Pro's Kit SS-956 User manual

SS-956

SMART REWORK STATION WITH VACUUM

PICKUP

User’s Manual

1st Edition,2017

©2017 Copyright by Prokit’s Industries Co., Ltd.

请换 SS-968 图

1

Thank you for purchasing Pro’sKit product. The SS-956 Smart Rework Station with Vacuum Pickup has

been designed to meet high quality standards. Please properly use and take care of your product for

prolonging service life. Please store the manual in a safe, easily accessible place for future reference.

Safety Instructions

WARNING

Warnings and cautions are placed at critical points in this manual to direct the operator's

attention to significant items. They are defined as follows:

WARNING: Failure to comply with a WARNING may result in serious injury or death.

CAUTION: Failure to comply with a CAUTION may result in injury to the operator, or damage to the

items involved. Two examples are given below.

NOTE: A NOTE indicates a procedure or point that is important to the process being described.

EXAMPLE: AN EXAMPLE is given to demonstrate a particular procedure, point or process.

Be sure to comply with following WARNINGS and CAUTIONS for your safety.

WARNING

When the power is ON, the temperature of the hot air and the nozzle ranges will be increased

from indoor temperature to 480°C ( 896°F).

To avoid injury to personnel or damage to items in the work area, observe the following:

Do not direct the hot air toward personnel or touch the metal parts near the nozzle.

Do not use the product near combustible gases or flammable materials.

Advise those in the work area that the unit can reach very high temperatures and should be

considered potentially dangerous.

Turn the power OFF when no longer using the Pro’sKit SS-956 or when leaving it unattended.

Before replacing parts or storing the unit, allow the unit to cool and then turn the power OFF.

To prevent accidents and failures, be sure to take the following precautions:

Do not strike the hand piece against hard surfaces or otherwise subject it to physical shock.

Be sure the unit is grounded. Always connect power to a grounded receptacle.

Do not disassemble the pump.

Do not modify the unit.

Use only genuine Pro’sKit replacement parts.

Do not wet the unit or use the unit with wet hands.

Remove power cord by holding the plug –not the wires.

Make sure the work area is well ventilated.

The Pro’sKit SS-956 is not intended for use by children or infirm persons without supervision.

Children should be supervised to ensure that they do not play with the SS-956.

2

Packing List and Name of Parts

Name of Parts:

Packing List:

1. SS-956 Smart Rework Station with Vacuum Pickup with Two Holders

2. User’s Manual

3. Hot Air Gun

4. Air Nozzle x 3

5. Vacuum Suction Pen

6. Suction Cup : Φ12.5mm,Φ10mm ,Φ6.5mm, Φ3mm

7. IC Popper : 15mm ,20mm

8. Power Cord

Features and Specifications

Features:

Microprocessor-controlled with closed circuit sensor design provides better performance and

accurate temperature control.

Temperature calibration function.

Handle with sensor design switches work & sleep mode for real-time operation convenience.

Provide 600W high power and wide temperature range up to 480°C.

Auto cool-off process to prolong the lifetime of heating element

ESD safe design prevents static and electric leakage to damage the PCB.

Complies with CE and ESD standard, conforms to RoHS.

High quality air pump supply and quiet operation.

Silicone handpiece cord wire heat-resistant up to 200℃.

Additional ground contact and power cord socket.

Interchangeable and applicable to most of branded hot air nozzles.

Hot air gun

Set button

UP button

(to increase temperature or air

speed.)

Down button

(to decrease

temperature or air

speed.)

Suction pen

Power switch

3

Specifications:

Specification

SS-956B

SS-956H

SS-956E

Power Input

220V~240V~, 50Hz

110V~120V~,60Hz

Power Consumption

600W

Temperature Range

Room Temperature~480°C(896°F)

Heating Element

Metal Heating Core

Temperature Calibration

0~699℃(0~999℉) , Adjustable

Pump/Motor Type

Diaphragm Pump

Air Capacity

24L/min(Max)

Suction Capacity

100g

Auto Sleep Function

YES

Auto Cool-Off Function

YES

Equipment Noise

<50dB

Temperature Display

LCD (60mm X 35mm,Backlight)

Fuse

5A/250V (φ5x20mm)

8A/250V (φ5x20mm)

Power Plug

B

H

E

Heating Element Model

No.

5SS-989NB-H

5SS-989NE-H

Hot Air Gun Model No.

9SS-968B-HG

9SS-968E-HG

Nozzle

9SS-900-A1 (ID:Ø 2.2mm) x 1pce

9SS-900-A2 (ID:Ø 6.6mm) x 1pce

9SS-900-A3 (ID:Ø 8.5mm) x 1pce

Suction Cup: Φ12.5mm/Φ10mm/Φ6.5mm/Φ3mm x 1pce

Opening Lever(Width) : 15mm/20mm x 1pce

Dimensions

250(L)*230(W)*170(H)mm

Weight

3.2kg

Package

Color Box

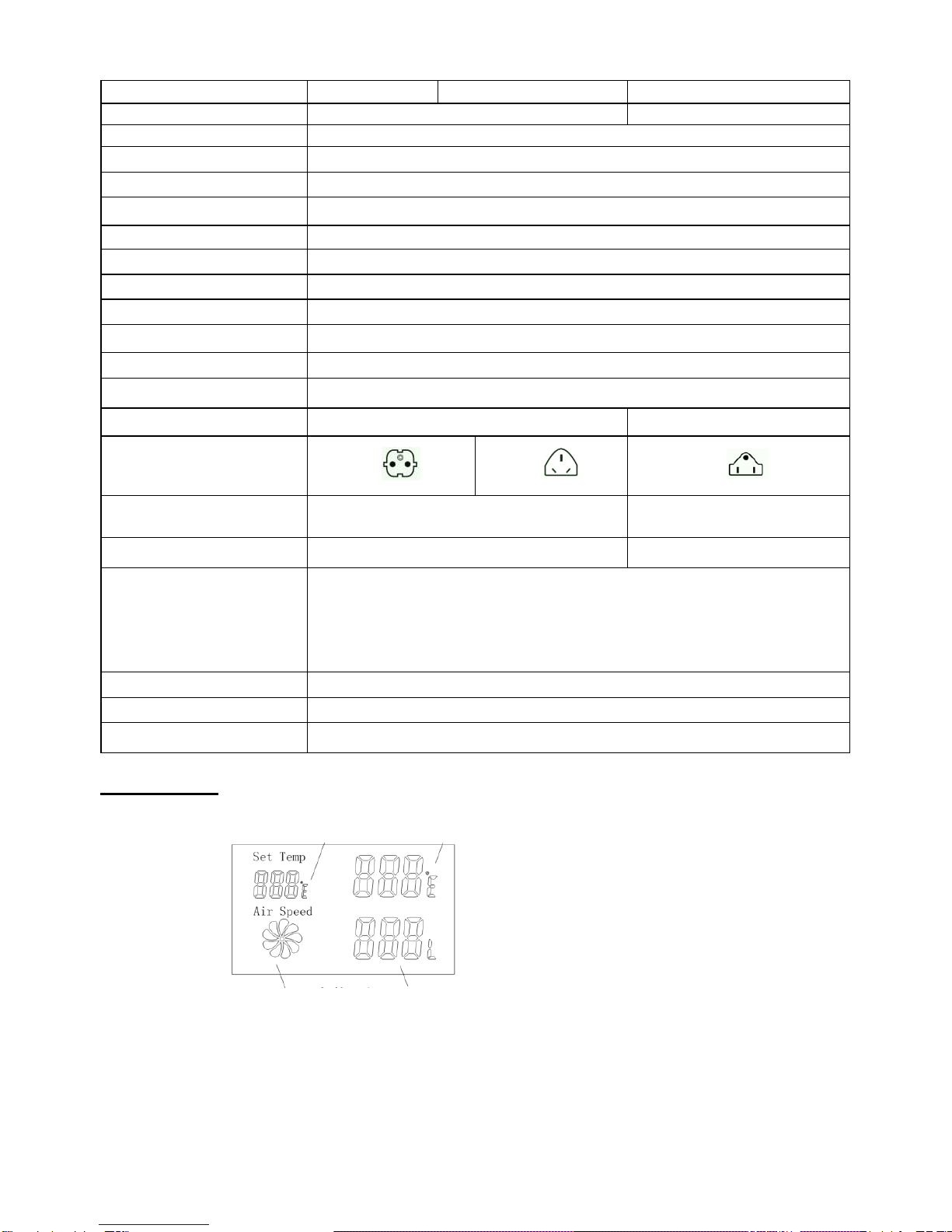

Main menu

Real Temperature

Air capacity

Air speed

Temperature setting

Real Temperature

4

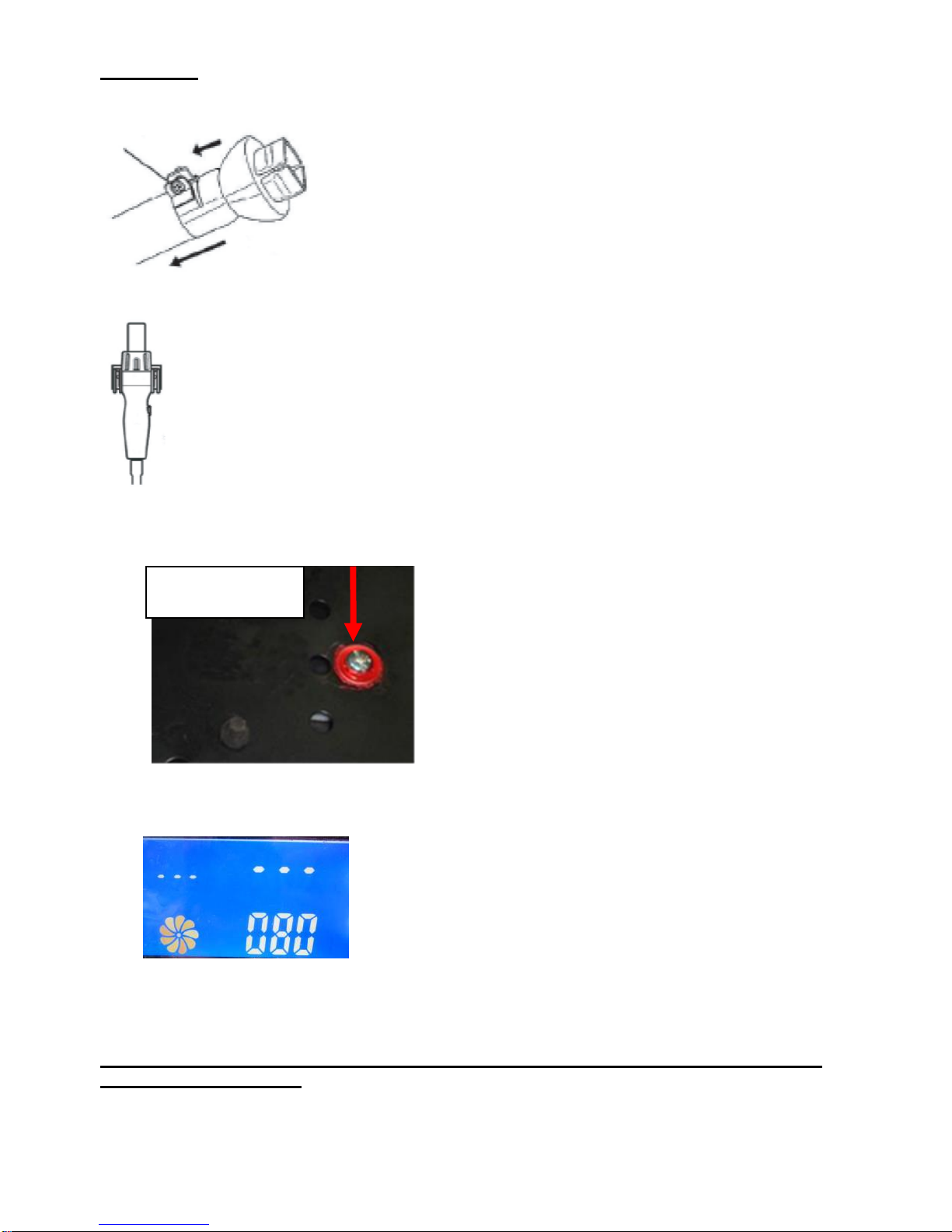

Assembly

1. Loosen the nozzle mounting screw, attach the nozzle on hot air gun, then screw shows as the

figure 1.

Fig. 1

2. Place the hot air gun on the holder.(Fig. 2)

Fig. 2

3. Please remove the pump securing screw (M5x12 with red mark) from the bottom of the rework

station.

Failure to do so may result in serious problems (See below pictures)

4. Insert the power plug into socket.

5. Power on the rework station, and LCD screen will display standby status after two seconds

(Fig.3). When lift the hot air gun, LCD screen will display the last setting temperature..

Fig.3

6. Do not unplug the power plug instantly after turning off the power switch, because the fan will

keep operating to cool down the heating element. The power plug only can be unplugged while

the fan stops operation completely.

Temperature and Air Speed Setting (Hot air gun can not be placed on the

holder while setting)

1. Power on the rework station, lift the hot air gun, LCD screen will display main menu (Fig. 4), last

setting temperature will display.

2. Press the “SET” button for one second; then choose temperature setting mode or air speed

setting mode.

Remove the

screw before use

5

3. In temperature setting mode, the ”Set Temp”words will shinning, adjust the temperature by

using the UP▲and DOWN▼buttons. In another way, you can also press the UP▲and DOWN

▼buttons directly in the main menu to set the temperature.

4. In the air speed setting mode, the ”Air Speed ”words will shinning, adjust the air speed by

using the UP▲and DOWN▼buttons(air speed range from 20~100). After stopping operation

around two seconds, it will go back to the main menu.

Fig.4

5. Quick setting mode : Press the “SET” button for two seconds, the digit will shinning(Fig.5), adjust

the temperature or air speed by using the UP▲or DOWN▼buttons. In the quick setting mode,

press “SET” button to confirm every digit; otherwise, digit will not stop shinning until it is

confirmed.

Fig.5

Temperature Calibration Setting

The hot air gun should be recalibrated after changing the gun, replacing the heating element or nozzle.

1. Press “SET” button and Down button “▼” in the same time, and main menu will display ”CAL”

and setting temperature(Fig.6). Press UP ▲or DOWN ▼to input actual temperature, press

“SET”button to confirm and back to the main menu.

Fig. 6

2. When the status display under temperature is "---"(Fig. 7), it means temperature has not been

calibrated.

Fig.7

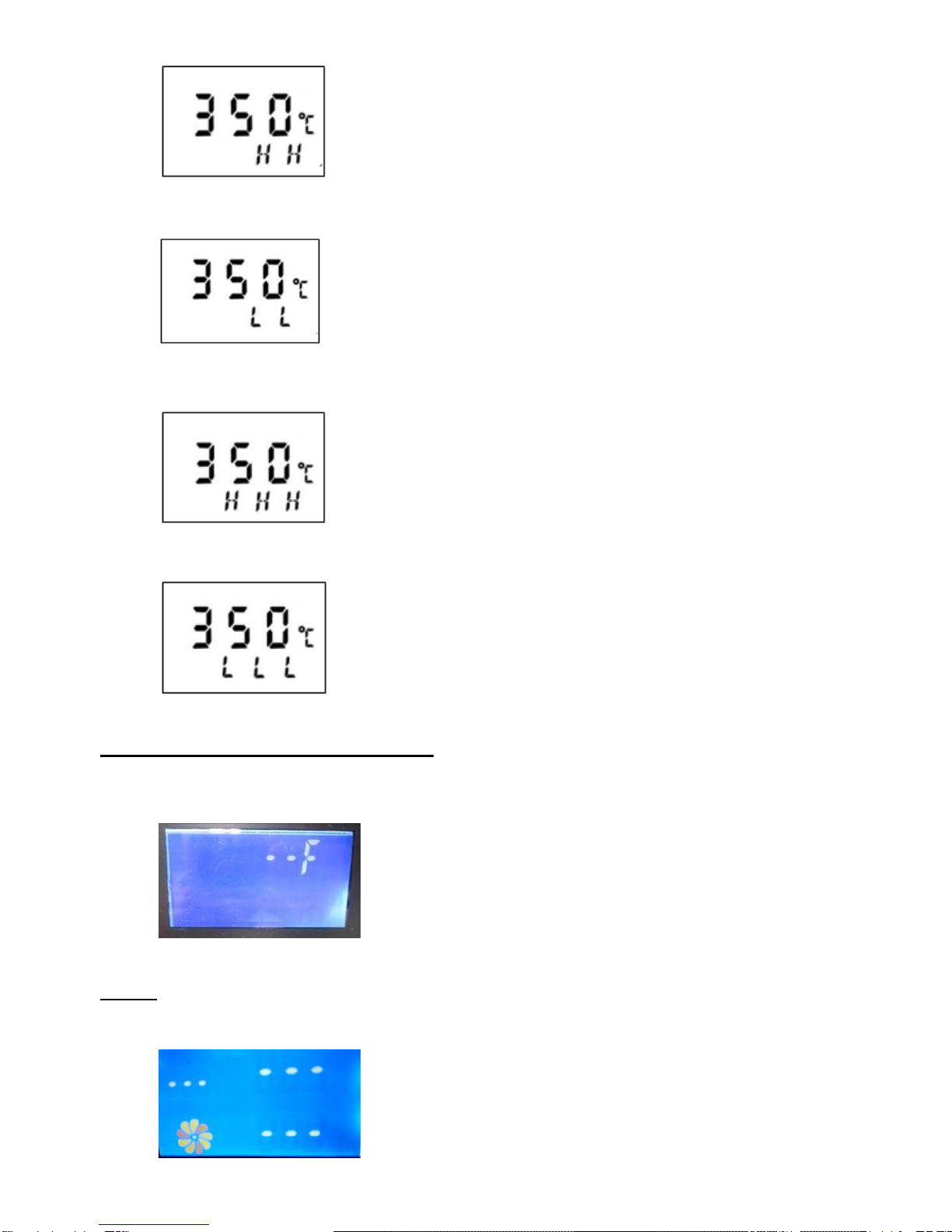

3. When the status display under temperature is "H” or “HH"(Fig. 8), it means temperature has been

calibrated and increased before.

6

Fig.8

4. When the status display under temperature is "L” or “L L"(Fig. 9), it means temperature has been

calibrated and decreased before.

Fig. 9

5. When the status display under temperature is "HHH"(Fig. 10), it means temperature has been

calibrated to max. temperature, which can not be increased but only decreased.

Fig. 10

6. The status display under temperature is "LLL"(Fig. 11), it means temperature has calibrated to

minimum temperature, which can not be decreased but only increased..

Fig. 11

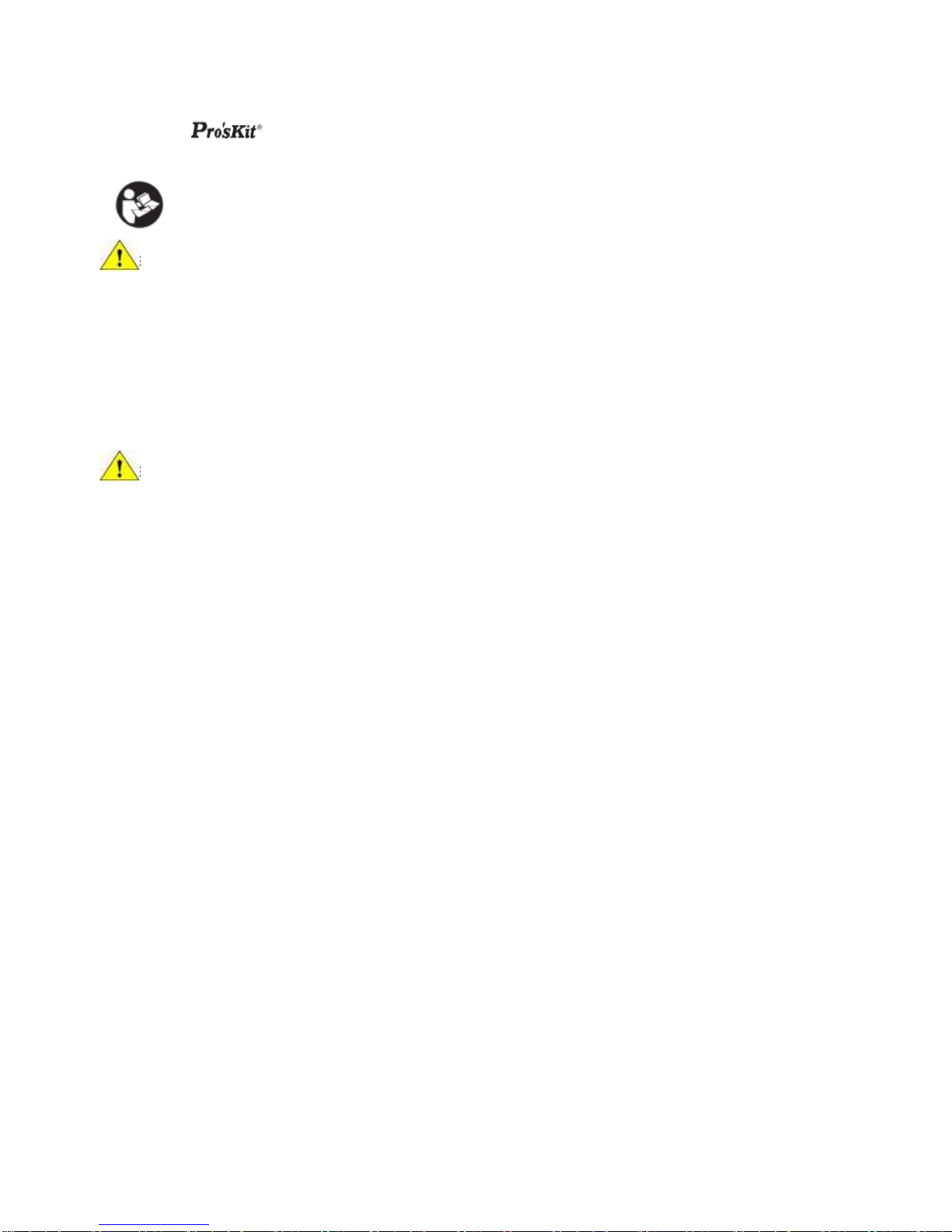

Fahrenheit andCentigrade Selection

Press the “SET” button and turn on the power switch to power on the station as Fig.12, and switch the

temperature display from ℃to ℉by pressing the UP ▲or Down button ▼. After selection, press

“SET” button to confirm and back to the main menu

Fig.12

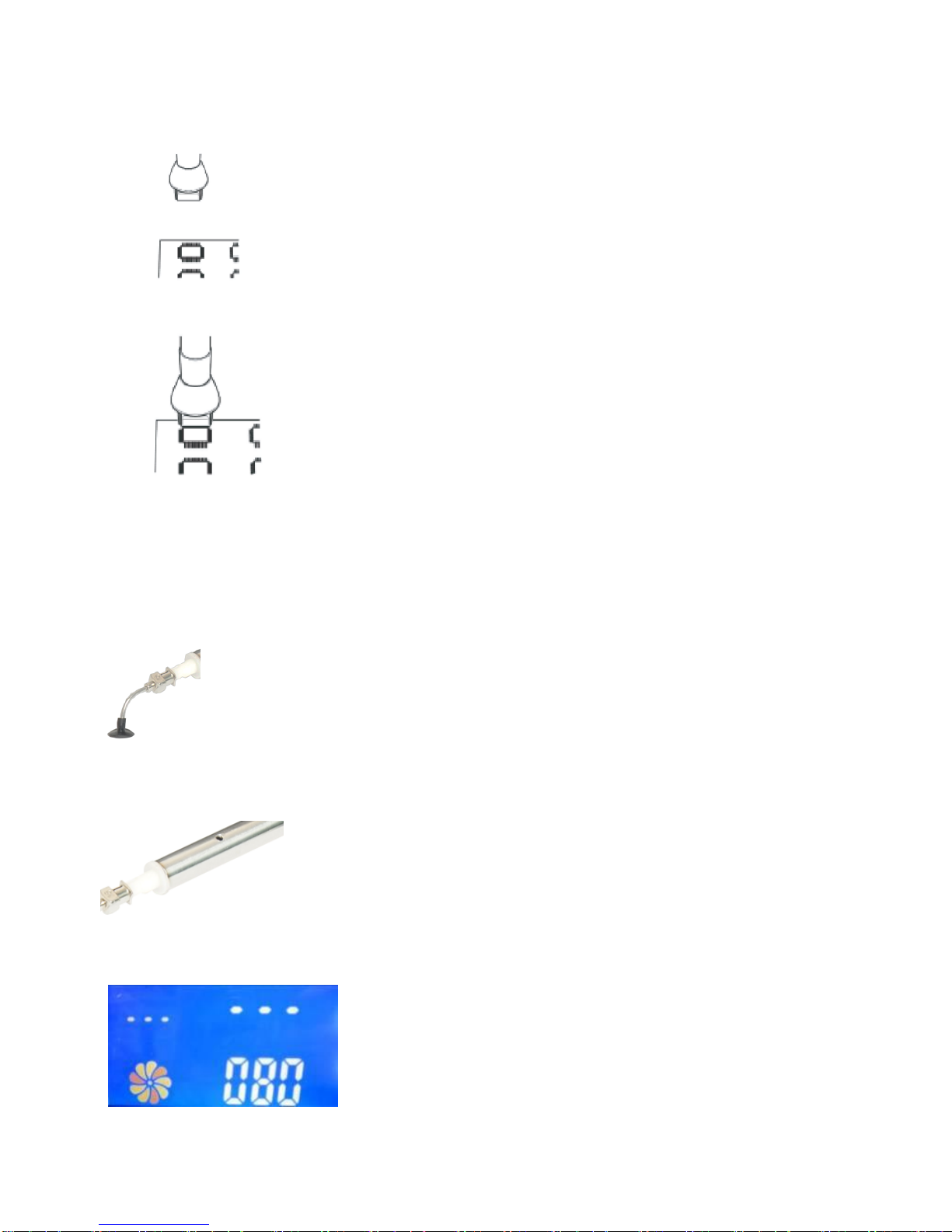

Reset

Press the UP ▲and DOWN ▼button in the same time, rework station will be back to the initial

setting; after one second, LCD screen be back to the standby mode(Fig.13).

Fig.13

7

CAUTION: Choose reset mode will modify all the parameter to the initial setting, please do it

carefully.

Auto Sleep

When hot air gun put on the holder, the temperature of hot air gun will start to decrease (Fig.14), and

the display will show “ SLP“ to indicate hot air gun is in sleep mode now. When the temperature is lower

than 100℃, the station will display as Fig.3. It will awake the rework station when hot air gun lift from

the holder.

Fig.14

Auto Cool-Off

After the rework station is turned off, the auto cool-off process leaves the blower on until the heating

element cool down to 100℃(Fig 15.), then rework station will shut off automatically.

Fig.15

CAUTION: Do not unplug the power plug when the auto cool off process is work on.

Do not touch the pin of plug to prevent electrical shock for human body.

Operation Instructions (SMD rework)

Remove SMD components (such as QFP, SOP, PLCC and so on)

1. Adjust air speed and hot air gun temperature to desired level

2. Slip the pick-up puller (optional part) under the component lead. (Fig. 16) If the component

width does not match the size of the pick-up, adjust the width of the pick-up by squeezing

the wire. Use tweezers to remove PLCC or small components such as chip resistors,

desolder, etc.

Fig. 16

3. Hold the hot air gun above the SMD components (do not touch the components directly),

allowing the hot air to melt the solder. Be careful not to touch the leads of the components

with nozzle.

4. When the soldering tin is melted, remove the SMD components by lifting the pick-up puller

(Fig. 17)

8

Fig. 17

5. After removing SMD components, remove residual soldering solder tin with desoldering

tool.

SMD Rework Operation Instructions

1. Apply proper quantity of solder paste and install the SMD components on PCB.

2. Refer to Fig. 18 to preheat components

Fig. 18

3. Heat the lead frame evenly (Fig. 19)

Fig. 19

4. Cleaning

When soldering is completed, clean the residual flux from the board with appropriate cleaner.

How to use suction pen

1) Choose a proper suction cup according to the weight (less than 100g) and size of object. Install

the cap with the suction pen.

Fig.20

2) Put the suction cup horizontally with the surface of the adsorbed object. Cover the hole on the

suction pen, and the object will be absorbed.

Fig.21

3) Move out the absorbed object, and then open the hole on the suction pen to release the object.

4) If need to use suction pen only, put the hot air gun on holder, and rework station will be in the auto

sleep mode. Press the UP ▲or Down button ▼to adjust air speed(air speed range from

9

20~100)

NOTE:

1. The tube cannot be bent, or it may influence airflow and suction.

2. Absorbed object surface should be smooth in order to be sucked.

3. Pay attention to prevention of ESD, so as not to damage the device

4. Before using vacuum pickup pen, turn off the hot air gun.

5. Do not overexert while fixing nozzle, use pliers to pull the nozzle, or screw breech block too

tight.

6. Be careful when working with high temperature.

7. Do not use this product near flammable gas, paper, or other flammable things.

8. The temperature of nozzle and hot air is very high and could injury user. Don’t touch the

heating part or blow the hot air to body

9. Use hot air to solder is feasible, but it could cause the problem of solder link or solder ball, for

which we highly recommend you to check it carefully.

10. For the new machine, it might occur smoke in a short time when it starts to work in the first time

due to heating insulation material inside the handle, and this is normal.

Trouble Shooting

Warning:

Before checking the inside of the SS-956 or replacing parts, be sure to disconnect the power plug.

Failure to do so may result in electric shock.

Defect Situation

Possible Problem

Solution

Dead, doesn’t work

Blown fuse

Change new fuse

SS-956E(110V) : 250V / 8A

SS-956B(220V) : 250V / 5A

SS-956H(220V) : 250V / 5A

Hot air gun - Air

temperature doesn’t

heat up

Display S-E, plug doesn’t connect

properly

Reconnect the plug of hot air gun

(as Fig-22)

Calibration parameter changes

Calibrate again

Heating element is broken

Replace heating element

5SS-989NE-H(110V)

5SS-989NB-H(220V)

Hot air gun - Airflow

level abnormal

Internal pipe is obstructed or loose

which causes air leakage

Clear the internal pipe, reconnect

the pipe tightly.

Pump securing screws are not

loosened

Loosen the pump securing screw,

which on the bottom of rework

station.

Suction function

abnormal

Tube is broken or not installed properly

Change new tube or re-install tube

Suction cup is aging or not installed

properly

Change new suction cup or

re-install suction cup

Display shows

abnormal

Transportation causes inside PCB

board connect improperly

Open the case, reconnect the PCB

board

Input voltage lower than standard

request

Check with local power service

provider

Temperature unit

display abnormal

IC broken

Contact vendor for repair

10

Replace the Heating Element

Warning:

Before checking the inside of the SS-956 or replacing parts, be sure to disconnect the power plug.

Failure to do so may result in electric shock.

1. Dissemble hot air gun and air tube

2. Loosen 3 screws of the hot air gun shell and open the shell (fig.22)

Fig. 22

3. Press the white plug to pull it out, and then take out the heating element.

4. Change the new 5SS-989NB-H heating element, then assemble the shell and air tube .

5. After replacing a new heating element, please check to see if it has air leakage (set in low

temperature and block air outlet).

6. Use meter to check the setting temperature is as the same as real temperature; if not, back to the

“Temperature Calibration Setting" process.

Fuse Replacement

When fuse is blown, replace with the same type of fuse. (refer to below picture)

1. Unplug the power cord from the power receptacle.

2. The fuse holder is located under the AC power receptacle (fig.23). Use the slotted (–) screwdriver

to loosen the fuse holder.

3. Replace the fuse with new one, 5A/250V(220V-240V~)or 8A/250V (110V~), dimension Φ5x20mm.

(suggest use fuse that complied with UL standard)

4. Put the fuse holder back in place.

Fig. 23

11

SS-956 智慧型熱吹吸筆焊台使用說明書

感謝您選購 SS-956 LCD 智能熱風拆焊台。使用焊台前請詳閱本使用說明書,閱後請妥為收

存,以備日後查閱。

警告! 為降低傷害風險,用戶必須閱讀 使用手冊。

警告

本說明書之注意事項,區分為如下的”警告” 及“注意” 二者加以表示。請充分理解其內容後再閱讀本文。

警告: 濫用可能導致使用者死亡或是重傷。

注意: 可能導致使用者受傷或對涉及物體造成實質破壞,為了使用者的安全著想,請嚴格遵守”注意事

項”。下面舉二個例子說明之。

備註: 備註是在指示一個步驟或是在指出敘述那是一個重要的程式。

舉例: 舉例是在證明一個特別的步驟、重點或是程式。

為了您的安全,請務必遵守下面的 ”警告” 及”注意” 事項。

注意

當電源是”開”的狀況,熱風槍噴嘴的溫度範圍約在室溫到 480°C ( 896°F)之間。為了避免傷害使用者或

是損壞使用區域物件,請注意下列事項:

請勿將熱風對著人吹或碰觸熱風嘴的金屬部份。

請勿在可燃氣體或可燃材料附近使用本產品。

本產品使用時會產生高溫,在工作區域內應注意其潛在的危險性。

當長時間不使用或是無人在旁時請將本產品 SS-956 的電源關閉。

在更換零件或收藏前,應關閉總電源並讓其冷卻到室溫。

為了預防意外的發生,請遵從下列的注意事項:

請勿將手握持的部位敲打堅硬的地方,否則會造成主體的震動而損壞。

請確認產品電源是連結在有接地的插座上。

請勿拆開氣泵。

請勿任意修改任何組件。

請設定合適的溫度及風量,當機體內部溫度過高時將會啟動機器安全過溫保護裝置

熱風拆焊器在停止使用時,務必進行自動冷卻,在此冷卻時間內請勿拔掉插頭。

請使用本公司所提供的替換元件。

請勿弄濕產品或是用濕的手去使用產品。

請握住插頭位置拔掉插頭,請勿直接拉電線拔除。

請確認工作的區域通風良好。

兒童不可操作本產品 SS-956,不熟悉 SS-956 產品的人員使用時,需有熟悉操作的人員指導使

用。

兒童必須被監督以確保他們不會玩弄機台。

如果電源軟線損壞,為了避免危險,必須由製造商、其維修部或類似部門的專業人員更換

一、 產品特點:

本產品獨特採用最新型長壽蜂窩式發熱體及大螢幕液晶屏顯示。

600W 大功率快速恒溫,隨開隨用

全新單片 SMD 電路板,搭配精密 CPU 和智慧軟體,控溫精准、風量穩定、維修容易。

熱風採用前置溫度感測器與電子式閉回路溫度控制,風溫更準確。

12

靜音式大風量膜片式空氣幫浦,噪音低、風量穩定。

手柄掛機休眠功能。將手柄放在拆焊架上時機器進入休眠狀態,休眠溫度 100℃。當拿起手柄時

機器會迅速升溫到設定溫度。

防靜電設計,防止因靜電及漏電而損壞 PCB 板的設計。

熱風管及吸筆管採用矽膠材料,耐溫達 200℃,不易因誤觸而損壞。

吸物筆可選擇單獨使用,不會產生無效功耗。

分離式電源線座,適合精密電子廠和各國插頭使用。

符合全新安規規範和歐盟環保規範,更安全、更環保。

熱風槍具備防漏氣設計,能輕易更換發熱芯。

熱風嘴規格齊全,尺寸通用性高,內附 3 個常用圓型熱風嘴。

二、 各部件名稱及包裝清單

各部件名稱

包裝清單:

1. SS-956 熱吹吸筆焊台主機(含熱風槍掛架) x1

2. 使用說明書 x1

3. 熱風槍 x1

4. 噴氣嘴配件 x 3pcs

5. 撬棒(寬):15mm/20mm x 各1

6. 吸筆支架 x1

7. 吸筆 x1

8. 吸盤:Φ12.5mm,Φ10mm ,Φ6.5mm, Φ3mm

9. 電源線 x1

電源開關

UP 加鍵

(調升溫度或風速)

DOWN 減鍵

(降低溫度或風速)

設定功能鍵

熱風槍

吸筆

13

三、 規格

產品規格

SS-956B

SS-956H

SS-956E

輸入電壓

220V~240V~, 50Hz

110V~120V~, 60Hz

消耗功率

600W

熱風溫度範圍

室溫~ 480˚C (室溫~ 896˚F)

熱風槍發熱芯

鎳鉻絲發熱芯

空氣幫浦

膜片式

空氣量

24 公升/每分鐘(最大)

吸物重量

100g

智能校溫範圍

0~699℃(0~999℉),可調整設定

運作噪音

<50dB

溫度顯示

LCD (60mm x 35mm,背光功能)

休眠模式

放入手柄架休眠

休眠溫度

100℃/212℉

關機吹焊延時

自動降低至 100℃/212℉關機

保險絲管規格

5A / 250V (Φ5x20mm)

8A /250V (Φ5x20mm)

插頭型號

B

H

E

選購發熱體型號

5SS-989NB-H

5SS-989NE-H

選購熱風槍型號

9SS-968B-HG

9SS-968E-HG

配件

熱風嘴 9SS-900-A1 (Ø 2.2mm) x 1 個

熱風嘴 9SS-900-A2 (Ø 6.6mm) x 1 個

熱風嘴 9SS-900-A3 (Ø 8.5mm) x 1 個

吸盤 Φ12.5mm/Φ10mm/Φ6.5mm/Φ3mmx 各1個

撬棒(寬):15mm/20mm x 各1個

尺寸 (mm)

250*215*170mm(含提手/熱風手柄架/吸筆支架)

重量

約3.2kg

包裝方式

彩盒

※上述規格如有更改不另行通知,請以產品實物為准

※建議勿將溫度長時間設定高於450℃,以盡可能延長機器壽命

14

四、 LCD 顯示面板

五、 使用方法

1. 組裝

●鬆開熱風嘴的安裝用螺絲,將熱風嘴裝入後鎖緊螺絲(圖1),原配 3個圓形熱風嘴只需插入風嘴即

可。

圖1

●將熱風槍放到熱風槍拆焊架上(圖 2)

圖2

●第一次使用前請拆除機身底部緊固氣泵之螺絲後(如下紅色標記),方可通電,否則將可能引起嚴重

故障。(如下方照片)

●將電源插頭插入插座

●打開電源開關,LCD 顯示幕亮起 (圖3),拿起熱風槍後螢幕顯示上次關機前設定的溫度”。

紧泵螺丝,使用前请先拆下

風量(吸力)比例顯示

風速指示

溫度設定

實際溫度

15

圖3

●關閉電源開關後, 氣泵會繼續送風使發熱元件降溫, 此時請勿將插頭拔起。待氣泵完全靜止後才可

以將插頭拔掉.

2. 設定吹焊槍溫度和風量的方法(以下操作吹焊手柄不可在焊槍擱置架內)

2.1 開機後進入主畫面(圖4),輕按 SET 鍵1秒即可切換為溫度設定或風量設定。當”Set Temp”字樣閃

爍時,代表進入溫度設定模式,此時可以按▲或▼來調整溫度。也可在主畫面直接按▲或▼來調整

溫度(溫度調整範圍 0~480℃)。

2.2 當”AIR Speed” 字樣閃爍時,代表進入風量設定模式,此時可以按▲或▼來調整風量(風量調整範

圍20~100),停止操作約 2秒後即自動返回主畫面。

圖4

2.3 長按 2秒SET 鍵可以快速設定溫度和風量(圖 5),當數字顯示閃爍時,此時可以藉由按▲或▼來

調整,調整完後再輕按 1秒SET 鍵切換下一個數字位置,依次設定溫度和風量數值,直到全數確

認完成再退出設定狀態。

注意:進入快速設定後,需依序確認所有數位直到退出返回工作狀態,不然數位將一直閃爍等待確

認。

圖5

3. 溫度校準

3.1 同時按SET和▼,畫面會顯示“CAL”和溫度值(圖6),藉由按▲或▼輸入實際溫度值後,輕按SET

鍵1秒切換不同數碼位置並確認後, 退出溫度校準狀態。

圖6

3.2 當溫度數值下方顯示”- - -“(圖7),表示焊台溫度未被校準過, 出廠時通過物理方法(校溫電位器)

調整至最佳狀態。

16

圖7

3.3 當溫度數值下方顯示“H”或”HH” (圖8),表示焊台溫度已被校準調高過。例:設定溫度350℃,實際溫

度320℃,如圖3.1進行溫度校準後,溫度將由320℃調升到350。

圖8

3.4 當溫度數值下方顯示“L”或”LL”(圖9),表示焊台溫度已被校準調低過。

圖9

3.5 當溫度數值下方顯示“HHH” (圖10),表示焊台溫度已調整至最高溫度或校溫幅度過大,為了機器安

全考慮,此時無法再繼續調升溫度,但可調降溫度。

圖10

3.6 當溫度數值下方顯示“LLL” (圖11),表示焊台溫度已調整至最低溫度,為了機器安全考慮,此時無法

再繼續向下調降溫度,但可調升溫度。

圖11

4. ℃/℉切換

按住 SET 鍵並打開開關, 畫面顯示如下圖, 此時可按▲或▼切換℃/℉單位,再按 SET 鍵確認後退

出。

圖12

5. 恢復出廠設定

同時按▲和▼鍵開機,自動進行恢復(圖 13),大約 1秒後自動轉入正常主畫面

圖13

6. 休眠

手柄放入拆焊架後, 溫度會自動降溫至 100℃,之後進入休眠(圖14)以保護發熱元件壽命, 低於

17

100℃後螢幕轉回(圖3), 繼續降溫至環境溫度。

圖14

7. 電源關機延時

當關閉電源後,拆焊台會用最大風量將發熱元件降溫至 100℃再關機(圖 15)以確保安全。

圖15

警告:

1.氣泵停止前請不要拔掉插頭;

2.不要用手接觸剛剛拔掉插頭的極片,以免產品內部放電造成對人體電擊

8. SMD.吹焊作業

●取下(QFP)

1. 調整風速及溫度按鍵

安裝起拔器(選配) , 將起拔器套入元器件底下(圖 16)如果元器件寬度不適合起拔鋼線尺寸,可

擠壓鋼線寬度以適應之。PLCC,積體電路電阻等部件,請用小鑷子拆下。

圖16

2. 加熱

將熱風槍放在積體電路正上面,熱風嘴對準所要熔化焊錫部份,吹出熱風熔化焊錫。熱風嘴不可

觸及元器件引線

3. 拆下部件

焊錫熔化時,拉起起拔器移開部件(圖 17)

圖17

4. 清除焊錫

移開部件後,使用吸錫器或除錫工具清除殘餘焊錫

18

●安裝(QFP)

1. 塗抹適量錫膏,將部件放在線路板上

2. 預備加熱

參閱(圖 18)預熱部件

圖18

3. 焊接

向引線框平均噴出熱風(圖 19)

圖19

4. 清理

焊接完畢,清除殘餘助焊劑

●吸筆使用

1.依據需要提取的物品重量(建議不大於100g)及表面大小,選擇使用的吸盤規格安裝在吸筆的頭部(圖

20)

圖20

2.將吸盤平整放置在被吸物的表面, 用手指按住吸筆上的孔位(圖 21),使吸筆吸住物品.

3.將被吸物移動到放置的位置,鬆開堵住吸筆小孔上的手指,物品會脫離吸盤.

圖21

4.單獨使用吸筆的吸力調整, 熱風手柄在擱置架內休眠狀態時,按▲和▼鍵可調節吸筆吸力大小,調節範圍

(20~100)

19

注意事項:

使用吹焊搶及吸筆時注意皮管不可彎折、受壓變形,以免影響風量和吸力.

裝噴咀時勿用力過大,或用鉗子拉動邊緣,勿過度擰緊螺絲.

小心高溫操作, 切勿在易燃氣體、紙質、或其他易燃物品附近,使用本拆焊台,噴咀十分灸熱,為

免灼傷身體,切勿觸摸發熱管,或以熱氣直噴身體部位.

對於新機,因手柄內有隔熱材料—雲母管,開機後短時間內冒白煙,這屬正常現象.

熱氣焊接是有效的,但也可能導致焊劑球、焊劑搭連等問題。我們建議您仔細檢查焊接元件

確保被吸物表面需要光潔, 以利被吸取.

注意防靜電措施, 以免損壞器件.

六、 故障排除說明

警告:檢查前請先移除插頭

故障現象

可能原因

解決方法

打開電源不工作

保險絲燒毀

更換相同型號保險絲

SS-956E(110V) : 250V / 8A

SS-956B(220V) : 250V / 5A

SS-956H(220V) : 250V / 5A

熱風溫度不正常

顯示 S-E,感測器接觸不良

內部連接頭重新拔插(如圖 22)

校準參數被更改

重新校準

發熱芯燒毀

更換發熱芯 5SS-989NE-H(110V)

5SS-989NB-H(220V)

熱風風量不正常

內部器件異物阻礙或管通路開裂漏氣

清除雜物,接好開裂處

氣泵底部螺絲未松脫

拆解底部緊泵螺絲

吸物異常

管路開裂漏氣或吸盤老化裝配不當

接好開裂處,更換吸盤

顯示不正常

因為運輸振動造成接觸不良

重新插接 PCB 板插頭

使用電源電壓偏低

檢查插座電壓是否正常

死機

器件損毀

請退回廠商維修

上述故障現象以外之問題, 請聯絡經銷商

七、 替換發熱元件

警告:替換前請先移除插頭

1. 將手柄尾部與氣管連接部分拆開

2. 將手柄 3個固定螺絲拆除,打開外殼(圖 22)

圖22

3. 按住白色插頭凸起部分,拔出插頭內的損壞的 5SS-989NB-H 發熱芯

4. 更換新的 5SS-989NB-H 發熱芯後,裝回外殼並連接氣管

5. 裝配好後請檢查功能是否恢復,確認是否存在漏氣現象(將溫度調至最低,用手堵住出風口檢查)

Table of contents

Other Pro's Kit Rework Station manuals