is an air lock in the pump and

you will need to bleed the air from system. Conrm both valves are open and try cycling the power to the pump

OFF and ON . If still no ow, turn power o and carefully open the plug located on the stainless steel head of the

pump, bleed air from pump head and re-tighten pump head plug.

STEP 7

After 15-30 minutes of ushing, turn STAGE / CHILLER switches OFF and drain the water from system and

tank. If no tank is installed open up your piping inside the processing plant and drain water. It is important to

drain as much water as possible from tank jackets and heat exchangers. Any remaining water will dilute glycol

concentration and could also leave contaminants within piping loop.

If a tank is installed use a Wet/Dry vacuum to clean out any particles inside the tank. It is important to get as

much debris as possible. Any debris left in the system can cause solenoid valves to hang open or not fully open.

STEP 8

Close the piping system and we are now ready to charge the system with a minimum of 35% USP Grade Propyl-

ene Glycol / 65% Water. Use a refractometer or glycol percentage tester to insure the proper glycol concentration.

With the system completely drained, charge the system with one part glycol for every 2 parts of clean water. As

you introduce the glycol to the piping system, additional glycol/water will need to be added. Operating level of

the glycol solution must be within 4-6” from top of tank.

12 | Pro Refrigeration, Inc

STEP 9

Open all Refrigerant Valves on the chiller refrigeration systems. Quantity of valves and location vary based on

compressor/condensing unit make. Check name plate and documentation to conrm the make of your chiller’s

compressor/condensing unit.

To OPEN, remove Valve Stem Covers and adjust valve stem all the way out by turning counter clockwise. It is

advised to have a refrigeration technician open these valves, it may require the use of a special valve wrench to

open.

STEP 10

Compressor/Condensing unit fuses are shipped inside the main electrical enclosure in a plastic bag. Install these

into the fuse block associated with your condensing unit. If chiller has circuit breakers switch them to the ON

position.

Danfoss Condensing Units:

* Receiver Valve

(located on small receiver tank),

* Suction Service Valve

(located on compressor)

* Discharge Service Valve

(located on compressor).

Emerson Condensing Units:

* Receiver Valve

(located on small receiver tank),

* Suction Service Valve

(located near accumulator)

WARNING Verify that all external power sources have been removed before servicing

System with fuse blocks System with circuit breakers

Receiver Valve

SuctionValve

Discharge Valve

Suction Valve

ReceiverValve

Provided Fuses

Fuse Block

Fuse Block Circuit Breaker

Circuit Breaker

Packaged Glycol Chiller Systems | 13

STEP 11

Close electrical panel door and turn electrical disconnect to to the ON position. Turn CHILLER or STAGE

switches to ON. e chiller circulation pump should start running and compressors should stage on/o according

to the glycol setpoint temperature.

Please call Pro Refrigeration Inc’s Technical Support with any questions at 800-845-7781

14 | Pro Refrigeration, Inc

SYSTEM WARRANTY

1. All orders must be in writing and are subject to acceptance by PRO REFRIGERATION INC. at its principle

oce in Auburn, Washington, United States of America.

2. Prices are subject to change without prior notice and PRO REFRIGERATION INC. reserves the right to

invoice the products sold at prices in eect at the time or times of shipment. Prices do not include any LOCAL,

STATE, FEDERAL, OR FOREIGN TAXES OR EXCISES.

3. Risk or loss shall in every case pass to purchaser upon delivery of goods to the possession of the freight car-

rier or customer. PRO REFRIGERATION INC. shall have no responsibility for any claimed shortages unless

1) PRO is notied within ten (10) days after receipt of goods, 2) Agent or carrier has with-in such time has been

notied of such shortages by purchaser, or 3) Purchaser has led claim with carrier for the damage or shortage

claimed.

4. Any delivery dates that may be indicated herein are estimates only and are not guaranteed, Pro Refrigeration

shall not be held liable for any delay in performance or for non-performance caused by circumstances or events

beyond its reasonable control, including but not limited to: Fire, Labor Disputes or Shortages, Accidents, Factory

Conditions, War, Government Action, or Inability to Obtain Material, Fuel, Equipment, Supplies, or Transporta-

tion.

5. PRO REFRIGERATION INC. reserves the right to change Specications, Design, & Material in the interest

of product improvement, without incurring obligation to purchaser.

6. PRO REFRIGERATION, INC. EXPRESSLY DISCLAIMS ALL WARRANTIES, EITHER EXPRESS

OR IMPLIED, AND SPECIFICALLY DISCLAIMS ALL WARRANTIES OF MERCHANTABILITY

AND OF FITNESS FOR A PARTICULAR PURPOSE, OF THE MATERIALS OR EQUIPMENT

DELIVERED TO PURCHASER EXCEPT AS EXPRESSLY PROVIDED HEREIN. Purchaser assumes

all risk and liability of the use of any materials or equipment purchased from Pro Refrigeration, Inc. Any materi-

als or equipment not manufactured by Pro Refrigeration, Inc. are only warranted in so much as warranted by the

manufacturer or distributor of such goods and in no event shall any warranty period be greater than two (2) years

from the date of shipment to Purchaser. Under no circumstances shall Pro Refrigeration, Inc. provide any warranty

of any kind beyond two (2) years of the date of shipment to Purchaser. In the event of the discovery (and writ-

ten notice to Pro Refrigeration, Inc.) within two (2) years from the date of shipment to Purchaser of any defect in

goods manufactured by Pro Refrigeration, Inc., Pro Refrigeration, Inc.’s liability, whether in contract, in tort, under

any warranty, in negligence, or otherwise, is limited to repair or replacement of the defective goods, at the option

of Pro Refrigeration, Inc. In all instances, labor for repairs is warranted for a period of no greater than one (1) year

from the date of shipment to Purchaser. Otherwise, all such goods from Pro Refrigeration, Inc. are sold on an “AS

IS” basis. UNDER NO CIRCUMSTANCES DOES PRO REFRIGERATION, INC. ASSUME OR AGREE

TO LIABILITY FOR ANY SPECIAL, INDIRECT, INCIDENTAL, CONSEQUENTIAL OR OTHER

DAMAGES arising out of or related to any defective goods hereunder.

7. No products sold by Pro Refrigeration Inc. shall be returned without Pro Refrigeration’s written permission.

Products returned shall be subject to a handling and transportation charge.

WARRANTY REPAIR PROCEDURE

Unfortunately, there will be situations where a component will fail or a chiller will fail due to a problem that was

not detected at the factory. We will assist in any way we can when a situation does occur. We pride ourselves on

building a high quality system that will give the customer years of service, if a problem occurs it is a top priority

that the problem is repaired. e information listed below is based on our standard system warranty. If the chiller

system fails within the warranty period, due to defective components or awed factory workmanship, please follow

Packaged Glycol Chiller Systems | 15

the steps outlined below.

FAULTY COMPONENT

In the event of a component failure, please call our Support Department at (206) 735-9466. If it is determined

that the equipment is within the warranty period they will issue an RMA number. When the defective compo-

nent is received a replacement will then be shipped. All freight costs must be pre-paid. Component warranties

are void if the component or chiller system is being used outside of the design parameters.

WORKMANSHIP FLAW

Our chillers are warranted against aws in workmanship for a period of one year from the date of factory ship-

ment. All of our chillers must pass a stringent quality check list before being approved for shipment. If a system

is found to possess a workmanship aw please call the factory and inform us of the defect which was detected.

We will request a written quotation by a certied refrigeration mechanic to perform the repair. All supplies that

are used for the repair will be supplied by us or they must be listed in a written quotation. We will then decide

either to accept the quotation or have the repair performed by a refrigeration contractor of our choice.

If a repair is needed immediately, please call us at (253) 735-9466 and we will do our best to take care of the problem

promptly.

PLEASE SHIP ALL PRE-APPROVED RETURNS TO:

PRO REFRIGERATION INC.

ATTN: WARRANTY DEPARTMENT

326 8TH ST SW

AUBURN, WA 98001

PHONE (253) 735-9466 FAX (253) 735-2631

16 | Pro Refrigeration, Inc

CHILLER SYSTEM START-UP SHEET

CHILLER MODEL #:

CHILLER SERIAL #:

CUSTOMER :

START-UP DATE :

PRE START-UP CHECK LIST

All Electrical Connections are tight, these may loosen during shipment

Main Disconnect Energized for 24Hr. to allow Crankcase Heater to boil any liquid refrigerant out of crankcase.

Field Process Piping has been leak checked

VOLTAGE on Chiller System matches customer supplied VOLTAGE

Glycol / Water Solution freeze point is at least 20 F. (11 C.) below T-Stat Setpoint

Glycol Pump Motors Rotation is CLOCKWISE when viewed from motor end

Glycol Storage Tank is at least 80% Full

Pressure Bypass Valve tested. To test, Close a valve on the Glycol Supply and visually check for return flow into storage tank.

Chiller location allows adequate air flow to and from Air Cooled Condenser. (Air Cooled Only)

Adequate water supply provided to Water Cooled Condenser (Water Cooled Only)

X DESCRIPTION DATA #1 DATA #2 DATA #3 DATA #4

Percentage of Propylene Glycol to Water in System

Glycol / Water Solution freeze point (Refractor Reading)*

Incoming Line Voltage Reading (L1-L2, L2-L3, L1-L3)

Control Transformer Secondary Voltage Reading

Circulation Pump Motor Amp Readings

Process Pump Motor Amp Readings

PRESSURE CONTROL SETTINGS (refer to Operation Manual for Factory Settings)

High Pressure Cut-Out

Low Pressure Cut-In

Low Pressure Cut-Out

Oil Failure Control

P29NC-3 FREEZE PROTECTION SETTINGS (refer to Operation Manual for Factory Settings)

Low Pressure Cut-Out

TEMPERATURE CONTROL SETTINGS (refer to Operation Manual for Factory Settings)

Setpoint Temperature

Differential Setting

OPERATING DATA**

Glycol Solution Temperature (Thermostat Display Temp.)

Suction Pressure (PSI)

Suction Line Temperature at Compressor

Discharge Line Pressure (PSI)

Discharge Line Temperature

Liquid Line Pressure (PSI)

Liquid Line Temperature

Glycol Temperature at Evaporator Inlet

Glycol Temperature at Evaporator Outlet

Ambient Air Temperature

Condenser Water Temperature Inlet & Outlet (If applicable)

Compressor Amp Draw

Complete Chiller System Amp Draw

* A Refractometer should be used to obtain the actual Glycol Solution Freeze Point. To order a Refractometer please

call Technical Assistance at (253) 735-9466, these are also available from most propylene glycol suppliers.

** Operating Data should be recorded in the order listed. To determine proper operation of the chiller system, please

record all Data simultaneously, or record all data completely with-in as short of period as possible. Data should

be recorded at different Glycol Operating Temperatures (example: record at 45 F. / 35 F. / 25 F.)

FOR TECHNICAL ASSISTANCE CALL (253) 735-9466 , Monday thru Friday 6:00 AM TO 5:00 PM PACIFIC STAND. TIME

TECHNICIAN: COMPANY:

SIGNATURE: TEL. #:

7-2

Packaged Glycol Chiller Systems | 17

OPERATING AND SAFETY CONTROL SET POINT GUIDE

Below you will nd all our standard electrical controls listed with

the recommended settings at dierent operating conditions.

ese settings are based on systems using Refrigerant R404A

Please check the set point before starting the system.

Unauthorized adjustment of freeze protection will void the warranty. Please consult the

factory ( 253-735-9466 ) prior to adjusting the setpoint.

On remote or air remote condensing unit systems, operating controls may have to be defeated to allow for system

charging of refrigerant. Be sure to set reset any defeated controls before completing start-up procedures.

To order a refractometer (glycol solution tester) please contact your sales

representative or contact the factory at the above listed phone number

DESIRED

GLYCOL

GLYCOL

FREEZE

CONTROL

CUT IN

CUT OUT

TEMP

POINT

GLYCOL %

High Pressure Control

400 psi

25 °F

0 to -10°F

36-42%

Low Pressure Control

30 psi

10 psi

25 °F

0 to -10°F

36-42%

Freeze Control ( PENN P29NC-3)

30 psi

25 °F

0 to -10°F

36-42%

High Pressure Control

400 psi

30 °F

0 to 5°F

33-36%

Low Pressure Control

30 psi

10 psi

30 °F

0 to 5°F

33-36%

Freeze Control ( PENN P29NC-3)

35 psi

30 °F

0 to 5°F

33-36%

High Pressure Safety

400 psi

35 °F

0 to 5°F

33-36%

Low Pressure Control

30 psi

10 psi

35 °F

0 to 5°F

33-36%

Freeze Control ( PENN P29NC-3)

35 psi

35 °F

0 to 5°F

33-36%

High Pressure Safety

400 psi

40 °F

0 to 10°F

30-36%

Low Pressure Control

30 psi

10 psi

40 °F

0 to 10°F

30-36%

Freeze Control ( PENN P29NC-3)

40 psi

40 °F

0 to 10°F

30-36%

18 | Pro Refrigeration, Inc

CHART #1

Weight % Volume % Freezing Freezing Degree

Propylene Propylene Point* in Point* in Brix**

Glycol Glycol Fahrenheit Celsius

0 0 32 0.0 0

5 4.8 29.1 -1.6 4.8

10 9.6 26.1 -3.3 8.4

15 14.5 22.9 -5.1 12.9

20 19.4 19.2 -7.1 15.4

21 20.4 18.3 -7.6 16

22 21.4 17.6 -8.0 16.7

23 22.4 16.6 -8.6 17.4

24 23.4 15.6 -9.1 18.4

25 24.4 14.7 -9.6 19

26 25.4 13.7 -10.2 19.6

27 26.4 12.6 -10.8 20.2

28 27.4 11.5 -11.4 20.8

29 28.4 10.4 -12.0 21.4

30 29.4 9.2 -12.7 22

31 30.4 7.9 -13.4 22.7

32 31.4 6.6 -14.1 23.6

33 32.4 5.3 -14.8 24.4

34 33.4 3.9 -15.6 25.3

35 34.4 2.4 -16.5 26.1

36 35.4 0.8 -17.3 26.9

37 36.4 -0.8 -18.2 27.5

38 37.4 -2.4 -19.1 28

39 38.4 -4.2 -20.1 28.5

40 39.4 -6 -21.1 29.1

41 40.4 -7.8 -22.1 29.6

42 41.4 -9.8 -23.2 30.2

43 42.4 -11.8 -24.4 30.7

44 43.4 -13.9 -25.5 31.3

45 44.4 -16.1 -26.7 31.8

46 45.4 -18.3 -28.0 32.4

47 46.4 -20.7 -29.3 33

48 47.4 -23.1 -30.6 33.5

49 48.4 -25.7 -32.1 34.1

50 49.4 -28.3 -33.5 34.7

51 50.4 -31 -35.0 35.5

shaded area represents recommended Glycol Water Percentage

*Glycol freeze point should be 20 to 25 F. below operating temperature or below coldest

winter ambient conditions. Whichever is coldest.

** Degree Brix is a measure of sugar concentration in a fluid and is important in fermentation

applications. Although there are no sugars in glycol, it will affect the refractive index of

the fluid in a similar fashion.

This manual suits for next models

1

Table of contents

Popular Chiller manuals by other brands

CHILLY

CHILLY 45-M instruction manual

HIdRos

HIdRos LDA Series Technical manual

SMC Networks

SMC Networks HRS Series Operation manual

Pfannenberg

Pfannenberg DTS series operating manual

Parker Hiross

Parker Hiross Hyperchill ICE076 user manual

FRIULAIR

FRIULAIR PURESTREAM CHILLERS CWE-Q Series Use and maintenance manual

Carrier

Carrier 16LJ-01 Operation manual

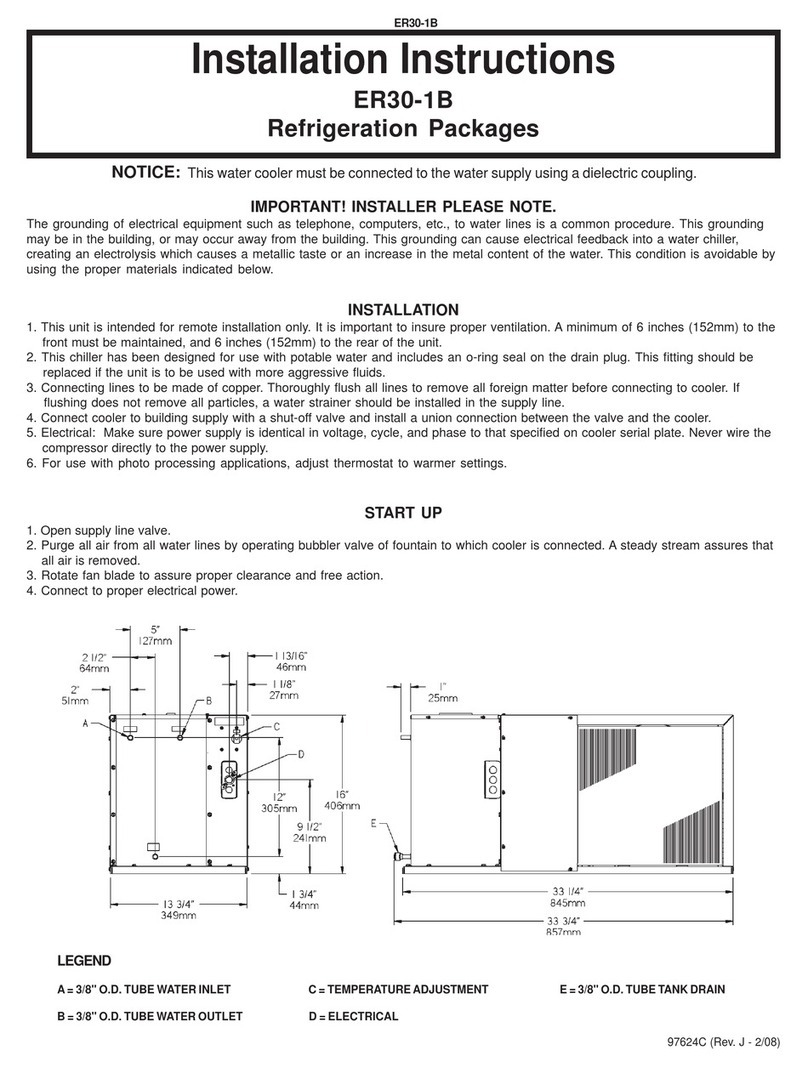

Elkay

Elkay ER30-1B installation instructions

Nemco

Nemco 9020 Operating and maintenance instructions

Carrier

Carrier 30RBM 160 Installation, operation and maintenance instructions

York

York YCAL0012EC Installation operation & maintenance

Carrier

Carrier AQUASNAP 30RAP010-150 Start up & operation manual